Abstract

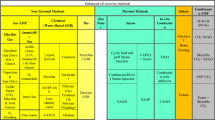

This review comprehensively summarizes potential applications of SiO2–polymer composites especially in oil industries: enhanced oil recovery (EOR), loss circulation (LC), and relative permeability modification (RPM). The significance of these materials has been widely recognized as high-performance functional materials as they combine the flexural properties of the polymer and enhanced thermo-mechanical characteristics of SiO2 nanoparticles (NPs). The composite exhibits increased impact resistance and tensile strength without decreasing the flexibility of the polymer. The addition of SiO2 into the polymer matrices can further extend the possibility of creating hierarchically structured materials, and therefore, SiO2–polymer composites have attracted great interest in various industries. Compared to other materials, suspended NPs/polymer composites offer various advantages, such as high thermal stability, long-term stability, salinity tolerance, and viscosity increment which are very crucial criteria for increased oil production.

Graphical abstract

Reproduced with permission from Elsevier

Reproduced with permission from Elsevier

Reproduced with permission from Elsevier

Reproduced with permission from Taylor and Francis [201]

Similar content being viewed by others

References

Firozjaii AM, Saghafi HR (2020) Review on chemical enhanced oil recovery using polymer flooding: fundamentals, experimental and numerical simulation. Petroleum 6:115–122

Peng B, Tang J, Luo J et al (2018) Applications of nanotechnology in oil and gas industry: progress and perspective. Can J Chem Eng 96:91–100. https://doi.org/10.1002/cjce.23042

Huh C, Daigle H, Prigiobbe V, Prodanovic M (2019) Practical nanotechnology for petroleum engineers. CRC Press

Panchal H, Patel H, Patel J, Shah M (2021) A systematic review on nanotechnology in enhanced oil recovery. Petrol Res 6:204

Ngata MR, Yang B, Aminu MD et al (2021) Review of developments in nanotechnology application for formation damage control. Energy Fuels 36:80

Cheraghian GG, Afrand M (2021) Nanotechnology for drilling operations. In: Emerging Nanotechnologies for Renewable Energy. Elsevier, pp 135–148

Rajabi MS, Moradi R, Kavehpour HP (2021) An overview of nanotechnology in upstream and downstream of oil and gas industry: challenges and solutions. J Energy Res Technol 144:1–52

Fakoya MF, Shah SN (2017) Emergence of nanotechnology in the oil and gas industry: emphasis on the application of silica nanoparticles. Petroleum 3:391–405. https://doi.org/10.1016/j.petlm.2017.03.001

Ali JA, Kalhury AM, Sabir AN et al (2020) A state-of-the-art review of the application of nanotechnology in the oil and gas industry with a focus on drilling engineering. J Petrol Sci Eng 191:107118

Maagi MT, Lupyana SD, Jun G (2020) Nanotechnology in the petroleum industry: focus on the use of nanosilica in oil-well cementing applications—A review. J Petrol Sci Eng 193:107397

Mady MF, Kelland MA (2020) Review of nanotechnology impacts on oilfield scale management. ACS Appl Nano Mater 3:7343–7364

Han J, Sun J, Lv K et al (2022) Polymer gels used in oil-gas drilling and production engineering. Gels 8:637

Bila A, Stensen JÅ, Torsæter O (2019) Experimental investigation of polymer-coated silica nanoparticles for enhanced oil recovery. Nanomaterials 9:822

Negi G, Anirbid S, Sivakumar P (2021) Applications of silica and titanium dioxide nanoparticles in enhanced oil recovery: promises and challenges. Petrol Res 6:224–246

Agista M, Guo K, Yu Z (2018) A state-of-the-art review of nanoparticles application in petroleum with a focus on enhanced oil recovery. Appl Sci 8:871

Liu F, Zheng Z, Wang X et al (2022) Novel modified nano-silica/polymer composite in water-based drilling fluids to plug shale pores. Energy Sour Part A Recov Utilizat Environ Eff 44:8662–8678

Fan G, Li M, Chen X et al (2021) Polymer-nanosilica-assisted to evaluate oil recovery performances in sandstone reservoirs. Energy Rep 7:2588–2593

Olivieri F, Castaldo R, Cocca M et al (2021) Mesoporous silica nanoparticles as carriers of active agents for smart anticorrosive organic coatings: a critical review. Nanoscale 13:9091–9111

Narayan R, Nayak UY, Raichur AM, Garg S (2018) Mesoporous silica nanoparticles: a comprehensive review on synthesis and recent advances. Pharmaceutics 10:118

Suzuki N, Zakaria MB, Chiang Y-D et al (2012) Thermally stable polymer composites with improved transparency by using colloidal mesoporous silica nanoparticles as inorganic fillers. Phys Chem Chem Phys 14:7427–7432

Murugadoss S, Lison D, Godderis L et al (2017) Toxicology of silica nanoparticles: an update. Arch Toxicol 91:2967–3010

Manzano M, Vallet-Regí M (2020) Mesoporous silica nanoparticles for drug delivery. Adv Func Mater 30:1902634

Wu S-H, Mou C-Y, Lin H-P (2013) Synthesis of mesoporous silica nanoparticles. Chem Soc Rev 42:3862–3875

Jeelani PG, Mulay P, Venkat R, Ramalingam C (2020) Multifaceted application of silica nanoparticles. Rev Silicon 12:1337–1354

Kankala RK, Han Y, Na J et al (2020) Nanoarchitectured structure and surface biofunctionality of mesoporous silica nanoparticles. Adv Mater 32:1907035

Zhou S, Zhong Q, Wang Y et al (2022) Chemically engineered mesoporous silica nanoparticles-based intelligent delivery systems for theranostic applications in multiple cancerous/non-cancerous diseases. Coord Chem Rev 452:214309

Krishnan MR, Chien Y-C, Cheng C-F, Ho R-M (2017) Fabrication of mesoporous polystyrene films with controlled porosity and pore size by solvent annealing for templated syntheses. Langmuir 33:8428–8435

Ke Y, Stroeve P (2005) Polymer-layered silicate and silica nanocomposites. Elsevier

Kickelbick G (2003) Concepts for the incorporation of inorganic building blocks into organic polymers on a nanoscale. Prog Polym Sci 28:83–114. https://doi.org/10.1016/S0079-6700(02)00019-9

Lee DW, Yoo BR (2016) Advanced silica/polymer composites: materials and applications. J Ind Eng Chem 38:1–12. https://doi.org/10.1016/j.jiec.2016.04.016

Paul DR, Robeson LM (2008) Polymer nanotechnology: nanocomposites. Polymer 49:3187–3204. https://doi.org/10.1016/j.polymer.2008.04.017

Peters ST (2013) Handbook of composites. Springer Science & Business Media

Sanchez C, Belleville P, Popall M, Nicole L (2011) Applications of advanced hybrid organic–inorganic nanomaterials: from laboratory to market. Chem Soc Rev 40:696–753. https://doi.org/10.1039/C0CS00136H

Wei L, Hu N, Zhang Y (2010) Synthesis of polymer—mesoporous silica nanocomposites. Materials 3:4066–4079

Yang F, Nelson GL (2006) Polymer/silica nanocomposites prepared via extrusion. Polym Adv Technol 17:320–326

Zou H, Wu S, Shen J (2008) Polymer/silica nanocomposites: preparation, characterization, properties, and applications. Chem Rev 108:3893–3957

Yin P, Xu M, Liu W et al (2014) High efficient adsorption of gold ions onto the novel functional composite silica microspheres encapsulated by organophosphonated polystyrene. J Ind Eng Chem 20:379–390. https://doi.org/10.1016/j.jiec.2013.04.032

Neoh KG, Tan KK, Goh PL et al (1999) Electroactive polymer–SiO2 nanocomposites for metal uptake. Polymer 40:887–893. https://doi.org/10.1016/S0032-3861(98)00297-3

Javadian H, Sorkhrodi FZ, Koutenaei BB (2014) Experimental investigation on enhancing aqueous cadmium removal via nanostructure composite of modified hexagonal type mesoporous silica with polyaniline/polypyrrole nanoparticles. J Ind Eng Chem 20:3678–3688. https://doi.org/10.1016/j.jiec.2013.12.066

Setshedi KZ, Bhaumik M, Onyango MS, Maity A (2014) Breakthrough studies for Cr(VI) sorption from aqueous solution using exfoliated polypyrrole-organically modified montmorillonite clay nanocomposite. J Ind Eng Chem 20:2208–2216. https://doi.org/10.1016/j.jiec.2013.09.052

Taha AA, Wu Y, Wang H, Li F (2012) Preparation and application of functionalized cellulose acetate/silica composite nanofibrous membrane via electrospinning for Cr(VI) ion removal from aqueous solution. J Environ Manage 112:10–16. https://doi.org/10.1016/j.jenvman.2012.05.031

Mirzabe GH, Keshtkar AR (2015) Application of response surface methodology for thorium adsorption on PVA/Fe3O4/SiO2/APTES nanohybrid adsorbent. J Ind Eng Chem 26:277–285. https://doi.org/10.1016/j.jiec.2014.11.040

Rosenberg E (2005) Silica polyamine composites: advanced materials for metal ion recovery and remediation. In: Macromolecules Containing Metal and Metal‐Like Elements. Wiley, Ltd, pp 51–78

Choi K, Lee S, Park JO et al (2018) Chromium removal from aqueous solution by a PEI-silica nanocomposite. Sci Rep 8:1–10

Gonon P, Sylvestre A, Teysseyre J, Prior C (2001) Dielectric properties of epoxy/silica composites used for microlectronic packaging, and their dependence on post-curing. J Mater Sci: Mater Electron 12:81–86. https://doi.org/10.1023/A:1011241818209

Jang J, Ha J, Lim B (2006) Synthesis and characterization of monodisperse silica–polyaniline core–shell nanoparticles. Chem Commun. https://doi.org/10.1039/B600167J

Karthik R, Meenakshi S (2014) Removal of hexavalent chromium ions using polyaniline/silica gel composite. J Water Process Eng 1:37–45. https://doi.org/10.1016/j.jwpe.2014.03.001

Mahmoud ME, Mohamed AK, Amira MF, Seleim SM (2020) Water-stable metal-organic framework/amine-modified silica/poly (piperazine-cresol) hybrids for efficient uptake of La (III) ions. Mater Chem Phys 251:123107

Osman AM, Hendi A, Saleh TA (2020) Simultaneous adsorption of dye and toxic metal ions using an interfacially polymerized silica/polyamide nanocomposite: Kinetic and thermodynamic studies. J Mol Liq 314:113640

Zhang T, Zhang L, Li C (2011) Study of the Preparation and properties of PBT/Epoxy/SiO2 nanocomposites. J Macromol Sci Part B 50:967–974. https://doi.org/10.1080/00222348.2010.497112

Chou Y-C, Wang Y-Y, Hsieh T-E (2007) Transparent photo-curable co-polyacrylate/silica nanocomposites prepared by sol-gel process. J Appl Polym Sci 105:2073–2082. https://doi.org/10.1002/app.26228

Kang DJ, Park GU, Park HY, Im H-G (2017) A robust transparent encapsulation material: silica nanoparticle-embedded epoxy hybrid nanocomposite. Compos Sci Technol 144:107–113

Liu S, Chen T (2020) Synthesis and luminescent properties of polymer-silica multilayer-encapsulated perovskite quantum dots for optoelectronics. J Chin Chem Soc 67:109–115

Morozova S, Alikina M, Vinogradov A, Pagliaro M (2020) Silicon quantum dots: synthesis, encapsulation, and application in light-emitting diodes. Front Chem 8:191

Park JH, Baek S-D, Cho JI et al (2019) Characteristics of transparent encapsulation materials for OLEDs prepared from mesoporous silica nanoparticle-polyurethane acrylate resin composites. Compos B Eng 175:107188

Wang Y-Y, Hsieh T-E (2007) Effect of UV curing on electrical properties of a UV-curable co-polyacrylate/silica nanocomposite as a transparent encapsulation resin for device packaging. Macromol Chem Phys 208:2396–2402. https://doi.org/10.1002/macp.200700229

Yoon C, Yang KP, Kim J et al (2020) Fabrication of highly transparent and luminescent quantum dot/polymer nanocomposite for light emitting diode using amphiphilic polymer-modified quantum dots. Chem Eng J 382:122792

Wong CP, Bollampally RS (1999) Thermal conductivity, elastic modulus, and coefficient of thermal expansion of polymer composites filled with ceramic particles for electronic packaging. J Appl Polym Sci 74:3396–3403. https://doi.org/10.1002/(SICI)1097-4628(19991227)74:14%3c3396::AID-APP13%3e3.0.CO;2-3

Bosc D, Devoldere N, Loisel B (1999) Mixed silica/polymer active directional coupler, in integrated optics

Jiguet S, Bertsch A, Hofmann H, Renaud P (2005) Conductive SU8 photoresist for microfabrication. Adv Func Mater 15:1511–1516. https://doi.org/10.1002/adfm.200400575

Jang J-H, Ullal CK, Maldovan M et al (2007) 3D Micro- and nanostructures via interference lithography. Adv Func Mater 17:3027–3041. https://doi.org/10.1002/adfm.200700140

Cho J-D, Ju H-T, Park Y-S, Hong J-W (2006) Kinetics of cationic photopolymerizations of UV-curable epoxy-based SU8-negative photoresists with and without silica nanoparticles. Macromol Mater Eng 291:1155–1163. https://doi.org/10.1002/mame.200600124

Battaglin G, Cattaruzza E, Gonella F et al (2004) Structural and optical properties of Cu:silica nanocomposite films prepared by co-sputtering deposition. Appl Surf Sci 226:52–56. https://doi.org/10.1016/j.apsusc.2003.11.030

Yu Y-Y, Chen W-C (2003) Transparent organic–inorganic hybrid thin films prepared from acrylic polymer and aqueous monodispersed colloidal silica. Mater Chem Phys 82:388–395. https://doi.org/10.1016/S0254-0584(03)00259-1

Chang C-C, Chen W-C (2002) Synthesis and optical properties of polyimide-silica hybrid thin films. Chem Mater 14:4242–4248. https://doi.org/10.1021/cm0202310

Bifulco A, Parida D, Salmeia KA et al (2020) Improving flame retardancy of in-situ silica-epoxy nanocomposites cured with aliphatic hardener: combined effect of DOPO-based flame-retardant and melamine. Compos Part C Open Access 2:100022

Chiang CL, Ma CCM, Wu DL, Kuan HC (2003) J Polym Sci A: Polym Chem 41:1162

Członka S, Strąkowska A, Strzelec K et al (2020) Melamine, silica, and ionic liquid as a novel flame retardant for rigid polyurethane foams with enhanced flame retardancy and mechanical properties. Polym Test 87:106511

Kashiwagi T, Morgan AB, Antonucci JM et al (2003) Thermal and flammability properties of a silica–poly(methylmethacrylate) nanocomposite. J Appl Polym Sci 89:2072–2078. https://doi.org/10.1002/app.12307

Bae I, Oh K-H, Yun S-H, Kim H (2017) Asymmetric silica composite polymer electrolyte membrane for water management of fuel cells. J Membr Sci 542:52–59. https://doi.org/10.1016/j.memsci.2017.07.058

Chen C-Y, Garnica-Rodriguez JI, Duke MC et al (2007) Nafion/polyaniline/silica composite membranes for direct methanol fuel cell application. J Power Sources 166:324–330. https://doi.org/10.1016/j.jpowsour.2006.12.102

Chia MY, San Thiam H, Leong LK et al (2020) Study on improvement of the selectivity of proton exchange membrane via incorporation of silicotungstic acid-doped silica into SPEEK. Int J Hydrog Energy 45:22315–22323

Geng H, Wu H, Li J et al (2020) Preparing proton exchange membranes via incorporating silica-based nanoscale ionic materials for the enhanced proton conductivity. Solid State Ionics 349:115294. https://doi.org/10.1016/j.ssi.2020.115294

Lee C, Na H, Jeon Y et al (2019) Poly(ether imide) nanofibrous web composite membrane with SiO2/heteropolyacid ionomer for durable and high-temperature polymer electrolyte membrane (PEM) fuel cells. J Ind Eng Chem 74:7–13. https://doi.org/10.1016/j.jiec.2019.01.034

Mishra AK, Bose S, Kuila T et al (2012) Silicate-based polymer-nanocomposite membranes for polymer electrolyte membrane fuel cells. Prog Polym Sci 37:842–869. https://doi.org/10.1016/j.progpolymsci.2011.11.002

Sambandam S, Ramani V (2007) SPEEK/functionalized silica composite membranes for polymer electrolyte fuel cells. J Power Sources 170:259–267. https://doi.org/10.1016/j.jpowsour.2007.04.026

Shaari N, Kamarudin SK (2019) Recent advances in additive-enhanced polymer electrolyte membrane properties in fuel cell applications: an overview. Int J Energy Res. https://doi.org/10.1002/er.4348

Sharma PP, Gupta H, Kulshrestha V (2020) Phosphorylated hybrid silica-sulfonated polyethersulfone composite proton-exchange membranes: magnetic resonance investigation for enhanced proton-exchange dynamics. Int J Hydrog Energy 45:16955–16964

Tripathi BP, Shahi VK (2011) Organic–inorganic nanocomposite polymer electrolyte membranes for fuel cell applications. Prog Polym Sci 36:945–979. https://doi.org/10.1016/j.progpolymsci.2010.12.005

Wang H, Holmberg BA, Huang L et al (2002) Nafion-bifunctional silica composite proton conductive membranes. J Mater Chem 12:834–837. https://doi.org/10.1039/B107498A

Wen S, Gong C, Tsen W-C et al (2010) Sulfonated poly(ether sulfone)/silica composite membranes for direct methanol fuel cells. J Appl Polym Sci 116:1491–1498. https://doi.org/10.1002/app.31699

Borisova D, Möhwald H, Shchukin DG (2011) Mesoporous silica nanoparticles for active corrosion protection. ACS Nano 5:1939–1946

Golestaneh M, Amini G, Najafpour GD, Beygi MA (2010) Evaluation of mechanical strength of epoxy polymer concrete with silica powder as filler. World Appl Sci J 9:216–220

Yeh J-M, Chang K-C (2014) J Ind Eng Chem 20:275

Cho YK, Park EJ, Kim YD (2014) Removal of oil by gelation using hydrophobic silica nanoparticles. J Ind Eng Chem 20:1231–1235. https://doi.org/10.1016/j.jiec.2013.08.005

Izevbekhai OU, Gitari WM, Tavengwa NT et al (2020) Response surface optimization of oil removal using synthesized polypyrrole-silica polymer composite. Molecules 25:4628

Ma Q, Liu Y, Dong Z, et al (2015) Hydrophobic and nanoporous chitosan–silica composite aerogels for oil absorption. J Appl Polym Sci 132

Nguyen ST, Feng J, Ng SK et al (2014) Advanced thermal insulation and absorption properties of recycled cellulose aerogels. Colloids Surf, A 445:128–134. https://doi.org/10.1016/j.colsurfa.2014.01.015

Wang H, Zhang C, Zhou B et al (2020) Hydrophobic silica nanorod arrays vertically grown on melamine foams for oil/water separation. ACS Appl Nano Mater 3:1479–1488

Lei Q, Guo J, Noureddine A et al (2020) Sol–gel-based advanced porous silica materials for biomedical applications. Adv Func Mater 30:1909539

Li H, Huang D, Ren K, Ji J (2020) Inorganic-polymer composite coatings for biomedical devices. Smart Mater Med 2:1–14

McInnes SJ, Irani Y, Williams KA, Voelcker NH (2012) Controlled drug delivery from composites of nanostructured porous silicon and poly(L-lactide). Nanomedicine 7:995–1016. https://doi.org/10.2217/nnm.11.176

Ramakrishna S, Mayer J, Wintermantel E, Leong KW (2001) Biomedical applications of polymer-composite materials: a review. Compos Sci Technol 61:1189–1224

Rho W-Y, Kim H-M, Kyeong S et al (2014) Facile synthesis of monodispersed silica-coated magnetic nanoparticles. J Ind Eng Chem 20:2646–2649. https://doi.org/10.1016/j.jiec.2013.12.014

Salernitano E, Migliaresi C (2003) Composite materials for biomedical applications: a review. J Appl Biomater Biomech 1:3–18

Wu H, Zhao Y, Mu X et al (2015) A silica–polymer composite nano system for tumor-targeted imaging and p53 gene therapy of lung cancer. J Biomater Sci Polym Ed 26:384–400. https://doi.org/10.1080/09205063.2015.1012035

Liu H, Xu J, Guo B, He X (2014) Preparation and performance of silica/polypropylene composite separator for lithium-ion batteries. J Mater Sci 49:6961–6966. https://doi.org/10.1007/s10853-014-8401-2

Raveh M, Liu L, Mandler D (2013) Electrochemical co-deposition of conductive polymer–silica hybrid thin films. Phys Chem Chem Phys 15:10876–10884. https://doi.org/10.1039/C3CP50457C

Zhong B, Shen L, Zhang X et al (2021) Reduced graphene oxide/silica nanocomposite-reinforced anticorrosive fluorocarbon coating. J Appl Polym Sci 138:49689

Kim D, Lee JS, Barry CMF, Mead JL (2007) Effect of fill factor and validation of characterizing the degree of mixing in polymer nanocomposites. Polym Eng Sci 47:2049–2056. https://doi.org/10.1002/pen.20920

Mittal V (2015) Synthesis techniques for polymer nanocomposites. Wiley

Yang F, Nelson GL (2004) PMMA/silica nanocomposite studies: synthesis and properties. J Appl Polym Sci 91:3844–3850

Ou C-F, Hsu M-C (2007) Preparation and characterization of cyclo olefin copolymer (COC)/silica nanoparticle composites by solution blending. J Polym Res 14:373–378. https://doi.org/10.1007/s10965-007-9119-5

Huang J-W, Wen Y-L, Kang C-C, Yeh M-Y (2007) Preparation of polyimide-silica nanocomposites from nanoscale colloidal silica. Polym J 39:654

Fielding LA, Tonnar J, Armes SP (2011) All-acrylic film-forming colloidal polymer/silica nanocomposite particles prepared by aqueous emulsion polymerization. Langmuir 27:11129–11144. https://doi.org/10.1021/la202066n

Zhou C, Xu S, Pi P et al (2018) Polyacrylate/silica nanoparticles hybrid emulsion coating with high silica content for high hardness and dry-wear-resistant. Prog Org Coat 121:30–37. https://doi.org/10.1016/j.porgcoat.2018.04.001

Zhang S-W, Zhou S-X, Weng Y-M, Wu L-M (2005) Synthesis of SiO2/polystyrene nanocomposite particles via miniemulsion polymerization. Langmuir 21:2124–2128. https://doi.org/10.1021/la047652b

Monteil V, Stumbaum J, Thomann R, Mecking S (2006) Silica/polyethylene nanocomposite particles from catalytic emulsion polymerization. Macromolecules 39:2056–2062. https://doi.org/10.1021/ma052737k

Hyde ED, Seyfaee A, Neville F, Moreno-Atanasio R (2016) Colloidal silica particle synthesis and future industrial manufacturing pathways: a review. Ind Eng Chem Res 55:8891–8913

Stöber W, Fink A, Bohn E (1968) Controlled growth of monodisperse silica spheres in the micron size range. J Colloid Interface Sci 26:62–69. https://doi.org/10.1016/0021-9797(68)90272-5

Burrows LC, Haeri F, Cvetic P et al (2020) A literature review of CO2, natural gas, and water-based fluids for enhanced oil recovery in unconventional reservoirs. Energy Fuels 34:5331–5380

Jin F (2017) Principles of enhanced oil recovery. In: Hu X, Hu S, Jin F, Huang S (eds) Physics of Petroleum Reservoirs. Springer, Berlin Heidelberg, pp 465–506

Zhe Z, Yuxiu A (2018) Nanotechnology for the oil and gas industry—An overview of recent progress. Nanotechnol Rev 7:341–353. https://doi.org/10.1515/ntrev-2018-0061

Kong X, Ohadi MM (2010) Applications of micro and nano technologies in the oil and gas industry-an overview of the recent progress. OnePetro

Lashari N, Ganat T (2020) Emerging applications of nanomaterials in chemical enhanced oil recovery: progress and perspective. Chin J Chem Eng 28:1995–2009

Cheraghian G, Rostami S, Afrand M (2020) Nanotechnology in enhanced oil recovery. Processes 8:1073

Gbadamosi A, Junin R, Manan M, et al (2019) Nanotechnology application in chemical enhanced oil recovery: current opinion and recent advances. Enhanced Oil Recovery Processes-New Technologies

Sun X, Zhang Y, Chen G, Gai Z (2017) Application of nanoparticles in enhanced oil recovery: a critical review of recent progress. Energies. https://doi.org/10.3390/en10030345

Alnarabiji MS, Husein MM (2020) Application of bare nanoparticle-based nanofluids in enhanced oil recovery. Fuel 267:117262

Joshi D, Maurya NK, Kumar N, Mandal A (2022) Experimental investigation of silica nanoparticle assisted Surfactant and polymer systems for enhanced oil recovery. J Petrol Sci Eng 216:110791

Sun Q, Retnanto A, Amani M (2020) Seismic vibration for improved oil recovery: a comprehensive review of literature. Int J Hydrog Energy 45:14756–14778. https://doi.org/10.1016/j.ijhydene.2020.03.227

Niu J, Liu Q, Lv J, Peng B (2020) Review on microbial enhanced oil recovery: mechanisms, modeling and field trials. J Petrol Sci Eng 192:107350. https://doi.org/10.1016/j.petrol.2020.107350

Rahimi K, Adibifard M (2015) Experimental study of the nanoparticles effect on surfactant absorption and oil recovery in one of the Iranian oil reservoirs. Pet Sci Technol 33:79–85

Negin C, Ali S, Xie Q (2016) Application of nanotechnology for enhancing oil recovery–A review. Petroleum 2:324–333

Sun X, Zhang Y, Chen G, Gai Z (2017) Application of nanoparticles in enhanced oil recovery: a critical review of recent progress. Energies 10:345

Yakasai F, Jaafar MZ, Sidek MA et al (2023) Co-precipitation and grafting of (3-Aminopropyl) triethoxysilane on Ferro nanoparticles to enhance oil recovery mechanisms at reservoir conditions. J Mol Liq 371:121007

Tavakkoli O, Kamyab H, Shariati M et al (2022) Effect of nanoparticles on the performance of polymer/surfactant flooding for enhanced oil recovery: a review. Fuel 312:122867

Ju B, Fan T, Ma M (2006) Enhanced oil recovery by flooding with hydrophilic nanoparticles. China Particuol 4:41–46

Khilar KC, Fogler HS (1998) Migrations of fines in porous media. Springer Science & Business Media

Afekare D, Garno J, Rao D (2021) Enhancing oil recovery using silica nanoparticles: nanoscale wettability alteration effects and implications for shale oil recovery. J Petrol Sci Eng 203:108897

Cheraghian G (2015) Effects of nanoparticles on wettability: a review on applications of nanotechnology in the enhanced Oil recovery

Bera A, Belhaj H (2016) Application of nanotechnology by means of nanoparticles and nanodispersions in oil recovery—A comprehensive review. J Nat Gas Sci Eng 34:1284–1309. https://doi.org/10.1016/j.jngse.2016.08.023

Hammond PS, Unsal E (2011) Spontaneous imbibition of surfactant solution into an oil-wet capillary: wettability restoration by surfactant-contaminant complexation. Langmuir 27:4412–4429

Chatzis I, Morrow NR (1984) Correlation of capillary number relationships for sandstone. Soc Petrol Eng J 24:555–562

Munshi A, Singh V, Kumar M, Singh J (2008) Effect of nanoparticle size on sessile droplet contact angle. J Appl Phys 103:084315

Chengara A, Nikolov AD, Wasan DT et al (2004) Spreading of nanofluids driven by the structural disjoining pressure gradient. J Colloid Interface Sci 280:192–201. https://doi.org/10.1016/j.jcis.2004.07.005

Keykhosravi A, Simjoo M (2019) Insights into stability of silica nanofluids in brine solution coupled with rock wettability alteration: an enhanced oil recovery study in oil-wet carbonates. Colloids Surf A 583:124008

Dehghan Monfared A, Ghazanfari MH, Jamialahmadi M, Helalizadeh A (2016) Potential application of silica nanoparticles for wettability alteration of oil–wet calcite: a mechanistic study. Energy Fuels 30:3947–3961

Wasan DT, Nikolov AD (2003) Spreading of nanofluids on solids. Nature 423:156–159. https://doi.org/10.1038/nature01591

Shah DO (2012) Improved oil recovery by surfactant and polymer flooding. Elsevier

Agi A, Junin R, Abdullah MO et al (2020) Application of polymeric nanofluid in enhancing oil recovery at reservoir condition. J Petrol Sci Eng 194:107476

Choi SK, Son HA, Kim HT, Kim JW (2017) Nanofluid enhanced oil recovery using hydrophobically associative zwitterionic polymer-coated silica nanoparticles. Energy Fuels 31:7777–7782

Zeyghami M, Kharrat R, Ghazanfari M (2014) Investigation of the applicability of nano silica particles as a thickening additive for polymer solutions applied in EOR processes. Energy Sources Part A Recov Utiliz Environ Eff 36:1315–1324

Cheraghian G, Hemmati M, Bazgir S (2014) Application of TiO2 and fumed silica nanoparticles and improve the performance of drilling fluids. American Institute of Physics, pp 266–270

Gbadamosi A, Patil S, Kamal MS et al (2022) Application of polymers for chemical enhanced oil recovery: a review. Polymers. https://doi.org/10.3390/polym14071433

Sandvik E, Maerker J (1977) Application of xanthan gum for enhanced oil recovery. ACS Publications

Navaie F, Esmaeilnezhad E, Choi HJ (2022) Xanthan gum-added natural surfactant solution of Chuback: a green and clean technique for enhanced oil recovery. J Mol Liq 354:118909

Li Q, Wei B, Lu L et al (2017) Investigation of physical properties and displacement mechanisms of surface-grafted nano-cellulose fluids for enhanced oil recovery. Fuel 207:352–364

Yusuf SM, Junin R, Muhamad Sidek MA et al (2022) Screening the synergy of sodium dodecylbenzenesulfonate and carboxymethyl cellulose for surfactant-polymer flooding. Petrol Res 7:308–317. https://doi.org/10.1016/j.ptlrs.2021.11.002

Bai Y, Shang X, Wang Z, Zhao X (2018) Experimental study on hydrophobically associating hydroxyethyl cellulose flooding system for enhanced oil recovery. Energy Fuels 32:6713–6725. https://doi.org/10.1021/acs.energyfuels.8b01138

Zhu J, Xie S, Yang Z et al (2021) A review of recent advances and prospects on nanocellulose properties and its applications in oil and gas production. J Nat Gas Sci Eng 96:104253. https://doi.org/10.1016/j.jngse.2021.104253

ShimaaM E, Zaki EG, Omar WAE et al (2021) Guar gum-based hydrogels as potent green polymers for enhanced oil recovery in high-salinity reservoirs. ACS Omega 6:23421–23431. https://doi.org/10.1021/acsomega.1c03352

Pu W, Shen C, Wei B et al (2018) A comprehensive review of polysaccharide biopolymers for enhanced oil recovery (EOR) from flask to field. J Ind Eng Chem 61:1–11. https://doi.org/10.1016/j.jiec.2017.12.034

Shoaib M, Quadri SMR, Wani OB et al (2020) Adsorption of enhanced oil recovery polymer, schizophyllan, over carbonate minerals. Carbohydr Polym 240:116263. https://doi.org/10.1016/j.carbpol.2020.116263

Han D-K, Yang C-Z, Zhang Z-Q et al (1999) Recent development of enhanced oil recovery in China. J Pet Sci Eng 22:181–188. https://doi.org/10.1016/S0920-4105(98)00067-9

Li G, Zhai L, Xu G et al (2000) Current tertiary oil recovery in China. J Dispers Sci Technol 21:367–408. https://doi.org/10.1080/01932690008913277

Lake LW, Venuto PB (1990) A niche for enhanced oil recovery in the 1990s. Oil Gas J 88:62–67

Sorbie KS (2013) Polymer-improved oil recovery. Springer Science & Business Media

Gaillard N, Sanders DB, Favero C (2010) Improved oil recovery using thermally and chemically protected compositions based on co-and ter-polymers containing acrylamide. Soc Petrol Eng

Pancharoen M, Thiele MR, Kovscek AR (2010) Inaccessible pore volume of associative polymer floods. Soc Petrol Eng

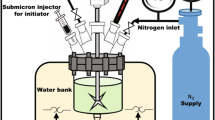

Almohsin A, Michal F, Alsharaeh E, et al (2019) Self-healing PAM composite hydrogel for water shutoff at high temperatures: thermal and rheological investigations. In: SPE-198664-MS. Society of Petroleum Engineers, Dubai, UAE, p 8

Krishnan M, Michal F, Alsoughayer S, et al (2019) Thermodynamic and kinetic investigation of water absorption by PAM composite hydrogel. In: SPE-198033-MS. Society of Petroleum Engineers, Mishref, Kuwait, p 11

Krishnan MR, Samitsu S, Fujii Y, Ichinose I (2014) Hydrophilic polymer nanofibre networks for rapid removal of aromatic compounds from water. Chem Commun 50:9393–9396. https://doi.org/10.1039/C4CC01786B

Michael FM, Krishnan MR, AlSoughayer S et al (2020) Thermo-elastic and self-healing polyacrylamide-2D nanofiller composite hydrogels for water shutoff treatment. J Pet Sci Eng 193:107391. https://doi.org/10.1016/j.petrol.2020.107391

Michael FM, Krishnan MR, Fathima A et al (2019) Zirconia/graphene nanocomposites effect on the enhancement of thermo-mechanical stability of polymer hydrogels. Mater Today Commun. https://doi.org/10.1016/j.mtcomm.2019.100701

Wang D, Xia H, Liu Z, Yang Q (2001) Study of the mechanism of polymer solution with visco-elastic behavior increasing microscopic oil displacement efficiency and the forming of steady" Oil thread" flow channels. Society of Petroleum Engineers

Zhang L, Guo F (2008) Micro-mechanisms of residual oil mobilization by viscoelastic fluids. Pet Sci 5:56–61

Bai B, Zhou J, Yin M (2015) A comprehensive review of polyacrylamide polymer gels for conformance control. Pet Explor Dev 42:525–532

Morgan SE, McCormick CL (1990) Water-soluble polymers in enhanced oil recovery. Prog Polym Sci 15:103–145

Sabhapondit A, Borthakur A, Haque I (2003) Characterization of acrylamide polymers for enhanced oil recovery. J Appl Polym Sci 87:1869–1878

Sabhapondit A, Borthakur A, Haque I (2003) Water soluble acrylamidomethyl propane sulfonate (AMPS) copolymer as an enhanced oil recovery chemical. Energy Fuels 17:683–688

Song H, Zhang S-F, Ma X-C et al (2007) Synthesis and application of starch-graft-poly (AM-co-AMPS) by using a complex initiation system of CS-APS. Carbohydr Polym 69:189–195

Levitt D, Pope GA (2008) Selection and screening of polymers for enhanced-oil recovery. Society of Petroleum Engineers

Abu-Sharkh B, Yahaya G, Ali S, Kazi I (2001) Solution and interfacial behavior of hydrophobically modified water-soluble block copolymers of acrylamide and N-phenethylacrylamide. J Appl Polym Sci 82:467–476

Metin CO, Baran JR, Nguyen QP (2012) Adsorption of surface functionalized silica nanoparticles onto mineral surfaces and decane/water interface. J Nanopart Res 14:1246

Ju B, Dai S, Luan Z, et al (2002) A study of wettability and permeability change caused by adsorption of nanometer structured polysilicon on the surface of porous media. Society of Petroleum Engineers

Wang L, Wang Z, Yang H, Yang G (1999) The study of thermal stability of the SiO2 powders with high specific surface area. Mater Chem Phys 57:260–263

Foroozesh J, Kumar S (2020) Nanoparticles behaviors in porous media: application to enhanced oil recovery. J Molecul Liq 316:113876. https://doi.org/10.1016/j.molliq.2020.113876

Mahian O, Kolsi L, Amani M et al (2019) Recent advances in modeling and simulation of nanofluid flows-part I: fundamentals and theory. Phys Rep 790:1–48. https://doi.org/10.1016/j.physrep.2018.11.004

Serna J (2016) Heat and mass transfer mechanisms in nanofluids boundary layers. Int J Heat Mass Transf 92:173–183. https://doi.org/10.1016/j.ijheatmasstransfer.2015.08.072

Zhang H, Ramakrishnan TS, Nikolov A, Wasan D (2018) Enhanced oil displacement by nanofluid’s structural disjoining pressure in model fractured porous media. J Colloid Interface Sci 511:48–56. https://doi.org/10.1016/j.jcis.2017.09.067

Rostami S, Ahmadlouydarab M, Haddad AS (2022) Effects of hot nanofluid injection on oil recovery from a model porous medium. Chem Eng Res Des 186:451–461

Minakov AV, Guzei DV, Pryazhnikov MI et al (2021) 3D pore-scale modeling of nanofluids-enhanced oil recovery. Pet Explor Dev 48:956–967. https://doi.org/10.1016/S1876-3804(21)60080-0

Hemmat Esfe M, Esfandeh S (2020) 3D numerical simulation of the enhanced oil recovery process using nanoscale colloidal solution flooding. J Molecul Liq 301:112094. https://doi.org/10.1016/j.molliq.2019.112094

Al-Yaari A, Ching DL, Sakidin H et al (2023) Optimum volume fraction and inlet temperature of an ideal nanoparticle for enhanced oil recovery by nanofluid flooding in a porous medium. Processes. https://doi.org/10.3390/pr11020401

Onyekonwu MO, Ogolo NA (2010) Investigating the use of nanoparticles in enhancing oil recovery. Society of Petroleum Engineers

Hendraningrat L, Li S, Torsaeter O (2013) Enhancing oil recovery of low-permeability berea sandstone through optimised nanofluids concentration. In: SPE-165283-MS. Society of Petroleum Engineers, Kuala Lumpur, Malaysia, p 10

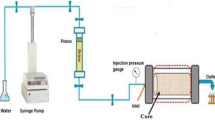

Yousefvand H, Jafari A (2015) Enhanced oil recovery using polymer/nanosilica. Procedia Mater Sci 11:565–570. https://doi.org/10.1016/j.mspro.2015.11.068

Zhu D, Han Y, Zhang J, et al (2014) Enhancing rheological properties of hydrophobically associative polyacrylamide aqueous solutions by hybriding with silica nanoparticles. J Appl Polym Sci 131

Aqcheli F, Salehi MB, Pahlevani H, Taghikhani V (2020) Rheological properties and the micromodel investigation of nanosilica gel-reinforced preformed particle gels developed for improved oil recovery. J Pet Sci Eng 192:107258

Kamibayashi M, Ogura H, Otsubo Y (2005) Viscosity behavior of silica suspensions flocculated by associating polymers. J Colloid Interface Sci 290:592–597

Otsubo Y, Umeya K (1984) Rheological properties of silica suspensions in polyacrylamide solutions. J Rheol 28:95–108

Aalaie J (2012) Rheological behavior of polyacrylamide/laponite nanoparticle suspensions in electrolyte media. J Macromol Sci Part B 51:1139–1147

Whitby CP, Scales PJ, Grieser F et al (2003) PAA/PEO comb polymer effects on rheological properties and interparticle forces in aqueous silica suspensions. J Colloid Interface Sci 262:274–281

Li Q, Yu X, Wang L, et al (2021) Nano-silica Hybrid Polyacrylamide/Polyethylenimine Gel for Enhanced Oil Recovery at Harsh Conditions. Colloids and Surfaces A: Physicochemical and Engineering Aspects 127898

Cao J, Song T, Wang X et al (2019) Studies on the rheological properties of amphiphilic nanosilica and a partially hydrolyzed polyacrylamide hybrid for enhanced oil recovery. Chem Eng Sci 206:146–155

Xu L, Liu S, Qiu Z et al (2021) Hydrophobic effect further improves the rheological behaviors and oil recovery of polyacrylamide/nanosilica hybrids at high salinity. Chem Eng Sci 232:116369

Gbadamosi AO, Junin R, Manan MA et al (2019) Hybrid suspension of polymer and nanoparticles for enhanced oil recovery. Polym Bull 76:6193–6230

Kennedy JR, Kent KE, Brown JR (2015) Rheology of dispersions of xanthan gum, locust bean gum and mixed biopolymer gel with silicon dioxide nanoparticles. Mater Sci Eng, C 48:347–353

Bera A, Shah S, Shah M et al (2020) Mechanistic study on silica nanoparticles-assisted guar gum polymer flooding for enhanced oil recovery in sandstone reservoirs. Colloids Surf, A 598:124833

Maurya NK, Mandal A (2016) Studies on behavior of suspension of silica nanoparticle in aqueous polyacrylamide solution for application in enhanced oil recovery. Pet Sci Technol 34:429–436

Maghzi A, Kharrat R, Mohebbi A, Ghazanfari MH (2014) The impact of silica nanoparticles on the performance of polymer solution in presence of salts in polymer flooding for heavy oil recovery. Fuel 123:123–132

Pu W-F, Liu R, Wang K-Y et al (2015) Water-soluble core-shell hyperbranched polymers for enhanced oil recovery. Ind Eng Chem Res 54:798–807. https://doi.org/10.1021/ie5039693

Shahrabadi A, Bagherzadeh H, Roostaie A, Golghanddashti H (2012) Experimental investigation of HLP nanofluid potential to enhance oil recovery: a mechanistic approach. In: SPE-156642-MS. Society of Petroleum Engineers, SPE, p 9

Hendraningrat L, Torsaeter O (2014) Unlocking the potential of metal oxides nanoparticles to enhance the oil recovery. In: OTC-24696-MS. Offshore Technology Conference, OTC, p 12

Sharma T, Kumar GS, Sangwai JS (2015) Comparative effectiveness of production performance of Pickering emulsion stabilized by nanoparticle–surfactant–polymerover surfactant–polymer (SP) flooding for enhanced oil recoveryfor Brownfield reservoir. J Pet Sci Eng 129:221–232. https://doi.org/10.1016/j.petrol.2015.03.015

Zhang T, Davidson D, Bryant SL, Huh C (2010) Nanoparticle-stabilized emulsions for applications in enhanced oil recovery. In: SPE-129885-MS. Society of Petroleum Engineers, Tulsa, Oklahoma, USA, p 18

Binks BP, Philip J, Rodrigues JA (2005) Inversion of silica-stabilized emulsions induced by particle concentration. Langmuir 21:3296–3302. https://doi.org/10.1021/la046915z

Son H, Kim H, Lee G et al (2014) Enhanced oil recovery using nanoparticle-stabilized oil/water emulsions. Korean J Chem Eng 31:338–342. https://doi.org/10.1007/s11814-013-0214-5

Maurya NK, Mandal A (2018) Investigation of synergistic effect of nanoparticle and surfactant in macro emulsion based EOR application in oil reservoirs. Chem Eng Res Des 132:370–384. https://doi.org/10.1016/j.cherd.2018.01.049

Sun Q, Zhang N, Li Z, Wang Y (2016) Nanoparticle-stabilized foam for mobility control in enhanced oil recovery. Energ Technol 4:1084–1096. https://doi.org/10.1002/ente.201600093

Yu J, Khalil M, Liu N, Lee R (2014) Effect of particle hydrophobicity on CO2 foam generation and foam flow behavior in porous media. Fuel 126:104–108. https://doi.org/10.1016/j.fuel.2014.02.053

Yadav US, Kumar H, Roy V et al (2020) Experimental evaluation of partially hydrolyzed polyacrylamide and silica nanoparticles solutions for enhanced oil recovery. J Pet Explor Prod Technol 10:1109–1114

Zheng C, Cheng Y, Wei Q et al (2017) Suspension of surface-modified nano-SiO2 in partially hydrolyzed aqueous solution of polyacrylamide for enhanced oil recovery. Colloids Surf A 524:169–177. https://doi.org/10.1016/j.colsurfa.2017.04.026

Cao J, Song T, Zhu Y et al (2018) Aqueous hybrids of amino-functionalized nanosilica and acrylamide-based polymer for enhanced oil recovery. RSC Adv 8:38056–38064

Liu J, Wang S, He L et al (2022) Preparation and properties of nano-silica hybrid hydrophobic associated polyacrylamide for polymer flooding. J Petrol Sci Eng 208:109434

Cao J, Song T, Zhu Y et al (2018) Application of amino-functionalized nanosilica in improving the thermal stability of acrylamide-based polymer for enhanced oil recovery. Energy Fuels 32:246–254

Zhu D, Wei L, Wang B, Feng Y (2014) Aqueous hybrids of silica nanoparticles and hydrophobically associating hydrolyzed polyacrylamide used for EOR in high-temperature and high-salinity reservoirs. Energies 7:3858–3871

Wang Y, He Z, Chen W et al (2020) Stability and rheological properties of HPAM/nanosilica suspensions: impact of salinity. Colloids Surf A 587:124320

Elhaei R, Kharrat R, Madani M (2020) Stability, flocculation, and rheological behavior of silica suspensions-augmented polyacrylamide and the possibility to improve polymer flooding functionality. J Mol Liq 322:114572

Haruna MA, Gardy J, Yao G et al (2020) Nanoparticle modified polyacrylamide for enhanced oil recovery at harsh conditions. Fuel 268:117186

Corredor LM, Husein MM, Maini BB (2019) Impact of PAM-grafted nanoparticles on the performance of hydrolyzed polyacrylamide solutions for heavy oil recovery at different salinities. Ind Eng Chem Res 58:9888–9899

Maghzi A, Mohebbi A, Kharrat R, Ghazanfari MH (2013) An experimental investigation of silica nanoparticles effect on the rheological behavior of polyacrylamide solution to enhance heavy oil recovery. Pet Sci Technol 31:500–508. https://doi.org/10.1080/10916466.2010.518191

Sharma T, Iglauer S, Sangwai JS (2016) Silica nanofluids in an oilfield polymer polyacrylamide: interfacial properties, wettability alteration, and applications for chemical enhanced oil recovery. Ind Eng Chem Res 55:12387–12397

Muggeridge A, Cockin A, Webb K et al (2014) Recovery rates, enhanced oil recovery and technological limits. Philos Trans Royal Soc A Math Phys Eng Sci 372:20120320

Lashari N, Ganat T, Elraies KA et al (2022) Impact of nanoparticles stability on rheology, interfacial tension, and wettability in chemical enhanced oil recovery: a critical parametric review. J Petrol Sci Eng 212:110199

Nwidee LN (2017) Nanoparticles for enhanced oil recovery processes

Al-shajalee F, Wood C, Xie Q, Saeedi A (2019) Effective mechanisms to relate initial rock permeability to outcome of relative permeability modification. Energies. https://doi.org/10.3390/en12244688

Kalfayan LJ, Dawson JC (2004) Successful implementation of resurgent Relative Permeability Modifier (RPM) technology in well treatments requires realistic expectations. OnePetro

Grattoni C, Luckham P, Jing X et al (2004) Polymers as relative permeability modifiers: adsorption and the dynamic formation of thick polyacrylamide layers. J Petrol Sci Eng 45:233–245

Qin L, Arjomand E, Myers MB et al (2020) Mechanistic aspects of polymeric relative permeability modifier adsorption onto carbonate rocks. Energy Fuels 34:12065–12077

Esmaeili S, Sarma H, Harding T, Maini B (2019) Review of the effect of temperature on oil-water relative permeability in porous rocks of oil reservoirs. Fuel 237:91–116

Di Lullo G, Rae P (2002) New Insights into water control—A review of the state of the art. In: SPE-77963-MS. Society of Petroleum Engineers, SPE, p 10

Fathima A, Almohsin A, Michael FM et al (2018) Polymer nanocomposites for water shutoff application—A review. Mater Res Express 6:032001

Sydansk RD, Seright RS (2006) When and where relative permeability modification water-shutoff treatments can be successfully applied. In: SPE-99371-MS. Society of Petroleum Engineers, Tulsa, Oklahoma, USA, p 15

Zaltoun A, Kohler N, Guerrinl Y (1991) Improved polyacrylamide treatments for water control in producing wells. J Petrol Technol 43:862–867

Zaitoun A, Kohler N, Marrast J, Guerrini Y (1990) On the use of polymers to reduce water production from gas wells. In Situ;(USA) 14

Sparlin DD (1976) An evaluation of polyacrylamides for reducing water production (includes associated papers 6561 and 6562). J Petrol Technol 28:906–914

Vasquez J, Eoff L (2013) A relative permeability modifier for water control: candidate selection, case histories, and lessons learned after more than 3000 well interventions. OnePetro

Maffra DA, Freitas TC, da Cruz GF et al (2018) Evaluation of barium sulfate scale inhibition using relative permeability modifier polymers as adsorption enhancer for mature offshore well treatments in Campos Basin, Brazil. Ind Eng Chem Res 57:11493–11504

Chiappa L, Mennella A, Lockhart TP, Burrafato G (1999) Polymer adsorption at the brine/rock interface: the role of electrostatic interactions and wettability. J Petrol Sci Eng 24:113–122

Marra J, Hair ML (1988) Interactions between two adsorbed layers of poly (ethylene oxide)/polystyrene diblock copolymers in heptane—Toluene mixtures. Colloids Surf 34:215–226

Cohen Y, Christ F (1986) Polymer retention and adsorption in the flow of polymer solutions through porous media. SPE Reserv Eng 1:113–118

Willhite GP, Zhu H, Natarajan D et al (2002) Mechanisms causing disproportionate permeability reduction in porous media treated with chromium acetate/HPAM gels. SPE J 7:100–108

Seright RS, Prodanovic M, Lindquist WB (2006) X-ray computed microtomography studies of fluid partitioning in drainage and imbibition before and after gel placement: disproportionate permeability reduction. SPE J 11:159–170

Liang B, Jiang H, Li J et al (2018) Mechanism study of disproportionate permeability reduction using nuclear magnetic resonance T2. Energy Fuels 32:4959–4968

Yao C, Wang D, Wang J et al (2017) Effect of ionic strength on the transport and retention of polyacrylamide microspheres in reservoir water shutoff treatment. Ind Eng Chem Res 56:8158–8168

Han M, Zhou X, Alhasan FB, et al (2012) Laboratory investigation of the injectivity of sulfonated polymer solutions into carbonate reservoir rocks. OnePetro

Seright R, Brattekas B (2021) Water shutoff and conformance improvement: an introduction. Pet Sci 18:450–478

Seright R, Liang J (1994) A survey of field applications of gel treatments for water shutoff. OnePetro

Krishnan MR, Almohsin A, Alsharaeh EH (2022) Syntheses and fabrication of mesoporous styrene-co-methyl methacrylate-graphene composites for oil removal. Diam Relat Mater 130:109494

Almohsin A, Alsharaeh E, Krishnan MR, Alghazali M (2022) Coated nanosand as relative permeability modifier

Eoff L, Dalrymple ED, Reddy BR, Everett D (2001) Structure and process optimization for the use of a polymeric relative-permeability modifier in conformance Control. OnePetro

Liang J, Seright R (2001) Wall-effect/gel-droplet model of disproportionate permeability reduction. SPE J 6:268–272

Al-Sharji H, Grattoni C, Dawe R, Zimmerman R (2001) Flow of oil and water through elastic polymer gels. Oil Gas Sci Technol 56:145–152

Stavland A, Nilsson S (2001) Segregated flow is the governing mechanism of disproportionate permeability reduction in water and gas shutoff. OnePetro

Zaitoun A, Kohler N (1988) Two-phase flow through porous media: effect of an adsorbed polymer layer. OnePetro

Cohen Y (1988) Hydrodynamic thickness of adsorbed polymers in steady shear flow. Macromolecules 21:494–499

Ranjbar M, Rupp J, Prusch G (1991) Influence of pore radi distribution on polymer retention in natural sandstones. European Association of Geoscientists & Engineers, p cp-44

Goudarzi A, Zhang H, Varavei A et al (2015) A laboratory and simulation study of preformed particle gels for water conformance control. Fuel 140:502–513

Al-Shajalee F, Arif M, Machale J et al (2020) A multiscale investigation of cross-linked polymer gel injection in sandstone gas reservoirs: implications for water shutoff treatment. Energy Fuels 34:14046–14057

El-Hoshoudy A, Mohammedy M, Ramzi M et al (2019) Experimental, modeling and simulation investigations of a novel surfmer-co-poly acrylates crosslinked hydrogels for water shut-off and improved oil recovery. J Mol Liq 277:142–156

Mohamadian N, Ghorbani H, Wood DA, Khoshmardan MA (2019) A hybrid nanocomposite of poly (styrene-methyl methacrylate-acrylic acid)/clay as a novel rheology-improvement additive for drilling fluids. J Polym Res 26:33

Lenji MA, Haghshenasfard M, Sefti MV, Salehi MB (2018) Experimental study of swelling and rheological behavior of preformed particle gel used in water shutoff treatment. J Petrol Sci Eng 169:739–747

Saghafi HR, Emadi MA, Farasat A et al (2016) Performance evaluation of optimized preformed particle gel (PPG) in porous media. Chem Eng Res Des 112:175–189

Imqam A, Bai B, Delshad M (2015) Preformed particle gel propagation through super-K permeability sand and its resistance to water flow during conformance control. Society of Petroleum Engineers

Heidari A, Vasheghani-Farahani E, Vafaie-Sefti M (2019) Preformed particle gels of sulfonated polyacrylamide: preparation, characterization, and application as permeability modifier. Iran Polym J 28:1001–1013

Qin L, Myers MB, Otto C, et al (2021) Further insights into the performance of silylated polyacrylamide-based relative permeability modifiers in carbonate reservoirs and influencing factors. ACS omega

Ahmed AA, Mohd Saaid I, Mohd Shafian S (2020) Novel relative permeability modifier using polymer grafted nanoclay. Energy Fuels 34:2703–2709

Gramain P, Myard P (1981) Elongational deformation by shear flow of flexible polymers adsorbed in porous media. Macromolecules 14:180–184

Mennella A, Chiappa L, Lockhart TP, Burrafato G (2001) Candidate and chemical selection guidelines for relative permeability modification (RPM) treatments. SPE Prod Facil 16:181–188

Chiappa L, Andrei M, Lockhart TP, et al (2003) Polymer design for relative permeability modification treatments at high temperature. SPE, p SPE-80202

Qi Z, Wang Y, Liu C et al (2013) A laboratory evaluation of a relative permeability modifier for water production control. Pet Sci Technol 31:2357–2363

Fulin Z, Dai Caili WY, Decheng F, Kai C (2006) Comprehension of water shutoff in oil wells and its technical keys. Acta Petrolei Sinica 27:71

Al-Shajalee F, Saeedi A, Wood C (2019) A new dimensionless approach to assess relative permeability modifiers. Energy Fuels 33:3448–3455

Li W, Sahu Q (2023) A review: progress of diverter technology for oil and gas production applications in the past decade. SPE, p D031S038R002

Yang C, Navarrete R, Asadi M (2020) A novel relative permeability modifier polymer. OnePetro

Magzoub MI, Salehi S, Hussein IA, Nasser MS (2020) Loss circulation in drilling and well construction: the significance of applications of crosslinked polymers in wellbore strengthening: a review. J Petrol Sci Eng 185:106653

Alkinani HH, Al-Hameedi ATT, Dunn-Norman S, et al (2019) State-of-the-art review of lost circulation materials and treatments—Part I: general trends and uses. Society of Petroleum Engineers

Feng Y, Jones JF, Gray K (2016) A review on fracture-initiation and-propagation pressures for lost circulation and wellbore strengthening. SPE Drill Complet 31:134–144

Zhu Q, Wang Y, Zhang Y, et al (2018) Successful Applications of a Novel Compound Lost Circulation Additive With Variable Structure. Society of Petroleum Engineers

Al-Arfaj M, Amanullah M, Al-Ouhali R (2018) Loss circulation materials testing methods: literature review. Society of Petroleum Engineers

Boukadi F, Yaghi B, Al-Hadrami H et al (2004) A comparative study of lost circulation materials. Energy Sources 26:1043–1051

Elkatatny S, Ahmed A, Abughaban M, Patil S (2020) Deep illustration for loss of circulation while drilling. Arab J Sci Eng 45:483–499

Feng Y, Gray KE (2017) Review of fundamental studies on lost circulation and wellbore strengthening. J Petrol Sci Eng 152:511–522. https://doi.org/10.1016/j.petrol.2017.01.052

Savari S, Whitfill DL (2019) Managing Lost Circulation in Highly Fractured, Vugular Formations: Engineering the LCM Design and Application. Society of Petroleum Engineers

de Andrade AR, Borges RA, Guilherme HC et al (2019) A new loss circulation control strategy combining a cross-linkable polymer and magnetic fluid. J Petrol Sci Eng 180:958–966

Wagle V, Kalgaonkar R, Al-Yami AS (2018) Nanoparticle-based chemical treatment for preventing loss circulation. OnePetro

Addagalla AK, Jadhav P, Yadav P, et al (2020) A novel phase transition loss circulation solution for severe losses scenario: case histories from Middle East and Africa. OnePetro

Alanqari K, Wagle V, Al-Yami A, Mohammed A (2021) A novel epoxy resin composition as a lost circulation material: formulation, lab testing and field execution. OnePetro

Whaley K, Jackson PJ, Wolanski M, et al (2021) Paradigm shift in completion limits: open hole gravel pack in highly depleted reservoirs drilled with well bore strengthening technology. OnePetro

Messenger JU (1981) Lost circulation

Alsaba M, Nygaard R, Hareland G, Contreras O (2014) Review of lost circulation materials and treatments with an updated classification. pp 1–9

Schmid G (2011) Nanoparticles: from theory to application. Wiley

Ma L, Luo P, He Y et al (2019) Ultra-stable silica nanoparticles as nano-plugging additive for shale exploitation in harsh environments. Nanomaterials 9:1683

Hoelscher KP, De Stefano G, Riley M, Young S (2012) Application of nanotechnology in drilling fluids. OnePetro

Javeri SM, Haindade ZW, Jere CB (2011) Mitigating loss circulation and differential sticking problems using silicon nanoparticles. OnePetro

Okunade OA, Yekeen N, Padmanabhan E et al (2021) Shale core wettability alteration, foam and emulsion stabilization by surfactant: Impact of surfactant concentration, rock surface roughness and nanoparticles. J Petrol Sci Eng 207:109139

Maagi MT, Jun G (2020) Application of nanoparticles for strengthening wellbore cement-formation bonding. Oil Gas Sci Technol-Revue d’IFP Energies nouvelles 75:64

Li H, Sun J, Lv K et al (2022) Wettability alteration to maintain wellbore stability of shale formation using hydrophobic nanoparticles. Colloids Surf A 635:128015

Ko S, Huh C (2019) Use of nanoparticles for oil production applications. J Petrol Sci Eng 172:97–114

Gang W, Honghai F, Jie F et al (2020) Performance and application of high-strength water-swellable material for reducing lost circulation under high temperature. J Petrol Sci Eng 189:106957

Pu L, Xu P, Xu M et al (2022) Lost circulation materials for deep and ultra-deep wells: a review. J Petrol Sci Eng 214:110404

Ramasamy J, Gooneratne P C, Amanullah M (2019) Current methods and novel solutions for mitigating lost circulation. OnePetro

Yang J, Sun J, Bai Y et al (2022) Status and prospect of drilling fluid loss and lost circulation control technology in fractured formation. Gels 8:260

Hamza A, Shamlooh M, Hussein IA et al (2019) Polymeric formulations used for loss circulation materials and wellbore strengthening applications in oil and gas wells: a review. J Petrol Sci Eng 180:197–214

Lei S, Sun J, Lv K et al (2022) Types and performances of polymer gels for oil-gas drilling and production: a review. Gels 8:386

Paul JM, Strom ET (1987) Oil reservoir permeability control using polymeric gels

Bruton JR, Ivan CD, Heinz TJ (2001) Lost circulation control: evolving techniques and strategies to reduce downhole mud losses. OnePetro

Bai Y, Liu C, Sun J et al (2022) High temperature resistant polymer gel as lost circulation material for fractured formation during drilling. Colloids Surf A 637:128244

Sadeghalvaad M, Sabbaghi S (2015) The effect of the TiO2/polyacrylamide nanocomposite on water-based drilling fluid properties. Powder Technol 272:113–119. https://doi.org/10.1016/j.powtec.2014.11.032

Ahmad HM, Iqbal T, Kamal MS, Al-Harthi MA (2020) Influence of hydrophobically modified polymer and titania nanoparticles on shale hydration and swelling properties. Energy Fuels 34:16456–16468

Davidson E, Richardson L, Zoller S (2000) Control of lost circulation in fractured limestone reservoirs. In: SPE-62734-MS. Society of Petroleum Engineers, SPE, p 9

Fan X, Zhao P, Zhang Q et al (2018) A polymer plugging gel for the fractured strata and its application. Materials 11:856

Alkinani HH, Al-Hameedi ATT, Dunn-Norman S, Al-Bazzaz WH (2020) State-of-the-Art review of lost circulation materials and treatments–Part ii: probability and cost analyses. OnePetro

Lavrov A (2016) Lost circulation: mechanisms and solutions. Gulf professional publishing

Ahmed A, Elkatatny S, Ali A, et al (2020) Application of artificial intelligence techniques in predicting the lost circulation zones using drilling sensors. J Sens 2020

Jinsheng S, Yingrui B, Cheng R et al (2021) Research progress and prospect of plugging technologies for fractured formation with severe lost circulation. Pet Explor Dev 48:732–743

Keishnan MR, Michael FM, Almohsin AM, Alsharaeh EH (2020) Thermal and rheological investigations on N,N’-methylenebis acrylamide cross-linked polyacrylamide nanocomposite hydrogels for water shutoff applications. In: OTC-30123-MS. Offshore Technology Conference, OTC, p 9

Michael FM, Fathima A, AlYemni E et al (2018) Enhanced polyacrylamide polymer gels using zirconium hydroxide nanoparticles for water shutoff at high temperatures: thermal and rheological investigations. Ind Eng Chem Res 57:16347–16357

Almohsin A, Alsharaeh E, Michael FM, Krishnan MR (2022) Polymer-nanofiller hydrogels

Almohsin A, Alsharaeh E, Krishnan MR (2022) Polymer-sand nanocomposite lost circulation material

Michael FM, Krishnan MR, Li W, Alsharaeh EH (2020) A review on polymer-nanofiller composites in developing coated sand proppants for hydraulic fracturing. J Nat Gas Sci Eng 83:103553. https://doi.org/10.1016/j.jngse.2020.103553

Krishnan MR, Aldawsari YF, Alsharaeh EH (2020) Three-dimensionally cross-linked styrene-methyl methacrylate-divinyl benzene terpolymer networks for organic solvents and crude oil absorption. J Appl Polym Sci 138:49942

Krishnan MR, Aldawsari YF, Alsharaeh EH (2021) 3D-poly(styrene-methyl methacrylate)/divinyl benzene-2D-nanosheet composite networks for organic solvents and crude oil spill cleanup. Polym Bull. https://doi.org/10.1007/s00289-021-03565-5

Acknowledgements

This study is part of research project agreement no. AFU-01-2017 in collaboration with EXPEC Advanced Research Centre, Saudi Aramco. The authors gratefully acknowledge the continued support from AlFaisal University and its Office of Research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No potential conflict of interest was reported by the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Krishnan, M.R., Omar, H., Almohsin, A. et al. An overview on nanosilica–polymer composites as high-performance functional materials in oil fields. Polym. Bull. 81, 3883–3933 (2024). https://doi.org/10.1007/s00289-023-04934-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-023-04934-y