Abstract

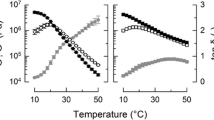

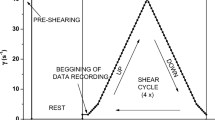

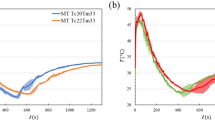

In view of the significant differences in spinnability, BASF PA6 chips (BASF, Germany, stable in high-speed spinning) and domestic PA6 chips (GC, China, unstable in high-speed spinning) were employed. The screw extrusion process of PA6 melt in high-speed spinning was simulated by capillary rheometer, with the aid of which shear rheology and extensional rheology of PA6 chips were both investigated deeply. To determine suitable and reliable experimental conditions, the influencing factors including moisture of PA6 chips, capillary disassembly and experiment repeatability on rheological results were also discussed. The moisture of PA6 chips is confirmed to be a crucial factor and the shear viscosity and extensional viscosity of GC chips are both greater than that of BASF chips. Moreover, the shear viscosity of GC chips increases with the extension of melting time, while that of BASF chips is basically unchanged, showing good spinnability in high-speed spinning.

Similar content being viewed by others

References

Zhu SF, Shi MW, Zhu MF (2013) Thermal and anti-dripping properties of γ-irradiated PA6 fiber with the presence of sensitizers. Mate Lett 99:28–30

Stephen MK, Bucknall DG (2005) Microstructural characterisation of surfactant treated nylon fibres. Polymer 46:11424–11434

Razafimahefa L, Sabine Chlebicki, Vroman I et al (2005) Effect of nanoclay on the dyeing ability of PA6 nanocomposite fibers. Dyes Pigments 66:55–60

Bowling JF (1960) Process for producing crimpable polyamide filaments:USA, US2957747[P]

Koyama K, Suryadevara J, Spuriell JE (1986) Effect of molecular weight on high-speed melt spinning of nylon 6. J Appl Polym Sci 31:2203–2229

Griswold PH, Cuculo JA (1974) An experimental study of the relationship between rheological properties and spinnability in the dry spinning of cellulose acetate-acetone solutions. J Appl Polym Sci 18:2887–2902

Chang TK, John C (1992) Influence of Polymer Characteristics and melt-spinning conditions on the production of fine denier poly (Ethylene Terephthalate) fibers (part 1: rheological characterization of PET polymer melt fibers. J Appl Polym Sci 46:55–65

Jiang ZH, Jia Z, Li ZY et al (2014) A comparative study of rheological behavior of PET and PET/carbon black composite masterbatch. Polym Bull 71:3197–3208

Tsou SY, Lin HS, Cheng PJ et al (2007) Rheological aspect on electrospinning of polyamide 6 solutions. Eur Polym J 43:3619–3629

Cogswell FN (1972) Converging flow of polymer melts in extrusion dies. Polym Eng Sci 12:64–73

Binding DM, Walters K (1988) On the use of flow through a contraction in estimating the extensional viscosity of mobile polymer solutions. J Non-newton Fluid 30:233–250

Binding DM (1988) An approximate analysis for contraction and converging flows. J Non-newton Fluid 27:173–189

Khanna YP, Han PK, Day ED (1996) New developments in the melt rheology of nylons. I: effect of moisture and molecular weight. Polym Eng Sci 36:1745–1754

Carreras ES, Kissi NE, Piau JM et al (2006) Pressure effects on viscosity and flow stability of polyethylene melts during extrusion. Rheol Acta 45:209–222

Wang QJ, Huang HX (2013) Detecting extensional viscosity of polypropylene melt using the Rheotens test: a comparison between standard and steady state test modes. Polym Test 32:1400–1407

Acknowledgements

The authors gratefully acknowledge the financial support of the Doctoral Scientific Research Funds of Shandong University of Technology (4041-413047), Shandong Province Higher Educational Science and Technology Program (J14LA56), Shandong Provincial Natural Science Foundation, China (ZR2014EMP004), and the Open Project Program of the Key Laboratory of Eco-Textiles, Ministry of Education, Jiangnan University (No. KLET1401).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiang, Z., Li, C., Tian, M. et al. Rheological properties of PA6 chips with different spinnability in high-speed spinning. Polym. Bull. 74, 2787–2797 (2017). https://doi.org/10.1007/s00289-016-1865-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-016-1865-2