Abstract

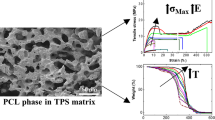

Thermoplastic starch (TPS) as a renewable filler and biodegradable polyester polylactic acid (PLA) blending is a cost-effective and feasible method. To improve the performance and compatibility of PLA/TPS blends, an epoxy-terminated hyperbranched polymer (EHBP) was designed and synthesized. The end epoxide group of EHBP formed chemical micro-crosslinking with the carboxyl group and hydroxyl group of PLA and TPS, thus improving the compatibility between PLA and TPS. The formation of chemical micro-crosslinks and improved compatibility of PLA/TPS blends were demonstrated. The tensile strength, elongation at break, impact strength, composite viscosity and energy storage modulus of the blends were significantly improved. When the EHBP content reached 5phr, the tensile strength, elongation at break and impact strength of the sample increased by 115.01%, 341.11% and 205.51%, respectively. However, the addition of EHBP resulted in a lower crystallinity and a slight decrease in biodegradability due to the occurrence of chemical micro-crosslinking. Nevertheless, the use of EHBP has great potential in PLA/TPS biodegradable packaging materials.

Similar content being viewed by others

Data Availability

The authors will supply the relevant data in response to reasonable requests.

References

Jin Y, Sun X, Song C, Cai F, Liu G, Chen C (2023) Understanding the mechanism of enhanced anaerobic biodegradation of biodegradable plastics after alkaline pretreatment. Sci Total Environ 873:162324

Mahani H, Karevan M, Safavi M (2023) Comparative performance of fused deposit modeling 3D-printed and injection molded polylactic acid/thermoplastic starch/nanoclay bio-based nanocomposites. Polym Adv Technol 34:1901–1917

Wang J, Euring M, Ostendorf K, Zhang K (2022) Biobased materials for food packaging. J Bioresour Bioprod 7:1–13

Deeksha B, Sadanand V, Hariram N, Rajulu AV (2021) Preparation and properties of cellulose nanocomposite fabrics with in situ generated silver nanoparticles by bioreduction method. J Bioresour Bioprod 6:75–81

Balanon DAG, Sane A, Jariyasakoolroj P, Leelaphiwat P (2023) Application of biodegradable film as modified atmosphere packaging for red chili (Capsicum annuumcv. Jinda). Packag Technol Sci 36:379–388

Dmitruk A, Ludwiczak J, Skwarski M, Makuła P, Kaczyński P (2023) Influence of PBS, PBAT and TPS content on tensile and processing properties of PLA-based polymeric blends at different temperatures. J Mater Sci 58:1991–2004

Noivoil N, Yoksan R (2020) Oligo(lactic acid)-grafted starch: a compatibilizer for poly(lactic acid)/thermoplastic starch blend. Int J Biol Macromol 160:506–517

Zhong J, Xin Y (2023) Preparation, compatibility and barrier properties of attapulgite/poly (lactic acid)/thermoplastic starch composites. Int J Biol Macromol 24:124727

Zhang J, Liu C, Cheng J, Miao M, Zhang D (2018) Simultaneous toughening and strengthening of diglycidyl ether of bisphenol-a using epoxy-ended hyperbranched polymers obtained from thiol-ene click reaction. Polym Eng Sci 58:1703–1709

Han XL, Han Y, Jin YJ, Tian HF, Wang Z, Huang JW, Men S, Kumar R (2022) Tailoring compatibility and toughness of microbial poly (3-hydroxybutyrate-co-3-hydroxyvalerate)/bio-based polyester elastomer blends by epoxy-terminated hyperbranched polyester. Int J Biol Macromol 220:1163–1176

Guo M, Jin Y, Han X, Sun J, Yuan J, Tian H (2023) Biodegradable poly (Butylene Adipate-Co-Terephthalate) and thermoplastic starch sustainable blends modified by epoxy-terminated hyperbranched polyester with excellent mechanical properties and high transparency. Starch - Stärke 75:2200169

Xiaolong H, Yi H, Yujuan J, Huafeng T, Zhao W, Jiawei H, Shuang M, Rakesh K (2022) Tailoring compatibility and toughness of microbial poly (3-hydroxybutyrate-co-3-hydroxyvalerate) /bio-based polyester elastomer blends by epoxy-terminated hyperbranched polyester. Int J Biol Macromol 220:1163–1176

Kodal M, Wis AA, Ozkoc G (2018) The mechanical, thermal and morphological properties of γ-irradiated PLA/TAIC and PLA/OvPOSS. Radiat Phys Chem 153:214–225

Camacho-Munoz R, Villada-Castillo HS, Solanilla-Duque JF (2020) Anaerobic biodegradation under slurry thermophilic conditions of poly(lactic acid)/starch blend compatibilized by maleic anhydride. Int J Biol Macromol 163:1859–1865

Wei X-F, Bao R-Y, Cao Z-Q, Yang W, Xie B-H, Yang M-B (2014) Stereocomplex crystallite network in asymmetric PLLA/PDLA blends: formation, structure, and confining effect on the crystallization rate of homocrystallites. Macromolecules 47:1439–1448

Wadaugsorn K, Panrong T, Wongphan P, Harnkarnsujarit N (2022) Plasticized hydroxypropyl cassava starch blended PBAT for improved clarity blown films: morphology and properties. Ind Crops Prod 176:114311

Li F, Yu H-Y, Li Y, Hussain Abdalkarim SY, Zhu J, Zhou Y (2021) “Soft-rigid” synergistic reinforcement of PHBV composites with functionalized cellulose nanocrystals and amorphous recycled polycarbonate. Compos B Eng 206:108542

Palai B, Mohanty S, Nayak SK (2021) A comparison on biodegradation behaviour of polylactic Acid (PLA) based blown films by Incorporating Thermoplasticized Starch (TPS) and Poly (Butylene Succinate-co-Adipate) (PBSA) biopolymer in soil. J Polym Environ 29:2772–2788

Nazrin A, Sapuan SM, Zuhri MYM, Tawakkal ISMA, Ilyas RA (2021) Flammability and physical stability of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch/poly(lactic acid) blend bionanocomposites. Nanotechnol Rev 11(1):86–95

Fonseca-Garcia A, Osorio BH, Aguirre-Loredo RY, Calambas HL, Caicedo C (2022) Miscibility study of thermoplastic starch/polylactic acid blends: thermal and superficial properties. Carbohydr Polym 293:119744

Zhai X, Wang W, Zhang H, Dai Y, Dong H, Hou H (2020) Effects of high starch content on the physicochemical properties of starch/PBAT nanocomposite films prepared by extrusion blowing. Carbohydr Polym 239:116231

Quynh TM, Mitomo H, Nagasawa N, Wada Y, Yoshii F, Tamada M (2007) Properties of crosslinked polylactides (PLLA & PDLA) by radiation and its biodegradability. Eur Polym J 43:1779–1785

Camani PH, Souza AG, Barbosa RFS, Zanini NC, Mulinari DR, Rosa DS (2021) Comprehensive insight into surfactant modified-PBAT physico-chemical and biodegradability properties. Chemosphere 269:128708

Tian J, Xu T, Tan Y, Zhang Z, Tang B, Sun Z (2019) Effects of non-covalent functionalized graphene oxide with hyperbranched polyesters on mechanical properties and mechanism of epoxy composites. Materials (Basel) 12:3103

Kervran M, Vagner C, Cochez M, Ponçot M, Saeb MR, Vahabi H (2022) Thermal degradation of polylactic acid (PLA)/polyhydroxybutyrate (PHB) blends: a systematic review. Polym Degrad Stab 201:109995

Dang KM, Yoksan R, Pollet E, Averous L (2020) Morphology and properties of thermoplastic starch blended with biodegradable polyester and filled with halloysite nanoclay. Carbohydr Polym 242:116392

Yoksan R, Boontanimitr A, Klompong N, Phothongsurakun T (2022) Poly(lactic acid)/thermoplastic cassava starch blends filled with duckweed biomass. Int J Biol Macromol 203:369–378

Zhang X, Zhang Y (2016) Reinforcement effect of poly(butylene succinate) (PBS)-grafted cellulose nanocrystal on toughened PBS/polylactic acid blends. Carbohydr Polym 140:374–382

Chotiprayon P, Chaisawad B, Yoksan R (2020) Thermoplastic cassava starch/poly(lactic acid) blend reinforced with coir fibres. Int J Biol Macromol 156:960–968

Jullanun P, Yoksan R (2020) Morphological characteristics and properties of TPS/PLA/cassava pulp biocomposites. Polym Test 88:106522

Abdelwahab MA, Flynn A, Chiou B-S, Imam S, Orts W, Chiellini E (2012) Thermal, mechanical and morphological characterization of plasticized PLA–PHB blends. Polym Degrad Stab 97:1822–1828

Sikhosana ST, Gumede TP, Malebo NJ, Ogundeji AO, Motloung B (2023) The influence of cellulose content on the morphology, thermal, and mechanical properties of poly(lactic acid)/ Eucomis autumnalis cellulose biocomposites. Polym Eng Sci 63:1411–1422

Akhir MAM, Zubir SA, Mariatti J (2022) Effect of different starch contents on physical, morphological, mechanical, barrier, and biodegradation properties of tapioca starch and poly(butylene adipate-co-terephthalate) blend film. Polym Adv Technol 34:717–730

Ruggero F, Onderwater RCA, Carretti E, Roosa S, Benali S, Raquez J-M, Gori R, Lubello C, Wattiez R (2021) Degradation of film and rigid bioplastics during the thermophilic phase and the maturation phase of simulated composting. J Polym Environ 29:3015–3028

Salomez M, George M, Fabre P, Touchaleaume F, Cesar G, Lajarrige A, Gastaldi E (2019) A comparative study of degradation mechanisms of PHBV and PBSA under laboratory-scale composting conditions. Polym Degrad Stab 167:102–113

Funding

The authors are grateful to the financial support of Beijing Young Top-notch Personnel Foundation (CIT&TCD201804030).

Author information

Authors and Affiliations

Contributions

MG, YJ, HT and JH: The experimental idea was proposed. GM: The method design and data analysis were conducted. XH and JS: The preparation of experimental materials was completed. Maolin Guo wrote the main manuscript text and prepared all the figures. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Conflict of interest

There are no conflicts of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Guo, M., Jin, Y., Han, X. et al. Simultaneously Strengthening and Toughening Biodegradable Polylactic Acid/Thermoplastic Starch Blends by Compatibilizing with Epoxy-Terminated Hyperbranched Polyester. J Polym Environ (2023). https://doi.org/10.1007/s10924-023-03113-4

Accepted:

Published:

DOI: https://doi.org/10.1007/s10924-023-03113-4