Abstract

This research focuses on the preparation of several coating pastes using polyacrylate PA, polyurethane PU and Latex mixed with different ionic liquids, namely [Py, PF6] and [A, PF6]. These prepared pastes were applied to one side of a cotton/polyester blend fabric, by knife coating to improve their flame resistance and water repellency. The morphology of pristine fabric and fabric coated with ionic liquids was studied by scanning electron microscope. The mechanical resistance according to NF EN ISO 13934-1:2013 standard shows that the functionalization of fabrics by [A, PF6] and [Py, PF6] using the knife coating method does not affect the mechanical resistance of the fabrics elaborated. The vertical burning test according to ISO 6940:2004 (F) shows that fabrics treated with polymers + ionic liquids do not burn even increasing the flame time to 20 s with a residue of 98% for PU + 2% [Py, PF6]. Thermogravimetric analysis shows that the thermal stability of fabrics coated with polymers + ionic liquids \({\text{PF}}_{6}^{ - }\) has been improved compared to that of pristine fabric and fabrics coated only with polymers. The washing test carried out according to the ISO 105-C06:2010 standard shows that fabrics treated with ionic + polymer liquids retain the flame-retardant property for up to 12 washing cycles. Then, a drop test and a rain test confirmed that the textile materials coated with polymers + \({\text{PF}}_{6}^{ - }\) do not absorb water.

Similar content being viewed by others

References

de Jesus SS, MacielFilho R (2022) Are ionic liquids eco-friendly? Renew Sustain Energy Rev 157:112039. https://doi.org/10.1016/j.rser.2021.112039

Miao L, Song Z, Zhu D, Li L, Gan L, Liu M (2021) Ionic liquids for supercapacitive energy storage: a mini-review. Energy Fuels 35:8443–8455. https://doi.org/10.1021/acs.energyfuels.1c00321

Ray A, Saruhan B (2021) Application of ionic liquids for batteries and supercapacitors. Materials 14:2942. https://doi.org/10.3390/ma14112942

Wu J et al (2021) Deep eutectic solvents for boosting electrochemical energy storage and conversion: a review and perspective. Adv Funct Mater 31:2011102. https://doi.org/10.1002/adfm.202011102

Brzęczek-Szafran A et al (2021) Protic ionic liquids from di- or triamines: even cheaper Brønsted acidic catalysts. Green Chem 23:4421–4429. https://doi.org/10.1039/D1GC00515D

Qu Y, Zhao Y, Li D, Sun J (2022) Task-specific ionic liquids for carbon dioxide absorption and conversion into value-added products. Curr Opin Green Sustain Chem 34:100599. https://doi.org/10.1016/j.cogsc.2022.100599

Rogstad DT, Einarsrud M-A, Svensson AM (2021) Evaluation of selected ionic liquids as electrolytes for silicon anodes in Li-ion batteries. J Electrochem Soc 168:110506. https://doi.org/10.1149/1945-7111/ac330f

Vereshchagin AN, Frolov NA, Egorova KS, Seitkalieva MM, Ananikov VP (2021) Quaternary ammonium compounds (QACs) and ionic liquids (ILs) as biocides: from simple antiseptics to tunable antimicrobials. Int J Mol Sci 22:6793. https://doi.org/10.3390/ijms22136793

Feng T et al (2022) Ionic liquid modified boron nitride nanosheets for interface engineering of epoxy resin nanocomposites: improving thermal stability, flame retardancy, and smoke suppression. Polym Degrad Stab 199:109899. https://doi.org/10.1016/j.polymdegradstab.2022.109899

Wu R, Ma L, Liu XY (2022) From mesoscopic functionalization of silk fibroin to smart fiber devices for textile electronics and photonics. Adv Sci 9:2103981. https://doi.org/10.1002/advs.202103981

Gao M, Guo G, Chai Z, Yi D, Qian L (2022) The flame retardancy of ionic liquid functionalized graphene oxide in unsaturated polyester resins. Fire Mater 46:743–752. https://doi.org/10.1002/fam.3020

Wang Y, Jia X, Shi H, Hao J, Qu H, Wang J (2021) Graphene nanoplatelets hybrid flame retardant containing ionic liquid and ammonium polyphosphate for modified bismaleimide resin: excellent flame retardancy, thermal stability, water resistance and unique dielectric properties. Materials 14:6406. https://doi.org/10.3390/ma14216406

Liu S-H, Xu Z-L, Zhang L (2021) Effect of cyano ionic liquid on flame retardancy of melamine. J Therm Anal Calorim 144:305–314. https://doi.org/10.1007/s10973-020-10245-5

Guo Y, Chen X, Cui J, Guo J, Zhang H, Yang B (2021) Effect of ionic liquid octyltriphenylphosphonium-chelated orthoborates on flame retardance of epoxy. Polym Adv Technol 32:1579–1596. https://doi.org/10.1002/pat.5195

Luo T, Jiao C, Chen X, Jiang H (2022) Flame-retardant effect of modified molecular sieve by ionic liquid in TPU. J Therm Anal Calorim 147:4141–4150. https://doi.org/10.1007/s10973-021-10840-0

Wei R, Yang B, He C, Jin L, Zhang X, Zhao C (2022) Versatile and robust poly (ionic liquid) coatings with intelligent superhydrophilicity/superhydrophobicity switch in high-efficient oil-water separation. Sep Purif Technol 282:120100. https://doi.org/10.1016/j.seppur.2021.120100

Xu J, Zhi Y, Wei S, Wei Y, Chen L (2021) Environmental and performance assessment of fabricated hydrophobic and flame-retardant cotton fabrics with functional integrated grapheme. In Review, preprint, https://doi.org/10.21203/rs.3.rs-830309/v1

Yan J, Mangolini F (2021) Engineering encapsulated ionic liquids for next-generation applications. RSC Adv 11:36273–36288. https://doi.org/10.1039/D1RA05034F

Ficanha AMM, Oro CED, Franceschi E, Dallago RM, Mignoni ML (2021) Evaluation of different ionic liquids as additives in the immobilization of lipase CAL B by sol–gel technique. Appl Biochem Biotechnol 193:2162–2181. https://doi.org/10.1007/s12010-021-03533-9

El Messoudi M, Boukhriss A, Cherkaoui O, El Kouali M, Gmouh S (2020) Adsorption–desorption kinetics of silica coated on textile fabrics by the sol–gel process. J Coat Technol Res 17:371–380. https://doi.org/10.1007/s11998-019-00281-8

Che Q, Fan H, Duan X, Feng F, Mao W, Han X (2018) Layer by layer self-assembly fabrication of high temperature proton exchange membrane based on ionic liquids and polymers. J Mol Liq 269:666–674. https://doi.org/10.1016/j.molliq.2018.08.030

Yoshida Y, Fujie K, Lim D, Ikeda R, Kitagawa H (2019) Superionic conduction over a wide temperature range in a metal-organic framework impregnated with ionic liquids. Angew Chem Int Ed 58:10909–10913. https://doi.org/10.1002/anie.201903980

Suo H, Xu L, Xue Y, Qiu X, Huang H, Hu Y (2020) Ionic liquids-modified cellulose coated magnetic nanoparticles for enzyme immobilization: Improvement of catalytic performance. Carbohydr Polym 23:115914. https://doi.org/10.1016/j.carbpol.2020.115914

Bhushan T, Chandrashekhar A, Prasat SV, Reddy IR (2020) Effect of substrate surface roughness on adhesion of titanium nitride coatings deposited by physical vapour deposition technique. In: IOP conference series: materials science and engineering, vol 981, pp 042022. https://doi.org/10.1088/1757-899X/981/4/042022

Smith WC (2019) Commentary/overview of textile coating and lamination. Smart textile coatings and laminates. Elsevier, Amsterdam, pp 3–10. https://doi.org/10.1016/B978-0-08-102428-7.00001-8

Tian Y et al (2022) Applications of adhesives in textiles: a review. Eur Polym J 167:111089. https://doi.org/10.1016/j.eurpolymj.2022.111089

Sobkowicz-Kline M, Budhlall BM, Mead JL (2017) Synthetic resins and plastics. In: Kent JA, Bommaraju TV, Barnicki SD (eds) Handbook of industrial chemistry and biotechnology. Springer International Publishing, Cham, pp 1397–1462. https://doi.org/10.1007/978-3-319-52287-6_25

Wu Y et al (2020) A type of silicone modified styrene-acrylate latex for weatherable coatings with improved mechanical strength and anticorrosive properties. React Funct Polym 148:104484. https://doi.org/10.1016/j.reactfunctpolym.2020.104484

Dogan M, Dogan SD, Savas LA, Ozcelik G, Tayfun U (2022) Flame retardant effect of boron compounds in polymeric materials. Compos Part B Eng 222:109088. https://doi.org/10.1016/j.compositesb.2021.109088

Liu X et al (2019) Enhancing the flame retardancy of thermoplastic polyurethane by introducing montmorillonite nanosheets modified with phosphorylated chitosan. Compos Part Appl Sci Manuf 119:291–298. https://doi.org/10.1016/j.compositesa.2019.02.009

Wang X, Zhang J, Liu J, Luo J (2022) Phytic acid-based adhesion promoter for UV-curable coating: high performance, low cost, and eco-friendliness. Prog Org Coat 167:106834. https://doi.org/10.1016/j.porgcoat.2022.106834

Feng Y, Zhou Y, Li D, He S, Zhang F, Zhang G (2017) A plant-based reactive ammonium phytate for use as a flame-retardant for cotton fabric. Carbohydr Polym 175:636–644. https://doi.org/10.1016/j.carbpol.2017.06.129

He P et al (2018) Preparation and flame retardancy of reactive flame retardant for cotton fabric. J Therm Anal Calorim 132:1771–1781. https://doi.org/10.1007/s10973-018-7057-6

Lin D, Zeng X, Li H, Lai X, Wu T (2019) One-pot fabrication of superhydrophobic and flame-retardant coatings on cotton fabrics via sol-gel reaction. J Colloid Interface Sci 533:198–206. https://doi.org/10.1016/j.jcis.2018.08.060

Boukhriss A, Gmouh S, Hannach H, Roblin J-P, Cherkaoui O, Boyer D (2016) Treatment of cotton fabrics by ionic liquid with PF6—anion for enhancing their flame retardancy and water repellency. Cellulose 23:3355–3364. https://doi.org/10.1007/s10570-016-1016-9

Fakin D, Golob D, Stjepanovič Z (2008) The effect of pretreatment on the environment and dyeing properties of a selected cotton knitted fabric. Fibres & Textiles in Eastern Europe, vol 16, issue 2, pp 101–104

Bentis A, Boukhriss A, Grancaric AM, El Bouchti M, El Achaby M, Gmouh S (2019) Flammability and combustion behavior of cotton fabrics treated by the sol gel method using ionic liquids combined with different anions. Cellulose 26:2139–2153. https://doi.org/10.1007/s10570-018-2206-4

Bramhecha I, Sheikh J (2019) Development of sustainable citric acid-based polyol to synthesize waterborne polyurethane for antibacterial and breathable waterproof coating of cotton fabric. Ind Eng Chem Res 58:21252–21261. https://doi.org/10.1021/acs.iecr.9b05195

de Oliveira CRS, Batistella MA, Lourenço LA, de ArrudaGuelliUlsonde Souza de Souza SM, de Souza AAU (2021) Cotton fabric finishing based on phosphate/clay mineral by direct-coating technique and its influence on the thermal stability of the fibers. Prog Org Coat 150:105949. https://doi.org/10.1016/j.porgcoat.2020.105949

Li YW (2014) The study of melamine modified by imidazolium based ionic liquid [BMIM]PF6 on the flame retardancy of rigid polyurethane foam. Adv Mater Res 1030–1032:241–245. https://doi.org/10.4028/www.scientific.net/AMR.1030-1032.241

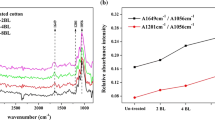

Liu L, Huang Z, Pan Y, Wang X, Song L, Hu Y (2018) Finishing of cotton fabrics by multi-layered coatings to improve their flame retardancy and water repellency. Cellulose 25:4791–4803. https://doi.org/10.1007/s10570-018-1866-4

Mohamed KS, Padma DK (1985) Spectral studies on pyridinium hexafluorophosphate. Spectrochim Acta Part Mol Spectrosc 41:725–728. https://doi.org/10.1016/0584-8539(85)80181-1

Messali M (2015) Eco-friendly synthesis of a new class of pyridinium-based ionic liquids with attractive antimicrobial activity. Molecules 20:14936–14949. https://doi.org/10.3390/molecules200814936

Jiao C, Wang H, Chen X, Tang G (2019) Flame retardant and thermal degradation properties of flame-retardant thermoplastic polyurethane based on HGM@[EOOEMIm][BF4]. J Therm Anal Calorim 135:3141–3152. https://doi.org/10.1007/s10973-018-7505-3

Qiu S et al (2018) Melamine-containing polyphosphazene wrapped ammonium polyphosphate: A novel multifunctional organic -inorganic hybrid flame retardant. J Hazard Mater 344:839–848. https://doi.org/10.1016/j.jhazmat.2017.11.018

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Latifi, S., Boukhriss, A., Saoiabi, S. et al. Flame retardant coating of textile fabrics based on ionic liquids with self-extinguishing, high thermal stability and mechanical properties. Polym. Bull. 80, 9253–9274 (2023). https://doi.org/10.1007/s00289-022-04513-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-022-04513-7