Abstract

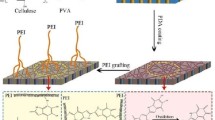

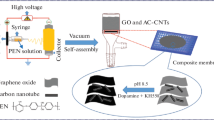

High-performance multifunctional filtration membranes are highly required in treating practically complex oily wastewater systems, but still a challenge unsolved. Herein, we propose a facile route to address these challenges simultaneously by simply constructing electrospun pre-oxidized polyacrylonitrile nanofibrous membrane (p-PAN NM). Given the pre-oxidation process, the p-PAN NM displays not only robust anti-corrosive tolerance against diverse corrosive media, but also superhydrophilicity/underwater superoleophobicity. Additionally, ~ 99% separation efficiency, ~ 100% oil-fouling recovery, and ultra-long service life (up to 265 h) have been realized in separating large-scale surfactant stabilized soybean/crude oil-in-water emulsions. Furthermore, strong anti-corrosive performance against various corrosive media (e.g., 1 M HCl, 1 M NaOH, or 10 wt% NaCl) has been achieved as well. Spin-unrestricted density functional theory (DFT) computations implemented in the Dmol3 modulus has been conducted to understand the robust fouling recovery and the variation of surficial wettability after pre-oxidation. These outstanding filtration functions make our NM hold great potential in separating viscous oil/water emulsions under harsh conditions.

Graphical Abstract

Similar content being viewed by others

Data availability

The data are available from the corresponding authors on reasonable request.

References

Al-Majed AA, Adebayo AR, Hossain ME. A sustainable approach to controlling oil spills. J Environ Manage. 2012;113C:213.

Yin ZZ, Yuan F, Li M, Xue MS, Zhou DP, Chen YC, Liu XQ, Luo YD, Hong Z, Xie C, Ou JF. Self-cleaning, underwater writable, heat-insulated and photocatalytic cellulose membrane for high-efficient oil/water separation and removal of hazardous organic pollutants. Pro Org Coat. 2021;157: 106311.

Xia Y, Zhang R, Cao Y, Xing Y, Gui X. Role of molecular simulation in understanding the mechanism of low-rank coal flotation: a review. Fuel. 2020;262: 116535.

Yin ZZ, Li M, Li ZH, Deng YT, Xue MS, Chen YH, Ou JF, Lei S, Luo YD, Xie C. A harsh environment resistant robust Co(OH)2@stearic acid nanocellulose-based membrane for oil-water separation and wastewater purification. J Environ Manage. 2023;342: 118127.

Wu JF, Cui ZW, Yu Y, Han H, Tian D, Hu JD, Qu JF, Cai YH, Luo JL, Li JZ. A 3D smart wood membrane with high flux and efficiency for separation of stabilized oil/water emulsions. J Hazard Mater. 2023;441: 129900.

Liu KY, Yin ZZ, Luo RK, Qiu BR, Chen YH, Yang CG, Luo YD, Hong Z, Xue MS. Durable Co(OH)2/stearic acid-based superhydrophobic/superoleophilic nanocellulose membrane for highly efficient oil/water separation and simultaneous removal of soluble dye. Ind Crop Prod. 2023;203: 117190.

Yin ZZ, Li ZH, Deng YT, Xue MS, Chen YH, Ou JF, Xie Y, Luo YD, Xie C, Hong Z. Multifunctional CeO2-coated pulp/cellulose nanofibers (CNFs) membrane for wastewater treatment: Effective oil/water separation, organic contaminants photodegradation, and anti-bioadhesion activity. Ind Crop Prod. 2023;197: 116672.

Yin ZZ, Chen XX, Zhou TH, Xue MS, Li M, Liu KY, Zhou DP, Ou JF, Xie Y, Ren ZM, Luo YD, Hong Z. Mussel-inspired fabrication of superior superhydrophobic cellulose-based composite membrane for efficient oil emulsions separation, excellent anti-microbial property and simultaneous photocatalytic dye degradation. Sep Purif Technol. 2022;286: 120504.

Yin ZZ, Cheng Y, Deng YT, Li ZH, Liu KY, Li M, Chen XX, Xue MS, Ou JF, Lei S, Luo YD, Xie C, Hong Z. Functional and versatile colorful superhydrophobic nanocellulose-based membrane with high durability, high-efficiency oil/water separation and oil spill cleanup. Surf Coat Technol. 2022;445: 128714.

Long QW, Chen JX, Wang Z, Zhang Z, Qi GX, Liu ZQ. Vein-supported porous membranes with enhanced superhydrophilicity and mechanical strength for oil-water separation. Sep Purif Technol. 2021;254: 117517.

Lu JQ, Bai T, Wang D, Yu HJ, Wang QX, Niu ZX, Hu Y, Liu XY, Han GP, Cheng WL. Electrospun polyacrylonitrile membrane in situ modified with cellulose nanocrystal anchoring TiO2 for oily wastewater recovery. Adv Fiber Mater. 2023;5:2055–68.

Zhao HD, He YL, Wang ZH, Zhao YB, Sun L. Mussel-inspired fabrication of PDA@PAN electrospun nanofibrous membrane for oil-in-water emulsion separation. Nanomaterials. 2021;11:3434.

Jiang DH, Tsai PC, Kuo CC, Jhuang FC, Guo HC, Chen SP, Liao YC, Satoh T, Tung SH. Facile preparation of Cu/Ag core/shell electrospun nanofibers as highly stable and flexible transparent conductive electrodes for optoelectronic devices. Acs Appl Mater Interfaces. 2019;11:10118.

Yan XH, Xiao X, Au C, Mathur S, Huang LJ, Wang YX, Zhang ZJ, Zhu ZJ, Kipper MJ, Tang JG, Chen J. Electrospinning nanofibers and nanomembranes for oil/water separation. J Mater Chem A. 2021;9:21659.

Liu C, Ren QQ, Zhang SW, Yin BS, Que LF, Zhao L, Sui XL, Yu FD, Li XF, Gu DM, Wang ZB. High energy and power lithium-ion capacitors based on Mn3O4/3D-graphene as anode and activated polyaniline-derived carbon nanorods as cathode. Chem Eng J. 2019;370:1485.

Liang LP, Dong YY, Wang HF, Meng X. Smart cotton fabric with CO2-responsive wettability for controlled oil/water separation. Adv Fiber Mater. 2019;1:222.

Oh S, Bang J, Jin HJ, Kwak HW. Green fabrication of underwater superoleophobic biopolymeric nanofibrous membranes for effective oil-water separation. Adv Fiber Mater. 2023;5:603.

Chen SY, Deng YF, Huang T, Zhang N, Wang Y. Polydopamine-assisted MXene decoration on electrospun polylactide fibers toward oil/water separation and organic dye adsorption. Sep Purif Technol. 2024;328: 125040.

Su Y, Fan TT, Cui WY, Li YA, Ramakrishna S, Long YZ. Advanced electrospun nanofibrous materials for efficient oil/water separation. Adv Fiber Mater. 2022;4:938.

Tao LL. Bio-inspired anti-oil-fouling chitosan-coated mesh for oil/water separation suitable for broad pH range and hyper-saline environments. Acs Appl Mater Interfaces. 2013;5:11971–6.

Sun A, Zhan YQ, Feng QY, Yang W, Dong HY, Liu YC, Chen XM, Chen YW. Assembly of MXene/ZnO heterojunction onto electrospun poly(arylene ether nitrile) fibrous membrane for favorable oil/water separation with high permeability and synergetic antifouling performance. J Membr Sci. 2022;663: 120933.

Li BZ, Zhao J, Lin XX, Tu DG, Meng Y, Li YQ, Huang P, Zhang H. Highly efficient sunlight-driven self-cleaning electrospun nanofiber membrane NM88B@HPAN for water treatment. J Clean Prod. 2022;355: 131812.

Chen XM, Zhan YQ, Sun A, Feng QY, Yang W, Dong HY, Chen YW, Zhang YJ. Anchoring the TiO2@crumpled graphene oxide core-shell sphere onto electrospun polymer fibrous membrane for the fast separation of multi-component pollutant-oil-water emulsion. Sep Purif Technol. 2022;298: 121605.

Ma WJ, Li YS, Zhang MJ, Gao ST, Cui JX, Huang CB, Fu GD. Biomimetic durable multifunctional self-cleaning nanofibrous membrane with outstanding oil/water separation, photodegradation of organic contaminants, and antibacterial performances. Acs Appl Mater Interfaces. 2020;12:34999.

Dong D, Zhu Y, Fang W, Ji M, Wang A, Gao S, Lin H, Huang R, Jin J. Double-defense design of super-anti-fouling membranes for oil/water emulsion separation. Adv Funct Mater. 2022;32:2113247.

Zhu Y, Wang J, Zhang F, Gao S, Wang A, Fang W, Jin J. Zwitterionic nanohydrogel grafted PVDF membranes with comprehensive antifouling property and superior cycle stability for oil-in-water emulsion separation. Adv Funct Mater. 2018;28:1804121.

Zhu Z, Wang W, Qi D, Luo Y, Liu Y, Xu Y, Cui F, Wang C, Chen X. Calcinable polymer membrane with revivability for efficient oily-water remediation. Adv Mater. 2018;30:1801870.

Yin ZZ, Yuan F, Zhou DP, Xue MS, Luo YD, Hong Z, Xie C. Ultra dynamic water repellency and anti-icing performance of superhydrophobic ZnO surface on the printed circuit board (PCB). Chem Phys Lett. 2021;771: 138558.

Yin ZZ, Yuan F, Xue MS, Xue YH, Xie Y, Ou JF, Luo YD, Hong Z, Xie C. A multifunctional and environmentally safe superhydrophobic membrane with superior oil/water separation, photocatalytic degradation and anti-biofouling performance. J Colloid Interface Sci. 2022;611:93.

Cheng XQ, Jiao Y, Sun Z, Yang X, Cheng Z, Bai Q, Zhang Y, Wang K, Shao L. Constructing scalable superhydrophobic membranes for ultrafast water-oil separation. ACS Nano. 2021;15:3500.

Yin ZZ, Xue MS, Luo YD, Hong Z, Xie C, Ren ZM, Wang H. Excellent static and dynamic anti-icing properties of hierarchical structured ZnO superhydrophobic surface on Cu substrates. Chem Phys Lett. 2020;755: 137806.

Wang WW, Lin JX, Cheng JQ, Cui ZX, Si JH, Wang QT, Peng XF, Turng LS. Dual super-amphiphilic modified cellulose acetate nanofiber membranes with highly efficient oil/water separation and excellent antifouling properties. J Hazard Mater. 2020;385: 121582.

Zhan YQ, He SJ, Wan XY, Zhao SM, Bai YL. Thermally and chemically stable poly(arylene ether nitrile)/halloysite nanotubes intercalated graphene oxide nanofibrous composite membranes for highly efficient oil/water emulsion separation in harsh environment. J Membr Sci. 2018;567:76.

Chen XX, Yin ZZ, Yan JL, Xue MS, Chen YH, Yang CG, Luo YD. Fabrication of ZnO@Fe2O3 superhydrophobic coatings with high thermal conductivity. Surf Coat Technol. 2023;467: 129701.

Deng YT, Xu FL, Yin ZZ, Xue MS, Chen YH, He P, Wu JS, Ou JF, Wang FJ, Luo YD, Hong Z. Controllable fabrication of superhydrophobic alloys surface on 304 stainless steel substrate for anti-icing performance. Ceram Int. 2023;49:25135.

Chen X, Yin Z, Deng Y, Li Z, Xue M, Chen Y, Xie Y, Liu W, He P, Luo Y, Hong Z, Xie C. Harsh environment-tolerant and robust superhydrophobic graphene-based composite membrane for wearable strain sensor. Sens Actuator A Phys. 2023;362: 114630.

Li M, Liu W, Yin Z, Yang H, Chen Y, Yang C, Luo Y, Hong Z, Xie C, Xue M. Facile fabrication of superhydrophobic and photocatalytic self-cleaning flexible strain sensor membrane for human motion. Sens Actuator A Phys. 2023;363: 114750.

Wu JX, Zhang J, Kang YL, Wu G, Chen SC, Wang YZ. Reusable and recyclable superhydrophilic electrospun nanofibrous membranes with in situ co-cross-linked polymer-chitin nanowhisker network for robust oil-in-water emulsion separation. Acs Sustain Chem Eng. 2018;6:1753.

Zhang LS, Fan W, Liu TX. Flexible hierarchical membranes of WS2 nanosheets grown on graphene-wrapped electrospun carbon nanofibers as advanced anodes for highly reversible lithium storage. Nanoscale. 2016;8:16387.

Liu JH, Zhang C, Guo SH, Xu L, Xiao SJ, Shen ZG. Microwave treatment of pre-oxidized fibers for improving their structure and mechanical-properties. Ceram Int. 2019;45:1379.

Tian D, Chen SH, Zhu WD, Wang C, Lu XF. Metal-organic framework derived hierarchical Ni/Ni3S2 decorated carbon nanofibers for high-performance supercapacitors. Mater Chem Front. 2019;3:1653.

Ye W, Sun QL, Zhang GY. Effect of heat treatment conditions on properties of carbon-fiber-based electromagnetic-wave-absorbing composites. Ceram Int. 2019;45:5093.

Zheng YW, Zhao W, Jia DD, Cui L, Liu JQ. Thermally-treated and acid-etched carbon fiber cloth based on pre-oxidized polyacrylonitrile as self-standing and high area-capacitance electrodes for flexible supercapacitors. Chem Eng J. 2019;364:70.

Mao Q, Rajabpour S, Kowalik M, van Duin ACT. Predicting cost-effective carbon fiber precursors: Unraveling the functionalities of oxygen and nitrogen-containing groups during carbonization from ReaxFF simulations. Carbon. 2020;159:25.

Sun SC, Cao WY. Evolution of microstructure within carbon fiber during pre-carbonization revealed by mean field theory. Compos Commun. 2022;34: 101272.

Krishnamoorthi R, Anbazhagan R, Tsai H-C, Wang C-F, Lai J-Y. Biodegradable, superwettable caffeic acid/chitosan polymer coated cotton fibers for the simultaneous removal of oils, dyes, and metal ions from water. Chem Eng J. 2022;427: 131920.

Xiao SJ, Cao WY, Wang B, Xu LH, Chen BH. Mechanism and kinetics of oxidation during the thermal stabilization of polyacrylonitrile fibers. J Appl Polym Sci. 2013;127:3198.

Liu Y, Xue Y, Ji H, Liu J. Kinetics of the cyclization and isomerization reactions in polyacrylonitrile based carbon fiber precursors during thermal-oxidative stabilization. J Appl Polym Sci. 2020;137:48819.

Karki HP, Kafle L, Ojha DP, Song JH, Kim HJ. Three-dimensional nanoporous polyacrylonitrile-based carbon scaffold for effective separation of oil from oil/water emulsion. Polymer. 2018;153:597.

Pan H, Yang J, Wang S, Xiong Z, Cai W, Liu J. Facile fabrication of porous carbon nanofibers by electrospun PAN/dimethyl sulfone for capacitive deionization. J Mater Chem A. 2015;3:13827.

Ma YX, Wan JY, Yang YF, Ye YS, Xiao X, Boyle DT, Burke W, Huang ZJ, Chen H, Cui Y, Yu ZA, Oyakhire ST. Scalable, ultrathin, and high-temperature-resistant solid polymer electrolytes for energy-dense lithium metal batteries. Adv Energy Mater. 2022;12:2103720.

Sun X-L, Liu Z, Cheng Z-L. Design and fabrication of in-situ N-doped paper-like carbon nanofiber film for thiophene removal from a liquid model fuel. J Hazard Mater. 2020;389: 121879.

Piper DM, Yersak TA, Son S-B, Kim SC, Kang CS, Oh KH, Ban C, Dillon AC, Lee S-H. Conformal Coatings of cyclized-PAN for mechanically resilient si nano-composite anodes. Adv Energy Mater. 2013;3:697.

Wu M, Wang Q, Li K, Wu Y, Liu H. Optimization of stabilization conditions for electrospun polyacrylonitrile nanofibers. Polym Degrad Stab. 2012;97:1511.

Kang HJ, Cheng ZJ, Lai H, Ma HX, Liu YY, Mai XM, Wang YS, Shao Q, Xiang LC, Guo XK, Guo ZH. Superlyophobic anti-corrosive and self-cleaning titania robust mesh membrane with enhanced oil/water separation. Sep Purif Technol. 2018;201:193.

Chen FZ, Lu Y, Liu X, Song JL, He GJ, Tiwari MK, Carmalt CJ, Parkin IP. Table salt as a template to prepare reusable porous PVDF-MWCNT foam for separation of immiscible oils/organic solvents and corrosive aqueous solutions. Adv Funct Mater. 2017;27:1702926.

Li J, Kang RM, Tang XH, She HD, Yang YX, Zha F. Superhydrophobic meshes that can repel hot water and strong corrosive liquids used for efficient gravity-driven oil/water separation. Nanoscale. 2016;8:7638.

Zhang ES, Cheng ZJ, Lv T, Qian YH, Liu YY. Anti-corrosive hierarchical structured copper mesh film with superhydrophilicity and underwater low adhesive superoleophobicity for highly efficient oil-water separation. J Mater Chem A. 2015;3:13411.

Hayase G, Kanamori K, Fukuchi M, Kaji H, Nakanishi K. Facile synthesis of marshmallow-like macroporous gels usable under harsh conditions for the separation of oil and water. Angew Chem Int Ed. 1986;2013:52.

Li Z, Zhang TC, Mokoba T, Yuan S. Superwetting Bi2MoO6/Cu3(PO4)2 nanosheet-coated copper mesh with superior anti-oil-fouling and photo-fenton-like catalytic properties for effective oil-in-water emulsion separation. Acs Appl Mater Interfaces. 2021;13:23662.

Modi A, Jiang Z, Kasher R. Hydrostable ZIF-8 layer on polyacrylonitrile membrane for efficient treatment of oilfield produced water. Chem Eng J. 2022;434: 133513.

Chen S, Liu Y, Wang Y, Xu K, Zhang X, Zhong W, Luo G, Xing M. Dual-functional superwettable nano-structured membrane: from ultra-effective separation of oil-water emulsion to seawater desalination. Chem Eng J. 2021;411: 128042.

Zhang N, Yang N, Zhang L, Jiang B, Sun Y, Ma J, Cheng K, Peng F. Facile hydrophilic modification of PVDF membrane with Ag/EGCG decorated micro/nanostructural surface for efficient oil-in-water emulsion separation. Chem Eng J. 2020;402: 126200.

Yang C, Wang Z, Long M, Qin B, Wang Y, Zhi K, Zheng Y, Zhao J, Li W, Wang Z, Zhang M, Zhang R, Wu H, Jiang Z. Antifouling poly(phenylene sulfide) membrane with an amphiphilic surface for efficient oil/water separation. J Membr Sci. 2023;679: 121690.

Wang Y, Yang H, Yang Y, Zhu L, Zeng Z, Liu S, Li Y, Liang Z. Poly(vinylidene fluoride) membranes with underwater superoleophobicity for highly efficient separation of oil-in-water emulsions in resisting fouling. Sep Purif Technol. 2022;285: 120298.

Zhu YZ, Xie W, Zhang F, Xing TL, Jin J. Superhydrophilic in-situ-cross-linked zwitterionic polyelectrolyte/PVDF-blend membrane for highly efficient oil/water emulsion separation. Acs Appl Mater Interfaces. 2017;9:9603.

Zhang LY, He Y, Luo PY, Ma L, Fan Y, Zhang SH, Shi H, Li SS, Nie YL. A heterostructured PPy/ZnO layer assembled on a PAN nanofibrous membrane with robust visible-light-induced self-cleaning properties for highly efficient water purification with fast separation flux. J Mater Chem A. 2020;8:4483.

Zhang LY, He Y, Ma L, Chen JY, Fan Y, Zhang SH, Shi H, Li ZY, Luo PY. Hierarchically stabilized PAN/β-FeOOH nanofibrous membrane for efficient water purification with excellent antifouling performance and robust solvent resistance. Acs Appl Mater Interfaces. 2019;11:34487.

Jing J, Yin R, Yuan Y, Shi Y, Sun J, Zhang M. Determination of the transportation limits of heavy crude oil using three combined methods of heating, water blending, and dilution. ACS Omega. 2020;5:9870.

Mason TJ. Ultrasonic cleaning: an historical perspective. Ultras Sonochem. 2016;29:519.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 52073238 and 52173301), Open Funds of State Key Laboratory of Oil and Gas Reservoir Geology and Exploitation (PLN202205, SWPU), and Natural Science Foundation of Sichuan Province (2022NSFSC0356).

Funding

National Natural Science Foundation of China, 52273055, Ce Wang, State Key Laboratory of Oil and Gas Reservoir Geology and Exploitation, PLN202205, Jingyu Chen, Sichuan Engineering Technology Research Center of Basalt Fiber Composites Development and Application, 2022SCXWYXWFC006, Jingyu Chen, Natural Science Foundation of Sichuan Province, 2022NSFSC0356, Jingyu Chen.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Su, H., Hu, H., Li, Z. et al. Pre-oxidized PAN Nanofibrous Membrane to Efficiently and Continuously Separate Large-Scale Viscous Oil-in-Water Emulsions Under Harsh Conditions with Ultra-Long-Term Oil-Fouling Recovery. Adv. Fiber Mater. (2024). https://doi.org/10.1007/s42765-024-00383-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42765-024-00383-y