Abstract

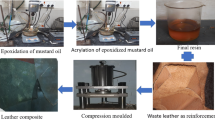

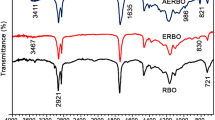

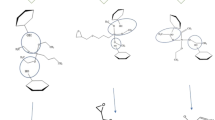

Presently synthesis of edible oil for resin formation and using scrap paper as reinforcement for composite fabrication is still not carried out. In this work, acrylate epoxidized mustard oil (AEMO) was used after blending with a crosslinker N-Vinyl-2-Pyrrolidone (NVP) to fabricate scrap paper reinforced green composites. Mustard oil (MO), Epoxidized mustard oil (EMO) and acrylate epoxidized mustard oil (AEMO) were characterized using iodine value, oxirane content, acid value, FTIR, NMR and viscosity properties. The composites were fabricated using 50:50 ratio of AEMO: NVP and paper loading of 15%, 30% and 60% along with the neat sample. With an increase in paper loading, there was a significant improvement in mechanical properties giving 158.9, 150, 233, 566.66 and 140% improvement in tensile, young’s, flexural strength, flexural moduli and impact strength at 60% loading. The elongation at break showed a value of 20% due to the stiff nature of composite. Biodegradability testing proved an increase in weight loss of composite with time, recording the highest weight loss of 7% for 60% composite sample. Dimensional stability showed excellent result for the neat and lower loaded composite samples. Thermogravimetric and differential scanning colorimetry analysis indicated improvement in thermal stability with higher loading %. Morphological analysis confirmed excellent interfacial adhesion and bonding with higher paper loading %. Dynamic mechanical analysis demonstrated a significant rise in storage modulus (E') and loss modulus (E'') and decline in tan δ with broadening of the peak for maximum loading. Chemical resistance was poor for the highest loaded samples with respect to acids and bases.

Graphic abstract

Similar content being viewed by others

References

Halden RU (2010) Plastics and health risks. Annu Rev Public Health 31:179–194

Zhang C, Garrison TF, Madbouly SA, Kessler MR (2017) Recent advances in vegetable oil-based polymers and their composites. Prog Polym Sci 71:91–143

Hillmyer MA (2008) Polymers from renewable resources: a perspective for a special issue of polymer reviews. Polym Rev 48:1–10

Yao K, Tang C (2013) Controlled polymerization of next-generation renewable monomers and beyond. Macromolecules 46:1689–1712

Yuan L, Wang Z, Trenor NM, Tang C (2015) Robust amidation transformation of plant oils into fatty derivatives for sustainable monomers and polymers. Macromolecules 48:1320–1328

Wang Z, Yuan L, Ganewatta MS, Lamm ME, Rahman MA (2017) Plant oil-derived epoxy polymers toward sustainable biobased thermosets. Macromol Rapid Commun 38:1700009

Crivello JV, Narayan R, Sternstein SS (1997) Fabrication and mechanical characterization of glass fiber reinforced UV-cured composites from epoxidized vegetable oils. J Appl Polym Sci 64(11):2073–2087

Mohanty AK, Misra M, Drzal LT, Kazemizadeh M (2004) Novel soy oil-based polyurethane composites: fabrication and dynamic mechanical properties evaluation. J Mater Sci 39(5):1887–1890

Henna PH, Kessler MR, Larock RC (2008) Fabrication and properties of vegetable-oil-based glass fiber composites by ring-opening metathesis polymerization. Macromol Mater Eng 293(12):979–990

Kale RD, Jadhav NC, Pal S (2019) Fabrication of green composites based on rice bran oil and anhydride cross-linkers. Iran Polym J 28(6):471–482

Laurent F, Houria K, Mylène S, Olivia G, Christine JD, Vincent L, Jean-Jacques R (2013) The use of renewable feedstock in UVcurable materials—a new age for polymers and green chemistry. Prog Polym Sci 38:932–962

Henna P, Larock RC (2009) Novel thermosets obtained by the ring-opening metathesis polymerization of a functionalized vegetable oil and dicyclopentadiene. J Appl Polym Sci 112:1788–1797

Vendamme R, Schüwer N, Eevers W (2014) Recent synthetic approaches and emerging bio-inspired strategies for the development of sustainable pressure-sensitive adhesives derived from renewable building blocks. J Appl Polym Sci 131:8379–8394

Russo D, Dassisti M, Lawlor V, Olabi AG (2012) State of the art of biofuels from pure plant oil. Renew Sustain Energy Rev 16:4056–4070

Lligadas G, Ronda JC, Galia M, Cádiz V (2010) Plant oils as platform chemicals for polyurethane synthesis: current state-ofthe-art. Biomacromol 11:2825–2835

Petrović ZS (2008) Polyurethanes from vegetable oils. Polym Rev 48:109–155

Rangarajan B, Havey A, Grulke EA, Culnan PD (1995) Kinetic parameters of a two-phase model for in situ epoxidation of soybean oil. J Am Oil Chem Soc 72:1161–1169

Sylvain C, Myriam D, Gilles B, Cédric L, Rémi A, Bernard B (2012) Synthesis of new polyester polyols from epoxidized vegetable oils and biobased acids. Eur J Lipid Sci Technol 114:1447–1459

Guo A, Demydov D, Wei Z, Petrovic ZS (2002) Polyols and polyurethanes from hydroformylation of soybean oil. J Polym Environ 10:49–52

Das B, Konwar U, Mandal M, Karak N (2013) Sunflower oil-based biodegradable hyperbranched polyurethane as a thin film material. Ind Crops Prod 44:396–404

Ionescu M, Radojčić D, Wan X, Petrović ZS, Upshaw TA (2015) Functionalized vegetable oils as precursors for polymers by thiolene reaction. Eur Polym J 67:439–448

La SJ, Wool RP (2002) The effect of fatty acid composition on the acrylation kinetics of epoxidized triacylglycerols. J Am Oil Chem Soc 79:59–63

Pelletier H, Belgacem N, Gandini A (2006) Acrylated vegetable oils as photocrosslinkable materials. J Appl Polym Sci 99:3218–3221

Ma S, Li T, Liu X, Zhu J (2016) Research progress on bio-based thermosetting resins. Polym Int 65:164–173

Kolot V, Grinberg S (2010) Vernonia oil–based acrylate and methacrylate polymers and interpenetrating polymer networks with epoxy resins. J Appl Polym Sci 91:3835–3843

Kun L, Samy M, Michael K (2015) Biorenewable thermosetting copolymer based on soybean oil and eugenol. Eur Polym J 69:16–28

Wilbon PA, Tang ChuF, C, (2013) Progress in renewable polymers from natural terpenes, terpenoids, and rosin. Macromol Rapid Commun 34:8–37

Huda MS, Drzal LT, Mohanty AK, Misra M (2006) Chopped glass and recycled newspaper as reinforcement fibers in injection molded poly (lactic acid) (PLA) composites: a comparative study. Compos Sci Technol 66(11–12):1813–1824

Wang H, Liu X, Liu B, Zhang J, Xian M (2009) Synthesis of rosin-based flexible anhydride-type curing agents and properties of the cured epoxy. Polym Int 58:1435–1441

Ma Q, Liu X, Zhang R, Zhu J, Jiang Y (2013) Synthesis and properties of full bio-based thermosetting resins from rosin acid and soybean oil: the role of rosin acid derivatives. Green Chem 15:1300–1310

Yang Y, Shen M, Huang X, Zhang H, Shang S, Song J (2017) Synthesis and performance of a thermosetting resin: acrylated epoxidized soybean oil curing with a rosin-based acrylamide. J Appl Polym Sci 134:44545

Chowdhury K, Banu LA, Khan S, Latif A (2007) Studies on the fatty acid composition of edible oil. Bangladesh J Sci Ind Res 42:311–316

Liu X, Xin W, Zhang J (2009) Rosin-based acid anhydrides as alternatives to petrochemical curing agents. Green Chem 11:1018–1025

Kale RD, Jadhav NC, Pal S (2019) Fabrication of green composites based on rice bran oil and anhydride cross-linkers. Iran Polym J 28:471–482

Sharmin E, Ashraf SM, Ahmad S (2007) Epoxidation, hydroxylation, acrylation and urethanation of Linum usitatissimum seed oil and its derivatives. Eur J Lipid Sci Technol 109(2):134–146

Salih AM, Ahmad MB, Ibrahim NA, Dahlan KZHM, Tajau R, Mahmood MH, Yunus WM, Wan Z (2015) Synthesis of radiation curable palm oil–based epoxy acrylate: NMR and FTIR spectroscopic investigations. Molecules 20(8):14191–14211

Zhang C, Yan M, Cochran EW, Kessler MR (2015) Biorenewable polymers based on acrylated epoxidized soybean oil and methacrylated vanillin. Mater Today Commun 5:18–22

Baştürk E, İnan T, Güngör A (2013) Flame retardant UV-curable acrylated epoxidized soybean oil based organic–inorganic hybrid coating. Prog Org Coat 76(6):985–992

Sahoo SK, Khandelwal V, Gaurav M (2019) Sisal fibers reinforced epoxidized nonedible oils-based epoxy green composites and its potential applications. In: Muthu S (ed) Green composites Textile science and clothing technology. Springer, Singapore

Goud VV, Pradhan NC, Patwardhan AV (2006) Epoxidation of karanja (Pongamia glabra) oil by H2O2. J Am Oil Chem Soc 83:635–640

Dinda S, Patwardhan AV, Goud VV, Pradhan NC (2008) Epoxidation of cottonseed oil by aqueous hydrogen peroxide catalysed by liquid inorganic acids. Bioresour Technol 99:3737–3744

Sathishkumar TP, Navaneethakrishnan P, Shankar O (2012) Tensile and flexural properties of snake grass natural fiber reinforced isophthallic polyester composites. Compos Sci Technol 72(10):1183–1190

Kumar R, Yakubu MK, Anandjiwala RD (2010) Biodegradation of flax fiber reinforced poly lactic acid eXPRESS. Polymer Letters 7:423–430

Jadhav NC, Kale RD (2020) Scrap leather valorization through composite fabrication using mustard oil resin and N-vinyl-2-pyrrolidone. Iran Polym J 29:1–14

Kale RD, Jadhav NC (2019) Utilization of waste leather for the fabrication of composites and to study its mechanical and thermal properties. SN Appl Sci 1:1231

Popa MI, Pernevan S, Sirghie C, Spiridon I, Chambre D, Copolovici DM, Popa N (2013) Mechanical properties and weathering behavior of polypropylene-hemp shives composites. Journal of Chemistry 2013:1–8

Liu W, Chen T, Xie T, Qiu R (2016) Soybean oil-based thermosets with N-vinyl-2-pyrrolidone as crosslinking agent for hemp fiber composites. Compos Part A Appl Sci Manuf 82:1–7

Budtova T, Navard P (2016) Cellulose in NaOH–water-based solvents: a review. Cellulose 23:5–55

Nair KM, Thomas S, Groeninckx G (2001) Thermal and dynamic mechanical analysis of polystyrene composites reinforced with short sisal fibres. Compos Sci Technol 61(16):2519–2529

Acknowledgement

The authors would like to acknowledge the facilities made available by the DST, UGC BSR, Government of India, through FIST and World Bank funded TEQIP-II in completing this research project.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jadhav, N.C., Kale, R.D. Mustard oil thermosets using N-vinyl-2-pyrrolidone as crosslinking agent for scrap paper composites. Polym. Bull. 79, 883–904 (2022). https://doi.org/10.1007/s00289-020-03519-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-020-03519-3