Abstract

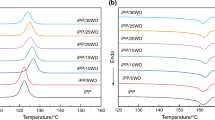

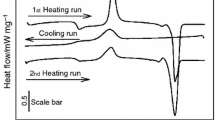

A novel composite filler sodium lignosulfonate/nano calcium carbonate (SL/CaCO3) was prepared by dry ball milling. Thermogravimetric analysis revealed that the composite filler SL/CaCO3 had improved thermal properties. The crystallization and melting behavior of isotactic polypropylene (iPP) modified by the composite filler was studied by differential scanning calorimetry. The best complex ratio (1:3) and optimal addition amount (2 wt%) of iPP nucleated by SL/CaCO3 were confirmed. The results reflected that a small amount of SL/CaCO3 into iPP could improve the nucleation ability, and excellent mechanical properties were obtained. The relative contents of β‐crystals (Kβ) in iPP were above 0.83 after addition of the composite filler. At the same time, nano CaCO3 played a significant role in crystallizing the iPP nucleated and greatly influenced the content of β-crystals. The elongation at break was increased by 32.27% and the impact strength was increased by 62.38% compared to those of pure iPP.

Similar content being viewed by others

References

Kang J, Chen D, Xiong B (2019) Facile route for the fabrication of polypropylene separators for lithium-ion batteries with high elongation and strong puncture resistance. Ind Eng Chem Res 58(51):23135–23142

Song T, Ren Z, Li H (2019) Modification of illite with calcium pimelate and its influence on the crystallization and mechanical property of isotactic polypropylene. Compos A Appl Sci Manuf 123:200–207

Guo Z, Wang Z, Fang Z (2020) Fabrication of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide-decorated fullerene to improve the anti-oxidative and flame-retardant properties of polypropylene. Compos Part B: Eng 183:107672

Petchwattana N, Naknaen P, Sanetuntikul J (2019) Transformation of β to α phase of isotactic polypropylene nucleated with nano styrene butadiene rubber-based β-nucleating agent under microwave irradiation. J Cent South Univ 25(12):3098–3106

Zhang YF, Zhou PZ, Mao JJ (2018) Influences of octamethylenedicarboxylic dibenzoylhydrazide on crystallization, melting behaviors, and properties of isotactic polypropylene. Polym Bull 76(4):1685–1696

Zhang YF, Zhou PZ, Li Y (2019) The influences of α/β compound nucleating agents based on octamethylenedicarboxylic dibenzoylhydrazide on crystallization and melting behavior of isotactic polypropylene. Polym Adv Technol 30(7):1777–1788

Ding C, Wu GG, Zhang Y (2019) Effect of surfactant assisted β-nucleating agent self-assembly on the crystallization of polypropylene. Polymer 184:121895

Wadi VS, Jena KK, Halique K (2020) Enhanced mechanical toughness of isotactic polypropylene using bulk molybdenum disulfide. ACS Omega 5(20):11394–11401

Sangroniz L, van Drongelen M, Cardinaels R (2020) Effect of shear rate and pressure on the crystallization of PP nanocomposites and PP/PET polymer blend nanocomposites. Polymer 186:121950

Zhai Z, Liu Z, Feng LJ (2014) Interfacial adhesion of glass fibre reinforced polypropylene-maleic anhydride modified polypropylene copolymer composites. J Reinf Plast Compos 33(8):785–793

Arapova OV, Chistyakov AV, Tsodikov MV (2020) Lignin as a renewable resource of hydrocarbon products and energy carriers (a review). J Pet Chem 60(3):227–243

Peng Y, Liu R, Cao J (2014) Effects of UV weathering on surface properties of polypropylene composites reinforced with wood flour, lignin, and cellulose. Appl Surf Sci 317:385–392

Xu X, He Z, Lu S (2014) Enhanced thermal and mechanical properties of lignin/polypropylene wood-plastic composite by using flexible segment-containing reactive compatibilizer. Macromol Res 22(10):1084–1089

Yeo J-S, Seong D-W, Hwang S-H (2015) Chemical surface modification of lignin particle and its application as filler in the polypropylene composites. J Ind Eng Chem 31:80–85

Ghaffar SH, Fan M (2014) Lignin in straw and its applications as an adhesive. Int J Adhes Adhes 48:92–101

del Angel-Monroy M, Escobar-Barrios V, Peña-Juarez MG (2020) Effect of silicon dots into coconut fibers on the nucleating capacity of β-crystals of polypropylene. Revista Mexicana de Ingeniería Química 20(1):479–492

Chen F, Liu W, Seyed Shahabadi SI (2016) Sheet-like lignin particles as multifunctional fillers in polypropylene. ACS Sustain Chem Eng 4(9):4997–5004

Nagendra B, Mohan K, Gowd EB (2015) Polypropylene/layered double hydroxide (ldh) nanocomposites: influence of ldh particle size on the crystallization behavior of polypropylene. ACS Appl Mater Interfaces 7(23):12399–12410

Lora JH, Glasser WG (2002) Recent industrial applications of lignin: a sustainable alternative to nonrenewable materials. J J Polym Environ 10(1–2):39–48

Yang H, Yu B, Xu X (2020) Lignin-derived bio-based flame retardants toward high-performance sustainable polymeric materials. Green Chem 22(7):2129–2161

Jung D, Persi I, Bhattacharyya D (2019) synergistic effects of feather fibers and phosphorus compound on chemically modified chicken feather/polypropylene composites. ACS Sustain Chem Eng 7(23):19072–19080

Davachi SM, Heidari BS, Sahraeian R (2019) The effect of nanoperlite and its silane treatment on the crystallinity, rheological, optical, and surface properties of polypropylene/nanoperlite nanocomposite films. Compos Part B: Eng 175:107088

Catto AL, Dahlem Júnior MA, Hansen B (2019) Characterization of polypropylene composites using yerba mate fibers as reinforcing filler. Compos Part B: Eng 174:106935

Lee MG, Lee S, Cho J (2020) Effect of the fluorination of graphene nanoflake on the dispersion and mechanical properties of polypropylene nanocomposites. Nanomaterials (Basel) 10(6):1171

Kong S, Seo H, Shin H (2019) Improvement in mechanical and thermal properties of polypropylene nanocomposites using an extremely small amount of alkyl chain-grafted hexagonal boron nitride nanosheets. Polymer 180:121714

Wang D, Xuan L, Han G (2020) Preparation and characterization of foamed wheat straw fiber/polypropylene composites based on modified nano-TiO2 particles. Compos Part A: Appl Sci Manuf 128:105674

He J, Zhang YF, Ren X-Q (2019) Nucleation effect of α/β compound nucleating agents based on 1,3,5-benzenetricarboxylic acid tris(cyclohexylamide) in isotactic polypropylene. Polym Bull 76(11):5559–5575

Leoné N, Roy M, Saidi S (2019) Improving processing, crystallization, and performance of poly-l-lactide with an amide-based organic compound as both plasticizer and nucleating agent. ACS Omega 4(6):10376–10387

Barczewski M, Sałasińska K, Kloziński A (2019) Application of the basalt powder as a filler for polypropylene composites with improved thermo-mechanical stability and reduced flammability. Polym Eng Sci 59(s2):E71–E79

Bula K, Klapiszewski Ł, Jesionowski T (2015) A novel functional silica/lignin hybrid material as a potential bio-based polypropylene filler. Polym Compos 36(5):913–922

Isiaka O, Ibrahim O, Akeem D (2019) Effect of mercerization on the mechanical and thermal response of hybrid bagasse fiber/CaCO3 reinforced polypropylene composites. Polym Test 76:192–198

Zhang Q-X, Yu Z-Z, Xie X-L (2004) Crystallization and impact energy of polypropylene/CaCO3 nanocomposites with nonionic modifier. Polymer 45(17):5985–5994

Jiang X, Zhao S, Meng X (2018) Effect of the metal phenylphosphonates on the nonisothermal crystallization and performance of isotactic polypropylene. J Polym Sci, Part B: Polym Phys 57(3):161–173

Zhang K, Han R, Nie M (2019) Polymorphic effect of transcrystalline layer on interfacial strength of polypropylene/polyamide blend. Ind Eng Chem Res 58(49):22283–22289

He B, Lin X-F, Zhang Y-F (2018) Effect of a novel compound nucleating agent calcium sulfate whisker/β-nucleating agent dicyclohexyl-terephthalamide on crystallization and melting behavior of isotactic polypropylene. J Therm Anal Calorim 132(2):1145–1152

Yue Y, Hu D, Zhang Q (2018) The effect of structure evolution upon heat treatment on the beta-nucleating ability of calcium pimelate in isotactic polypropylene. Polymer 149:55–64

Bajsić EG, Filipan V, Bulatović VO (2016) The influence of filler treatment on the mechanical properties and phase behavior of thermoplastic polyurethane/polypropylene blends. Polym Bull 74(8):2939–2955

De Rosa C, Auriemma F, Tarallo O (2017) The “nodular” α form of isotactic polypropylene: stiff and strong polypropylene with high deformability. Macromolecules 50(14):5434–5446

Kersch M, Pischke L, Schmidt HW (2014) Influence of trisamide-based additives on the morphological and mechanical properties of isotactic polypropylene. Polymer 55(15):3227–3233

Li L, Song G, Tang G (2012) Morphology, crystallization and dynamical mechanical behavior of iPP/Nano-CaCO3 composites. Polym-Plast Technol Eng 51(11):1083–1089

Acknowledgements

The authors are grateful to Changsha Science and Technology Bureau (No. kq2202184), National Natural Science Foundation of China (No. 21376031) and Hunan Provincial Natural Science Foundation of China (No. 2019JJ40294) for financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, ZQ., Zhang, YF., Li, Y. et al. Effect of sodium lignosulfonate/nano calcium carbonate composite filler on properties of isotactic polypropylene. Polym. Bull. 80, 3103–3117 (2023). https://doi.org/10.1007/s00289-022-04209-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-022-04209-y