Abstract

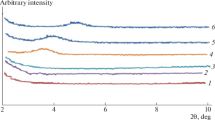

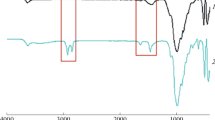

Sodium and organic modified montmorillonite (MMT) clays were used to prepare poly(vinyl acetate)-based nanocomposites through a semi-continuous emulsion polymerization process. Poly(vinyl alcohol) (PVOH) in aqueous solution (7.5 and 10 wt% based on monomer), ammonium persulfate and sodium bicarbonate acted as polymeric stabilizer, initiator and pH regulator, respectively. The stabilization of the system was provided only by PVOH, with no additional surfactant. The materials were characterized by dynamic light scattering (DLS), transmission electron microscopy (TEM), dynamic-mechanical analysis (DMA), thermogravimetric analysis (TGA), and X-ray diffraction (XRD). Results showed that latexes prepared with 10 wt% PVOH presented better colloidal stability compared to the ones synthesized with 7.5 wt%. The coagulum content of hybrid latexes prepared with 10 wt% PVOH were lower than 0.1%, and the presence of clay reduced the coagulum content up to 50% in comparison with pure PVAc. The reaction kinetics and the final properties of the hybrid materials were influenced by the presence of clay. Lower monomer conversion was observed at initial stages of polymerization when more hydrophobic clays were used. Hybrid latexes with reduced particle size and low viscosity were obtained at the end of polymerizations performed in the presence of MMT. The polydispersity of pure and hybrid latexes was observed in both DLS and TEM. The hybrid films exhibited improved mechanical and thermal properties, as deduced from DMA and TGA results, respectively. XRD measurements showed that nanocomposites with intercalated structures were formed when hybrid latexes were synthesized with organic modified MMT, whereas exfoliated structure was obtained when preparing the latex with sodium MMT. The hybrid materials with improved physicochemical, mechanical and thermal properties obtained in this study may represent a new approach to preparing waterborne polymer for several relevant industrial application, such as adhesives.

Similar content being viewed by others

References

Alexandre M, Dubois P (2000) Polymer-layered silicate nanocomposites: preparation, properties and uses of a new class of materials. Mater Sci Eng 28:1–63

Zhang J, Wilkie CA (2004) A carbocation substituted clay and its styrene nanocomposite. Polym Deg Stab 83:301–307

Moraes RP, Santos AM, Oliveira PC, Souza FCT, Amaral M, Valera TS, Demarquette NR (2006) Poly(styrene-co-butyl acrylate)-Brazilian montmorillonite nanocomposites, synthesis of hybrid latexes via miniemulsion polymerization. Macromol Symp 245:106–115

Moraes RP, Valera TS, Demarquette NR, Oliveria PC, Silva MLCP, Santos AM (2009) Influence of granulometry and organic treatment of a Brazilian montmorillonite on the properties of poly(styrene-co-butyl acrylate)/layered silicate nanocomposites prepared by miniemulsion polymerization. J Appl Polym Sci 12:1949–1958

Moraes RP, Valera TS, Pereira AMC, Demarquette NR (2011) Influence of the type of quaternary ammonium slat used in the organic treatment of montmorillonite on the properties of poly(styrene-co-butyl acrylate)/layered silicate nanocomposite prepared by in situ miniemulsion polymerization. J Appl Polym Sci 119:3658–3669

Fecchio BD, Valandro SR, Neumann MG, Cavalheiro CCS (2016) Thermal decomposition of polymer/montmorillonite nanocomposites synthesized in situ on a clay surface. J Braz Chem Soc 27:278–284

Pasquale G, Pollicino A (2015) PMMA/o-MMT nanocomposites obtained using thermally stable surfactants. J Appl Polym Sci 41393:1–9

Abd El-Ghaffar MA, Youssef AM, Abd El-Hakin AA (2015) Polyaniline nanocomposites via in situ emulsion polymerization based on montmorillonite: preparation and characterization. Arab J Chem 8:771–779

Youssef AM, Malhat FM, Abdel Hakin AA, Dekany I (2017) Synthesis and utilization of poly (methylmethacrylate) nanocomposites based on modified montmorillonite. Arab J Chem 10:631–642

Youssef AM, Youssef M, Abd El-Aziz ME, Ayad DM, Sarhan AA (2016) Novel polystyrene nanocomposites based on Na+ montmorillonite for removing organochlorine pesticide from wastewater. KGK KAUT GUMMI KUNST 69:43–48

Bourgeat-Lami E, Guimaraes TR, Pereira AMC, Alves GM, Moreira JC, Putaux JL, Santos AM (2010) High solids content, soap-free, film-forming latexes stabilized by laponite clay platelets. Macromol Rapid Commun 31:1874–1880

Guimaraes TR, Chaparro TC, D’Agosto F, Lansalot M, Santos AM, Bourgeat-Lami E (2014) Synthesis of multi-hollow clay-armored latexes by surfactant-free emulsion polymerization of styrene mediated by poly(ethylene oxide)-based macroRAFT/Laponite complexes. Polym Chem 5:6611–6622

Brunier B, Sheibat-Othman N, Chniguir M, Chevalier Y, Bourgeat-Lami E (2016) Investigation of four different laponite clays as stabilizers in Pickering emulsion polymerization. Lagmuir 32:6046–6057

Abdel Rehim MH, Youseff AM, Essawy HA (2010) Hybridization of kaolinite by consecutive intercalation: preparation and characterization of hyperbranched poly(amidoamine)-kaolinite nanocomposites. Mat Chem Phys 119:546–552

Corobea MC, Uricanu VI, Donescu D, Radovici C, Serban S, Garea S, Iovu H (2007) Poly(vinyl acetate)-clay hybrids prepared via emulsion polymerization, assisted by a nonionic surfactant. Mater Chem Phys 103:118–126

Diaconu G, Paulis M, Leiza JR (2008) High solids content waterborne acrylic/montmorillonite nanocomposites by miniemulsion polymerization. Macromol React Eng 4:80–89

Cui HW, Du GB (2013) Synthesis and characterization of PVAc-MMT-DOAB exfoliated nanocomposites: reducing polymerization time and water in the system. Adv In Polym Tech 32:21343

Cui HW, Fang Q, Du GB (2014) Exfoliated nanocomposites of polyvinyl acetate-N-hydroxymethyl acrylamide and intercalated montmorillonite from an octadecyl trimethyl ammonium bromide surfactant. Polym Plast Technol Eng 53:961–968

Cui HW, Du GB (2013) Influence of synthesis processes on the properties of PVAc-MMT-STAB exfoliated nanocomposites. Polym Plast Technol Eng 52:571–580

Cui HW, Du GB (2014) Rheology of exfoliated nanocomposite of polyvinyl acetate and organic montmorillonite synthesized by different process. Polym Bull 71:659–972

Mohsen-Nila M, Doulabi FSM (2011) Synthesis and characterization of polyvinyl acetate/montmorillonite nanocomposite by in situ emulsion polymerization technique. Polym Bull 66:1255–1265

Mohsen-Nila M, Doulabi FSM (2012) Preparation and characterization of exfoliated poly(vinyl acetate-co-methyl acrylate)/Cloisite 30B nanocomposite. Polym Bull 68:1663–1675

Sahu M, Samal R, Biswal T, Sahoo PK (2014) Synthesis and characterization of poly(vinyl acetate)/MMT nanocomposite flame retardant. Int J Mater Sci 4:91–98

Gerasin VA, Kurenkov VV, Pashkov OV, Ilyin SO (2017) Structure and rheology of aqueous poly(vinyl acetate) dispersions modified with montmorillonite. Colloid J 79:588–595

Yamak HB (2010) In: Yilmaz F (ed) Emulsion polymerization: effects of polymerization variables on the properties of vinyl acetate based emulsion polymers. Rijeka, InTech, pp 35–72

Guyot A, Chu F, Schneider M, Graillat C, Mckenna TF (2002) High solids content latexes. Prog Polym Sci 27:1573–1615

Carra S, Sliepcevich A, Canevarolo A, Carra S (2005) Grafting and adsorption of poly(vinyl) alcohol in vinyl acetate emulsion polymerization. Polymer 46:1379–1384

Budhall BM, Sudol ED, Dimonie VL, Klein A, El-Aasser MS (2001) Role of grafting in the emulsion polymerization of vinyl acetate with poly(vinyl alcohol) as an emulsifier. I. Effect of the degree of blockiness on the kinetics and mechanism of grafting. J Pol Sci A Polym Chem 39:3633–3654

Xing J, Xu Z, Deng B (2018) Enhanced oxidation resistance of polyphenylene sulfide composites based on montmorillonite modified by benzimidazolium salt. Polymers 10:83. https://doi.org/10.3390/polym10010083

Morgan AB, Gilman JW (2003) Characterization of polymer-layered silicate (clay) nanocomposites by transmission electron microscopy and x-ray diffraction: a comparative study. J Appl Polym Sci 87:1329–1338

Ray SS, Okamoto M (2003) Polymer/layered silicate nanocomposites: a review from preparation to processing. Prog Polym Sci 28:1539–1641

Ajayan P, Shcadler LS, Braun PV (2003) Nanocomposite science technology, 1st edn. Wiley, Weinheim

Mansenelli-Varlot K, Vigier G, Vermogen A, Gauthier C, Cavaille JY (2007) Quantitative structural characterization of polymer-clay nanocomposites and discussion of an “ideal” microstructure, leading to the highest mechanical reinforcement. J Polym Sci B 45:1243–1251

Pinnavaia TJ, Beall GW (2000) Polymer-clay nanocomposites, 1st edn. Wiley, New York

Manias E, Chen H, Krishnamoorti R, Genzer J, Kramer EJ, Giannelis EP (2000) Intercalation kinetics of long polymers in 2 nm confinements. Macromolecules 33:7955–7966

Xi Y, Ding Z, He H, Frost RL (2004) Structure of organoclays—an X-ray diffraction and thermogravimetric analysis study. J Colloid Interface Sci 277:116–120

Noh M, Lee DC (1999) Synthesis and characterization of PS-clay nanocomposite by emulsion polymerization. Polym Bull 42:619–626

Yeh JM, Huang HY, Chen CL, Su WF, Yu YH (2006) Siloxane-modified epoxy resin-clay nanocomposite coatings with advanced anticorrosive properties prepared by a solution dispersion approach. Surf Coat Technol 200:2753–2763

Choi YS, Xu M, Chung IJ (2005) Synthesis of exfoliated acrylonitrile-butadiene-styrene copolymer (ABS) clay nanocomposites: role of clays as a colloidal stabilizer. Polymer 46:531–538

Choi YS, Wang KH, Xu M, Chung IJ (2002) Synthesis of exfoliated polyacrylonitrile/Na-MMT nanocomposites via emulsion polymerization. Chem Mater 14:2936–2939

Kim YK, Choi YS, Wang KH, Chung IJ (2002) Synthesis of exfoliated PS/Na-MMT nanocomposites via emulsion polymerization. Chem Mater 14:4990–4995

Blazevska-Gilev J, Spaseska D (2005) Thermal degradation of PVAc. J Chem Technol Metall 40:287–290

Kim MS, Kim DW, Chowdhury SR, Kim GH (2006) Melt-compounded butadiene rubber nanocomposites with improved mechanical properties and abrasion resistance. J Appl Polym Sci 102:2062–2066

McNeill IC, McGuiness RC (1983) The effect of zinc bromide on the thermal degradation of poly(vinyl acetate). Polym Deg and Stab 5:303–316

Anders H, Zimmermann H (1987) A comparison of the thermal degradation behaviours of poly(vinyl acetate), poly(vinyl alcohol) and poly(vinyl chloride). Polym Deg and Stab 18:111–122

Costa L, Avataneo M, Bracco P, Brunella V (2002) Char formation in polyvinyl polymers I.Polyvinyl acetate. Polym Deg Stab 77:503–510

Rimez B, Rahier H, Van Assche G, Artoos T, Biesemans M, Van Mele B (2008) The thermal degradation of poly(vinyl acetate) and poly(ethylene-co-vinyl acetate), Part I: experimental study of the degradation mechanism. Polym Deg Stab 93:800–810

Acknowledgements

The authors would like to thank FAPESP for supporting this research and Hexion, Celanese and Southern Clay Products for supplying VAc, PVOH and MMT, respectively.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cazotti, J.C., Salvato, R.C.P.J.S., Alves, G.M. et al. Effect of clay type on the properties of hybrid latexes of poly(vinyl acetate) and montmorillonite prepared via surfactant-free emulsion polymerization. Polym. Bull. 76, 6305–6325 (2019). https://doi.org/10.1007/s00289-019-02708-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-019-02708-z