Abstract

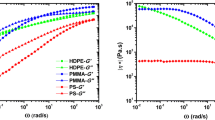

In this study, the miscibility of ethylene vinyl acetate/olefin block copolymer (EVA/OBC) blends was investigated through the determination of melt-state viscoelastic properties as well as by morphological analysis using experimental and theoretical approaches. The SEM micrographs showed droplet-matrix morphology, and the blend containing a higher content of OBC exhibited the highest OBC-dispersed phase domain size. The complex viscosity of EVA/OBC blends showed a positive deviation from the log-additivity rule at all compositions, which indicates the strong interaction between phases. Cole–Cole and Han plots indicated miscibility in the molten state between EVA and OBC. The interfacial tension of EVA/OBC blends was determined by the implementation of Palierne and Bousmina emulsion models. Moreover, the blend samples were characterized in terms of creep properties using a dynamic mechanical analyzer, which demonstrated that the OBC increased the creep strains of the blends. The four-element Burger model and the Findley power law model were employed to model the creep behaviors of the EVA, OBC, and blend samples. The model predictions indicated that the incorporation of OBC into the EVA improved the creep rate of EVA/OBC blends significantly.

Similar content being viewed by others

References

Arriola DJ, Carnahan EM, Hustad PD et al (2006) Catalytic production of olefin block copolymers via chain shuttling polymerization. Science 80(312):714–719. https://doi.org/10.1126/science.1125268

Wang HP, Khariwala DU, Cheung W et al (2007) Characterization of some new olefinic block copolymers. Macromolecules 40:2852–2862. https://doi.org/10.1021/ma061680e

Chum PS, Swogger KW (2008) Olefin polymer technologies-History and recent progress at the Dow chemical company. Prog Polym Sci 33:797–819. https://doi.org/10.1016/j.progpolymsci.2008.05.003

Dias P, Lin YJ, Poon B et al (2008) Adhesion of statistical and blocky ethylene-octene copolymers to polypropylene. Polymer 49:2937–2946. https://doi.org/10.1016/j.polymer.2008.04.022

Liu G, Zhang X, Li X et al (2012) Correlation of miscibility and mechanical properties of polypropylene/olefin block copolymers: effect of chain composition. J Appl Polym Sci 125:666–675. https://doi.org/10.1002/app.36244

Ren Q, Fan J, Zhang Q et al (2016) Toughened polypropylene random copolymer with olefin block copolymer. Mater Des 107:295–301. https://doi.org/10.1016/j.matdes.2016.06.052

Zhang Q, Fan J, Feng J, Lu X (2015) Regulation of crystalline morphologies and mechanical properties of olefin multiblock copolymers by blending polymer with similar architecture of constituent blocks. Polymer 73:139–148. https://doi.org/10.1016/j.polymer.2015.07.034

Wu M, Wu Z, Wang K et al (2014) Simultaneous the thermodynamics favorable compatibility and morphology to achieve excellent comprehensive mechanics in PLA/OBC blend. Polymer 55:6409–6417. https://doi.org/10.1016/j.polymer.2014.10.004

Lin X, Liu Y, Chen X et al (2020) Reactive compatibilization of polyamide 6/olefin block copolymer blends: phase morphology, rheological behavior, thermal behavior, and mechanical properties. Materials 13:1146. https://doi.org/10.3390/ma13051146

Lai SM, You PY, Chiu YT, Kuo CW (2017) Triple-shape memory properties of thermoplastic polyurethane/olefin block copolymer/polycaprolactone blends. J Polym Res. https://doi.org/10.1007/s10965-017-1319-z

Lai SM, Li CH, Kao HC, Liu LC (2019) Shape memory properties of melt-blended olefin block copolymer (OBC)/ethylene-vinyl acetate blends. J Macromol Sci Part B Phys 58:174–191. https://doi.org/10.1080/00222348.2018.1558593

Yang ZX, Chen Y, Liu X et al (2020) Fabrication of poly(ε-caprolactone) (PCL)/poly(propylene carbonate) (PPC)/ethylene-α-octene block copolymer (OBC) triple shape memory blends with cycling performance by constructing a co-continuous phase morphology. Polym Int 69:702–711. https://doi.org/10.1002/pi.6005

Lai SM, Fan Jiang SY, Chou HC et al (2021) Novel two-way multiple shape memory effects of olefin block copolymer (OBC)/polycaprolactone (PCL) blends. Polym Test 102:107333. https://doi.org/10.1016/j.polymertesting.2021.107333

Lai S-M, Chen Y-J, Yu BY (2021) Preparation and characterization of two-way shape memory olefin block copolymer/silicone elastomeric blends. J Appl Polym Sci 138:e51238. https://doi.org/10.1002/app.51238

Ercan N, Korkmaz E (2021) Structural, thermal, mechanical and viscoelastic properties of ethylene vinyl acetate (EVA)/olefin block copolymer (OBC) blends. Mater Today Commun 28:102634. https://doi.org/10.1016/j.mtcomm.2021.102634

Ren Q, Wang XJ, Zhao YQ et al (2021) Thermo-responsive shape memory behavior of methyl vinyl silicone rubber/olefin block copolymer blends via co-crosslinking. Int Polym Process 36:26–34. https://doi.org/10.1515/ipp-2020-3927

Zuo F, Burger C, Chen X et al (2010) An in situ x-ray structural study of olefin block and random copolymers under uniaxial deformation. Macromolecules 43:1922–1929. https://doi.org/10.1021/ma902105v

Faker M, Razavi Aghjeh MK, Ghaffari M, Seyyedi SA (2008) Rheology, morphology and mechanical properties of polyethylene/ethylene vinyl acetate copolymer (PE/EVA) blends. Eur Polym J 44:1834–1842. https://doi.org/10.1016/j.eurpolymj.2008.04.002

Park HE, Dealy JM, Marchand GR et al (2010) Rheology and structure of molten, olefin multiblock copolymers. Macromolecules 43:6789–6799. https://doi.org/10.1021/ma1012122

Arsac A, Carrot C, Guillet J (1999) Rheological characterization of ethylene vinyl acetate copolymers. J Appl Polym Sci 74:2625–2630. https://doi.org/10.1002/(SICI)1097-4628(19991209)74:11%3c2625::AID-APP9%3e3.0.CO;2-G

Williamson RV (1929) The flow of pseudoplastic materials. Ind Eng Chem 21:1108–1111. https://doi.org/10.1021/ie50239a035

Minale M, Moldenaers P, Mewis J (1997) Effect of shear history on the morphology of immiscible polymer blends. Macromolecules 30:5470–5475. https://doi.org/10.1021/ma9617330

Utracki LA, Kanial MR (1982) Melt rheology of polymer blends. Polym Eng Sci 22:96–114. https://doi.org/10.1002/pen.760220211

Utracki LA (1991) On the viscosity-concentration dependence of immiscible polymer blends. J Rheol 35:1615–1637. https://doi.org/10.1122/1.550248

Hajiraissi R (2020) Linear and nonlinear melt viscoelastic properties of fibrillated blend fiber based on polypropylene/polytrimethylene terephthalate. Polym Bull 77:2423–2442. https://doi.org/10.1007/s00289-019-02865-1

Khademzadeh Yeganeh J, Goharpey F, Foudazi R (2012) Can only rheology be used to determine the phase separation mechanism in dynamically asymmetric polymer blends (PS/PVME)? RSC Adv 2:8116–8127. https://doi.org/10.1039/c2ra21307a

Khademzadeh Yeganeh J, Goharpey F, Foudazi R (2010) Rheology and morphology of dynamically asymmetric LCST blends: polystyrene/poly(vinyl methyl ether). Macromolecules 43:8670–8685. https://doi.org/10.1021/ma101421s

Bousmina M, Lavoie A, Riedl B (2002) Phase segregation in SAN/PMMA blends probed by rheology, microscopy, and inverse gas chromatography techniques. Macromolecules 35:6274–6283. https://doi.org/10.1021/ma020053w

Zhang Z, Yu F, Zhou N, Zhang H (2015) Compatibilization by olefin block copolymer (OBC) in polypropylene/ethylene-propylene-diene terpolymer (PP/EPDM) blends. J Macromol Sci Part B Phys 54:159–176. https://doi.org/10.1080/00222348.2014.996497

Chen Y, Zou H, Liang M, Liu P (2013) Rheological, thermal, and morphological properties of low-density polyethylene/ultra-high-molecular-weight polyethylene and linear low-density polyethylene/ultra-high-molecular-weight polyethylene blends. J Appl Polym Sci 129:945–953. https://doi.org/10.1002/app.38374

Jafari SH, Hesabi MN, Khonakdar HA, Asl-Rahimi M (2011) Correlation of rheology and morphology and estimation of interfacial tension of immiscible COC/EVA blends. J Polym Res 18:821–831. https://doi.org/10.1007/s10965-010-9479-0

Dae Han C, Kim J (1987) Rheological technique for determining the order-disorder transition of block copolymers. J Polym Sci Part B Polym Phys 25:1741–1764. https://doi.org/10.1002/polb.1987.090250815

Walha F, Lamnawar K, Maazouz A et al (2016) Rheological, morphological and mechanical studies of sustainably sourced polymer blends based on poly(lactic acid) and polyamide 11. Polymers. https://doi.org/10.3390/polym8030061

Kwag H, Rana D, Cho K et al (2000) Binary blends of metallocene polyethylene with conventional polyolefins: rheological and morphological properties. Polym Eng Sci 40:1672–1681. https://doi.org/10.1002/pen.11299

Yoon KH, Park S, Kim YC (2012) Study of the rheological properties and crystallization behavior of branched PP/silicate composites. Polym J 44:1098–1104. https://doi.org/10.1038/pj.2012.68

Lamnawar K, Vion-Loisel F, Maazouz A (2010) Rheological, morphological, and heat seal properties of linear low density polyethylene and cyclo olefine copolymer (LLDPE/COC) blends. J Appl Polym Sci 116:2015–2022. https://doi.org/10.1002/app.31804

Khonakdar HA, Jafari SH, Hesabi MN (2015) Miscibility analysis, viscoelastic properties and morphology of cyclic olefin copolymer/polyolefin elastomer (COC/POE) blends. Compos Part B Eng 69:111–119. https://doi.org/10.1016/j.compositesb.2014.09.034

Cole KS, Cole RH (1941) Dispersion and absorption in dielectrics I. Alternating current characteristics. J Chem Phys 9:341. https://doi.org/10.1063/1.1750906

Codou A, Anstey A, Misra M, Mohanty AK (2018) Novel compatibilized nylon-based ternary blends with polypropylene and poly(lactic acid): morphology evolution and rheological behaviour †. RSC Adv 8:15709–15724. https://doi.org/10.1039/c8ra01707g

Huang Y, He Y, Ding W et al (2017) Improved viscoelastic, thermal, and mechanical properties of in situ microfibrillar polypropylene/ polyamide 6,6 composites via direct extrusion using a triple-screw extruder. RSC Adv 7:5030–5038. https://doi.org/10.1039/c6ra26734c

Tian J, Yu W, Zhou C (2006) The preparation and rheology characterization of long chain branching polypropylene. Polymer 47:7962–7969. https://doi.org/10.1016/j.polymer.2006.09.042

Palierne JE (1990) Linear rheology of viscoelastic emulsions with interfacial tension. Rheol Acta Rheol Acta 29:204–214. https://doi.org/10.1007/BF01331356

Gramespacher H, Meissner J (1992) Interfacial tension between polymer melts measured by shear oscillations of their blends. J Rheol 36:1127–1141. https://doi.org/10.1122/1.550304

Lee HM, Park OO (1994) Rheology and dynamics of immiscible polymer blends. J Rheol 38:1405–1425. https://doi.org/10.1122/1.550551

Bousmina M (1999) Rheology of polymer blends: linear model for viscoelastic emulsions. Rheol Acta 38:73–83. https://doi.org/10.1007/s003970050157

Calvão PS, Yee M, Demarquette NR (2005) Effect of composition on the linear viscoelastic behavior and morphology of PMMA/PS and PMMA/PP blends. Polymer 46:2610–2620. https://doi.org/10.1016/j.polymer.2005.02.010

Jozaghkar MR, Jahani Y, Arabi H, Ziaee F (2019) Effect of polyethylene molecular architecture on the dynamic viscoelastic behavior of polyethylene/polyhexene-1 blends and its correlation with morphology. Polym Technol Mater 58:560–572. https://doi.org/10.1080/03602559.2018.1493125

Liao H, Liao R, Li S et al (2021) Rheology of a polypropylene/low-density polyethylene blending melt: fitting dynamic rheological data by Palierne model and Lee and Park model. Polym Bull 79:4957–4970. https://doi.org/10.1007/s00289-021-03720-y

Findley WN, Lai JS, Onaran K (1976) Creep and relaxation of nonlinear viscoelastic materials: with an introduction to linear viscoelasticity. North Holland Publishing Company, New York

Yang JL, Zhang Z, Schlarb AK, Friedrich K (2006) On the characterization of tensile creep resistance of polyamide 66 nanocomposites. Part II: modeling and prediction of long-term performance. Polymer 47:6745–6758. https://doi.org/10.1016/j.polymer.2006.07.060

Xu Y, Wu Q, Lei Y, Yao F (2010) Creep behavior of bagasse fiber reinforced polymer composites. Bioresour Technol 101:3280–3286. https://doi.org/10.1016/j.biortech.2009.12.072

Acknowledgements

This study was supported by The Research Fund of Istanbul University-Cerrahpasa, with the grant number of FYL-2018-32296.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ercan, N., Korkmaz, E. Rheological, morphological and solid-state viscoelastic properties of ethylene vinyl acetate copolymer/olefin block copolymer (EVA/OBC) blends. Polym. Bull. 81, 4993–5010 (2024). https://doi.org/10.1007/s00289-023-04943-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-023-04943-x