Abstract

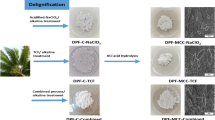

This study investigate extraction and green hydrophobic modification of cellulose from oil palm waste in aqueous medium. Cellulose is isolate from empty oil palm bunch (EOPB) and palm frond (PF), respectively, and modify in an aqueous medium using benzoyl chloride to produce cellulose benzoate esters. Characterization is performed using X-ray diffraction (XRD), thermogravimetric analysis (TGA), Fourier transform infrared spectroscopy (FTIR), scanning electron microscopy (SEM) and energy disperse X-ray spectroscopy (EDX). The green synthesis techniques using water and sodium hydroxide as a reaction medium is fast, safe, eco-friendly, save cost, effective, and the product is pure. From XRD results, the crystallinity of cellulose isolate from EOPB and PF is 66.12% and 71.98%, while the crystallinity of hydrophobically modified cellulose is 61.38% and 61.6%, respectively. EDX results show that isolated cellulose is very pure (> 98% pure) and have carbon and oxygen as major elemental composition. TGA, EDX, SEM and FTIR show that the integrity of the cellulose structure is well-preserved after modification in the aqueous medium. Hence, cellulose isolated from oil palm waste and modified via green synthesis techniques can be used as commercial cellulose. Also, the green synthesis technique gives very pure modified cellulose products and solves problems of environmental challenges often associated with other methods of chemical modification of cellulose.

Similar content being viewed by others

References

Abidi N, Cabrales L, Haigler CH (2014) Changes in the cell wall and cellulose content of developing cotton fibers investigated by FTIR spectroscopy. Carbohydr Polym 100:9–16

Abdulwaha RD, Owolabi F, Chaturbhuj KS, Abdul Khalil HPS, Paridah MT, Hazwan CICM, Kamoldeen AA, Masri MM, Rosamah E, Aditiawati P (2016) Preparation and fundamental characterization of cellulose nanocrystal from oil palm fronds biomass. J Environ Polym Degrad 25:1–9

Abdullah H, Wu H (2009) Biochar as a fuel: 1. Properties and grindability of biochars produced from the pyrolysis of mallee wood under slow-heating conditions. Energy Fuels 23:4174–4181. https://doi.org/10.1021/ef900494t

Abinash D, Togam R, Sampad G, Nabakumar P (2022) A comprehensive review on recent advances in preparation, physicochemical characterization, and bioengineering applications of biopolymers. Polym Bull. https://doi.org/10.1007/s00289-022-04443-4

Acharya S, Hu Y, Moussa H, Abidi N (2017) Preparation and characterization of transparent cellulose films using an improved cellulose dissolution process. J Appl Polym Sci. https://doi.org/10.1002/APP.44871

Adewuyi A, Fabiano VP (2018) Isolation and characterization of cellulose from underexploited golden melon skin. J Mater Sci 22:121–126

Ahmad SA, Das SS, Khatoon A, Ansari MT, Afzal M, Hasnain MS, Nayak AK (2020) Bactericidal activity of silver nanoparticles: a mechanistic review. Mater Sci Energy Technol 3:756–769. https://doi.org/10.1016/j.mset.2020.09.002

Ajayi SM, Olusanya SO, Sodeinde KO, Olumayede EG, Lawal OS, Didunyemi AE, Atunde MO, Fapojuwo DP (2022) Application of hydrophobically modified cellulose from oil palm frond in Pickering emulsions stabilization. Carbohydr Polym Technol Appl 4:100248

Balat M, Balat M, Kirtay E, Balat H (2009) Main routes for the thermo-conversion of biomass into fuels and chemicals. Part 1: pyrolysis systems. Energy Convers Manag 50:3147–3157. https://doi.org/10.1016/j.enconman.2009.08.014

Carrier M, Loppinet-Serani A, Denux D, Lasnier JM, Ham-Pichavant F, Cansell F, Aymonier C (2011) Thermogravimetric analysis as a new method to determine the lignocellulosic composition of biomass. J Biomol Bioenergy 35:298–307

Chauhan GS, Bhatt SS, Kaur I, Kaith BS, Singha AS (2000) Evaluation of optimum grafting parameters and the effect of ceric ion initiated grafting of methyl methacrylate onto jute fiber on the kinetics of thermal degradation and swelling behavior. J Polym Degrad Stab 69:261–265

Charles T (1992) Chemistry and technology of fabric preparation and finishing. In: Department of Textile Engineering, Chemistry and Science. North Carolina State University

Chen W, Feng Y, Zhang M, Wu J, Zhang J, Gao X, Hea J, Zhang J (2015) Homogeneous benzoylation of cellulose in 1-allyl-3-methylimidazolium chloride: Hammett correlation, mechanism and regioselectivity. R Soc Chem Adv 5:58536-58542 | 58537. https://doi.org/10.1039/c5ra08911e

Chunyan G (2022) Risk assessment and analysis of biomass energy engineering project management under the concept of sustainable development. Adsorpt Sci Technol 2022:5323021. https://doi.org/10.1155/2022/5323021

Colom X, Carrillo F, Nogue F, Garriga P (2003) Structural analysis of photodegraded wood by means of FTIR spectroscopy. J Polym Degrad Stab 80:543–549

Cropper M, Griffiths C (1994) The interaction of population growth and environmental quality. Am Econ Rev 84:250–254. https://doi.org/10.2307/2117838

Golmohammadi H, Morales-Narváez E, Naghdi T, Merkoçi A (2017) Nanocellulose in Sensing and Biosensing. Chem Mater 29:5426–5446

Du Le H, Loveday SM, Singh H, Sarkar A (2020) Pickering emulsions stabilised by hydrophobically modified cellulose nanocrystals: responsiveness to pH and ionic strength. Food Hydrocolloids 99:105344

Du Lee KY, Tammelin T, Schulfter K, Kiiskinen H, Samela J, Bismarck A (2012) High performance cellulose nanocomposites: comparing the reinforcing ability of bacterial cellulose and nanofifibrillated cellulose. ACS Appl Mater Interfaces 4:4078–4086

De Morais TE, Bondancia TJ, Teodoro KB, Correa AC, Mar-concini JM, Mattoso LH (2011) Sugarcane bagasse whiskers: extraction and characterizations. J Ind Crop Products 33:63–66

Elanthikkal S, Gopalakrishnapanicker U, Varghese S, Guthrie JT (2010) Cellulose microfibers produced from banana plant wastes: isolation and characterization. J Carbohydr Polym 80:852–859

Fatiha I, Nur EA, Noorshamsiana AW, Fazliana AH, Astimar AA (2021) Preparation of microcrystalline cellulose from oil palm empty fruit bunch fiber using steam-assisted acid hydrolysis. J Adv Res Fluid Mech Therm Sci 8:88–98

Gea S, Panindia N, Piliang AF, Sembiring A, Hutapea YA (2018) All-cellulose composite isolated from oil palm empty fruit bunch. J Phys: Conf Ser 1116:042013

Gabrielli V, Frasconi M (2022) Cellulose-based functional materials for sensing. Rev Chemosensors 10:352. https://doi.org/10.3390/chemosensors10090352

Habibi Y, Lucia LA, Rojas OJ (2010) Cellulose nanocrystals: chemistry, self-assembly, and applications. J Chem Rev 110:3479–3500

Hajji L, Boukir A, Assouik J, De Carvalho ML, Lakhiari H, Kerbal A, Doumenq P, Mille G (2015) Conservation of Moroccan manuscript papers aged 150, 200 and 800 years. Analysis by infrared spectroscopy (ATR-FTIR), X-ray diffraction (XRD), and scanning electron microscopy energy dispersive spectrometry (SEM-EDS). Spectrochim Acta A 136:1038–1046

Kikuchi Y (2022) Application of PSE into social changes: biomass based production, recycling systems, and regional systems design and assessment. Comput Aided Chem Eng 49(2):41–46

Klemm D, Heinze TH, Stein A, Liebert T (1995) Polyglucane derivatives with regular substituent distribution. Macromol Symp 99(1):129–140. https://doi.org/10.1002/masy.19950990114

Klemm D, Philipp B, Heinze T, Heinze U, Wagenknecht W (1998) Comprehensive cellulose chemistry: functionalization of cellulose, vol 2. Wiley, Weinheim

Krerkkaiwan S, Mueangta S, Thammarat P, Jaisat L, Kuchonthara P (2015) Catalytic biomass-derived tar decomposition using char from the copyrolysis of coal and giant Leucaena wood biomass. Energy Fuels 29:3119–3126. https://doi.org/10.1021/ef502792x

Laysandra L, Kartika Sari MWM, Soetaredjo FE, Foe K, Putro JN, Kurniawan A, Ju Y, Ismadji S (2017) Adsorption and photocatalytic performance of bentonite titanium dioxide composites for methylene blue and rhodamine B decoloration. Heliyon 3:e00488

Li M, Zheng Y, Chen Y, Zhu X (2014) Biodiesel production from waste cooking oil using a heterogeneous catalyst from pyrolyzed rice husk. Bioresour Technol 154:345–348. https://doi.org/10.1016/j.biortech.2013.12.070

Lin N, Huang J, Dufresne A (2012) Preparation, properties and applications of polysaccharide nanocrystals in advanced functional nanomaterials: a review. Nanoscale 4:32–74

Liu WJ, Jiang H, Yu HQ (2015) Development of biochar-based functional materials: toward a sustainable platform carbon material. Chem Rev 115:12251–12285. https://doi.org/10.1021/acs.chemrev.5b00195

Luisa MV, Niedja FV, Diego L, Morsyleide FR, Enrique R, Fabia KA, Rodrigo SV (2022) Microwave-assisted periodate oxidation as a rapid and efficient alternative to oxidize bacterial cellulose wet membrane. Polym Bull. https://doi.org/10.1007/s00289-022-04617-0

Megashah LN, Ariffin H, Zakaria MR, Hassan MA (2018) Properties of cellulose extract from different types of oil palm biomass. IOP Conf Ser: Mater Sci Eng 368:012049

Miandad R, Rehan MNizami AS, El-Fetouh Barakat MA, Ismail IM (2016) The energy and value-added products from pyrolysis of waste plastics. Environ Footpr Eco-Des Products Process. https://doi.org/10.1007/978-981-10-0150-5_12

Miandad R, Barakat MA, Aburiazaiza AS, Rehan M, Ismail IMI, Nizami AS (2017) Effect of plastic waste types on pyrolysis liquid oil. Int Biodeterior Biodegrad 119:239–252. https://doi.org/10.1016/j.ibiod.2016.09.017

Murid H, Samir B, Francesco G, Guido S, Nunzio R (2010). Photocatalytic degradation of ethylene emitted by fruits with TiO2 nanoparticles. J Ind Eng Chem Res 50:2536–2543

Nazir MS, Wahjoedi BA, Yussof AW, Abdullah MA (2013) Eco-friendly extraction and characterization of cellulose from oil palm empty fruit bunches. J Bioresour 8:2161–2172

Narayan T, Bhattacharya T, Chakraborty S, Konar S (2018) Long-term statistical characteristics of air pollutants in a traffic-congested area of Ranchi, India. Commun Math Stat 6:141–162. https://doi.org/10.1007/s40304-018-0129-x

Noor AN, Othman S, Rokiah H, Mohamad H, Mohamad K (2017) Oil palm frond waste for the production of cellulose nanocrystals. J Phys Sci 8:115–126

Noor AN, Othman S, Rokiah H, Mohamad H, Mohamad K (2016) Characterization of different parts of oil palm fronds (Elaeis Guineensis) and its properties. Int J Adv Sci Eng Inf Technol 6:2088–5334

Pääkkö M, Vapaavuori J, Silvennoinen R, Kosonen H, Ankerfors M, Lindström T, Berglund LA, Ikkala O (2008) Long and entangled native cellulose I nanofifibers allow flexible aerogels and hierarchically porous templates for functionalities. Soft Matter 4:2492–2499

Pang B, Liu H, Liu P, Peng X, Zhang K (2018) Water-in-oil Pickering emulsions stabilized by stearoylated microcrystalline cellulose. J Colloid Interface Sci 513:629–637

Rahn K, Diamantoglou M, Klemm D, Berghmans H, Heinze Angew T (1996) The role of novel solvents and solution complexes for the preparation of highly engineered cellulose derivatives. J Macromol Chem 238:143–163

Reddy C, Reddy V, Oshel R, Verkade JG (2006) Room-temperature conversion of soybean oil and poultry fat to biodiesel catalyzed by nanocrystalline calcium oxides. Energy Fuels 20:1310–1314. https://doi.org/10.1021/ef050435d

Ridzuan R, Norhafzan J, Beg Mohammad DH, Rosli MY (2015) Microcrystalline cellulose (MCC) from oil palm empty fruit bunch (EFB) fiber via simultaneous ultrasonic and alkali treatment. Int J Chem Nucl Mater Metall Mater Eng 9(1):1–4

Roberts AD, Li X, Zhang H (2014) Porous carbon spheres and monoliths: morphology control, pore size tuning and their applications as Li-ion battery anode materials. Chem Soc Rev 43:4341–4356. https://doi.org/10.1039/c4cs00071d

Rosa M, Campos-Martin SJM, Fierro JLG (2012) High glucose yields from the hydrolysis of cellulose dissolved in ionic liquids. J Chem Eng 181–182:538–541

Rosa MF, Medeiros ES, Malmonge JA, Gregorski KS, Wood DF, Mattoso LHC, Glenn G, Orts WJ, Imam SH (2010) Cellulose nanowhiskers from coconut husk fibers: effect of preparation conditions on their thermal and morphological behavior. Carbohydr Polym 81:83–92

Rudi D, Abdulwaha OF, Chaturbhuj KS, Abdul Khalil HPS, Paridah MT, Hazwan CICM, Kamoldeen AA, Masri MM, Rosamah E, Aditiawati P (2016) Preparation and fundamental characterization of cellulose nanocrystal from oil palm fronds biomass. J Environ Polym Degrad 25(3):1–9

Saleh TA, Shetti NP, Shanbhag MM, Raghava RK, Aminabhavi TM (2020) Recent trends in functionalized nanoparticles loaded polymeric composites: an energy application. Mater Sci Energy Technol 3:515–525. https://doi.org/10.1016/j.mset.2020.05.005

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Resour J 29(10):786–794

Siegmund G. (1993) Diploma thesis. Friedrich-Schiller-University of Jena

Singh BP, Cowie AL, Smernik RJ (2012) Biochar carbon stability in a clayey soil as a function of feedstock and pyrolysis temperature. Environ Sci Technol 46:11770–11778. https://doi.org/10.1021/es302545b

Siqueira G, Bras J, Dufresne A (2008) Cellulose whiskers versus microfifibrils: inflfluence of the nature of the nanoparticle and its surface functionalization on the thermal and mechanical properties of nanocomposites. J Biomacromol 10:425–432

Siqueira G, Tapin-Lingua S, Bras J, da Silva Perez D, Dufresne A (2010) Morphological investigation of nanoparticles obtained from combined mechanical shearing, and enzymatic and acid hydrolysis of sisal fibers. J Cellul 17:1147–1158. https://doi.org/10.1007/s10570-010-9449-z

Shabangu S, Woolf D, Fisher EM, Angenent LT, Lehmann J (2014) Technoeconomic assessment of biomass slow pyrolysis into different biochar and methanol concepts. Fuel 117:742–748. https://doi.org/10.1016/j.fuel.2013.08.053

Sharma RK (2012) A study in thermal properties of graft copolymers of cellulose and methacrylates. Adv Appl Sci Res 3:3961–3969

Shen Y, Linville JL, Urgun-Demirtas M, Schoene RP, Snyder SW (2015) Producing pipeline-quality biomethane via anaerobic digestion of sludge amended with corn stover biochar with in-situ CO2 removal. Appl Energy 15:300–309. https://doi.org/10.1016/j.apenergy.2015.08.016

Sodeinde KO, Ojo AM, Olusanya SO, Ayanda OS, Adeoye AO, Dada TM, Lawal OS (2021) Cellulose isolated from Delonix regia pods: characterisation and application in the encapsulation of vitamin A. J Ind Crops Products 60:113138

Stein A (1991) Thesis. Friedrich-Schiller-University of Jena. 82

Sugiwati S, Suaidah S, Triwahyuni E, Muryanto M, Andriani Y, Abimanyu H (2021) Hydrolysis of cellulose from oil palm empty fruit bunch using Aspergillus niger. E3S Web of Conferences 226(1):7. https://doi.org/10.1051/e3sconf/202122600042

Syamani FA, Suryani A (2015) Changes in oil palm frond fiber morphology cellulose crystallinity and chemical functional groups during cellulose extraction phases. J Chem Mater Res 7:105–114

Tang C, Chen Y, Luo J, Low MY, Shi Z, Tang J, Zhang Z, Peng B, Tam KC (2019) Pickering emulsions stabilized by hydrophobically modified nanocellulose containing various structural characteristics. Cellulose 26:7753–7767

Terbojevich M, Cosani A, Camilot M, Focher B (1995) Solution studies of cellulose tricarbanilates obtained in homogeneous phase. J Appl Polym Sci 55:1663–1671

Viera RG, Rodrigues FG, de Assuncao RM, Meireles CdS, Vieira JG, de Oliveira GS (2007) Synthesis and characterization of methylcellulose from sugar cane bagasse cellulose. J Carbohydr Polym 67:182–189

Willberg-Keyrilainen P, Vartiainen J, Harlin A, Ropponen J (2016) The effect of side-chain length of cellulose fatty acid esters on their thermal, barrier and mechanical properties. Cellulose 24:1–13

Yimlamai B, Choorit W, Chisti Y, Prasertsan P (2021) Cellulose from oil palm empty fruit bunch fiber and its conversion to carboxymethylcellulose. J Chem Technol Biotechnol 96:1656–1666

Zghari B, Hajji L, Boukir A (2018) Effect of moist and dry heat weathering conditions on cellulose degradation of historical manuscripts exposed to accelerated ageing: 13C NMR and FTIR spectroscopy as a non-invasive monitoring approach. J Mater Environ Sci 9:641–654

Zhang J, Wu J, Cao Y, Sang S, Zhang J, He J (2008) Synthesis of cellulose benzoates under homogeneous conditions in an ionic liquid. Cellulose 16:299–308. https://doi.org/10.1007/s10570-008-9260-2

Zhao D, Zhu Y, Cheng W, Wu Y, Yu H (2021) Cellulose-based flexible functional materials for emerging intelligent electronics. Adv Mater 33:2000619

Acknowledgements

The authors acknowledge with thanks, the Institutional based research funding from the Tertiary Education Trust Fund of Nigeria, TEFfund.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Olusanya, S.O., Ajayi, S.M., Sodeinde, K.O. et al. Hydrophobic modification of cellulose from oil palm waste in aqueous medium. Polym. Bull. 81, 1349–1371 (2024). https://doi.org/10.1007/s00289-023-04756-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-023-04756-y