Abstract

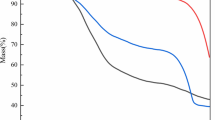

The development of high-performance and low-cost composite nucleating agents has become a pioneering point in expanding the application of isotactic polypropylene (iPP). To this end, this article used a physical blending method to mix nucleating agent organic phosphate salt (LPN-9081) with inorganic fillers such as wollastonite and talc powder. Change the ratio of nucleated mineral-reinforced composition LPN-9081/wollastonite (L/WO) and LPN-9081/talc powder (L/Tac) to study their effects on the crystallization, melting behavior, and mechanical properties of iPP. And a preliminary exploration was conducted on its mechanism. The results suggest that the nucleated mineral-reinforced composition more significantly enhance the crystallization temperature, increasing it by up to 10 °C. Furthermore, it was observed that the mechanical properties of iPP were significantly improved via the synergistic effect of LPN-9081 and the inorganic fillers. In the iPP/L/WO system, the addition of the composite nucleating agent improved rigidity by 146% while maintaining toughness. Similarly, compared with iPP system, the iPP/L/Tac system has improved its rigidity by 107% and toughness by 50%. Using the nucleated mineral-reinforced compositions mentioned above can reduce industrial expenses, while increases the rigidity and toughness of iPP, expanding its potential of applications.

Similar content being viewed by others

References

Wang Z-Q, Zhang Y-F, Li Y, Zhong J-R. Effect of sodium lignosulfonate/nano calcium carbonate composite filler on properties of isotactic polypropylene. Polym Bull. 2022;80(3):3103–17.

Jeon C, Kim DW, Chang S, Kim JG, Seo M. Synthesis of polypropylene via catalytic deoxygenation of poly (methyl acrylate). ACS Macro Lett. 2019;8(9):1172–8.

Qin Y, Zhang X, Chai J, Xu Z, Li S. Experimental study of compressive behavior of polypropylene-fiber-reinforced and polypropylene-fiber-fabric-reinforced concrete. Constr Build Mater. 2019;194:216–25.

Xu X, Li X-P, Jin B-Q, Sheng Q, Wang T, Zhang J. Influence of morphology evolution on the mechanical properties of beta nucleated isotactic polypropylene in presence of polypropylene random copolymer. Polym Testing. 2016;51:13–9.

Govada L, Rubio N, Saridakis E, Balaskandan K, Leese HS, Li Y, Wang B, Shaffer MS, Chayen N. Graphene-based nucleants for protein crystallization. Adv Func Mater. 2022;32(42):2202596.

Gahleitner M, Grein C, Kheirandish S, Wolfschwenger J. Nucleation of polypropylene homo-and copolymers. Int Polym Proc. 2011;26(1):2–20.

Long L, He W, Li J, Qin S, Yu J. Nucleation ability of nonmetallic organophosphate derivatives in isotactic polypropylene. J Therm Anal Calorim. 2016;127(3):2283–91.

Deng Z, Tong C, Xin Z, Meng X, Fan M, Gong W, Shu C. Enhanced crystallization property and equilibrious mechanical properties of a novel self-assembly nucleating system based phosphate for polypropylene. J Polym Res. 2022;29(7):297.

Li Y, Kong J, Xin S, Han C, Xiao L. Crystallization and melting characteristics of iPP nucleated by a sustainable eggshell powder-supported β-nucleating agent. J Therm Anal Calorim. 2017;128:1093–106.

He B, Lin X-F, Zhang Y-F. Effect of a novel compound nucleating agent calcium sulfate whisker/β-nucleating agent dicyclohexyl-terephthalamide on crystallization and melting behavior of isotactic polypropylene. J Therm Anal Calorim. 2018;132(2):1145–52.

Wei Z, Zhang W, Chen G, Liang J, Yang S, Wang P, Liu L. Crystallization and melting behavior of isotactic polypropylene nucleated with individual and compound nucleating agents. J Therm Anal Calorim. 2010;102(2):775–83.

Wu J, Li Y, Zhao Y, Wu C, Li Z, Lu A. The effects of MgF2 in four complex nucleating agents on the performance and crystallization of lithium aluminum silicate glasses. J Non-Cryst Solids. 2022;583: 121469.

Zhang YF. Crystallization and melting behaviors of isotactic polypropylene nucleated with compound nucleating agents. J Polym Sci, Part B: Polym Phys. 2008;46(9):911–6.

Carmeli E, Di Sacco F, Portale G, Cavallo D, Kadar R, Gitsas A, Gkourmpis T, Tranchida D. Crystallization kinetics of melt-mixed 3d hierarchical graphene/polypropylene nanocomposites at processing-relevant cooling rates. Compos B Eng. 2022;247: 110287.

Leong Y, Abu Bakar M, Ishak ZM, Ariffin A, Pukanszky B. Comparison of the mechanical properties and interfacial interactions between talc, kaolin, and calcium carbonate filled polypropylene composites. J Appl Polym Sci. 2004;91(5):3315–26.

Linares PB, Castillo LA, Barbosa SE. Pro-degradant effect of talc nanoparticles on polypropylene films. J Polym Environ. 2019;27(8):1666–76.

Sun H, Wang L, Yi J, Wang F, Gao Y, Sha X, Feng J. The influence of melt temperature on the crystal orientation of polypropylene containing talc. Polymer. 2022;256: 125179.

Awad SA, Khalaf EM. Investigation of improvement of properties of polypropylene modified by nano silica composites. Compos Commun. 2019;12:59–63.

Tang H, Dong Q, Liu P, Ding Y, Wang F, Gao C, Zhang S, Yang M. Isothermal crystallization of polypropylene/surface modified silica nanocomposites. Sci China Chem. 2016;59(10):1283–90.

Liang JZ, Li B, Ruan JQ. Crystallization properties and thermal stability of polypropylene composites filled with wollastonite. Polym Test. 2015;42:185–91.

Ribas RG, Campos TMB, Schatkoski VM, De Menezes BRC, Do Amaral Montanheiro TL, Thim GP. α-wollastonite crystallization at low temperature. Ceram Int. 2020;46(5):6575–80.

Al-Jabareen A. Properties of antimony oxide-coated clay/polypropylene composites. Mater Sci Eng, B. 2018;236–237:18–23.

Mcgenity P, Hooper J, Paynter C, Riley A, Nutbeem C, Elton N, Adams J. Nucleation and crystallization of polypropylene by mineral fillers: relationship to impact strength. Polymer. 1992;33(24):5215–24.

Salas-Papayanopolos H, Morales AB, Lozano T, Laria J, Sanchez S, Rodriguez F, Martinez G, Cerino F. Improvement of toughness properties of polypropylene/wollastonite composites using an interface modifier. Polym Compos. 2014;35(6):1184–92.

Meng M-R, Dou Q. Effect of pimelic acid on the crystallization, morphology and mechanical properties of polypropylene/wollastonite composites. Mater Sci Eng, A. 2008;492(1–2):177–84.

Castillo LA, Barbosa SE, Capiati NJ. Influence of talc genesis and particle surface on the crystallization kinetics of polypropylene/talc composites. J Appl Polym Sci. 2012;126(5):1763–72.

Barczewski M, Mysiukiewicz O, Andrzejewski J, Matykiewicz D, Medycki D, Kloziński A, Skórczewska K, Szostak M. Thermo-mechanical and mechanical behavior of hybrid isotactic polypropylene glass fiber reinforced composites (GFRC) modified with calcium carbonate (CaCO3). Polym Eng Sci. 2020;60(7):1588–603.

Shi S, Zhang X, Liu Y, Nie M, Wang Q. Crystalline modification and morphology of polypropylene developed under the combined effects of montmorillonite and self-assembly β nucleating agent. Compos Sci Technol. 2016;135:76–82.

Alvarez VA, Pérez CJ. Effect of different inorganic filler over isothermal and non-isothermal crystallization of polypropylene homopolymer. J Therm Anal Calorim. 2011;107(2):633–43.

Bandyopadhyay J, Mekoa C, Makwakwa D, Skosana S, Ray SS. Influence of nucleation and growth mechanisms on the heat deflection temperature of a reactively processed polypropylene nanocomposite. Polym Eng Sci. 2021;61(4):1195–208.

Feng B, Li Z, Chen G, Zhu K, Zhao Y, Yuan X. Improving crystallization behaviors of isotactic polypropylene via a new POSS-sorbitol compound. Polym Eng Sci. 2017;57(4):357–64.

Lv C, Luo S, Guo W. Investigation of the crystallization and mechanical properties of wood fiber/polypropylene composites nucleated by a self-assembly β-nucleating agent. Polym Bull. 2023;80(5):5239–56.

Leaf-nosed bat [Z]. Encyclopædia Britannica. Encyclopædia Britannica Online. 2009

Girones J, Vo LTT, Haudin J-M, Freire L, Navard P. Crystallization of polypropylene in the presence of biomass-based fillers of different compositions. Polymer. 2017;127:220–31.

Luyt AS, Dramićanin MD, Antić Ž, Djoković V. Morphology, mechanical and thermal properties of composites of polypropylene and nanostructured wollastonite filler. Polym Test. 2009;28(3):348–56.

Singh UP, Biswas BK, Ray BC. Evaluation of mechanical properties of polypropylene filled with wollastonite and silicon rubber. Mater Sci Eng, A. 2009;501(1–2):94–8.

Liang J-Z, Ruan J-Q, Li B. Effects of the surface treatment of wollastonite on the tensile and flow properties for reinforced polypropylene composites. J Polym Eng. 2014;34(7):649–55.

Codolini A, Li Q, Wilkinson A. Influence of machining process on the mechanical behaviour of injection-moulded specimens of talc-filled Polypropylene. Polym Test. 2017;62:342–7.

Acknowledgements

This work was financially supported by Natural Science Foundation of Changsha (No. kq2202184) and Hunan Provincial Science & Technology Department (No. 2021GK5007).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wu, X., Li, Z., Dai, X. et al. Synergistic effect of organic phosphate salt nucleating agents and inorganic fillers on isotactic polypropylene. J Therm Anal Calorim 148, 13375–13384 (2023). https://doi.org/10.1007/s10973-023-12634-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12634-y