Abstract

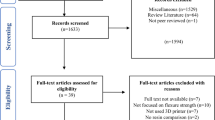

Additive manufacturing offers several advantages such as accuracy, agility, and ability to customize parts with different geometries and complexities. However, this method has a disadvantage the poor adhesion between the layers resulting from the printing process, which leads to inferior mechanical properties of the materials printed by this technique. Thus, using strategies that improve these properties is beneficial for application in materials used in prostheses and biomaterials. However, there is still no consensus in the literature on the best method and how to perform it. The aim of this systematic review was to evaluate the post-processing methods used to improve the mechanical properties of polymers printed by the fused filament fabrication method. This systematic review is in accordance with the Preferred Reporting Items for Systematic Review and Meta-Analysis guidelines, and it was registered with the Open Science Framework (OSF) (https://osf.io/ckn6y). PubMed, Science Direct, EMBASE, and Scopus were the databases used in the search. Articles were selected by two independent reviewers according to the inclusion criteria. The risk of bias was analyzed by using the Joanna Briggs Institute adapted quasi-experimental study evaluation tool. The studies included in the present review point to the improvement in the mechanical properties of printed polymers when submitted to different types of post-processing. Post-processing was beneficial for polymers printed by the FFF technique. Thermal post-processing improves the mechanical properties of both semi-crystalline and amorphous polymers. The crystallinity and viscosity had a significant influence on mechanical properties. Chemical and mechanical post-processing improves surface roughness. However, the mechanical method does not apply to complex geometries.

Similar content being viewed by others

References

Arjun P, Bidhun VK, Lenin UK, Amritha VP, Pazhamannil RV et al (2022) Effects of process parameters and annealing on the tensile strength of 3D printed carbon fiber reinforced polylactic acid. In press. https://doi.org/10.1016/j.matpr.2022.02.142

Salmi M (2020) Additive manufacturing processes in medical applications. Materials (Basel) 2021(14):191. https://doi.org/10.3390/ma14010191

Sulaiman TA (2020) Materials in digital dentistry-a review. J Esthet Restor Dent 32:171–181. https://doi.org/10.1111/jerd.12566

Oliveira TT, Reis AC (2019) Fabrication of dental implants by the additive manufacturing method: a systematic review. J Prosthet Dent 22:270–274. https://doi.org/10.1016/j.prosdent.2019.01.018

Darling CJ, Curtis C, Sciacca BJ, Sarkar K, Smith DA (2022) Fused filament fabrication of complex anatomical phantoms with infill-tunable image contrast. Addit Manuf 52:102695. https://doi.org/10.1016/j.addma.2022.102695

Khorsandi D, Fahimipour A, Abasian P, Saber SS, Seyedi M et al (2021) 3D and 4D printing in dentistry and maxillofacial surgery: Printing techniques, materials, and applications. Acta Biomater 122:26–49. https://doi.org/10.1016/j.actbio.2020.12.044

Mu M, Ou C-Y, Wang J, Liu Y (2020) Surface modification of prototypes in fused filament fabrication using chemical vapour smoothing. Addit Manuf. https://doi.org/10.1016/j.addma.2019.100972

Dua R, Rashad Z, Spears J, Dunn G, Maxwell M (2021) Applications of 3D-printed PEEK via fused filament fabrication: a systematic review. Polymers (Basel) 13:4046. https://doi.org/10.3390/polym13224046

Javaid M, Haleem A (2019) Current status and applications of additive manufacturing in dentistry: a literature-based review. J Oral Biol Craniofac Res 9:179–185. https://doi.org/10.1016/j.jobcr.2019.04.004

Revilla-Léon M, Özcan M (2019) Additive manufacturing technologies used for processing polymers: current status and potential application in prosthetic dentistry. J Prosthodont 28:146–158. https://doi.org/10.1111/jopr.12801

Rekow ED (2020) Digital dentistry: the new state of the art - is it disruptive or destructive? Dent Mater 36:9–24. https://doi.org/10.1016/j.dental.2019.08.103

Roseti L, Parisi V, Petretta M, Cavallo C, Desando G et al (2017) Scaffolds for bone tissue engineering: state of the art and new perspectives. Mater Sci Eng C Mater Biol Appl 78:1246–1262. https://doi.org/10.1016/j.msec.2017.05.017

Rashid AA, Koç M (2021) Fused filament fabrication process: a review of numerical simulation techniques. Polymers (Basel) 13:3534. https://doi.org/10.3390/polym13203534

Amza CG, Zapciu A, Constantin G, Baciu F, Vasile MI (2021) Enhancing mechanical properties of polymer 3D printed parts. Polymers (Basel) 13:562. https://doi.org/10.3390/polym13040562

Alammar A, Kois JC, Revilla-León M, Att W (2022) Additive manufacturing technologies: current status and future perspectives. J Prosthodont 31:4–12. https://doi.org/10.1111/jopr.13477

Bhandari S, Lopez-Anido RA, Gardner DJ (2019) Enhancing the interlayer tensile strength of 3D printed short carbon fiber reinyforced PETG and PLA composites via annealing. Addit Manuf 30:100922. https://doi.org/10.1016/j.addma.2019.100922

Klüver E, Baltzer M, Langer A, Meyer M (2022) Additive manufacturing with thermoplastic collagen. Polymers (Basel) 14:974. https://doi.org/10.3390/polym14050974

Vidakis N, Petousis M, Velidakis E, Mountakis N, Fisher-Griffiths, et al (2022) Fused Filament Fabrication 3D printed polypropylene/alumina nanocomposites: effect of filler loading on the mechanical reinforcement. Polym Testing 109:107545. https://doi.org/10.1016/j.polymertesting.2022.107545

Chen W, Zhang X, Tan D, Xu P, Yang B et al (2022) Improvement in mechanical properties of 3D-printed PEEK structure by nonsolvent vapor annealing. Macromol Rapid Commun. https://doi.org/10.1002/marc.202100874

Collinson DW, von Windheim N, Gall K, Brinson LC (2022) Direct evidence of interfacial crystallization preventing weld formation during fused filament fabrication of poly(ether ether ketone). Addit Manuf 51:102604. https://doi.org/10.1016/j.addma.2022.102604

Ferreira I, Melo C, Neto R, Machado M (2020) Study of the annealing influence on the mechanical performance of PA12 and PA12 fibre reinforced FFF printed specimens. Rapid Prototyping J 26:1761–1770. https://doi.org/10.1108/RPJ-10-2019-0278

Hart KR, Dunn RM, Wetzel ED (2020) Increased fracture toughness of additively manufactured semi-crystalline thermoplastics via thermal annealing. Polymer 211:123091. https://doi.org/10.1016/j.polymer.2020.123091

Matichescu A, Ardelean LC, Rusu L-C, Craciun D, Bratu EA, Babucea M et al (2020) Advanced biomaterials and techniques for oral tissue engineering and regeneration-a review. Materials (Basel) 13:5303. https://doi.org/10.3390/ma13225303

Pazhamannil RV, Krishnan N, Govindan P, Edacherian A (2021) Investigations into the effect of thermal annealing on fused filament fabrication process. Adv Mater Process Technol. https://doi.org/10.1080/2374068X.2021.1946753

Puerta APV, López-Castro FD, López AO, Vidal SRF (2021) On improving the surface finish of 3D printing polylactic acid parts by corundum blasting. Rapid Prototyping J 27:1398–1407. https://doi.org/10.1108/RPJ-05-2021-0105

Rane R, Kulkarni A, Prajati H, Taylor R, Jain A et al (2020) Post-process effects of isothermal annealing and initially applied static uniaxial loading on the ultimate tensile strength of fused filament fabrication parts. Materials (Basel) 13:352. https://doi.org/10.3390/ma13020352

Singh S, Singh M, Prakash C, Gupta MK, Mia M et al (2019) Optimization and reliability analysis to improve surface quality and mechanical characteristics of heat-treated fused filament fabricated parts. Int J Adv Manuf Technol 102:1521–1536. https://doi.org/10.1007/s00170-018-03276-8

Szust A, Adamski G (2022) Using thermal annealing and salt remelting to increase tensile properties of 3D FDM prints. Eng Fail Anal 132:105932. https://doi.org/10.1016/j.engfailanal.2021.105932

Arunprasath K, Vijayakumar M, Ramarao M, Arul TG, Pauldoss P, Selwin M et al (2021) Dynamic mechanical analysis performance of pure 3D printed polylactic acid (PLA) and acrylonitrile butadiene styrene (ABS). Mater Today Proceed. https://doi.org/10.1016/j.matpr.2021.09.113

Bohl MA, Morgan CD, Mooney MA, Repp GJ, Lehrman JN, Kelly BP et al (2019) Biomechanical Testing of a 3D-printed L5 Vertebral Body Model. Cureus. 11:e3893. https://doi.org/10.7759/cureus.3893

Mazzanti V, Malagutti L, Mollica F (2019) 3D printing of polymers containing natural fillers: a review of their mechanical properties. Polymers (Basel) 11:1094

Singh S, Singh R (2016) Fused deposition modelling based rapid patterns for investment casting applications: a review. Rapid Prototyping J 22:123–143. https://doi.org/10.1108/RPJ-02-2014-0017

Clifton W, Nottmeier E, Damon A, Dove C, Chen SG, Pichelman M (2019) A feasibility study for the production of three-dimensional-printed spine models using simultaneously extruded thermoplastic polymers. Cureus. 11:e4440. https://doi.org/10.7759/cureus.4440

Elsawy MA, Kim KH, Park JW, Deep A (2017) Hydrolytic degradation of polylactic acid (PLA) and its composites. Renew Sust Energ Rev 79:1346–1352. https://doi.org/10.1016/j.rser.2017.05.143

Molinero-Mourelle P, Canals S, Gómez-Polo M, Solá-Ruiz MF, Highsmith JDR, Viñuela AC (2018) Polylactic Acid as a Material for Three-Dimensional Printing of Provisional Restorations. Int J Prosthodont 31:349–350. https://doi.org/10.11607/ijp.5709

Papathanasiou I, Kamposiora P, Papavasiliou G, Ferrari M (2020) The use of PEEK in digital prosthodontics: a narrative review. BMC Oral Health 20:217. https://doi.org/10.1186/s12903-020-01202-7

Ruban SR, Jannet S, Raja R, Kakur N, Arumugaprabu V (2022) Enhancing Mechanical Behavior of As-Built and Annealed Polyethylene Terephthalate Glycol (PETG) Fabricated With Fused Filament Fabrication by Varying Infill Densities. https://doi.org/10.1016/B978-0-12-820352-1.00241-8

Worch JC, Weems AC, Yu J, Arno MC, Wilks TR et al (2020) Elastomeric polyamide biomaterials with stereochemically tuneable mechanical properties and shape memory. Nat Commun 11:3250. https://doi.org/10.1038/s41467-020-16945-8

Winnacker M (2017) Polyamides and their functionalization: recent concepts for their applications as biomaterials. Biomater Sci 5:1230–1235. https://doi.org/10.1039/C7BM00160F

Winnacker M, Beringer AJG, Gronauer TF, Güngör HH, Reinschlüssel L et al (2019) Polyamide/PEG blends as biocompatible biomaterials for the convenient regulation of cell adhesion and growth. Macromol Rapid Commun 40:e1900091. https://doi.org/10.1002/marc.201900091

Alp G, Johnston WM, Yilmaz B (2019) Optical properties and surface roughness of prepolymerized poly(methyl methacrylate) denture base materials. J Prosthet Dent 121:347–352

Batak B, Çakmak G, Johnston WM, Yilmaz B (2021) Surface roughness of high-performance polymers used for fixed implant-supported prostheses. J Prosthet Dent 126:254.e1-254.e6. https://doi.org/10.1016/j.prosdent.2020.11.029

Rohr N, Bertschinger N, Fischer J, Filippi A, Zitzmann NU (2020) Influence of material and surface roughness of resin composite cements on fibroblast behavior. Oper Dent 45:528–536. https://doi.org/10.2341/19-113-L

Mei L, Busscher HJ, van der Mei HC, Ren Y (2011) Influence of surface roughness on streptococcal adhesion forces to composite resins Dent Mater 27:770–778. https://doi.org/10.1016/j.dental.2011.03.017

Vidakis N, Vairis A, Petousis M, Savvakis K, Kechagias J (2016) Fused deposition modelling parts tensile strength characterisation. Acad J Manuf Eng 14:87–94

Bankupalli N, Rao DS, Krishna TSV (2021) Effect of process parameters and butadiene content on friction and wear behaviour of ABS components. Mater Today Proceed 41:416–421. https://doi.org/10.1016/j.matpr.2020.09.808

Fontana L, Minetola P, Iuliano L, Rifuggiato S, Khandpur MS et al (2022) An investigation of the influence of 3d printing parameters on the tensile strength of PLA material. Mater Today Proceed. https://doi.org/10.1016/j.matpr.2022.02.078

Kaur G, Singari RM, Kumar H (2022) A review of fused filament fabrication (FFF): process parameters and their impact on the tribological behavior of polymers (ABS). Mater Today Proceed 51:854–860. https://doi.org/10.1016/j.matpr.2021.06.274

Kumar MA, Khan MS, Mishra SB (2020) Effect of machine parameters on strength and hardness of FDM printed carbon fiber reinforced PETG thermoplastics. Mater Today Proceed 27:975–983. https://doi.org/10.1016/j.matpr.2020.01.291

Wang Y, Müller W-D, Rumjahn A, Schmidt F, Schwitalla AD (2021) Mechanical properties of fused filament fabricated PEEK for biomedical applications depending on additive manufacturing parameters. J Mech Behav Biomed Mater 115:104250. https://doi.org/10.1016/j.jmbbm.2020.104250

Singh J, Singh CR (2017) Pre and post processing techniques to improve surface characteristics of FDM parts: a state of art review and future applications. Rapid Prototyping J 23:495–513. https://doi.org/10.1108/RPJ-05-2015-0059

Page MJ, McKenzie JE, Bossuyt PM, Boutron I, Hoffmann TC, Mulrow CD et al (2021) The PRISMA 2020 statement: an updated guideline for reporting systematic reviews. BMJ 372:n71. https://doi.org/10.1136/bmj.n71

Tufanaru C, Munn Z, Aromataris E, Campbell J, Hopp L (2017) Chapter 3: Systematic reviews of effectiveness. In: Aromataris E, Munn Z (eds) Joanna Briggs Institute Reviewer’s Manual. The Joanna Briggs Institute, Adelaide. https://doi.org/10.46658/JBIMES-20-04

Singh R, Davim JP (2019) Additive manufacturing applications and innovations. CRC Press, Boca Raton. https://doi.org/10.1201/b22179

Pou J, Riveiro A, Davim P (2021) Additive Manufacturing. Elsevier, Amsterdam. https://doi.org/10.1016/C2018-0-00910-X

Davim JP (2019) Mechanical Behavior of Biomaterials Woodhead Publishing Series in Biomaterials. Elsevier, Amsterdam. https://doi.org/10.1016/C2016-0-04173-6

Kurdi A, Alhazmi N, Alhazmi H, Tabbakh T (2020) Practice of simulation and life cycle assessment in tribology –a review. Materials 13:3489. https://doi.org/10.3390/ma13163489

Davim, JP (2014) Biomedical Composites – Materials, Manufacturing and Engineering, De Gruyter

Yoon H-I, Jeon M-J, Kim H-L, Kim D-G, Han J-S (2018) Spatial variation of bone biomechanical properties around a dental implant using nanoindentation: a case study. J Mech Behav Biomed Mater 79:168–172. https://doi.org/10.1016/j.jmbbm.2017.12.027

Davim JP (2013) Biomaterials and medical tribology Woodhead Publishing series in biomaterials. Elsevier, Amsterdam. https://doi.org/10.1016/B978-0-85709-017-1.50011-9

Jiang D, Smith DR (2017) Anisotropic mechanical properties of oriented carbon fiber filled polymer composites produced with fused filament fabrication. Addit Manuf 18:84–94. https://doi.org/10.1016/j.addma.2017.08.006

Rezaei F, Yunus R, Ibrahim NA (2009) Effect of fiber length on thermomechanical properties of short carbon fiber reinforced polypropylene composites. Mater Des 30:260–263. https://doi.org/10.1016/j.matdes.2008.05.005

Prajapati H, Chalise D, Ravoori D, Taylor RM, Jain A (2019) Improvement in build-direction thermal conductivity in extrusion-based polymer additive manufacturing through thermal annealing. Addit Manuf 26:242–249. https://doi.org/10.1016/j.addma.2019.01.004

Ko YS, Herrmann D, Tolar O, Elspass WJ, Brändli C (2019) Improving the filament weld-strength of fused filament fabrication products through improved interdiffusion. Addit Manuf 29:100815. https://doi.org/10.1016/j.addma.2019.100815

Seppala JE, Han KEH, Hillgartner KE, Davis CS, Migler KB (2017) Weld formation during material extrusion additive manufacturing. Soft Matter 13:6761–6769. https://doi.org/10.1039/c7sm00950j

Ravi AK, Deshpande A, Hsu KHJ (2016) An in-process laser localized pre-deposition heating approach to inter-layer bond strengthening in extrusion based polymer additive manufacturing. Manuf Process 24:179. https://doi.org/10.1016/j.jmapro.2016.08.007

Yang Y, Wang T, Wang S, Cong X, Zhang S et al (2020) Strong interface construction of carbon fiber–reinforced PEEK composites: an efficient method for modifying carbon fiber with crystalline PEEK. Macromol Rapid Commun 41:2000001. https://doi.org/10.1002/marc.202000001

Garg A, Bhattacharya A, Batish A (2017) Chemical vapor treatment of ABS parts built by FDM: analysis of surface finish and mechanical strength. Int J Adv Manuf Technol 89:2175–2191. https://doi.org/10.1007/s00170-016-9257-1

Aguirre BC, Chen J-H, Kontogiorgos ED, Murchison DF, Nagy WW (2020) Flexural strength of denture base acrylic resins processed by conventional and CAD-CAM methods. J Prosthet Dent 123:641–646. https://doi.org/10.1016/j.prosdent.2019.03.010

Holanda KAB, Caldas RA, Amaral M, Concilio LRS, Vitti RP (2021) Biomechanical evaluation of anterior implants associated with titanium and zirconia abutments and monotype zirconia implants. J Prosthodont Res 65:73–77. https://doi.org/10.2186/jpr.JPOR_2019_527

Shahabi M, Fazel SM, Rangrazi A (2021) Incorporation of chitosan nanoparticles into a cold-cure ortho-dontic acrylic resin: effects on mechanical properties. Biomimetics (Basel) 6:7. https://doi.org/10.3390/biomimetics6010007

Zhu C, Zhang F, Jiao T (2017) Compressive resistances and failure modes of abutments with different transgingival heights and types on internal conical connected implants. Implant Dent 26:682–689. https://doi.org/10.1097/ID.0000000000000658

Ge T, Robbins MO, Perahia D, Grest GS (2014) Healing of polymer interfaces: interfacial dynamics, entanglements, and strength. Phys Rev E: Stat Nonlin Soft Matter Phys 90:012602. https://doi.org/10.1103/PhysRevE.90.012602

Bruijn DAC, Gómez-Gras G, Pérez MA (2021) On the effect upon the surface finish and mechanical performance of ball burnishing process on fused filament fabricated parts. Addit Manuf 46:102133. https://doi.org/10.1016/j.addma.2021.102133

Swirad S, Wdowik R (2019) Determining the effect of ball burnishing parameters on surface roughness using the Taguchi method. Proced Manuf 34:287–292. https://doi.org/10.1016/j.promfg.2019.06.152

Low KO, Wong KJ (2011) Influence of ball burnishing on surface quality and tribological characteristics of polymers under dry sliding conditions. Tribol Int 44:144–153. https://doi.org/10.1016/j.triboint.2010.10.005

Hurst SM, Farshchian B, Choi J, Kim J, Park S (2012) A universally applicable method for fabricating superhydrophobic polymer surfaces. Colloid Surface A 407:85–90. https://doi.org/10.1016/j.colsurfa.2012.05.012

Roach DJ, Roberts C, Wong J, Kuang X, Kovitz J, Zhang Q et al (2020) Surface modification of fused filament fabrication (FFF) 3D printed substrates by inkjet printing polyimide for printed electronics. Addit Manuf 36:101544. https://doi.org/10.1016/j.addma.2020.101544

Rajan AJ, Sugavaneswaran M, Prashanthi B, Deshmukh S, Jose S (2020) Influence of vapour smoothing process parameters on fused deposition modelling parts surface roughness at different build orientation. Mater Today Proced 22:2772–2778. https://doi.org/10.1016/j.matpr.2020.03.408

Gupta AK, Krishnanand TM (2022) The effect of process parameters in material extrusion processes on the part surface quality: a review. Mater Today Proced 50:1234–1242. https://doi.org/10.1016/j.matpr.2021.08.110

Hashmi AW, Mali HS, Meena A (2021) Improving the surface characteristics of additively manufactured parts: a review. Mater Today Proced. https://doi.org/10.1016/j.matpr.2021.04.223

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors report no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

de Campos, M.R., dos Reis, A.C. Effect of post-processing on the mechanical properties of polymers printed by the fused filament fabrication method used as prosthodontic materials and dental biomaterials: a systematic review. Polym. Bull. 81, 2001–2021 (2024). https://doi.org/10.1007/s00289-023-04816-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-023-04816-3