Abstract

Global growing concern on plastics disposal and their environmental impact has impulsed the development of lower impact biodegradable plastics, however their functional properties and processability are still limited. In this study, thermoplastic starch (TPS) was synthetized through reactive extrusion (REX) to obtain single oxidized thermoplastic (O-TPS) and single maleated thermoplastic (MA-TPS), as well as, dual (oxidized-maleated thermoplastic (O-MA-TPS) modified starches aiming to incorporate new functionalities, diminish the viscosity and improve TPS processability. Spectroscopic analysis showed different band intensities as a result of TPS modification. TPS presented B-type and V-type crystal structures. O-MA-TPS showed the lowest percentage of crystallinity and complex viscosity values compared to single modified TPS because the combination of modifications. The specific mechanical energy decreased with respect to chemical modifications of starch (TPS > O-TPS > MA-TPS > O-MA-TPS), which were associated with the diminishing of viscosity resulting from the modification and starch-glycerol interactions. These starches can be incorporated into mixtures with other plastic polymers, by allowing better mixing (minor viscosity difference) and the replacement of a greater amount of plastic with TPS or in applications where a TPS with lower viscosity and easier processability is required.

Similar content being viewed by others

References

Lekube BM, Fahrngruber B, Kozich M, Wastyn M, Burgstalleret C (2019) Influence of processing on the mechanical properties and morphology of starch-based blends for film applications. J Appl Polym Sci 136:1–8. https://doi.org/10.1002/app.47990

PlasticsEurope (2021) Plastics-the facts 2020. https://issuu.com/plasticseuropeebook/docs/plastics_the_facts-web-dec2020#:~:text=En%202019%2C%20global%20plastics%20production,almost%20reached%2058%20million%20tonnes.&text=In%202019%20China%20reached%2031,*%20production%3A%20368%20million%20tonnes. Accessed 01 Mayo 2022

Cheng H, Chen L, McClements DJ, Yang T, Zhang Z, Ren F, Miao M, Tian Y, Jin Z (2021) Starch-based biodegradable packaging materials: a review of their preparation, characterization and diverse applications in the food industry. Trends Food Sci Technol 114:70–82. https://doi.org/10.1016/j.tifs.2021.05.017

Ochoa-Yepes O, Di Giogio L, Goyanes S, Mauri A, Famá L (2019) Influence of process (extrusion/thermo-compression, casting) and lentil protein content on physicochemical properties of starch films. Carbohydr Polym 208:221–231. https://doi.org/10.1016/j.carbpol.2018.12.030

Chen J, Wang X, Long Z, Wang S, Zhang J, Wang L (2020) Preparation and performance of thermoplastic starch and microcrystalline cellulose for packaging composites: extrusion and hot pressing. Int J Biol Macromol 165:2295–2302. https://doi.org/10.1016/j.ijbiomac.2020.10.117

Gao W, Zhu J, Kang X, Wnag B, Liu P, Cui B, Abd El-Atyacd AM (2021) Development and characterization of starch films prepared by extrusion blowing: the synergistic plasticizing effect of water and glycerol. LWT 148:111820. https://doi.org/10.1016/j.lwt.2021.111820

do Val Siqueira L, Arias CILF, Maniglia BC, Tadini CC (2021) Starch-based biodegradable plastics: methods of production, challenges and future perspectives. Curr Opin Food Sci 38:122–130. https://doi.org/10.1016/j.cofs.2020.10.020

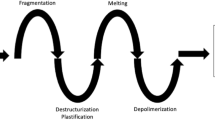

Logié N, Della Valle G, Rolland-Sabaté A, Descamps N, Soulestin J (2018) How does temperature govern mechanisms of starch changes during extrusion? Carbohydr Polym 184:57–65. https://doi.org/10.1016/j.carbpol.2017.12.040

do Val Siqueira L, Arias C, Maniglia B, Tadini C (2021) Starch-based biodegradable plastics: methods of production, challenges and future perspectives. Curr Opin Food Sci. https://doi.org/10.1016/j.cofs.2020.10.020

Ashogbon AO (2021) Dual modification of various starches: synthesis, properties and applications. Food Chem 342:128325. https://doi.org/10.1016/j.foodchem.2020.128325

Chen Q, Yu H, Wang L, ul Abdin Z, Chen Y, Wang J, Zhou W, Yang X, Khan RU, Zhang H, Chen X (2015) Recent progress in chemical modification of starch and its applications. RSC Adv 5:67459–67474. https://doi.org/10.1039/c5ra10849g

Masina N, Choonara YE, Kumar P, du Toit LC, Govender M, Indermun S, Pillay V (2017) A review of the chemical modification techniques of starch. Carbohydr Polym 157:1226–1236. https://doi.org/10.1016/j.carbpol.2016.09.094

Guz L, González-Seligra P, Ochoa-Yepes O, Estevez-Areco S, Famá L, Goyanes S (2021) Influence of different commercial modified cassava starches on the physicochemical properties of thermoplastic edible films obtained by flat-die extrusion. Starch-Stärke 73(3–4):2000167. https://doi.org/10.1002/star.202000167

Biduski B, da Silva FT, da Silva WM, ElHalal SL, Pinto VZ, Dias ARG, Zavareze EdR (2017) Impact of acid and oxidative modifications, single or dual, of sorghum starch on biodegradable films. Food Chem 214:53–60. https://doi.org/10.1016/J.FOODCHEM.2016.07.039

González-Soto RA, Núñez-Santiago MC, Bello-Pérez LA (2019) Preparation and partial characterization of films made with dual-modified (acetylation and crosslinking) potato starch. J Sci Food Agric 99:3134–3141. https://doi.org/10.1002/JSFA.9528

Cabrera-Canales ZE, Rodríguez-Marín ML, Gómez-Aldapa CA, Méndez-Montealvo G, Chávez-Gutiérrez M, Velazquez G (2020) Effect of dual chemical modification on the properties of biodegradable films from achira starch. J Appl Polym Sci 137:49411. https://doi.org/10.1002/APP.49411

Tanetrungroj Y, Prachayawarakorn J (2018) Effect of dual modification on properties of biodegradable crosslinked-oxidized starch and oxidized-crosslinked starch films. Int J Biol Macromol 120:1240–1246. https://doi.org/10.1016/j.ijbiomac.2018.08.137

Vergnes B, Berzin F (2006) Modeling of reactive systems in twin-screw extrusion: challenges and applications. Comptes Rendus Chim 9:1409–1418. https://doi.org/10.1016/j.crci.2006.07.006

Moad G (2011) Chemical modification of starch by reactive extrusion. Prog Polym Sci 36:218–237. https://doi.org/10.1016/j.progpolymsci.2010.11.002

Zuo Y, Gu J, Yang L, Qiao Z, Zhang Y (2016) Study on the preparation of maleated thermoplastic starch by reactive extrusion. J Thermoplast Compos Mater 29:397–409. https://doi.org/10.1177/0892705713518809

Fonseca-Florido HA, Soriano-Corral F, Yañez-Macías R, González-Morones P, Hernández-Rodríguez F, Aguirre-Zurita J, Ávila-Orta C, Rodríguez-Velázquez J (2019) Effects of multiphase transitions and reactive extrusion on in situ thermoplasticization/succination of cassava starch. Carbohydr Polym 225:115250. https://doi.org/10.1016/j.carbpol.2019.115250

Raquez JM, Nabar Y, Srinivasan M, Shin BY, Narayan R, Dubois P (2008) Maleated thermoplastic starch by reactive extrusion. Carbohydr Polym 74:159–169. https://doi.org/10.1016/j.carbpol.2008.01.027

Qin Y, Wang W, Zhang H, Dai Y, Hou H, Dong H (2019) Effects of citric acid on structures and properties of thermoplastic hydroxypropyl amylomaize starch films. Materials (Basel) 12:1–13. https://doi.org/10.3390/ma12091565

Wu CY, Lui WB, Peng J (2018) Optimization of extrusion variables and maleic anhydride content on biopolymer blends based on poly(hydroxybutyrate-co-hydroxyvalerate)/poly(vinyl acetate) with tapioca starch. Polymers (Basel). https://doi.org/10.3390/polym10080827

El HSLM, Colussi R, Pinto VZ, Bartz J, Radunz M, Carreño NLV, Dias ARG, EdaR Z (2015) Structure, morphology and functionality of acetylated and oxidised barley starches. Food Chem 168:247–256. https://doi.org/10.1016/j.foodchem.2014.07.046

Rivas-González M, Méndez-Montealvo MGC, Sánchez-Rivera MM, Núñez-Santiago MC, Bello-Pérez LA (2008) Caracterización morfológica, molecular y fisicoquímica del almidón de plátano oxidado y lintnerizado. Agrociencia 42(5):487–497

Yu C, Liu J, Tang X, Shen X, Liu S (2017) Correlations between the physical properties and chemical bonds of extruded corn starch enriched with whey protein concentrate. RSC Adv 7:11979–11986. https://doi.org/10.1039/C6RA26764E

Woggum T, Sirivongpaisal P, Wittaya T (2014) Properties and characteristics of dual-modified rice starch based biodegradable films. Int J Biol Macromol 67:490–502. https://doi.org/10.1016/j.ijbiomac.2014.03.029

Sudheesh C, Sunooj KV, George J (2019) Kithul palm (Caryota urens) as a new source of starch: effect of single, dual chemical modifications and annealing on the physicochemical properties and in vitro digestibility. Int J Biol Macromol 125:1084–1092. https://doi.org/10.1016/j.ijbiomac.2018.12.179

Raquez JM, Narayan R, Dubois P (2008) Recent advances in reactive extrusion processing of biodegradable polymer-based compositions. Macromol Mater Eng 293:447–470. https://doi.org/10.1002/mame.200700395

Ma Z, Yin X, Chang D, Hu X, Boye JI (2018) Long- and short-range structural characteristics of pea starch modified by autoclaving, α-amylolysis, and pullulanase debranching. Int J Biol Macromol 120:650–656. https://doi.org/10.1016/j.ijbiomac.2018.08.132

Hablot E, Dewasthale S, Zhao Y, Zhiguan Y, Shi X, Graiver D, Narayan R (2013) Reactive extrusion of glycerylated starch and starch–polyester graft copolymers. Eur Polym J 49:873–881. https://doi.org/10.1016/J.EURPOLYMJ.2012.12.005

Liu H, Adhikari R, Guo Q, Adhikari B (2013) Preparation and characterization of glycerol plasticized (high-amylose) starch-chitosan films. J Food Eng 116:588–597. https://doi.org/10.1016/j.jfoodeng.2012.12.037

Serrero A, Trombotto S, Cassagnau P, Bayon Y, Gravagna P, Montanari S, David L (2010) Polysaccharide gels based on chitosan and modified starch: structural characterization and linear viscoelastic behavior. Biomacromol 11:1534–1543. https://doi.org/10.1021/bm1001813

Elomaa M, Asplund T, Soininen P, Laatikainen R, Peltonen S, Hyvärinen S, Urtti A (2004) Determination of the degree of substitution of acetylated starch by hydrolysis, 1H NMR and TGA/IR. Carbohydr Polym 57:261–267. https://doi.org/10.1016/j.carbpol.2004.05.003

Lopez-Rubio A, Flanagan BM, Gilbert EP, Gidley MJ (2008) A novel approach for calculating starch crystallinity and its correlation with double helix content: a combined XRD and NMR study. Biopolymers 89:761–768. https://doi.org/10.1002/bip.21005

Sagnelli D, Hebelstrup KH, Leroy E, Sabaté AR, Guilois S, Kirkensgaard JJK, Mortensen K, Lourdin D, Blennow A (2016) Plant-crafted starches for bioplastics production. Carbohydr Polym 152:398–408. https://doi.org/10.1016/j.carbpol.2016.07.039

de Gamarano D, S, Pereira IM, da Silva MC, Mottin AC, Ayres E, (2020) Crystal structure transformations in extruded starch plasticized with glycerol and urea. Polym Bull 77:4971–4992. https://doi.org/10.1007/s00289-019-02999-2

Esmaeili M, Pircheraghi G, Bagheri R (2017) Optimizing the mechanical and physical properties of thermoplastic starch via tuning the molecular microstructure through co-plasticization by sorbitol and glycerol. Polym Int 66:809–819. https://doi.org/10.1002/pi.5319

Silva MC, Ibezim EC, Ribeiro TAA, Carvalho CWP, Andrade CT (2006) Reactive processing and mechanical properties of cross-linked maize starch. Ind Crops Prod 24:46–51. https://doi.org/10.1016/j.indcrop.2006.01.001

Zhang YR, Zhang SD, Wang XL, Chen RY, Wang YZ (2009) Effect of carbonyl content on the properties of thermoplastic oxidized starch. Carbohydr Polym 78:157–161. https://doi.org/10.1016/j.carbpol.2009.04.023

Dang KM, Yoksan R (2021) Thermoplastic starch blown films with improved mechanical and barrier properties. Int J Biol Macromol 188:290–299. https://doi.org/10.1016/j.ijbiomac.2021.08.027

Shi R, Zhang Z, Liu Q, Han Y, Zhang L, Chen D, Tian W (2007) Characterization of citric acid/glycerol co-plasticized thermoplastic starch prepared by melt blending. Carbohydr Polym 69:748–755. https://doi.org/10.1016/j.carbpol.2007.02.010

Zhang YR, Wang XL, Zhao GM, Wang YZ (2013) Influence of oxidized starch on the properties of thermoplastic starch. Carbohydr Polym 96:358–364. https://doi.org/10.1016/j.carbpol.2013.03.093

O’Brien S, Wang YJ, Vervaet C, Remon JP (2009) Starch phosphates prepared by reactive extrusion as a sustained release agent. Carbohydr Polym 76:557–566. https://doi.org/10.1016/j.carbpol.2008.11.024

Rodriguez-Gonzalez FJ, Ramsay BA, Favis BD (2004) Rheological and thermal properties of thermoplastic starch with high glycerol content. Carbohydr Polym 58:139–147. https://doi.org/10.1016/J.CARBPOL.2004.06.002

Acknowledgements

We are grateful to the support of CONACYT (Mexico) for giving financial support to this work through the FOMIX projects TLAX-2018-01-01-43129, FORDECYT 296356 and Laboratorio Nacional de Materiales Grafenicos and Laboratorio Nacional de Innovación y Desarrollo de Materiales Ligeros para la Industria Automotriz. The technical support of Jesús Alfonso Mercado Silva, Roberto Yañez Macías, Myrna Salinas Hernández, Guadalupe Méndez Padilla, Myriam Lozano Estrada and Adán Herrera Guerrero.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Methodology, investigation, data curation by EG-M; resources by CAÁ-O; writing – review and editing by ZEC-C, PYR-R and CACG; methodology, validation, investigation, data curation by JGR-V and JC-R; conceptualization, methodology, validation, investigation, data curation, writing – original draft, writing – review and editing, visualization, supervision by HAF-F. The first draft of the manuscript was written by HAF-F and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gutierrez-Montiel, E., Ávila-Orta, C.A., Cabrera-Canales, Z.E. et al. Effect of oxidized, maleate and dual chemical modification through extrusion on thermoplastic starch properties. Polym. Bull. 81, 2525–2544 (2024). https://doi.org/10.1007/s00289-023-04857-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-023-04857-8