Abstract

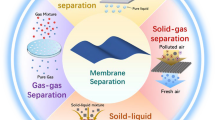

Flat membranes composed of blends have been studied in the treatment of wastewater due to the influence on their properties. The objective of this study is to develop flat membranes from pure polymers and polymeric blends of polyestersulfone/polysulfone, improving morphology and permeability, making them suitable for the treatment of oily waters. Initially, it was investigated the interaction between the two polymers from the analysis of spectroscopy in the infrared region with Fourier transform (FTIR) of pure polymers and of membranes produced from the blends. The influence on the hydrophilicity of the compositions was observed by altering the contact angle of the membranes produced. By X-ray diffraction (XRD), the similarity between the Psf and PES bands was perceived. Subsequently, the flat membranes were characterized by atomic force microscopy (AFM), scanning electron microscopy (SEM) and flow measurements, revealing that the different concentrations of the blends modified the morphology and water permeate flow of the membranes. By turbidity analysis, it was possible to visualize percentage that up to 99.5% of oil was removed.

Similar content being viewed by others

References

Almojjly A, Johnson DJ, Mandale S, Hilal N (2019) Optimisation of the removal of oil in water emulsion by using ceramic microfiltration membrane and hybrid coagulation/sand filter-MF. J Water Process Eng. https://doi.org/10.1016/j.jwpe.2018.11.007

Davies WJ, Le MS, Heath CR (1998) Intensified activated sludge process with submerged membrane microfiltration. Water Sci Technol. https://doi.org/10.1016/S0273-1223(98)00541-1

Yang Y, Zhang H, Wang P, Zheng Q, Li J (2007) The influence of nano-sized TiO2 fillers on the morphologies and properties of PSF UF membrane. J Membr Sci. https://doi.org/10.1016/j.memsci.2006.11.019

Arias A, Vallina I, Lorenzo Y, Komesli OT, Katsou E, Feijoo G, Moreira MT (2019) Water footprint of a decentralised wastewater treatment strategy based on membrane technology. Springer, Berlin

Arahman N, Arifin B, Mulyati S, Ohmukai Y, Matsuyama H (2012) Structure change of polyethersulfone hollow fiber membrane modified with pluronic F127, polyvinylpyrrolidone, and tetronic 1307. Mater Sci Appl. https://doi.org/10.4236/msa.2012.32011

Xiao T, Wang P, Yang X, Cai X, Lu J (2015) Fabrication and characterization of novel asymmetric polyvinylidene fluoride (PVDF) membranes by the nonsolvent thermally induced phase separation (NTIPS) method for membrane distillation applications. J Membr Sci. https://doi.org/10.1016/j.memsci.2015.03.081

Laitinen N, Luonsi A, Vilen J (2006) Landfill leachate treatment with sequencing batch reactor and membrane bioreactor. Desalination. https://doi.org/10.1016/j.desal.2005.08.012

Cerisuelo JP, Gavara R, Hernández-Muñoz P (2015) Diffusion modeling in polymer–clay nanocomposites for food packaging applications through finite element analysis of TEM images. J Membr Sci. https://doi.org/10.1016/j.memsci.2015.02.031

Ferreira RDSB, Oliveira SSL, Salviano AF, Araújo EM, Leite AMD, Lira HDL (2019) Polyethersulfone hollow fiber membranes developed for oily emulsion treatment. Mater Res. https://doi.org/10.1590/1980-5373-MR-2018-0854

Barth C, Gonçalves MC, Pires ATN, Roeder J, Wolf BA (2000) Asymmetric polysulfone and polyethersulfone membranes: effects of thermodynamic conditions during formation on their performance. J Membr Sci. https://doi.org/10.1016/S0376-7388(99)00344-0

Mannan HA, Mukhtar H, Murugesan T (2015) Preparation and characterization of newly developed polysulfone/polyethersulfone blend membrane for CO2 separation. Appl Mech Mater. https://doi.org/10.4028/www.scientific.net/AMM.699.325

Nasirian D, Salahshoori I, Sadeghi M, Rashidi N, Hassanzadeganroudsari M (2020) Investigation of the gas permeability properties from polysulfone/polyethylene glycol composite membrane. Polym Bull. https://doi.org/10.1007/s00289-019-03031-3

Li S, Cui Z, Zhang L, He B, Li J (2016) The effect of sulfonated polysulfone on the compatibility and structure of polyethersulfone-based blend membranes. J Membr Sci. https://doi.org/10.1016/j.memsci.2016.04.035

Abdel-Karim A, Gad-Allah TA, El-Kalliny AS, Ahmed SIA, Souaya ER, Badawy MI, Ulbricht M (2017) Fabrication of modified polyethersulfone membranes for wastewater treatment by submerged membrane bioreactor. Sep Purif Technol. https://doi.org/10.1016/j.seppur.2016.10.060

Steen ML, Hymas L, Havey ED, Capps NE, Castner DG, Fisher ER (2001) Low temperature plasma treatment of asymmetric polysulfone membranes for permanent hydrophilic surface modification. J Membr Sci. https://doi.org/10.1016/S0376-7388(01)00375-1

Steen ML, Jordan AC, Fisher ER (2002) Hydrophilic modification of polymeric membranes by low temperature H2O plasma treatment. J Membr Sci. https://doi.org/10.1016/S0376-7388(02)00061-3

Dias RA, Medeiros VDN, Silva BIA, Araújo EM, Lira HDL (2019) Study of the influence of viscosity on the morphology of polyethersulfone hollow fiber membranes/additives. Mater Res. https://doi.org/10.1590/1980-5373-MR-2018-0913

Habert A, Borges C, Kronemberger F, Ferraz H, Nobrega R (2006) Processos de separação por membranas. Rio de Janeiro

Sadare OO, Daramola MO (2021) Blended polysulfone/polyethersulfone (PSF/PES) membrane with enhanced antifouling property for separation of succinate from organic acids from fermentation broth. ACS Sustain Chem Eng. https://doi.org/10.1021/acssuschemeng.1c05059

Ntshangase NC, Sadare OO, Daramola MO (2021) Effect of silica sodalite functionalization and PVA coating on performance of sodalite infused PSF membrane during treatment of acid mine drainage. Membranes. https://doi.org/10.3390/membranes11050315

Rameetse MS, Aberefa O, Daramola MO (2020) Effect of loading and functionalization of carbon nanotube on the performance of blended polysulfone/polyethersulfone membrane during treatment of wastewater containing phenol and benzene. Membranes. https://doi.org/10.3390/membranes10030054

Qiu S, Wu L, Pan X, Zhang L, Chen H, Gao C (2009) Preparation and properties of functionalized carbon nanotube/PSF blend ultrafiltration membranes. J Membr Sci. https://doi.org/10.1016/j.memsci.2009.06.041

He L-H, Xue R, Yang D-B, Liu Y, Song R (2009) Effects of bleding chitosan with PEG on surface morphology, crystallization and thermal properties. Chin J Polym Sci. https://doi.org/10.1142/S0256767909004175

Macierzanka A, Szeląg H, Szumała P, Pawłowicz R, Mackie AR, Ridout MJ (2009) Effect of crystalline emulsifier composition on structural transformations of water-in-oil emulsions: emulsification and quiescent conditions. Colloids Surf A. https://doi.org/10.1016/j.colsurfa.2008.09.053

Richard Bowen W, Doneva TA, Yin HB (2001) Polysulfone—sulfonated poly(ether ether) ketone blend membranes: systematic synthesis and characterisation. J Membr Sci. https://doi.org/10.1016/S0376-7388(00)00541-X

Zeng K, Zhou J, Cui Z, Zhou Y, Shi C, Wang X, Zhou L, Ding X, Wang Z, Drioli E (2018) Insight into fouling behavior of poly(vinylidene fluoride)(PVDF) hollow fiber membranes caused by dextran with different pore size distributions. Chin J Chem Eng. https://doi.org/10.1016/j.cjche.2017.04.008

Salahi A, Gheshlaghi A, Mohammadi T, Madaeni SS (2010) Experimental performance evaluation of polymeric membranes for treatment of an industrial oily wastewater. Desalination. https://doi.org/10.1016/j.desal.2010.06.021

Acknowledgements

The authors thank to UFCG for their infrastructure and the Membrane Development and Characterization Laboratory (LDCM). This work was carried out with support from the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior/CAPES—Código de Financiamento 001. At the same time, the authors thank UFCG for the laboratories, MCTI/CNPq and Fundação de Apoio à Pesquisa do Estado da Paraíba (FAPESQ).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dias, R.A., Ferreira, R.S.B., Medeiros, V.N. et al. Flat membranes of polyethersulfone/polysulfone blends in water/oil separation. Polym. Bull. 80, 4289–4305 (2023). https://doi.org/10.1007/s00289-022-04258-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-022-04258-3