Abstract

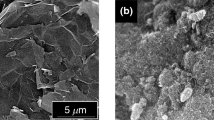

In this work, the effect of low-pressure cold plasma treatment, UV and the incorporation of TiO2 nanoparticles on thermal degradation and flammability of titanium dioxide (TiO2)/polyetherimide (PEI) nanofibers was evaluated. The morphology of nanocomposite fibers was studied using scanning electron microscopy (SEM), Fourier-transform infrared spectroscopy, X-ray photoelectron spectroscope (XPS), thermogravimetric analysis (TGA) and differential scanning calorimetry. SEM images of plasma- and UV-treated nanocomposites show that some samples, e.g., those treated at 248 W and 4 min of exposition, seem more brittle compared with other samples. XPS of treated PEI nanocomposite showed that cold plasma treatment breaks C–C/C–H, C–N and C–O bonds at the surface ether groups leading to an increase in carboxyl and O–C bonds. Moreover, UV treatment breaks C–C/C–H and C–N bonds. Surface modification leads also to changes in thermal stability of PEI nanofibers with a decrease of ~ 4 °C in glass transition temperature (Tg) and a reduction of ~ 200 °C in onset temperature under air compared to pristine PEI nanocomposite. Flammability results measured by pyrolysis-combustion flow calorimeter also showed a decrease in initial degradation temperature and a small increase in total heat released. Furthermore, incorporation of TiO2 nanoparticles leads, as expected, to an improved flame retardancy with a reduction of ~ 40% in peak heat release rate as a function of TiO2 content, but no significant difference was observed in onset degradation temperature observed by TGA. These results show that surface treatments do not significantly change thermal behavior of PEI nanocomposites and could be used for applications that require materials with improved characteristics.

Similar content being viewed by others

References

Courvoisier E, Bicaba Y, Colin X (2018) Multi-scale and multi-technical analysis of the thermal degradation of poly (ether imide). Polym Degrad Stab 147:177–186. https://doi.org/10.1016/j.polymdegradstab.2017.12.002

Pitchan MK, Bhowmik S, Balachandran M, Abraham M (2017) Process optimization of functionalized MWCNT/polyetherimide nanocomposites for aerospace application. Mater Des 127:193–203. https://doi.org/10.1016/j.matdes.2017.04.081

Hatui G, Malas A, Bhattacharya P et al (2015) Effect of expanded graphite and PEI-co-Silicon Rubber on the thermo mechanical, morphological as well as rheological properties of in situ composites based on poly (ether imide) and liquid crystalline polymer. J Alloys Compd 619:709–718. https://doi.org/10.1016/j.jallcom.2014.08.144

Dinari M, Ahmadizadegan H (2014) Synthesis, structural characterization and properties of novel functional poly (ether imide)/titania nanocomposite thin films. Polymer (Guildf) 55:6252–6260. https://doi.org/10.1016/j.polymer.2014.10.021

Hamciuc C, Hamciuc E, Asandulesa M et al (2018) Study on dielectric behavior and harvesting properties of new Ba0.5Sr0.4Ca0.1TiO3/poly(ether imide) composite films. Mater Res Bull 102:70–78. https://doi.org/10.1016/j.materresbull.2018.02.011

Kontou E, Anthoulis G (2007) The effect of silica nanoparticles on the thermomechanical properties of polystyrene. J Appl Polym Sci 105:1723–1731. https://doi.org/10.1002/app

Chrissafis K, Bikiaris D (2011) Can nanoparticles really enhance thermal stability of polymers? Part I: an overview on thermal decomposition of addition polymers. Thermochim Acta 523:1–24. https://doi.org/10.1016/j.tca.2011.06.010

Kiliaris P, Papaspyrides CD (2010) Polymer/layered silicate (clay) nanocomposites: an overview of flame retardancy. Prog Polym Sci 35:902–958. https://doi.org/10.1016/j.progpolymsci.2010.03.001

Wei QF, Gao WD, Hou DY, Wang XQ (2005) Surface modification of polymer nanofibres by plasma treatment. Appl Surf Sci 245:16–20. https://doi.org/10.1016/j.apsusc.2004.10.013

Shapira Y, Chaniel G, Bormashenko E (2018) Surface charging by the cold plasma discharge of lentil and pepper seeds in comparison with polymers. Coll Surf B Biointerfaces 172:541–544. https://doi.org/10.1016/j.colsurfb.2018.09.004

Foroughi Mobarakeh L, Jafari R, Farzaneh M (2018) Robust icephobic, and anticorrosive plasma polymer coating. Cold Reg Sci Technol 151:89–93. https://doi.org/10.1016/j.coldregions.2018.03.009

Pal D, Neogi S, De S (2015) Surface modification of polyacrylonitrile co-polymer membranes using pulsed direct current nitrogen plasma. Thin Solid Films 597:171–182. https://doi.org/10.1016/j.tsf.2015.11.050

Pasini SM, Valério A, Ulson Guelli, de Souza SMA et al (2019) Plasma-modified TiO2/polyetherimide nanocomposite fibers for photocatalytic degradation of organic compounds. J Environ Chem Eng 7:103213. https://doi.org/10.1016/j.jece.2019.103213

Içoglu HI, Ogulata RT (2013) Effect of Ambient Parameters on Morphology of Electrospun Polyetherimide (PEI) Fibers. Tekst ve Konf 23:313–318

Zhu H, Du M, Zhang M et al (2013) Facile fabrication of AgNPs/(PVA/PEI) nanofibers: high electrochemical efficiency and durability for biosensors. Biosens Bioelectron 49:210–215. https://doi.org/10.1016/j.bios.2013.04.016

Wang H, Zhang S, Zhu M et al (2018) Remarkable heat-resistant halloysite nanotube/polyetherimide composite nanofiber membranes for high performance gel polymer electrolyte in lithium ion batteries. J Electroanal Chem 808:303–310. https://doi.org/10.1016/j.jelechem.2017.12.034

Hu D, Xiao Y, Liu H et al (2018) Loading of Au/Ag bimetallic nanoparticles within electrospun PVA/PEI nanofibers for catalytic applications. Coll Surf A 552:9–15. https://doi.org/10.1016/j.colsurfa.2018.05.013

Zeytuncu B, Ürper M, Koyuncu İ, Tarabara VV (2018) Photo-crosslinked PVA/PEI electrospun nanofiber membranes: preparation and preliminary evaluation in virus clearance tests. Sep Purif Technol 197:432–438. https://doi.org/10.1016/j.seppur.2018.01.002

Guo Y, Wang R, Wang P et al (2017) Developing polyetherimide/graphitic carbon nitride floating photocatalyst with good photodegradation performance of methyl orange under light irradiation. Chemosphere 179:84–91. https://doi.org/10.1016/j.chemosphere.2017.03.085

Ben Ameur S, Hadjltaief BH, Barhoumi A et al (2018) Physical investigations and photocatalytic activities on ZnO and SnO2 thin films deposited on flexible polymer substrate. Vacuum 155:546–552. https://doi.org/10.1016/j.vacuum.2018.05.051

Kaleekkal NJ, Radhakrishnan R, Sunil V et al (2018) Performance evaluation of novel nanostructured modified mesoporous silica/polyetherimide composite membranes for the treatment of oil/water emulsion. Sep Purif Technol 205:32–47. https://doi.org/10.1016/j.seppur.2018.05.007

Zhang W, Camino G, Yang R (2017) Polymer/polyhedral oligomeric silsesquioxane (POSS) nanocomposites: an overview of fire retardance. Prog Polym Sci 67:77–125. https://doi.org/10.1016/j.progpolymsci.2016.09.011

Sikarwar S, Yadav BC, Sonker RK et al (2019) Synthesis and characterization of highly porous hexagonal shaped CeO2-Gd2O3-CoO nanocomposite and its opto-electronic humidity sensing. Appl Surf Sci 479:326–333. https://doi.org/10.1016/j.apsusc.2019.02.108

Mann JR, Bhattacharya RN (2010) Thin film growth of epitaxial gadolinium oxide, gadolinium yttrium oxide, and gadolinium cerium oxide by electrodeposition. Thin Solid Films 519:210–213. https://doi.org/10.1016/j.tsf.2010.07.109

Sonker RK, Rahul Sabhajeet SR (2018) ZnO nanoneedle structure based dye-sensitized solar cell utilizing solid polymer electrolyte. Mater Lett 223:133–136. https://doi.org/10.1016/j.matlet.2018.03.199

Sonker RK, Sikarwar S, Sabhajeet SR et al (2018) Spherical growth of nanostructures ZnO based optical sensing and photovoltaic application. Opt Mater (Amst) 83:342–347. https://doi.org/10.1016/j.optmat.2018.06.046

Sonker RK, Yadav BC, Gupta V, Tomar M (2019) Fabrication and characterization of ZnO-TiO2-PANI (ZTP) micro/nanoballs for the detection of flammable and toxic gases. J Hazard Mater 370:126–137. https://doi.org/10.1016/j.jhazmat.2018.10.016

Duncan E, Owens G (2019) Metal oxide nanomaterials used to remediate heavy metal contaminated soils have strong effects on nutrient and trace element phytoavailability. Sci Total Environ 678:430–437. https://doi.org/10.1016/j.scitotenv.2019.04.442

El Mragui A, Daou I, Zegaoui O (2019) Influence of the preparation method and ZnO/(ZnO + TiO2) weight ratio on the physicochemical and photocatalytic properties of ZnO-TiO2 nanomaterials. Catal Today 321–322:41–51. https://doi.org/10.1016/j.cattod.2018.01.016

Li P, Guo M, Wang Q et al (2019) Controllable synthesis of cerium zirconium oxide nanocomposites and their application for photocatalytic degradation of sulfonamides. Appl Catal B Environ. https://doi.org/10.1016/j.apcatb.2019.118107

El-Shafai NM, El-Khouly ME, El-Kemary M et al (2019) Fabrication and characterization of graphene oxide–titanium dioxide nanocomposite for degradation of some toxic insecticides. J Ind Eng Chem 69:315–323. https://doi.org/10.1016/j.jiec.2018.09.045

Ahmed L, Zhang B, Hatanaka LC, Mannan MS (2018) Application of polymer nanocomposites in the flame retardancy study. J Loss Prev Process Ind 55:381–391. https://doi.org/10.1016/j.jlp.2018.07.005

Hatanaka LC, Wang Q, Cheng Z, Mannan MS (2017) Effect of trimethylolpropane triacrylate cross-linkages on the thermal stability and char yield of poly (methyl methacrylate) nanocomposites. Fire Saf J 87:65–70. https://doi.org/10.1016/j.firesaf.2016.12.004

Morgan AB, Putthanarat S (2011) Use of inorganic materials to enhance thermal stability and flammability behavior of a polyimide. Polym Degrad Stab 96:23–32. https://doi.org/10.1016/j.polymdegradstab.2010.11.005

Zhu P, Liu B, Bao L (2018) Evaporation-induced surface coating of poly(p-phenylene benzobisoxazole) fibers with polyetherimide encapsulated nano-TiO2. Prog Org Coatings 116:43–50. https://doi.org/10.1016/j.porgcoat.2017.11.017

Gleich H, Criens RM, Mosl HG, Leute U (1989) The influence of plasma treatment on the surface properties of high- performance thermoplastics. Int J Adhes Adhes 9:88–94

Sharma M, Tiwari S, Bijwe J (2010) Optimization of material parameters for development of polyetherimide composites. Mater Sci Eng B 168:55–59. https://doi.org/10.1016/j.mseb.2009.10.018

Farong H, Xueqiu W, Shijin L (1987) The thermal stability of polyetherimide. Polym Degrad Stab 18:247–259

Carroccio S, Puglisi C, Montaudo G (1999) Thermal degradation mechanisms of polyetherimide investigated by direct pyrolysis mass spectrometry. Macromol Chem Phys 200:2345–2355

Zaragoza S, Álvarez A, Álvarez B et al (2015) Thermogravimetric study of thermal degradation of polyetherimide. J Appl Polym Sci 42329:1–8. https://doi.org/10.1002/app.42329

Amancio-filho ST, Roeder J, Nunes SP et al (2008) Thermal degradation of polyetherimide joined by friction riveting (FricRiveting). Part I: influence of rotation speed. Polym Degrad Stab 93:1529–1538. https://doi.org/10.1016/j.polymdegradstab.2008.05.019

ASTM D7309-13 (2013) Standard test method for determining flammability characteristics of plastics and other solid materials using microscale combustion calorimetry. ASTM International, West Conshohocken

Favvas EP, Stefanopoulos KL, Nolan JW et al (2014) Mixed matrix hollow fiber membranes with enhanced gas permeation properties. Sep Purif Technol 132:336–345. https://doi.org/10.1016/j.seppur.2014.05.013

Shin S, Jang J, Yoon SH, Mochida I (1997) A study on the effect of heat treatment on functional groups of pitch based activated carbon fiber using FTIR. Carbon N Y 35:1739–1743

Kuroda S, Mita I (1989) Degradation of aromatic polymers-II. The crosslinking during thermal a n d thermo-oxidative degradation of a polyimide. Eur Polym J 25:611

Koley T, Bandyopadhyay P, Mohanty AK, Banerjee S (2013) Synthesis and characterization of new aromatic poly(ether imide)s and their gas transport properties. Eur Polym J 49:4212–4223. https://doi.org/10.1016/j.eurpolymj.2013.10.001

Soler-Illia GJAA, Louis A, Sanchez C (2014) Synthesis and characterization of mesostructured titania-based materials through evaporation-induced self-assembly. Chem Mater 14:750–759

Chang GQ, Zheng X, Chen RY et al (2008) Silver nanoparticles filling in TiO2 hollow nanofibers by coaxial electrospinning. Acta Phys Chim Sin 24:1790–1796. https://doi.org/10.1016/S1872-1508(08)60073-X

Yu JC, Zhang L, Zheng Z, Zhao J (2003) Synthesis and characterization of phosphated mesoporous titanium dioxide with high photocatalytic activity. Chem Mater 15:2280–2286

Moulder JF, Stickle WF, Sobol PE, Bomben KD (1992) Handbook of X-ray photoelectron spectroscopy. Perkin-Elmer, Eden Prairie

Vandencasteele N, Reniers F (2010) Plasma-modified polymer surfaces: characterization using XPS. J Electron Spectros Relat Phenomena 178–179:394–408. https://doi.org/10.1016/j.elspec.2009.12.003

Kim CH, Kim BH, Yang KS (2012) TiO2 nanoparticles loaded on graphene/carbon composite nanofibers by electrospinning for increased photocatalysis. Carbon 50:2472–2481. https://doi.org/10.1016/j.carbon.2012.01.069

Huang Z, Xue K, Zhang Y et al (2017) TiO2 hybrid material film with high CO2 adsorption for CO2 photoreduction. J Alloys Compd 729:884–889. https://doi.org/10.1016/j.jallcom.2017.09.142

Wu N, Wang Y, Lei Y et al (2014) Flexible N-doped TiO2/C ultrafine fiber mat and its photocatalyticactivity under simulated sunlight. Appl Surf Sci 319:136–142. https://doi.org/10.1016/j.apsusc.2014.06.108

Yu D, Bai J, Liang H, Li C (2016) Electrospinning, solvothermal, and self-assembly synthesis of recyclable and renewable AgBr-TiO2/CNFs with excellent visible-light responsive photocatalysis. J Alloys Compd 683:329–338. https://doi.org/10.1016/j.jallcom.2016.05.103

Wu H, Wang L, Zhou J et al (2016) Facile preparation of porous In2TiO5-rutile composite nanotubes by electrospinning and sensitivity enhancement in NO2 gas at room temperature. J Colloid Interface Sci 466:72–79. https://doi.org/10.1016/j.jcis.2015.12.020

Lyon RE, Walters RN (2004) Pyrolysis combustion flow calorimetry. J Anal Appl Pyrolysis 71:27–46. https://doi.org/10.1016/S0165-2370(03)00096-2

Schartel B, Pawlowski KH, Lyon RE (2007) Pyrolysis combustion flow calorimeter: a tool to assess flame retarded PC/ABS materials? Thermochim Acta 462:1–14. https://doi.org/10.1016/j.tca.2007.05.021

Sonnier R, Vahabi H, Ferry L, Lopez-Cuesta JM (2012) Pyrolysis-combustion flow calorimetry: a powerful tool to evaluate the flame retardancy of polymers. ACS Symp Ser 1118:361–390. https://doi.org/10.1021/bk-2012-1118.ch024

Yang CQ, He Q, Lyon RE, Hu Y (2010) Investigation of the flammability of different textile fabrics using micro-scale combustion calorimetry. Polym Degrad Stab 95:108–115. https://doi.org/10.1016/j.polymdegradstab.2009.11.047

Courtat J, Melis F, Taulemesse J et al (2015) Effect of phosphorous-modified silica on the flame retardancy of polypropylene based nanocomposites. Polym Degrad Stab 119:260–274. https://doi.org/10.1016/j.polymdegradstab.2015.05.022

Vahabi H, Lin Q, Vagner C et al (2016) Investigation of thermal stability and flammability of poly (methyl methacrylate) composites by combination of APP with ZrO2, sepiolite or MMT. Polym Degrad Stab 124:60–67. https://doi.org/10.1016/j.polymdegradstab.2015.12.004

Hapuarachchi TD, Peijs T (2010) Multiwalled carbon nanotubes and sepiolite nanoclays as flame retardants for polylactide and its natural fibre reinforced composites. Compos Part A 41:954–963. https://doi.org/10.1016/j.compositesa.2010.03.004

Friederich B, Laachachi A, Ferriol M et al (2012) Investigation of fire-resistance mechanisms of the ternary system (APP/MPP/TiO2) in PMMA. Polym Degrad Stab 97:2154–2161. https://doi.org/10.1016/j.polymdegradstab.2012.08.013

Carroccio S, Puglisi C, Montaudo G (2003) Photo-oxidation products of polyetherimide ULTEM determined by MALDI-TOF-MS. Kinetics and mechanisms. Polym Degrad Stab 80:459–476. https://doi.org/10.1016/S0141-3910(03)00030-2

Lisa G, Hamciuc C, Hamciuc E, Tudorachi N (2016) Thermal and thermo-oxidative stability and probable degradation mechanism of some polyetherimides. J Anal Appl Pyrolysis 118:144–154. https://doi.org/10.1016/j.jaap.2016.01.012

Perng LH (2001) Thermal degradation mechanism of poly(ether imide) by stepwise Py–GC/MS. J Appl Polym Sci 79:1151–1161

Saimani S, Kumar A, Dal-Cin MM, Robertson G (2011) Synthesis and characterization of bis (4-maleimidophenyl) fluorene and its semi interpenetrating network membranes with polyether imide (Ultem® 1000). J Memb Sci 374:102–109. https://doi.org/10.1016/j.memsci.2011.03.020

Carroccio S, Puglisi C, Montaudo G (2005) New vistas in polymer degradation. thermal oxidation processes in poly (ether imide). Macromolecules 38:6849–6862. https://doi.org/10.1021/ma0502349

Pitchan KM, Bhowmik S, Balachandran M, Abraham M (2016) Effect of surface functionalization on mechanical properties and decomposition kinetics of high performance polyetherimide/MWCNT nano composites. Compos Part A 90:147–160. https://doi.org/10.1016/j.compositesa.2016.06.025

Lopez-Cuesta JM (2012) Flame-retardant polymer nanocomposites. Woodhead Publishing Limited, Sawston

Mylläri V, Ruoko TP, Järvelä P (2014) The effects of UV irradiation to polyetheretherketone fibres—Characterization by different techniques. Polym Degrad Stab 109:278–284. https://doi.org/10.1016/j.polymdegradstab.2014.08.003

He W, Zhu H, Xiang Y et al (2017) Enhancement of flame retardancy and mechanical properties of polyamide 6 by incorporating an aluminum salt of diisobutylphosphinic combined with organoclay. Polym Degrad Stab 144:442–453. https://doi.org/10.1016/j.polymdegradstab.2017.09.003

Acknowledgements

This study was financed in part by the Brazilian Coordination for the Improvement of Higher Education Personnel (CAPES) (Grant No. 2)-Finance Code 001, and National Council of Scientific and Technological Development (CNPq) (Grant No. 1). Finally, the authors are grateful to Ismael Graff for assistance on XPS equipment operation at the Federal University of Paraná (UFPR).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pasini, S.M., Batistella, M.A., de Souza, S.M.A.G.U. et al. Thermal degradation and flammability of TiO2–polyetherimide nanocomposite fibers. Polym. Bull. 77, 4937–4958 (2020). https://doi.org/10.1007/s00289-019-02970-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-019-02970-1