Abstract

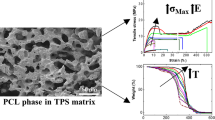

Thermoplastic starch (TPS) can be added to a synthetic polymer, including linear low-density polyethylene (LLDPE), as a low-cost renewable and biodegradable source, to reduce the PE content. Nevertheless, this mixture leads to a mechanical performance decrease due to the immiscibility between both polymers. The aim of this work was to investigate the effect of three different organic acids (3% phr): citric, capric, and palmitic on LLDPE/TPS blends, with a mass ratio of 70/30. The introduction of capric or palmitic acid strengthened TPS and LLDPE interfacial adhesion and improved the mechanical properties of the blends. The glass transition of the glycerol-rich phase (measured by DMA) occurs at higher temperatures for LLDPE/TPS/CITRIC blends, suggesting a plasticizer effect of this acid. It also could be seen by SEM, the images showed that improvements in the compatibility between the immiscible components were achieved by capric or palmitic acid incorporation. TPS’s incorporation had increased the water absorption because of its hydrophilic characteristic; however, acid incorporation reduced this property. In relation to colorimetric aspects, all blends had loss of brightness, but the ones with citric acid were darker, presenting higher color change than the blends with others acids.

Similar content being viewed by others

References

Sabetzadeh M, Bagheri R, Masoomi M (2015) Study on ternary low density polyethylene/linear low density polyethylene/thermoplastic starch blend films. Carbohydr Polym 119:126–133. doi:10.1016/j.carbpol.2014.11.038

Souza RCR, Andrade CT (2001) Processing and properties of thermoplastic starch and its blends with sodium alginate. J Appl Polym Sci 81:412–420. doi:10.1002/app.1453

Pedroso AG, Rosa DS (2005) Mechanical, thermal and morphological characterization of recycled LDPE/corn starch blends. Carbohydr Polym 59:1–9. doi:10.1016/j.carbpol.2004.08.018

Yun Y-H, Na Y-H, Yoon S-D (2006) Mechanical properties with the functional group of additives for starch/PVA blend film. J Polym Environ 14:71–78. doi:10.1007/s10924-005-8709-8

Rodriguez-Gonzalez F, Ramsay B, Favis B (2003) High performance LDPE/thermoplastic starch blends: a sustainable alternative to pure polyethylene. Polymer (Guildf) 44:1517–1526. doi:10.1016/S0032-3861(02)00907-2

Corradini E, de Carvalho AJF, da Curvelo AAS et al (2007) Preparation and characterization of thermoplastic starch/zein blends. Mater Res 10:227–231. doi:10.1590/S1516-14392007000300002

Ferreira WH, Khalili RR, Figueira MJM, Andrade CT (2014) Effect of organoclay on blends of individually plasticized thermoplastic starch and polypropylene. Ind Crop Prod 52:38–45. doi:10.1016/j.indcrop.2013.10.016

Liu H, Xie F, Yu L et al (2009) Thermal processing of starch-based polymers. Prog Polym Sci 34:1348–1368. doi:10.1016/j.progpolymsci.2009.07.001

Regazzi A, Dumont PJJ, Harthong B et al (2016) Effectiveness of thermo-compression for manufacturing native starch bulk materials. J Mater Sci 51:5146–5159. doi:10.1007/s10853-016-9817-7

Morán JI, Cyras VP, Vázquez A (2013) Preparation and characterization of three different derivatized potato starches. J Polym Environ 21:395–404. doi:10.1007/s10924-012-0539-x

Lu DR (2009) Starch-based completely biodegradable polymer materials. Express Polym Lett 3:366–375. doi:10.3144/expresspolymlett.2009.46

Pimentel TAPF, Durães JA, Drummond AL et al (2007) Preparation and characterization of blends of recycled polystyrene with cassava starch. J Mater Sci 42:7530–7536. doi:10.1007/s10853-007-1622-x

Kaseem M, Hamad K, Deri F (2012) Rheological and mechanical properties of polypropylene/thermoplastic starch blend. Polym Bull 68:1079–1091. doi:10.1007/s00289-011-0611-z

Roy SB, Ramaraj B, Shit SC, Nayak SK (2011) Polypropylene and potato starch biocomposites: physicomechanical and thermal properties. J Appl Polym Sci 120:3078–3086. doi:10.1002/app.33486

Ratanakamnuan U, Aht-Ong D (2006) Photobiodegradation of low-density polyethylene/banana starch films. J Appl Polym Sci 100:2725–2736. doi:10.1002/app.23048

Bikiaris D, Aburto J, Alric I et al (1999) Mechanical properties and biodegradability of LDPE blends with fatty-acid esters of amylose and starch. J Appl Polym Sci 71:1089–1100. doi:10.1002/(SICI)1097-4628(19990214)71:7<1089::AID-APP7>3.0.CO;2-I

Taguet A, Huneault MA, Favis BD (2009) Interface/morphology relationships in polymer blends with thermoplastic starch. Polymer (Guildf) 50:5733–5743. doi:10.1002/(SICI)1097-4628(19990214)71:7<1089::AID-APP7>3.0.CO;2-I

Olivato JB, Grossmann MVE, Yamashita F et al (2012) Citric acid and maleic anhydride as compatibilizers in starch/poly(butylene adipate-co-terephthalate) blends by one-step reactive extrusion. Carbohydr Polym 87:2614–2618. doi:10.1016/j.carbpol.2011.11.035

Al-Mulla A, Alfadhel K, Qambar G, Shaban H (2013) Rheological study of recycled polypropylene–starch blends. Polym Bull 70:2599–2618. doi:10.1007/s00289-013-0977-1

Shujun W, Jiugao Y, Jinglin Y (2005) Preparation and characterization of compatible thermoplastic starch/polyethylene blends. Polym Degrad Stab 87:395–401. doi:10.1016/j.polymdegradstab.2004.08.012

Taguet A, Bureau MN, Huneault MA, Favis BD (2014) Toughening mechanisms in interfacially modified HDPE/thermoplastic starch blends. Carbohydr Polym 114:222–229. doi:10.1016/j.carbpol.2014.07.073

Samper-Madrigal MD, Fenollar O, Dominici F et al (2015) The effect of sepiolite on the compatibilization of polyethylene–thermoplastic starch blends for environmentally friendly films. J Mater Sci 50:863–872. doi:10.1007/s10853-014-8647-8

Poletto M, Zattera AJ, Santana RMC (2014) Effect of natural oils on the thermal stability and degradation kinetics of recycled polypropylene wood flour composites. Polym Compos 35:1935–1942. doi:10.1002/pc.22852

Ning W, Jiugao Y, Xiaofei M, Ying W (2007) The influence of citric acid on the properties of thermoplastic starch/linear low-density polyethylene blends. Carbohydr Polym 67:446–453. doi:10.1016/j.carbpol.2006.06.014

Shi R, Zhang Z, Liu Q et al (2007) Characterization of citric acid/glycerol co-plasticized thermoplastic starch prepared by melt blending. Carbohydr Polym 69:748–755. doi:10.1016/j.carbpol.2007.02.010

Martins AB, Santana RMC (2016) Effect of carboxylic acids as compatibilizer agent on mechanical properties of thermoplastic starch and polypropylene blends. Carbohydr Polym 135:79–85

Inceoglu F, Menceloglu YZ (2013) Transparent low-density polyethylene/starch nanocomposite films. J Appl Polym Sci 129:1907–1914. doi:10.1002/app.38811

Hoque ME, Ye TJ, Yong LC, Mohd Dahlan K (2013) Sago starch-mixed low-density polyethylene biodegradable polymer: synthesis and characterization. J Mater 2013:1–7. doi:10.1155/2013/365380

Baldev R, Udaya Sankar K, Siddaramaiah H (2004) Low density polyethylene/starch blend films for food packaging applications. Adv Polym Technol 23(1):32–45

Garcia PS, Grossmann MVE, Shirai MA et al (2014) Improving action of citric acid as compatibiliser in starch/polyester blown films. Ind Crop Prod 52:305–312. doi:10.1016/j.indcrop.2013.11.001

Ghanbarzadeh B, Almasi H, Entezami AA (2011) Improving the barrier and mechanical properties of corn starch-based edible films: effect of citric acid and carboxymethyl cellulose. Ind Crop Prod 33:229–235. doi:10.1016/j.indcrop.2010.10.016

Jiugao Y, Ning W, Xiaofei M (2005) The effects of citric acid on the properties of thermoplastic starch plasticized by glycerol. Starch/Staerke 57:494–504. doi:10.1002/star.200500423

García NL, Famá L, Dufresne A et al (2009) A comparison between the physico-chemical properties of tuber and cereal starches. Food Res Int 42:976–982. doi:10.1016/j.foodres.2009.05.004

Zárate-Ramírez LS, Martínez I, Romero A et al (2011) Wheat gluten-based materials plasticised with glycerol and water by thermoplastic mixing and thermomoulding. J Sci Food Agric 91:625–633. doi:10.1002/jsfa.4224

Wang N, Zhang X, Han N, Bai S (2009) Effect of citric acid and processing on the performance of thermoplastic starch/montmorillonite nanocomposites. Carbohydr Polym 76:68–73. doi:10.1016/j.carbpol.2008.09.021

Seligra PG, Medina Jaramillo C, Famá L, Goyanes S (2016) Biodegradable and non-retrogradable eco-films based on starch–glycerol with citric acid as crosslinking agent. Carbohydr Polym 138:66–74. doi:10.1016/j.carbpol.2015.11.041

Olsson E, Hedenqvist MS, Johansson C, Järnström L (2013) Influence of citric acid and curing on moisture sorption, diffusion and permeability of starch films. Carbohydr Polym 94:765–772. doi:10.1016/j.carbpol.2013.02.006

BeMiller JN, Whistler RL (2009) Starch: chemistry and technology, 3rd edn. Academic Press, New York

Beg MDH, Kormin S, Bijarimi M, Zaman HU (2016) Preparation and characterization of low-density polyethylene/thermoplastic starch composites. Adv Polym Technol 35:21521. doi:10.1002/adv.21521

Acknowledgements

This work was supported by the National Council for Scientific and Technological Development (CNPq) and the Federal University of Rio Grande do Sul (UFRGS). The authors acknowledge the Polymeric Materials Lab (LAPOL), the Chemical Lab (K212), SIBRATEC and the post graduated program of Materials Engineering (PPGEM).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Martins, A.B., Cattelan, A.K. & Santana, R.M.C. How the compatibility between polyethylene and thermoplastic starch can be improved by adding organic acids?. Polym. Bull. 75, 2197–2212 (2018). https://doi.org/10.1007/s00289-017-2147-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-017-2147-3