Abstract

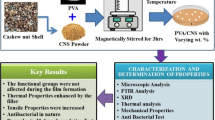

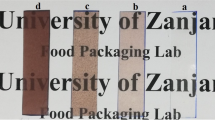

On the total earth wastes, nearly one-third was packaging wastes. Most of the packaging materials are non-biodegradable and non-recyclable. To overcome these issues, researchers turned their attention to develop biodegradable films(bio-films). In this article, through the solution casting method bio-films were developed by using water-soluble polyvinyl alcohol (PVA) and various proportions (5–25wt%) of rice hull powder as reinforcement filler. The effect of RHP on the PVA matrix was investigated by fourier-transform infrared spectroscopy (FTIR), x-ray diffraction (XRD), thermogravimetric analysis, differential scanning calorimeter, tensile test, surface morphology studies, water vapor permeability, and antibacterial testing. FTIR result revealed the proper bonding between PVA/RHP in bio-films via strong hydrogen bonds. XRD result reveals a slight increase in the intensity of bio-films and the crystalline size was reported between 5.53 and 13.28 nm. The infusion of RHP in the matrix shows that tensile strength and tensile modulus increases gradually and reaches the maximum value of 23.32 MPa and 684 MPa respectively at 25% of RHP in PVA. Thermal behavior proved that the bio-films were strong enough to withstand the temperature up to 350 °C. The lower values of WVP possess a higher interaction of polymer chains. The bio-film samples form a good inhibition zone against both gram-positive and gram-negative bacteria and display remarkable antibacterial activity. From the microstructure images, it is visible that bio-films were homogenous, away from cracks and phase separation. By this evidence, RHP added PVA can be used as a packaging material.

Similar content being viewed by others

References

Thiagamani SMK, Nagarajan R, Jawaid M et al (2017) Utilization of chemically treated municipal solid waste (spent coffee bean powder) as reinforcement in cellulose matrix for packaging applications. Waste Manag 69:445–454. https://doi.org/10.1016/j.wasman.2017.07.035

Morales A, Andrés MÁ, Labidi J, Gullón P (2019) UV–vis protective poly(vinyl alcohol)/bio-oil innovative films. Ind Crops Prod 131:281–292. https://doi.org/10.1016/j.indcrop.2019.01.071

Tripathi S, Mehrotra GK, Dutta PK (2009) Physicochemical and bioactivity of cross-linked chitosan-PVA film for food packaging applications. Int J Biol Macromol 45:372–376. https://doi.org/10.1016/j.ijbiomac.2009.07.006

SenthilMuthu Kumar T, Rajini N, Jawaid M et al (2018) Preparation and properties of cellulose/tamarind nut powder green composites: (green composite using agricultural waste reinforcement). J Nat Fibers 15:11–20. https://doi.org/10.1080/15440478.2017.1302386

Asad M, Saba N, Asiri AM et al (2018) Preparation and characterization of nanocomposite films from oil palm pulp nanocellulose/poly (vinyl alcohol) by casting method. Carbohydr Polym 191:103–111. https://doi.org/10.1016/j.carbpol.2018.03.015

Thiagamani SMK, Rajini N, Siengchin S et al (2019) Influence of silver nanoparticles on the mechanical, thermal and antimicrobial properties of cellulose-based hybrid nanocomposites. Compos Part B Eng 165:516–525. https://doi.org/10.1016/j.compositesb.2019.02.006

Balavairavan B, Saravanakumar SS, Manikandan KM (2020) Physicochemical and structural properties of green biofilms from poly (vinyl alcohol)/nano coconut shell filler. J Nat Fibers 00:1–15. https://doi.org/10.1080/15440478.2020.1723778

Rathinavel S, Saravanakumar SS (2020) Development and analysis of poly vinyl alcohol/orange peel powder biocomposite films. J Nat Fibers 00:1–10. https://doi.org/10.1080/15440478.2019.1711285

Perumal AB, Sellamuthu PS, Nambiar RB, Sadiku ER (2018) Development of polyvinyl alcohol/chitosan bio-nanocomposite films reinforced with cellulose nanocrystals isolated from rice straw. Appl Surf Sci. https://doi.org/10.1016/j.apsusc.2018.01.022

Fonseca-García A, Jiménez-Regalado EJ, Aguirre-Loredo RY (2021) Preparation of a novel biodegradable packaging film based on corn starch-chitosan and poloxamers. Carbohydr Polym. https://doi.org/10.1016/j.carbpol.2020.117009

Bijarimi M, Ahmad S, Alam AKMM (2017) Toughening effect of liquid natural rubber on the morphology and thermo-mechanical properties of the poly(lactic acid) ternary blend. Polym Bull 74:3301–3317. https://doi.org/10.1007/s00289-016-1889-7

Mirabella N, Castellani V, Sala S (2014) Current options for the valorization of food manufacturing waste: a review. J Clean Prod 65:28–41. https://doi.org/10.1016/j.jclepro.2013.10.051

Rashid S, Dutta H (2020) Characterization of nanocellulose extracted from short, medium and long grain rice husks. Ind Crops Prod 154:112627. https://doi.org/10.1016/j.indcrop.2020.112627

Li R, Cai J, Zhang L et al (2014) Properties of cellulose/turmeric powder green composite films. Cellul Chem Technol 48:321–324

Sarwar MS, Niazi MBK, Jahan Z et al (2018) Preparation and characterization of PVA/nanocellulose/Ag nanocomposite films for antimicrobial food packaging. Carbohydr Polym 184:453–464. https://doi.org/10.1016/j.carbpol.2017.12.068

Manikandan KM, Yelilarasi A, Senthamaraikannan P et al (2019) A green-nanocomposite film based on poly(vinyl alcohol)/ eleusine coracana: structural, thermal, and morphological properties. Int J Polym Anal Charact 24:257–265. https://doi.org/10.1080/1023666X.2019.1567087

SenthilMuthu Kumar T, Rajini N, Siengchin S et al (2019) Influence of Musa acuminate bio-filler on the thermal, mechanical and visco-elastic behavior of poly (propylene) carbonate biocomposites. Int J Polym Anal Charact 24:439–446. https://doi.org/10.1080/1023666X.2019.1602910

Otoni CG, Lodi BD, Lorevice MV et al (2018) Optimized and scaled-up production of cellulose-reinforced biodegradable composite films made up of carrot processing waste. Ind Crops Prod 121:66–72. https://doi.org/10.1016/j.indcrop.2018.05.003

Orsuwan A, Sothornvit R (2018) Reinforcement of banana flour biocomposite film with beeswax and montmorillonite and effects on water barrier and physical properties. Int J Food Sci Technol 53:2642–2649. https://doi.org/10.1111/ijfs.13859

da Silva ISV, de Sousa RMF, de Oliveira A et al (2018) Polymeric blends of hydrocolloid from chia seeds/apple pectin with potential antioxidant for food packaging applications. Carbohydr Polym 202:203–210. https://doi.org/10.1016/j.carbpol.2018.08.061

Engel JB, Ambrosi A, Tessaro IC (2019) Development of a cassava starch-based foam incorporated with grape stalks using an experimental design. J Polym Environ 27:2853–2866. https://doi.org/10.1007/s10924-019-01566-0

Loganathan L, Saravanakumar SS (2021) Physico–chemical and tensile properties of green bio-films from poly (vinyl alcohol)/nano ground nutshell filler. J Nat Fibers. https://doi.org/10.1080/15440478.2020.1863289

Biswas MC, Tiimob BJ, Abdela W et al (2019) Nano silica-carbon-silver ternary hybrid induced antimicrobial composite films for food packaging application. Food Packag Shelf Life 19:104–113. https://doi.org/10.1016/j.fpsl.2018.12.003

Priyadarshi R, Rhim JW (2020) Chitosan-based biodegradable functional films for food packaging applications. Innov Food Sci Emerg Technol 62:102346. https://doi.org/10.1016/j.ifset.2020.102346

Wang J, Ren H, Li X et al (2018) In situ monitoring of wastewater biofilm formation process via ultrasonic time domain reflectometry (UTDR). Chem Eng J 334:2134–2141. https://doi.org/10.1016/j.cej.2017.11.043

Ghanipour M, Dorranian D (2013) Effect of Ag-nanoparticles doped in polyvinyl alcohol on the structural and optical properties of PVA films. J Nanomater. https://doi.org/10.1155/2013/897043

Hema M, Selvasekerapandian S, Sakunthala A et al (2008) Structural, vibrational and electrical characterization of PVA-NH4Br polymer electrolyte system. Phys B Condens Matter 403:2740–2747. https://doi.org/10.1016/j.physb.2008.02.001

Khanna PK, Singh N, Charan S et al (2005) Synthesis and characterization of Ag/PVA nanocomposite by chemical reduction method. Mater Chem Phys 93:117–121. https://doi.org/10.1016/j.matchemphys.2005.02.029

Malathi J, Kumaravadivel M, Brahmanandhan GM et al (2010) Structural, thermal and electrical properties of PVA-LiCF3SO3 polymer electrolyte. J Non Cryst Solids 356:2277–2281. https://doi.org/10.1016/j.jnoncrysol.2010.08.011

Franco DSP, Tanabe EH, Dotto GL (2017) Continuous adsorption of a cationic dye on surface modified rice husk: statistical optimization and dynamic models. Chem Eng Commun 204:625–634. https://doi.org/10.1080/00986445.2017.1300150

Wazir AH, Wazir IU, Wazir AM (2020) Preparation and characterization of rice husk based physical activated carbon. Energy Sources, Part A Recover Util Environ Eff 00:1–11. https://doi.org/10.1080/15567036.2020.1715512

MoshiulAlam AKM, Beg MDH, Reddy Prasad DM et al (2012) Structures and performances of simultaneous ultrasound and alkali treated oil palm empty fruit bunch fiber reinforced poly(lactic acid) composites. Compos Part A Appl Sci Manuf 43:1921–1929. https://doi.org/10.1016/j.compositesa.2012.06.012

Sadanand V, Rajini N, VaradaRajulu A, Satyanarayana B (2018) Effect of sunlight on the preparation and properties of cellulose/silver nanoparticle composite films by in situ method using ocimum sanctum leaf extract as a reducing agent. Int J Polym Anal Charact 23:313–320. https://doi.org/10.1080/1023666X.2018.1440915

Barkoula NM, Alcock B, Cabrera NO, Peijs T (2008) Flame-retardancy properties of intumescent ammonium poly(phosphate) and mineral filler magnesium hydroxide in combination with graphene. Polym Polym Compos 16:101–113

Santhanam K, Kumaravel A, Saravanakumar SS, Arthanarieswaran VP (2016) Characterization of new natural cellulosic fiber from the Ipomoea staphylina plant. Int J Polym Anal Charact 21:267–274. https://doi.org/10.1080/1023666X.2016.1147654

Indira Devi MP, Nallamuthu N, Rajini N et al (2019) Biodegradable poly(propylene) carbonate using in-situ generated CuNPs coated tamarindus indica filler for biomedical applications. Mater Today Commun 19:106–113. https://doi.org/10.1016/j.mtcomm.2019.01.007

Xiao X, Jiang C, Zhang Y et al (2018) Preparation and characterization of formaldehyde-modified black liquor lignin/poly (propylene carbonate) composites. Int J Polym Anal Charact 23:346–353. https://doi.org/10.1080/1023666X.2018.1449624

Indira Devi MP, Nallamuthu N, Rajini N et al (2019) Antimicrobial properties of poly(propylene) carbonate/Ag nanoparticle-modified tamarind seed polysaccharide with composite films. Ionics (Kiel) 25:3461–3471. https://doi.org/10.1007/s11581-019-02895-9

Vimalanathan P, Venkateshwaran N, Srinivasan SP et al (2018) Impact of surface adaptation and acacia nilotica biofiller on static and dynamic properties of sisal fiber composite. Int J Polym Anal Charact 23:99–112. https://doi.org/10.1080/1023666X.2017.1387689

Mallakpour S, Rashidimoghadam S (2020) Preparation, characterization, and in vitro bioactivity study of glutaraldehyde crosslinked chitosan/poly(vinyl alcohol)/ascorbic acid-MWCNTs bionanocomposites. Elsevier B.V

Arthanarieswaran VP, Kumaravel A, Saravanakumar SS (2015) Characterization of new natural cellulosic fiber from acacia leucophloea bark. Int J Polym Anal Charact 20:367–376. https://doi.org/10.1080/1023666X.2015.1018737

Gan DKW, Loy ACM, Chin BLF et al (2018) Kinetics and thermodynamic analysis in one-pot pyrolysis of rice hull using renewable calcium oxide based catalysts. Bioresour Technol 265:180–190. https://doi.org/10.1016/j.biortech.2018.06.003

Yu Z, Li B, Chu J, Zhang P (2018) Silica in situ enhanced PVA/chitosan biodegradable films for food packages. Carbohydr Polym 184:214–220. https://doi.org/10.1016/j.carbpol.2017.12.043

Saravanakumar SS, Kumaravel A, Nagarajan T et al (2013) Characterization of a novel natural cellulosic fiber from prosopis juliflora bark. Carbohydr Polym 92:1928–1933. https://doi.org/10.1016/j.carbpol.2012.11.064

Gopinath R, Ganesan K, Saravanakumar SS, Poopathi R (2016) Characterization of new cellulosic fiber from the stem of sida rhombifolia. Int J Polym Anal Charact 21:123–129. https://doi.org/10.1080/1023666X.2016.1117712

Sajjan AM, Naik ML, Kulkarni AS et al (2020) Preparation and characterization of PVA-Ge/PEG-400 biodegradable plastic blend films for packaging applications. Chem Data Collect 26:100338. https://doi.org/10.1016/j.cdc.2020.100338

Han Y, Yu M, Wang L (2018) Preparation and characterization of antioxidant soy protein isolate films incorporating licorice residue extract. Food Hydrocoll 75:13–21. https://doi.org/10.1016/j.foodhyd.2017.09.020

Ghaderi J, Hosseini SF, Keyvani N, Gómez-Guillén MC (2019) Polymer blending effects on the physicochemical and structural features of the chitosan/poly(vinyl alcohol)/fish gelatin ternary biodegradable films. Food Hydrocoll 95:122–132. https://doi.org/10.1016/j.foodhyd.2019.04.021

Li J, Zhang J, Natarajan H et al (2019) Modification of agricultural waste tamarind fruit shell powder by in situ generation of silver nanoparticles for antibacterial filler applications. Int J Polym Anal Charact 24:421–427. https://doi.org/10.1080/1023666X.2019.1602319

Swaroop C, Shukla M (2018) Nano-magnesium oxide reinforced polylactic acid biofilms for food packaging applications. Int J Biol Macromol 113:729–736. https://doi.org/10.1016/j.ijbiomac.2018.02.156

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Both the authors of this paper have no financial or personal relationship with other people or organizations that could inappropriately influence or bias the content of the paper. It is specifically stated that “No Competing interests are at stake and there is No Conflict of Interest” with other people or organizations that could inappropriately influence or bias the content of the paper.

Ethical approval

This research meets all applicable standards concerning the ethics of experimentation and research integrity, and the following is being certified/declared true. As an expert researcher and along with co-author of the concerned field, the paper has been submitted with full responsibility, following the due ethical procedure, and there is no duplicate publication, fraud, plagiarism, or concerns about animal or human experimentation. Similarly, another author has seen and approved the manuscript and has contributed significantly to the paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ganesh Babu, A., Saravanakumar, S.S. Mechanical and physicochemical properties of green bio-films from poly(Vinyl Alcohol)/ nano rice hull fillers. Polym. Bull. 79, 5365–5387 (2022). https://doi.org/10.1007/s00289-021-03757-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-021-03757-z