Abstract

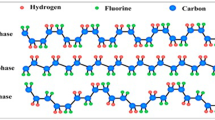

Polyvinylidene fluoride (PVDF) is a common semicrystalline fluoropolymer polymer. Due to its excellent piezoelectric properties, thermal stability, and mechanical strength, it has excellent processability and chemical tolerance to a range of materials such as acids, bases, organic solvents, grease, and fat. The current research provides an overview of recent advancements and developments in the implementation and modification of PVDF membranes, with a particular emphasis on sensors, biomedical engineering and devices, nanotechnology, solar applications, energy harvesting, and drug delivery carrier. Ferroelectric polymers are interesting from an electrical perspective. Ferroelectric polymers are insulating and polar and have a non-conjugated backbone, so they are known as strongly insulating materials from an optical perspective. Insulating polymers are particularly appealing for the study of charge transportation and storage. Because of their insulating properties and high concentration, such polymers often provide the best electrets for practical use. On the other hand, PMMA is an amorphous polymer, and poly (methyl methacrylate) (PMMA) advances have opened a wide variety of uses in nanotechnology. The understanding of PMMA properties has greatly aided recent advancements in the polymer’s synthesis, modification, and applications. As a result, this analysis aims to compare the physical, chemical, thermal, and mechanical properties of PVDF and PMMA. This article also gives a wise guide in the advancement of these two polymers in various fields of science and technology.

Similar content being viewed by others

References

Lovinger AJ (1982) Poly(vinylidene fluoride). Developments in crystalline polymers-1. Springer, Dordrecht, pp 195–273

Lovinger AJ (1982) Annealing of poly(vinylidene fluoride) and formation of a fifth phase. Macromolecules 15:40–44

Prest W Jr, Luca D (1978) The formation of the phase from the and polymorphs of polyvinylidene fluoride. J Appl Phys 49:5042–5047

Mohajir E, Heymans BE (2001) Changes in structural and mechanical behaviour of PVDF with processing and thermomechanical treatments. Change Struct Polym 42:5661–5667

Nalwa HS (1995) Ferroelectric polymers: chemistry, physics, and applications. CRC Press, Marcel Dekker Inc

Kawai H (1969) The piezoelectricity of polyvinylidene fluoride. Jpn J Appl Phys 8:975–976

Niizeki K, Nishidate I, Uchida K, Kuwahara M (2005) Unconstrained cardiorespiratory and body movement monitoring system for home care. Med Biol Eng Comput 43:716–724

Folke M, Cernerud L, Ekstrom M, Hok B (2003) Critical review of non-invasive respiratory monitoring in medical care. Med Biol Eng Comput 41:377–383

Tobin MJ (1988) Respiratory monitoring in the intensive care unit. Am Rev Respir Dis 138:1625–1642

Henri L (2007) Thermohygroelastic properties of polymethylmethacrylate. Netherlands, pp 11–13

Ruan L, Yao X, Chang Y, Zhou L, Qin G, Zhang X (2018) Properties and applications of the β phase poly(vinylidene fluoride). Polymers 10:228

Hashim H, Adam NI, Zaki NHM, Mahmud ZS, Said CMS, Yahya MZA, Ali AMM (2010) Natural rubber-grafted with 30% poly (methylmethacrylate) characterization for application in lithium polymer battery. Conference on science and social research 2010 (CSSR 2010) Kuala Lumpur Malaysia 485–488

Henry AC, Tutt TJ, Galloway M, Davidson YY, McWhorter CS, SoperMcCarley SARL (2000) Surface modification of poly (methyl methacrylate) used in the fabrication of micro- analytical devices. Anal Chem 72(21):5331–5337

Lee LH, Chen WC (2001) High-refractive-index thin films prepared from trialkoxysilane-capped poly (methyl methacrylate) titania materials. Chem Mater 15:1137–1142

Shah JJ, Geist J, Locascio LE, Gaitan M, Rao MV, Vreeland WN (2006) Surface modifi- cation of poly (methyl methacrylate) for improved adsorption of wall coating polymers for microchip electrophoresis. Electrophoresis 27(19):3788–3796

Adhikari B, Majumdar S (2004) Polymers in sensor applications. Prog Polym Sci 29(7):699–766

Isha A, Yusof NA, Ahmad M, Suhendra D, Yunus WMZW, Zainal Z (2006) A chemical sensor for trace V(V) ion determination based on fatty hydroxamic acid immobilized in poly- methylmethacrylate. Sens Actuators B Chem 114(1):344–349

Kost J, Langer R (2012) Responsive polymeric delivery systems. Adv Drug Deliv Rev 64:327–341

Beruto DT, Botter R, Fini M (2002) The effect of water in inorganic microsponges of calcium phosphates on the porosity and permeability of composites made with poly- methylmethacrylate. Biomaterials 23(12):2509–2517

Shi M, Kretlow JD, Spicer PP, Tabata Y, Demian N, Wong ME, Kasper FK, Mikos AG (2011) Antibiotic-releasing porous polymethylmethacrylate/gelatin/antibiotic constructs for craniofacial tissue engineering. J Control Release 152(1):196–205

Mishra S, Sen G (2011) Microwave initiated synthesis of polymethylmethacrylate grafted guar (GG-g-PMMA) characterizations and applications. Int J Biol Macromol 48(4):688–694

Wang M, Pramoda KP, Hong S (2005) Enhancement of the mechanical properties of poly (styrene co-acrylonitrile) with poly (methyl methacrylate) grafted multiwalled carbon nano- tubes. Polymer 46:11510–11516

Ford TA and Hanford WE (1948) Polyvinylidene fluoride and process for obtaining the same, U.S. Patent # 2435537

Lovinger AJ (1982) Poly (viny1idene fluoride): in developments in crystalline polymers. Applied Science Publishers, London, Bassett, D.C, p 195

Eisenmenger W, Schmidt H, Dehlen B (1999) Space charge and dipoles in polyvinylidenefluoride. Braz J Phys 29(2):295–305

Sajkiewicz P, Wasiak A, Goclowski Z (1999) Phase transition during stretching of poly (vinylidene fluoride). Eur Polym J 35(3):423–429

Davis GT, McKinney JE, Broadhurst MG, Roth SC (1978) Electric-field-induced phase changes in poly (vinylidene fluoride). J Appl Phys 49(10):4998–5002

Julius Dohany (2000) Kirk-othmer encyclopedia of chemical technology. Wiley, Fluorine-containing polymers poly(vinylidene fluoride). https://doi.org/10.1002/0471238961.1615122504150801.a01

Charles AH, Edward MP (2003) Plastics materials and processes. Concise encyclopedia. Wiley, NJ, pp 42–44

Van Krevelen DW, Nijenhuis KT (2000) Properties of polymers. Elsevier, Amsterdam, pp 106–322

Charles AH (2006) Handbook of plastics processes. Wiley, NJ, pp 1–7

Chang L, Woo EM (2010) Tacticity effects on glass transition and phase behavior in binary blends of poly (methyl methacrylate) of three different configurations. Polym Chem 1(2):198–202

Chen Chuanfu RC, Xi Fu (1995) Stereoregularity of poly (methyl methacrylate) obtained with chi- ral anionic initiator. Chin J Polym Sci 13(1):91–96

Ishitake K, Satoh K, Kamigaito M, Okamoto Y (2012) From-syndiotactic-to-isotactic stereogradient methacrylic polymers by RAFT copolymerization of methacrylic acid and its bulky esters. Polym Chem 3(7):1750–1757

Li L, Li B, Chen J, Zhou D, Xue G, Liu X (2004) Glass transition and structural relaxation of nano-particle aggregates of atactic poly(methyl methacrylate) formed in microemulsions. Polymer 45(8):2813–2816

Mark JE (2007) Physical properties of polymers handbook, 2nd edn. Springer, NY, pp 3–8

Semen J, Lando JB (1969) The acid hydrolysis of isotactic and syndiotactic poly (methyl meth- acrylate). Macromolecules 2(6):570–575

https://omnexus.specialchem.com/selection-guide/polyvinylidene-fluoride-pvdf-plastic

www.allplastics.com.au; all plastics- KYNAR(PVDF) data sheet.pdf

www.azom.com/article.aspx. Polymethylmethacrylate–acrylic–PMMA general purpose. Cited June 4, 2014-Nov. 22, 2014

Kutz M (2002) Handbook of materials selection. Wiley, NJ, p 341

Zeng WR, Li SF, Chow WK (2002) Preliminary studies on burning behavior of polymethylme- thacrylate (PMMA). J Fire Sci 20(4):297–317

Zhi CY, Bando Y, Wang WL, Tang CC, Kuwahara H, Golberg D (2008) Mechanical and thermal properties of polymethyl methacrylate-bn nanotube composites. J Nanomater 2008:1–5

www.teesing.com/properties of PVDF, rectus chemical resistance, rectum PVDF

www.burbert.com; Burkert: chemical resistance chart

www.ipexna.com; IPEX chemical resistance guide for PVDF (polyvinylidene fluoride for waste drainage systems chemical resistance data)

www.allplastic.com.au/ KYNAR (PVDF) chemical compatibility & chemical resistance chart

www.sevierlab.vet.cornell.edu/resources/Chemical-Resistance-Chart-Detail.pdf. Chemical compatibility guide: chemical resistance chart detail. Cited 2015, Feb 11

www.solutions-in-plastics.info. PMMA resistance to chemical. Cited 2015, Feb 11

Liu F, Hashim NA, Liu Y, Abed MRM, Li K (2011) Progress in the prodution and modification of PVDF membranes. J Membr Sci 375(1–2):1–27. https://doi.org/10.1016/j.memsci.2011.03.014

O’Hagan D (2008) Understanding organofluorine chemistry an introduction to the C–F bond. Chem Soc Rev 37(2):308–319. https://doi.org/10.1039/b711844a

Dargaville TR, George GA, Hill DJT, Whittaker AK (2003) High energy radiation grafting of fluoropolymers. Prog Polym Sci 28(9):1355–1376

Madorsky SL (1964) Thermal degradation of organic polymers fluorocarbon and chlorocarbon polymers. John Wiley & Sons Inc, pp 130–172

Lovinger AJ, Freed DJ (1980) Inhomogeneous thermal-degradation of poly(vinylidene fluoride) crystallized from the melt. Macromolecules 13(4):989–994. https://doi.org/10.1021/Ma60076a044

Collier A, Wang HJ, Yuan XZ, Zhang JJ, Wilkinson DP (2006) Degradation of polymer electrolyte membranes. Int J Hydrog Energy 31(13):1838–1854. https://doi.org/10.1016/j.ijhydene.2006.05.006

https://omnexus.specialchem.com/selection-guide/polyvinylidene-fluoride-pvdf-plastic PVDF material properties data sheet

Jeon JH, Kang SP, Lee S, Oh IK (2009) Novel biomimetic actuator based on SPEEK and PVDF. Sens Actuators B Chem 143:357–364

Panwar V, Cha K, Park JO, Park S (2012) High actuation response of PVDF/PVP/PSSA based ionic polymer metal composites actuator. Sens Actuators B Chem 161:460–470

Zhang Y, Niu H, Xie S, Zhang X (2008) Numerical and experimental investigation of active vibration control in a cylindrical shell partially covered by a laminated PVDF actuator. Smart Mater Struct 17:035024

Chen Z, Kwon KY, Tan X (2008) Integrated IPMC/PVDF sensory actuator and its validation in feedback control. Sens Actuators A Phys 144:231–241

Shirinov A, Schomburg W (2008) Pressure sensor from a PVDF film. Sens Actuators A Phys 142:48–55

Fujitsuka N, Sakata J, Miyachi Y, Mizuno K, Ohtsuka K, Taga Y, Tabata O (1998) Monolithic pyroelectric infrared image sensor using PVDF thin film. Sens Actuators A Phys 66:237–243

Mazurek B, Janiczek T, Chmielowiec J (2001) Assessment of vehicle weight measurement method using PVDF transducers. J Electrost 51:76–81

Xu G, Zhang M, Zhou Q, Chen H, Gao T, Li C, Shi G (2017) A small graphene oxide sheet/polyvinylidene fluoride bilayer actuator with large and rapid responses to multiple stimuli. Nanoscale 9:17465–17470

Wang F, Ko SY, Park JO, Park SH, Kee CD (2015) Electroactive polymer actuator based on PVDF and graphene through electrospinning. Adv Mater Res 1105:311–314

Fukushima T, Asaka K, Kosaka A, Aida T (2005) Fully plastic actuator through layer-by-layer casting with ionic-liquid-based bucky gel. Angew Chem Int Ed 44:2410–2413

Mukai K, Asaka K, Kiyohara K, Sugino T, Takeuchi I, Fukushima T, Aida T (2008) High performance fully plastic actuator based on ionic-liquid-based bucky gel. Electrochim Acta 53:5555–5562

Saketi P, Latifi SK, Hirvonen J, Rajala S, Vehkaoja A, Salpavaara T, Lekkala J, Kallio P (2015) PVDF microforce sensor for the measurement of Z-directional strength in paper fiber bonds. Sens Actuators A Phys 222:194–203

Choi SC, Park JS, Kim JH (2006) Active damping of rotating composite thin-walled beams using MFC actuators and PVDF sensors. Compos Struct 76:362–374

Ying Z, Jiang Y, Du X, Xie G, Yu J, Wang H (2007) PVDF coated quartz crystal microbalance sensor for DMMP vapor detection. Sens Actuators B Chem 125:167–172

Shin KY, Lee JS, Jang J (2016) Highly sensitive, wearable and wireless pressure sensor using free-standing ZnO nanoneedle/PVDF hybrid thin film for heart rate monitoring. Nano Energy 22:95–104

Yoon S, Prabu AA, Ramasundaram S, Kim KJ (2008) PVDF nanoweb touch sensors prepared using electro-spinning process for smart apparels applications. Adv Sci Technol 60:52–57

Wang Y, Zheng J, Ren G, Zhang P, Xu C (2011) A flexible piezoelectric force sensor based on PVDF fabrics. Smart Mater Struct 20:045009

Al-Saygh A, Ponnamma D, AlMaadeed MA, Poornima Vijayan P, Karim A, Hassan MK (2017) Flexible pressure sensor based on PVDF nanocomposites containing reduced graphene oxide-titania hybrid nanolayers. Polymers 9:33

Spanu A, Pinna L, Viola F, Seminara L, Valle M, Bonfiglio A, Cosseddu P (2016) A high-sensitivity tactile sensor based on piezoelectric polymer PVDF coupled to an ultra-low voltage organic transistor. Org Electron 36:57–60

Hong-Jie T, Tian W-C, Wu W-J (2013) P(VDF-TrFE) polymer-based thin films deposited on stainless steel substrates treated using water dissociation for flexible tactile sensor development. Sensors (Basel Switz) 13:14777–14796. https://doi.org/10.3390/s131114777

Tian T-J, Wei-ChengWen-Jong TWu (2013) Flexible PZT thin film tactile sensor for biomedical monitoring. Sensors 13(5):5478–5492. https://doi.org/10.3390/s130505478

Haibao L, Wei Min H, Xue Lian W, Yu Chun G, Fan Z, Yong Z, Junfeng G (2014) Heating/ethanol-response of poly methyl methacrylate (PMMA) with gradient pre-deformation and potential temperature sensor and anti-counterfeit applications. Smart Mater Struct 23(6):1–14

Michael F, Kee SM, Sam K (2010) A PMMA coated PMN–PT single crystal resonator for sensing chemical agents. Smart Mater Struct 19(3):1–12

Hargsoon Y, Jining X, Jose KA, Vijay KV, Paul BR (2006) Passive wireless sensors using electrical transition of carbon nanotube junctions in polymer matrix. Smart Mater Struct 15(1):S14–S20

Capan R, Ray AK, Tanrisever T, Hassan AK (2005) Spun thin films of poly (methyl methacry- late) polymer for benzene sensing. Smart Mater Struct 14(4):N11–N15

Haines CS, Li N, Spinks GM, Aliev AE, Di JT, Baughman RH (2016) New twist on artificial muscles. Proc Natl Acad Sci USA 113:11709–11716

Mirfakhrai T, Madden JDW, Baughman RH (2007) Polymer artificial muscles. Mater Today 10:30–38

Baniasadi M, Huang J, Xu Z, Moreno S, Yang X, Chang J, Quevedo-Lopez MA, Naraghi M, Minary-Jolandan M (2015) High-performance coils and yarns of polymeric piezoelectric nanofibres. ACS Appl Mater Interfaces 7:5358–5366

Harris GR, Preston RC, DeReggi AS (2000) The impact of piezoelectric pvdf on medical ultrasound exposure measurements, standards, and regulations. IEEE Trans Ultrason Ferroelectr Freq Control 47:1321–1335

Ackermann D, Schmitz G (2012) Investigation of kerfless PZT and PVDF based ultrasound arrays. Biomed Technol 57:119–122

Qiu XL (2010) Patterned piezo-, pyro-, and ferroelectricity of poled polymer electrets. J Appl Phys 108:011101

Woodward B, Chandra RC (1978) Underwater acoustic measurements on polyvinylidene fluoride transducers. Electrocompon Sci Technol 5:149–157

Lockwood GR, Ryan LK, Hunt JW, Foster FS (1991) Measurement of the ultrasonic properties of vascular tissues and blood from 35–65 MHZ. Ultrasound Med Biol 17:653–666

Foster FS, Harasiewicz EA, Sherar MD (2000) A history of medical and biological imaging with polyvinylidene fluoride (PVDF) transducers. IEEE Trans Ultrason Ferroelectr Freq Control 47:1363–1371

Jackson VP, Kellyfry E, Rothschild PA, Holden RW, Clark SA (1986) Automated breast sonography using a 7.5 mhz PVDF transducer preliminary clinical evaluation work in progress. Radiology 159:679–684

Vogt M, Ermert H, El Gammal S, Kaspar K, Hoffmann K and Altmeyer P (1998) Structural analysis of the skin using high frequency, broadband ultrasound in the range from 30 to 140 MHz. In proceedings of the 1998 IEEE ultrasonics symposium, Sendai, Japan, 5–8 October 1998 Eds. 1–2: 1685–1688

Oh JT, Li ML, Zhang HF, Maslov K, Stoica G, Wang LHV (2006) Three dimensional imaging of skin melanoma in vivo by dual-wavelength photoacoustic microscopy. J Biomed Opt 11:34032

Fleischman A, Modi R, Nair A, Talman J, Lockwood G, Roy S (2003) Miniature high frequency focused ultrasonic transducers for minimally invasive imaging procedures. Sens Actuator A Phys 103:76–82

Jung M, Kim MG, Lee JH (2009) IEEE. Micromachined ultrasonic transducer using piezoelectric PVDF film to measure the mechanical properties of bio cells. In proceedings of the 2009 IEEE sensors. Christch N Z 25–28:1225–1228

Laroche G, Marois Y, Schwarz E, Guidoin R, King MW, Paris E, Douville Y (1995) Polyvinylidene fluoride monofilament sutures can they be used safely for long-term anastomoses in the thoracic aorta. Artif Organs 19:1190–1199

Lambertz A, Schroder KM, Schob DS, Binnebosel M, Anurov M, Klinge U, Neumann UP, Klink CD (2015) Polyvinylidene fluoride as a suture material: evaluation of comet tail-like infiltrate and foreign body granuloma. Eur Surg Res 55:1–11

Laroche G, Marois Y, Guidoin R, King MW, Martin L, How T, Douville Y (1995) Polyvinylidene fluoride (PVDF) as a biomaterial—from polymeric raw-material to monofilament vascular suture. J Biomed Mater Res 29:1525–1536

Sokhanvar S, Packirisamy M, Dargahi J (2007) A multifunctional PVDF-based tactile sensor for minimally invasive surgery. Smart Mater Struct 16:989–998

Qasaimeh MA, Sokhanvar S, Dargahi J, Kahrizi M (2009) PVDF-based microfabricated tactile sensor for minimally invasive surgery. J Microelectromech Syst 18:195–207

Suaste-Gomez E, Rodriguez-Roldan G, Reyes-Cruz H, Teran-Jimenez O (2016) Developing an ear prosthesis fabricated in polyvinylidene fluoride by a 3D printer with sensory intrinsic properties of pressure and temperature. Sensors 16:332

Zhou YM, He JX, Wang HB, Qi K, Nan N, You XL, Shao WL, Wang LD, Ding B, Cui SZ (2017) Highly sensitive, self-powered and wearable electronic skin based on pressure-sensitive nanofiber woven fabric sensor. Sci Rep 7:12949

Zuhair J, Abdul Amer JKA, Sura Fahim A (2014) Chitosan/PMMA bioblend for drugs release applications. Int J Eng Technol 4(5):318–324

Zuber M, Tabasum S, Jamil T, Shahid M, Hussain R, Feras KS, Bhatti KP (2014) Biocompatibility and microscopic evaluation of polyurethane–poly (methyl methacrylate)–titnanium dioxide-based composites for dental applications. J Appl Polym Sci 131(3):1–9

Nien YH, Lin SW, Hsu YN (2013) Preparation and characterization of acrylic bone cement with high drug release. Mater Sci Eng, C 33(2):974–978

Langer K, Mutschler E, Lambrecht G, Mayer D, Troschau G (1997) Methylmethacrylate sulfo- propylmethacrylate copolymer nanoparticles for drug delivery part III: evaluation as drug delivery system for ophthalmic applications. Int J Pharm 158:219–231

Downes S (1991) Methods for improving drug release from poly (methyl) methacrylate bone cement. Clin Mater 7:227–231

Itokawa H, Hiraide T, Moriya M, Fujimoto M, Nagashima G, Suzuki R, Fujimoto T (2007) A 12-month in vivo study on the response of bone to a hydroxyapatite-polymethylmethacrylate cranioplasty composite. Biomaterials 28(33):4922–4927

Thomson LA, Law FC, James KH, Matthew CA, Rushton N (1992) Biocompatibility of par- ticulate poly (methyl methacrylate) bone cements: a comparative study in vitro and in vivo. Biomaterials 13(12):811–818

Alsharief A, Mustafa I, AlNahyan M et al (2020) CNT–PVDF freestanding sheets for direct solar evaporation toward continuous desalination applications. J Mater Sci 55:2860–2869. https://doi.org/10.1007/s10853-019-04217-w

Indradevi P, Ramachandran K (2010) Hybridized PVDF/PbS nanocomposites for solar cell applications. AIP Conf Proc 1276:183. https://doi.org/10.1063/1.3504295

Alaaeddin MH, Sapuan SM, Zuhri MYM, Zainudin ES, FarisOqla MAl (2019) Lightweight and durable PVDF-SSPF composites for photovoltaics backsheet applications: thermal optical and technical properties. Materials (Basel) 12(13):2104. https://doi.org/10.3390/ma12132104

Hammam M, El-Mansy MK, El-Bashir SM, El-Shaarawy MG (2007) Performance evaluation of thin-film solar concentrators for greenhouse applications. Desalination 209(1–3):244–250

Schissel P, Jorgensen G, Kennedy C, Goggin R (1994) Silvered-PMMA reflectors. Sol Energy Mater Sol Cells 33(2):183–197

Toor A and Pisano AP (2015) Gold nanoparticle/PVDF polymer composite with improved particle dispersion 2015 IEEE 15th international conference on nanotechnology (IEEE-NANO): 706–709. doi: https://doi.org/10.1109/NANO.2015.7388704

Chang C, Limkrailassiri K, Lin L (2008) Continuous near-field electrospinning for large area deposition of orderly nanofiber patterns. Appl Phys Lett 93(12):123111

Alhasssan Zainab Abu, Burezq Yasmeen S, Nair Remya, Shehata Nader (2018) Polyvinylidene difluoride piezoelectric electrospun nanofibers: review in synthesis, fabrication, characterizations, and applications. J Nanomater. https://doi.org/10.1155/2018/8164185 (Article ID 8164185)

Anum Imtiaz, Sher Jamal Khan, ErumAamir, Ishtiaq A. Qazi, Nadeem Iqbal and Nasir M. Ahmed (2013) Iron oxide nanoparticles incorporated polyvinylidene fluoride (PVDF) microfiltration membranes for industrial wastewater treatment, 3rd international conference on nanotek & expo, December 02–04, 2013 Hampton Inn Tropicana, Las Vegas, NV, USA

Perween M, Parmar DB, Bhadu GR, Srivastava DN (2014) Polymer-graphite composite: a versatile use and throw plastic chip electrode. Analyst 139(22):5919–5926

Wang X, Wang P, Jiang Y, Su Q, Zheng J (2014) Facile surface modification of silica nanoparticles with a combination of noncovalent and covalent methods for composites application. Compos Sci Technol 104:1–8

Jancar J, Douglas JF, Starr FW, Kumar SK, Cassagnau P, Lesser AJ, Sternstein SS, Buehler MJ (2010) Current issues in research on structure–property relationships in polymer nano- composites. Polymer 51(15):3321–3343

Wang M, Pramoda KP, Hong S (2005) Enhancement of the mechanical properties of poly (styrene co-acrylonitrile) with poly (methyl methacrylate) grafted multiwalled carbon nanotubes. Polymer 46:11510–11516

Cui L, Tarte NH, Woo SI (2011) Synthesis and properties of poly (methyl methacrylate)/carbon nanotube composites covalently integrated through in situ radical polymerization. J Appl Polym Sci 119(1):452–459

Baskaran D, Dunlap JR, Mays JW, Bratcher MS (2005) Grafting efficiency of hydroxy-terminated poly (methyl methacrylate) with multiwalled carbon nanotubes. Macromol Rapid Commun 26(6):481–486

Sung JH, Kim HS, Jin HJ, Choi HJ, Chin IJ (2004) Nanofibrous membranes prepared by multiwalled carbon nanotube/poly (methyl methacrylate) composites. Macromolecules 37(26):9899–9902

Lee M, Chen CY, Wang S, Cha SN, Park YJ, Kim JM, Chou LJ, Wang ZL (2012) A hybrid piezoelectric structure for wearable nanogenerators. Adv Mater 24:1759–1764

Gusarov B, Gusarova E, Viala B, Gimeno L, Boisseau S, Cugat O, Vandelle E, Louison B (2016) Thermal energy harvesting by piezoelectric PVDF polymer coupled with shape memory alloy. Sens Actuators A Phys 243:175–181

Tamang A, Ghosh SK, Garain S, Alam MM, Haeberle J, Henkel K, Schmeisser D, Mandal D (2015) DNA-assisted β phase nucleation and alignment of molecular dipoles in PVDF film: a realization of self-poled bioinspired flexible polymer nanogenerator for portable electronic devices. ACS Appl Mater Interfaces 7:16143–16147

Farinholt KM, Pedrazas NA, Schluneker DM, Burt DW, Farrar CR (2009) An energy harvesting comparison of piezoelectric and ionically conductive polymers. J Intell Mater Syst Struct 20:633–642

Sun C, Shi J, Bayerl DJ, Wang X (2011) PVDF microbelts for harvesting energy from respiration. Energy Environ Sci 4:4508–4512

Li S, Crovetto A, Peng Z, Zhang A, Hansen O, Wang M, Li X, Wang F (2016) Bi-resonant structure with piezoelectric PVDF films for energy harvesting from random vibration sources at low frequency. Sens Actuators A Phys 247:547–554

Pi Z, Zhang J, Wen C, Zhang ZB, Wu D (2014) Flexible piezoelectric nanogenerator made of poly(vinylidenefluoride-co-trifluoroethylene) (PVDF-TrFE) thin film. Nano Energy 7:33–41

Lallart M, Cottinet PJ, Lebrun L, Guiffard B, Guyomar D (2010) Evaluation of energy harvesting performance of electrostrictive polymer and carbon-filled terpolymer composites. J Appl Phys 108:034901

Cottinet PJ, Lallart M, Guyomar D, Guiffard B, Lebrun L, Sebald G, Putson C (2011) Analysis of AC-DC conversion for energy harvesting using an electrostrictive polymer P(VDF-TrFE-CFE). IEEE Trans Ultrason Ferroelectr Freq Control 58(1):30–42

Thanigai Arul K, Ramanjaneyulu M, Ramachandra Rao MS (2019) Energy harvesting of PZT/PMMA composite flexible films. Curr Appl Phys 19(4):375–380. https://doi.org/10.1016/j.cap.2019.01.003

Polat K (2020) Energy harvesting from a thin polymeric film based on PVDF-HFP and PMMA blend. Appl Phys A 126:497. https://doi.org/10.1007/s00339-020-03698-w

Barbosa J, Correia DM, Gonçalves R, Ribeiro C, Botelho G, Martins P, Lanceros-Mendez S (2016) Magnetically controlled drug release system through magnetomechanical actuation. Adv Healthc Mater 5:3027–3034

Webber MJ, Langer R (2017) Drug delivery by supramolecular design. Chem Soc Rev 46:6600–6620

Priya James H, John R, Alex A, Anoop KR (2014) Smart polymers for the controlled delivery of drugs–a concise overview. Acta Pharm Sin B 4:120–127

He T, Wang J, Huang P, Zeng B, Li H, Cao Q, Zhang S, Luo Z, Deng DYB, Zhang H et al (2015) Electrospinning polyvinylidene fluoride fibrous membranes containing anti-bacterial drugs used as wound dressing. Coll Surf B Biointerfaces 130:278–286

Abednejad A, Ghaee A, Morais ES, Sharma M, Neves BM, Freire MG, Nourmohammadi J, Mehrizi AA (2019) Polyvinylidene fluoride–hyaluronic acid wound dressing comprised of ionic liquids for controlled drug delivery and dual therapeutic behavior. Acta Biomater 100:142–157. https://doi.org/10.1016/j.actbio.2019.10.007

Carmen Alvarez-Lorenzo and Angel Concheiro (2019) Smart drug release from medical devices. J Pharmacol Exp Ther 370(3):544–554. https://doi.org/10.1124/jpet.119.257220

Bettencourt A, Almeida AJ (2012) Poly (methyl methacrylate) particulate carriers in drug delivery. J Microencapsul 29(4):353–367. https://doi.org/10.3109/02652048.2011.651500

Shaked E, Shani Y, Zilberman M, Scheinowitz M (2015) Poly (methyl methacrylate) particles for local drug delivery using shock wave lithotripsy: in vitro proof of concept experiment. J Biomed Mater Res B Appl Biomater 103(6):1228–1237. https://doi.org/10.1002/jbm.b.33301

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Saxena, P., Shukla, P. A comparative analysis of the basic properties and applications of poly (vinylidene fluoride) (PVDF) and poly (methyl methacrylate) (PMMA). Polym. Bull. 79, 5635–5665 (2022). https://doi.org/10.1007/s00289-021-03790-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-021-03790-y