Abstract

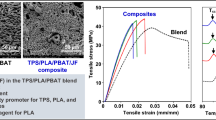

Poly (butylene adipate-co-terephthalate) (PBAT)/thermoplastic starch (TPS) films with additives (maleic anhydride (MA) and titanate coupling agent (TC)) were prepared. The thermal, mechanical, morphological, hydrophobic and biodegradable properties of the films were tested. With the addition of MA and TC, the compatibility and dispersibility of the composite demonstrate enormous improvement, which enhanced the mechanical properties of the films. The tensile strengths of PBAT/TPS films increased from 13.1 to 26.7 MPa in the machine direction (MD) and from 8.3 to 17.2 MPa in the transverse direction (TD). The Young’s modulus increased from 101.5 to 155.6 MPa in MD and from 84.3 to 120.7 MPa in TD. Meanwhile, the biodegradation test showed that the PBAT/TPS films had a higher aging resistance in the presence of MA/TC. These findings gave PBAT/TPS films great applications for designing and manufacturing biodegradation package in life.

Similar content being viewed by others

References

Song F, Tang DL, Wang XL et al (2011) Biodegradable soy protein isolate-based materials: a review. Biomacromol 12:3369–3380

Wright SL, Thompson RC, Galloway TS (2013) The physical impacts of microplastics on marine organisms: a review. Environ Pollut 178:483–492

Cózar A, Echevarría F, González-Gordillo JI et al (2014) Plastic debris in the open ocean. Proc Natl Acad Sci 111:10239–10244

Kaur B, Ariffin F, Bhat R et al (2012) Progress in starch modification in the last decade. Food Hydrocoll 26:398–404

Shogren RL (2003) Rapid preparation of starch esters by high temperature/pressure reaction. Carbohydr Polym 52:319–326

Han Z, Zeng XA, Zhang BS et al (2009) Effects of pulsed electric fields (PEF) treatment on the properties of corn starch. J Food Eng 93:318–323

Sharma V, Rausch KD, Tumbleson ME et al (2007) Comparison between granular starch hydrolyzing enzyme and conventional enzymes for ethanol production from maize starch with different amylose: amylopectin ratios. Starch-Stärke 59:549–556

Garcia PS, Grossmann MVE, Yamashita F et al (2011) Citric acid as multifunctional agent in blowing films of starch/PBAT. Quim Nova 34:1507–1510

Da Roz AL, Carvalho AJF, Gandini A, Curvelo AAS (2006) The effect of plasticizers on thermoplastic starch compositions obtained by melt processing. Carbohydr Polym 63:417–424

Qiao XY, Tang ZZ, Sun K (2011) Plasticization of corn starch by polyol mixtures. Carbohydr Polym 83:659–664

Bastioli C (2001) Global status of the production of biobased packaging materials. Starch-Stärke 53:351–355

de Graaf RA, Karman AP, Janssen LPBM (2003) Material properties and glass transition temperatures of different thermoplastic starches after extrusion processing. Starch-Stärke 55:80–86

Ma X, Chang PR, Yu J et al (2009) Properties of biodegradable citric acid-modified granular starch/thermoplastic pea starch composites. Carbohydr Polym 75:1–8

López OV, Zaritzky NE, Grossmann MVE et al (2013) Acetylated and native corn starch blend films produced by blown extrusion. J Food Eng 116:286–297

Yoon SD, Chough SH, Park HR (2006) Effects of additives with different functional groups on the physical properties of starch/PVA blend film. J App Polym Sci 100:3733–3740

Stagner JA, Alves VD, Narayan R (2012) Application and performance of maleated thermoplastic starch–poly (butylene adipate-co-terephthalate) blends for films. J App Polym Sci 126:E135–E142

Fourati Y, Tarrés Q, Mutjé P et al (2018) PBAT/thermoplastic starch blends: effect of compatibilizers on the rheological, mechanical and morphological properties. Carbohydr Polym 199:51–57

Olivato JB, Nobrega M, Müller CMO et al (2013) Mixture design applied for the study of the tartaric acid effect on starch/polyester films. Carbohydr Polym 92:1705–1710

Brandelero RPH, Grossmann MV, Yamashita F (2012) Films of starch and poly (butylene adipate co-terephthalate) added of soybean oil (SO) and Tween 80. Carbohydr Polym 90:1452–1460

Nayak SK (2010) Biodegradable PBAT/starch nanocomposites. Polym-Plast Technol Eng 49:1406–1418

Ma X, Jian R, Chang PR et al (2008) Fabrication and characterization of citric acid-modified starch nanoparticles/plasticized-starch composites. Biomacromolecules 9(11):3314–3320

Hablot E, Dewasthale S, Zhao Y et al (2013) Reactive extrusion of glycerylated starch and starch–polyester graft copolymers. Eur Polym J 49:873–881

Raquez JM, Nabar Y, Narayan R et al (2008) In situ compatibilization of maleated thermoplastic starch/polyester melt-blends by reactive extrusion. Polym Eng Sci 48:1747–1754

Lu Y, Zhang W, Li X et al (2017) Synthesis of new polyether titanate coupling agents with different polyethyleneglycol segment lengths and their compatibilization in calcium sulfate whisker/poly (vinyl chloride) composites. RSC Adv 7:31628–31640

Serrero A, Trombotto S, Cassagnau P et al (2010) Polysaccharide gels based on chitosan and modified starch: structural characterization and linear viscoelastic behavior. Biomacromol 11:1534–1543

Wang XY, Pan HW, Jia SL et al (2020) Mechanical properties, crystallization and biodegradation behavior of the polylactide/poly (3-hydroxybutyrate-co-4-hydroxybutyrate)/poly (butylene adipate-co-terephthalate) Blown Films. Chin J Polym Sci 38:1072–1081

Olivato JB, Grossmann MVE, Yamashita F et al (2012) Citric acid and maleic anhydride as compatibilizers in starch/poly (butylene adipate-co-terephthalate) blends by one-step reactive extrusion. Carbohydr Polym 87:2614–2618

Fowkes FM (1964) Attractive forces at interfaces. Ind Eng Chem 56:40–52

Owens DK, Wendt RC (1969) Estimation of the surface free energy of polymers. J Appl Polym Sci 13:1741–1747

Zhang Y, Yuan X, Thompson MR et al (2012) Characterization of extruded film based on thermoplastic potato flour. J Appl Polym Sci 125:3250–3258

Pan H, Hao Y, Zhao Y et al (2017) Improved mechanical properties, barrier properties and degradation behavior of poly (butylenes adipate-co-terephthalate)/poly (propylene carbonate) films. Korean J Chem Eng 34:1294–1304

Dammak M, Fourati Y, Tarrés Q et al (2020) Blends of PBAT with plasticized starch for packaging applications: mechanical properties, rheological behaviour and biodegradability. Ind Crops Prod 144:112061

Acknowledgements

This work was supported by the fund of Science and Technology Services Network Program of Chinese Science Academy (STS Project) (No. KFJ-STS-ZDTP-082), Chinese Academy of Sciences (Changchun Branch) (No. 2020SYHZ0002 and No. 2020SYHZ0047), and the National Science Foundation of Zhejiang Province of China (No. LQY19B040001).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, Z., Zhao, L., Jin, B. et al. Effect of maleic anhydride and titanate coupling agent as additives on the properties of poly (butylene adipate-co-terephthalate)/thermoplastic starch films. Polym. Bull. 79, 7193–7213 (2022). https://doi.org/10.1007/s00289-021-03841-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-021-03841-4