Abstract

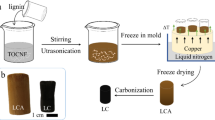

Polyacrylonitrile-based nascent fibers (PAN-NFs) with skin–core structure are commonly inferior fiber or waste fiber, which often abundanted in the industrial production process of polyacrylonitrile (PAN)-based carbon fibers. At present, the related research about the skin–core structure of PAN fiber mainly focuses on its regulation and elimination. Based on the different activation difficulty between skin part and core part, we proposed a new way to prepare activated carbon hollow fiber from PAN-NFs with skin–core structure. Phosphoric acid activation process is used in the facile fabrication of nitrogen, oxygen co-doped activated carbon hollow fiber (N/O-ACHF). The synthetic N/O-ACHF has the structural characteristics of smooth outer wall, while the inner wall is densely covered with micrometer-scale macropores (0.31–2.18 μm) and abundant micropores/mesopores (0–6 nm), which provides excellent structural conditions for hydrogen storage at atmospheric pressure. SBET, micropore volume, surface oxygen heteroatom content and surface nitrogen heteroatom content of N/O-ACHF are 545.72 m2/g, 0.188 cm3/g, 15.26 at% and 4.06 at%, respectively. The multistage pore structure and abundant surface functional groups provide excellent physical structure conditions for hydrogen storage. The preparative N/O-ACHF delivers a high hydrogen storage density of 1.35 wt% at atmospheric pressure.

Graphical abstract

Similar content being viewed by others

References

Guo X, Cheng Y, Fan Z, Feng Z, He L, Liu R, Xu J (2016) New insights into orientation distribution of high strength polyacrylonitrile-based carbon fibers with skin-core structure. Carbon 109:444–452

Yu M, Xu Y, Wang C, Hu X, Zhu B, Qiao K, Yuan H (2012) Heredity and difference of multiple-scale microstructures in PAN-based carbon fibers and their precursor fibers. J Appl Polym Sci 125(4):3159–3166

Zhou G, Liu Y, He L, Guo Q, Ye H (2011) Microstructure difference between core and skin of T700 carbon fibers in heat-treated carbon/carbon composites. Carbon 49(9):2883–2892

Li Y, Yuan H, Chen Y, Wei X, Sui K, Tan Y (2021) Application and exploration of nanofibrous strategy in electrode design. J Mater Sci Technol 74:189–202

Gao Q, Jing M, Chen M, Zhao S, Wang Y, Qin J, Yu M, Wang C (2020) Force field in coagulation bath at low temperature induced microfibril evolution within PAN nascent fiber and precursor fiber. J Appl Polym Sci 137(44):49380

Sha Y, Liu W, Li Y, Cao W (2019) Formation mechanism of skin-core chemical structure within stabilized polyacrylonitrile monofilaments. Nanoscale Res Lett 14(1):93

Gao Q, Jing M, Zhao S, Wang Y, Qin J, Yu M, Wang C (2020) From microfibrillar network to lamellae during the coagulation process of polyacrylonitrile fiber: visualization of intermediate structure evolution. Macromolecules 53(19):8663–8673

Du X, Zhao W, Wang Y, Wang C, Chen M, Qi T, Hua C, Ma M (2013) Preparation of activated carbon hollow fibers from ramie at low temperature for electric double-layer capacitor applications. Biores Technol 149:31–37

Kong Y, Qiu T, Qiu J (2013) Fabrication of novel micro-nano carbonous composites based on self-made hollow activated carbon fibers. Appl Surf Sci 265:352–357

Zhang S, Sukitpaneenit P, Chung TS (2014) Design of robust hollow fiber membranes with high power density for osmotic energy production. Chem Eng J 241:457–465

Sun J, Wang Q (2005) Effects of the oxidation temperature on the structure and properties of polyacrylonitrile-based activated carbon hollow fiber. J Appl Polym Sci 98(1):203–207

Asakura R, Morita M, Maruyama K, Hatori H, Yamada Y (2004) Preparation of fibrous activated carbons from wood fiber. J Mater Sci 39(1):201–206

He Y, Rezaei F, Kapila S, Rownaghi AA (2017) Engineering porous polymer hollow fiber microfluidic reactors for sustainable C–H functionalization. ACS Appl Mater Interfaces 9(19):16288–16295

Xue J, Chen Y, Wei Y, Feldhoff A, Wang H, Caro J (2016) Gas to liquids: natural gas conversion to aromatic fuels and chemicals in a hydrogen-permeable ceramic hollow fiber membrane reactor. ACS Catal 6(4):2448–2451

Li M, Zhao Z, Wang M, Zhang Y (2015) Controllable modification of polymer membranes by LDDLT plasma flow: antibacterial layer onto PE hollow fiber membrane module. Chem Eng J 265:16–26

Wang K, Wu Y, Cao X, Gu L, Hu J (2020) A Zn–CO2 flow battery generating electricity and methane. Adv Funct Mater 30:1908965

Qu G, Cheng J, Li X, Yuan D, Chen P, Chen X, Wang B, Peng H (2016) A fiber supercapacitor with high energy density based on hollow graphene/conducting polymer fiber electrode. Adv Mater 28(19):3646–3652

Nazri NAM, Lau WJ, Ismail AF, Matsuura T, Veerasamy D, Hilal N (2015) Performance of pan-based membranes with graft copolymers bearing hydrophilic pva and pan segments in direct ultrafiltration of natural rubber effluent. Desalination 358:49–60

Abidin MNZ, Goh PS, Said N, Ismail AF, Othman MHD, Hasbullah H, Abdulah MS, Ng BC, Kadir SHSA, Kamal F, Mansur S (2020) Co-adsorptive removal of creatinine and urea by a three-component dual layer hollow fiber membrane. ACS Appl Mater Interfaces 12(29):33276–33287

Sethia G, Sayari A (2016) Activated carbon with optimum pore size distribution for hydrogen storage. Carbon 99:289–294

Blankenship ITS, Balahmar N, Mokaya R (2017) Oxygen-rich microporous carbons with exceptional hydrogen storage capacity. Nat Commun 8(1):1545

Balahmar N, Mokaya R (2019) Pre-mixed precursors for modulating the porosity of carbons for enhanced hydrogen storage: towards predicting the activation behaviour of carbonaceous matter. J Mater Chem A 7:17466

Holec D, Kostoglou N, Tampaxis C, Babic B, Rebholz C (2018) Theory-guided metal-decoration of nanoporous carbon for hydrogen storage applications. Surf Coat Technol 351:42–49

Musyoka NM, Wdowin M, Rambau KM, Franus W, Panek R, Madej J, Juszkiewicz DC (2020) Synthesis of activated carbon from high-carbon coal fly ash and its hydrogen storage application. Renew Energy 155:1264–1271

Li Y, Xiao Y, Dong H, Zheng M, Liu Y (2019) Polyacrylonitrile-based highly porous carbon materials for exceptional hydrogen storage. Int J Hydrogen Energy 44(41):23210–23215

Morris EA, Weisenberger MC, Abdallah MG, Vautard F, Grappe H, Ozcan S, Paulauskas FL, Eberle C, Jackson D, Mecham SJ, Naskar AK (2016) High performance carbon fibers from very high molecular weight polyacrylonitrile precursors. Carbon 101:245–252

Yuan H, Li G, Dai E, Lu G, Huang X, Hao L, Tan Y (2020) Ordered honeycomb-pattern membrane. Chin J Chem 38:1767–1779

Wu S, Qin X (2014) Effects of the stabilization temperature on the structure and properties of polyacrylonitrile-based stabilized electrospun nanofiber microyarns. J Therm Anal Calorim 116(1):303–308

Smith JWH, Mcdonald M, Romero JV, MacDonald L, Lee JR, Dahn JR (2014) Small and wide angle X-ray studies of impregnated activated carbons. Carbon 75:420–431

Díez N, Mysyk R, Zhang W, Goikolea E, Carriazo D (2017) One-pot synthesis of highly activated carbons from melamine and terephthalaldehyde as electrodes for high energy aqueous supercapacitors. J Mater Chem A 5(28):14619–14629

Veerakumar P, Veeramani V, Chen SM, Madhu R, Liu SB (2016) Palladium nanoparticle incorporated porous activated carbon: electrochemical detection of toxic metal ions. ACS Appl Mater Interfaces 8(2):1319–1326

Li D, Ren X, Ai Q, Sun Q, Zhu L, Liu Y, Liang Z, Peng R, Si P, Lou J, Feng J, Ci L (2018) Facile fabrication of nitrogen-doped porous carbon as superior anode material for potassium-ion batteries. Adv Energy Mater 8:1802386

Chen H, Golder MR, Wang F, Jasti R, Swan AK (2014) Raman spectroscopy of carbon nanohoops. Carbon 67:203–213

Feng C, Xu J (2014) Studies on a novel nanofiltration membrane prepared by cross-linking of polyethyleneimine on polyacrylonitrile substrate. J Membr Sci 451:103–110

Li K, Tian S, Jiang J, Wang J, Chen X, Yan F (2016) Pine cone shell-based activated carbon used for CO2 adsorption. J Mater Chem A 4(14):5223–5234

Yu J, Chi C, Zhu B, Qiao K, Cai X, Cheng Y, Yan S (2020) High adsorptivity and recycling performance activated carbon fibers for Cu(II) adsorption. Sci Total Environ 700:134412

Li D, Dai L, Ren X, Ji F, Sun Q, Zhang Y, Ci L (2020) Foldable potassium-ion batteries enabled by free-standing and flexible SnS2@C nanofibers. Energy Environ Sci. https://doi.org/10.1039/D0EE02919J

Qiao K, Yu J, Zhu B, Chi C, Di C, Cheng Y, Shang M, Li C (2020) Oxygen-rich activated carbon fibers with exceptional Cu(II) adsorptivity and recycling performance. Ind Eng Chem Res 59(29):13088–13094

Yu J, Qiao K, Zhu B, Cai X, Cheng Y, Yuan X, Liu D (2018) Sonication-assisted reactivation process: a new method to enhance traditional chemical activation technology. J Taiwan Inst Chem Eng 95:308–314

Blankenship TS, Mokaya R (2017) Cigarette butt-derived carbons have ultra-high surface area and unprecedented hydrogen storage capacity. Energy Environ Sci 10(12):2552–2562

Wu R, Zhang X, Liu Y, Zhang L, Hu J, Gao M, Pan H (2020) A unique double-layered carbon nanobowl-confined lithium borohydride for highly reversible hydrogen storage. Small 16:2001963

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. 51473088), National Key Research and Development Plan of China (Project No. 2016YFC0301402), Key Research and Development Plan of Shandong (Project No. 2018GGX102029 and No. 2017CXGC0407) and Open Fund of Guangdong Provincial Key Laboratory of Advanced Energy Storage Materials, South China University of Technology (Project No. 20212163).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yu, J., Chen, F., Yan, S. et al. Facile fabrication of N/O co-doped activated carbon hollow fibers for hydrogen storage at atmospheric pressure. Polym. Bull. 80, 1385–1397 (2023). https://doi.org/10.1007/s00289-022-04080-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-022-04080-x