Abstract

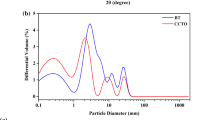

The development of a heat conductive formulation for rubber composites is essential for technical applications such as tire-curing bladders. The present study addresses the effects of three potential ceramic fillers, namely titanium carbide (TiC), silicon carbide (SiC), and alumina, on the mechanical and thermal properties of carbon black (CB)-filled butyl rubber composites. The composites were prepared using the melt compounding method. The curing, mechanical, and thermal conductivity properties of the composites were determined. The tensile strength and modulus of composites decreased slightly in the presence of ceramic fillers in lower amounts of filler loading (10 Phr). Further they reduced in a higher amount of filler loading (20 Phr). In addition, the thermal diffusivity coefficient of the composites increased in the presence of ceramic fillers with different values depending on the type and the amount of the filler with the rank of Al2O3 > SiC > TiC at 10 Phr of filler loading and SiC > TiC > Al2O3 at 20 Phr of filler loading. These different behaviors were discussed according to the state of filler dispersion in the rubber matrix and rubber–filler interactions according to the FeSEM visualization and the mechanical properties.

Similar content being viewed by others

References

Mirizzi L, Carnevale M, D’Arienzo M, Milanese C, Di Credico B, Mostoni S, Scotti R (2021) Tailoring the thermal conductivity of rubber nanocomposites by inorganic systems: opportunities and challenges for their application in tires formulation. Molecules 26:3555

Guo Y, Ruan K, Shi X, Yang X, Gu J (2020) Factors affecting thermal conductivities of the polymers and polymer composites: a review. Compos Sci Technol 193:108134

Li A, Zhang C, Zhang Y (2017) Thermal conductivity of graphene-polymer composites: mechanisms, properties and applications. Polymers 9:437

Guo B, Tang Z, Zhang L (2016) Transport performance in novel elastomer nanocomposites: mechanism, design and control. Prog Polym Sci 61:29–66

Niu H, Ren Y, Guo H, Małycha K, Orzechowski K, Bai S (2020) Recent progress on thermally conductive and electrical insulating rubber composites: design, processing and applications. Compos Commun 22:100430

Deniz V, Karaagac B, Ceyhan N (2007) Thermal stability of Butyl/EPDM/Neoprene based rubber compounds. J Appl Polym Sci 103:557–563

Ivan G, Buqaru E, Volintiru T (1988) A new activation system for resin curing of butyl rubber. Acta Polym 39:647–651

Samadi A, Razzaghi Kashani M (2010) Effects of organo-clay modifier on physical–mechanical properties of butyl-based rubber nano-composites. J Appl Polym Sci 116:2101–2109

Shiva M, Kamkar Dallakeh M, Ahmadi M, Lakhi M (2021) Effects of silicon carbide as a heat conductive filler in butyl rubber for bladder tire curing applications. Mater Today Commun 29:102773

Shiva M, Lakhi M, Robat AS (2019) Increase heat conductivity of bladder and calculate its effect on temperature profile of the tire in the curing process. Appl Res Chem—Polym Eng 3:93–105

Nasr GM, Badawy MM, Gwaily SE, Shash NM, Hassan HH (1995) Thermophysical properties of butyl rubber loaded with different types of carbon black. Polym Degrad Stab 48:237–241

Bian H, Xue J, Hao G, Hao Y, Xie M, Wang C, Wang Z, Zhu L, Xiao Y (2021) High thermal conductivity graphene oxide/carbon nanotubes/butyl rubber composites prepared by a dry ice expansion pre-dispersion flocculation method. J Appl Polym 139:e51897

Malas A, Das CK (2017) Influence of modified graphite flakes on the physical, thermo-mechanical and barrier properties of butyl rubber. J Alloy Compd 699:38–46

Gwaily SE, Nasr GM, Badawy MM, Hassan HH (1995) Thermal properties of ceramic-loaded conductive butyl rubber composites. Polym Degrad Stab 47:391–395

Meng D, Wang N, Li G (2014) Electric heating property from butyl rubber loaded boron carbide composites. J Wuhan Univ Technol-Mater Sci Ed 29:492–497

Babapoor A, Shahedi Asl M, Ahmadi Z, Sabahi Namini A (2018) Effects of spark plasma sintering temperature on densification, hardness and thermal conductivity of titanium carbide. Ceram Int 44:14541–14546

Pierson HO (1996) Handbook of refractory carbides and nitrides, Properties, Characteristics, In: Processing and Applications, NOYES Publications, USA

Hart L, Lense E (1990) Alumina chemicals: science and technology handbook. Wiley-American Ceramic Society, USA

Abdel-Aziz MM, Gwaily SE, Madani M (1998) Thermal and electrical behavior of radiation vulcanized EPDM/Al2O3 composites. Polym Degrad Stab 62:587–597

Chameswary J, Namitha LK, Brahmakumar M, Sebastian MT (2014) Material characterization and microwave substrate applications of alumina-filled butyl rubber composites. Int J Appl Ceram Technol 11:919–926

Guntur NPR, Yadav SG, Gopalan S (2020) Effect of titanium carbide as a filler on the mechanical properties of styrene butadiene rubber. Mater Today: Proc 24:1552–1560

Yadav SG, Guntur NPR, Rahulan N, Gopalan S (2021) Effect of titanium carbide powder as a filler on the mechanical properties of silicon rubber. Mater Today: Proc 46:665–671

Li Z, Chen H, Zhu Z, Zhang Y (2011) Study on thermally conductive ESBR vulcanizates. Polym Bull 67:1091–1104

Zhang F, Feng Y, Feng W (2020) Three-dimensional interconnected networks for thermally conductive polymer composites: design, preparation, properties, and mechanisms. Mater Sci Eng R 142:100580

Xu Y, Wang X, Hao Q (2021) A mini review on thermally conductive polymers and polymer-based composites. Compos Commun 24:100617

Leung SN (2018) Thermally conductive polymer composites and nanocomposites: processing-structure-property relationships. Compos B Eng 150:78–92

Yang D, Kong X, Ni Y, Gao D, Yang B, Zhu Y, Zhang L (2019) Novel nitrile-butadiene rubber composites with enhanced thermal conductivity and high dielectric constant. Compos A 124:105447

Song J, Wu L, Zhang Y (2020) Thermal conductivity enhancement of alumina/silicone rubber composites through constructing a thermally conductive 3D framework. Polym Bull 77:2139–2153

Wang ZY, Zhou XN, Li ZX, Xu SS, Hao LC, Zhao JP, Wang B, Yang JF, Ishizaki K (2021) Enhanced thermal conductivity of epoxy composites by constructing thermal conduction networks via adding hybrid alumina filler. Polym Compos 43:483–492

Yang K, Gu M (2010) Enhanced thermal conductivity of epoxy nanocomposites filled with hybrid filler system of triethylenetetramine-functionalized multi-walled carbon nanotube/silane-modified nano-sized silicon carbide. Compos A 41:215–221

Zhou W, Wang C, An Q, Ou H (2008) Thermal properties of heat conductive silicone rubber filled with hybrid fillers. J Compos Mater 42:173–187

Shiva M, Akhtari SS, Shayesteh M (2020) Effect of mineral fillers on physico-mechanical properties and heat conductivity of carbon black-filled SBR/butadiene rubber composite. Iran Polym J 29:957–974

Shiva M, Lakhi M (2019) Studying the effects of silica/alumina and silica/boehmite binary filler on the mechanical properties and the non-isothermal curing time of carbon black filled tyre tread composite. Compos Part B 175:107124

Ghoreishy M, Naderi G, Pahlavan M (2016) An investigation into the thermal transport properties of PP/EPDM/clay nanocomposites using a new combined experimental/numerical method. Plast, Rubber Compos 45:229–237

He Y, Chen ZC, Ma LX (2010) Thermal conductivity and mechanical properties of silicone rubber filled with different particle sized SiC. Adv Mater Res 87–88:137–142

Cheng JP, Liu T, Zhang J, Wang BB, Ying J, Liu F, Zhang XB (2014) Influence of phase and morphology on thermal conductivity of alumina particle/silicone rubber composites. Appl Phys A 117:1985–1992

Pierson H O (1996) Carbides of group IV: titanium, zirconium, and hafnium carbides. Handbook of refractory carbides and nitrides. Chapter 4:55-80

Williams Wendell S (1998) The thermal conductivity of metallic ceramics. Therm Manag, Overv 50:62–66

Morelli DT (1991) Thermal conductivity and thermoelectric power of titanium carbide single crystals. Phys Rev B 44:5453–5458

Vasilos T, Kingery WD (1954) Thermal conductivity: XI, conductivity of some refractory carbides and nitrides. J Am Ceram Soc-Vasilos Kingery 37:409–414

Pierson HO (1996) Carbides of group IV: titanium, characteristics and properties of silicon carbide and boron carbide. Handbook of refractory carbides and nitrides. Chapter 8: pp 137-154

Ouyang Y, Li X, Tian H, Bai L, Yuan F (2021) A novel branched Al2O3/Silicon rubber composite with improved thermal conductivity and excellent electrical insulation performance. Nanomaterials 11:2654

Zhuang C, Tao R, Liu X, Zhang L, Cui Y, Liu Y, Zhang Z (2021) Enhanced thermal conductivity and mechanical properties of natural rubber-based composites co-incorporated with surface treated alumina and reduced graphene oxide. Diam Relat Mater 116:108438

Wang Q, Gao W, Xie Z (2003) Highly thermally conductive room-temperature vulcanized silicone rubber and silicone Grease. J Appl Polym Sci 89:2397–2399

Acknowledgements

The authors greatly appreciate the support of Kavir Tire Company.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shiva, M., Ahmadi, M., Esmaili, E. et al. Heat diffusivity and mechanical properties of a tire bladder composite in the presence of ceramic fillers. Polym. Bull. 81, 1635–1649 (2024). https://doi.org/10.1007/s00289-023-04789-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-023-04789-3