Abstract

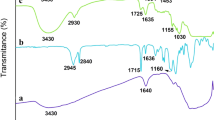

In this study, the in situ incorporation of the inorganic alumina nanoparticles into the reactants of tetraglycidyl-4, 4′-diaminodiphenylmethane (TGDDM) epoxy resin represented an efficient way for the preparation of alumina/TGDDM nanocomposite. The surface modification of the alumina nanoparticles was carried out using two individual silane coupling agents, namely, aminopropyltriethoxysilane (APS) and glycidoxypropyltrimethoxysilane (GPS). The degree of silane grafting was evaluated for both coupling agents using FTIR spectroscopy and thermogravimetric analysis. The epoxy equivalent weight (EEW) of the epoxy resin in addition to the weight percentage of the lost nanoparticles during TGDDM polymerization was used as measurements of the polymerization yield. The neat nano alumina has more adverse effect on the epoxy EEW value (171 g/mol) than both silane-modified nano alumina (143–157 g/mol, depending on the reaction conditions). The degree of nano alumina dispersion in the epoxy matrix was investigated using SEM micrographs. The longer and more deflected crack pathways on the fractured surface of the alumina/TGDDM nanocomposites may be attributed to a relatively good degree of dispersion of the silane-modified alumina nanoparticles in the epoxy matrix. Compared to neat alumina, the better dispersion of the silane-modified alumina nanoparticles may be related to the improved interfacial interactions between the oxiran or amine groups available on the silane-modified alumina nanoparticles and the TGDDM epoxy functional groups. Besides, the higher exothermic heat of cure (i.e., 30–53 %) as evidenced in differential scanning calorimetry may be due to a rather good state of dispersion of silane-modified alumina nanoparticles.

Similar content being viewed by others

References

Hergenrother PM, Thompson CM, Smith JG, Connell JW, Hinkley JA, Lyon RE (2005) Flame retardant aircraft epoxy resins containing phosphorus. Polymer 46(14):5012–5024

Park SJ, Jin FL (2004) Thermal stabilities and dynamic mechanical properties of sulfone-containing epoxy resin cured with anhydride. Poly Deg Stab 86:515–520

Park SJ, Jin FL, Lee JR (2004) Thermal and mechanical properties of tetrafunctional epoxy resin toughened with epoxidized soybean oil. Mater Sci Eng A 374:109–114

Dittanet P, Pearson RA (2012) Effect of silica nano particle size on toughening mechanisms of filled epoxy. Polymer 53:1890–1905

Gao J, Li J, Zhao S, Benicewicz BC, Hillborg H, Schadler LS (2013) Effect of graft density and molecular weight on mechanical properties of rubbery block copolymer grafted SiO2 nano particle toughened epoxy. Polym 54:3961–3973

Azeez AA, Rhee KY, Park SJ, Hui D (2013) Epoxy clay nanoparticles-processing properties and application: a review. Compos Part B Eng 45:308–320

Datta J, Marcin W (2014) Selected biotrends in development of epoxy resins and their composites. Polym Bull 71:3035–3049

Mustata F, Bicu I (2000) Multifunctional epoxy resins: synthesis and characterization. J Appl Polym Sci 77(11):2430–2436

Meenakshi KS, Sudhan EPJ (2011) Development of novel TGDDM epoxy nanocomposites for aerospace and high performance applications—study of their thermal and electrical behaviour. Ara J Chem 9(1):79–85

Anbazhagan S, Alagar M, Gnanasundaram P (2011) Synthesis and characterization of organic-inorganic hybrid clay filled and bismaleimide-siloxane modified epoxy nanocomposites. Int J Plas Tech 15(S1):30–45

Sanctuary R, Baller J, Zielinski B, Becker N, Kruger JK, Philipp M, Muller U, Ziehmer M (2009) Influence of Al2O3 nano particles on the isothermal cure of an epoxy resin. J Phys Condens Matte Inst Phys J 21(3):035118

Paz-Abuin S, Lopez-Quintela A, Pellin MP, Varela M, Prendes P (1998) Autoacceleration and inhibition: free volume. Epoxy-amine kinetics. J Polym Sci Part A Polym Chem 36(6):1001–1016

Altmann N, Halley PJ (2003) The effects of fillers on the chemorheology of highly filled epoxy resins: I. Effects on cure transitions and kinetics. Polym Int 52(1):113–119

Ji QL, Zhang MQ, Rong MZ, Wetzel B, Friedrich K (2004) Tribological properties of surface modified nano-alumina/epoxy composites. J Mater Sci 39(21):6487–6493

Sanctuary R, Baller J, Kruger JK, Schaefer D, Bactavatchalou R, Wetzel B, Possart W, Alnot P (2006) Complex specific heat capacity of two nanocomposite systems. Thermo Acta 445(2):111–115

Sanctuary R, Baller J, Zielinski B, Becker N, Krüger JK, Philipp M (2009) Influence of Al2O3 nano particles on the isothermal cure of an epoxy resin. J Phys Condens Matter Inst Phys J 21(3):035118

Wetzel B, Friedrich K (2004) Tribological properties of surface modified nano-alumina/epoxy composites. Polymer 9:6487–6493

Maghsodian S, Salimi A, Mirzataheri M (2016) The effect of nano alumina silanisation in tetraglycidylether epoxy adhesive. Int J Adhes Adhes (under revision)

Jessica A, Patricia A, Robert T (1987) Structure/property relationships for a series of crosslinked aromatic/aliphatic epoxy mixtures. Polym 28(6):929–940

Wang Y, Bhandari S, Mitra A, Parkin S, Moore J, Atwood DA (2005) Ambient-condition nano-alumina formation through molecular control. J Phys 2:2937–2941

Maldonado CS, Rivera J, Rosa D, Carlos J (2014) Low concentration fe-doped alumina catalysts using sol-gel and impregnation methods: the synthesis, characterization and catalytic performance during the combustion of trichloroethylene. Materials 7(3):2062–2086

Zhi-Qiang Y, Shu-Li Y, Zhen-Guo Y, Baier H (2011) Effect of surface functional modification of nano-alumina particles on thermal and mechanical properties of epoxy nanocomposites. Adv Comp Mater 20(5):487–502

Ghezelbash Z, Ashouri D, Mousavian S, Ghandi AH, Rahnama Y (2012) Surface modified Al2O3 in fluorinated polyimide/Al2O3 nanocomposites: synthesis and characterization. Bull Mater Sci 35(6):925–993

Pei-Chun W, Wha-Tzong W, Sheng-Chang C, Kuen R (2004) Effects of titania content and plasma treatment on the interfacial adhesion mechanism of nano titania-hybridized polyimide and copper system. Polymer 45(13):4465–4472

Becker O, Cheng YB, Varley RJ, Simon GP (2003) Layered silicate nanocomposites based on various high-functionality epoxy resins: the influence of cure temperature on morphology. Mechanical properties and free volume. Macromolecules 36(5):1616–1625

Prolongo SG, Gude MR, Sanchez J, Urena A (2009) Nanoreinforced epoxy adhesives for aerospace industry. J Adhes 85(4–5):180–199

Baller J, Thomassey M, Ziehmer M, Sanctuary R (2011) The catalytic influence of alumina nano particles on epoxy curing. Thermo Acta 517(1–2):34–39

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Salimi, A., Maghsoudian, S. & Mirzataheri, M. Synthesis and characterization of the nano alumina-filled tetraglycidyl-4, 4′-diaminodiphenylmethane epoxy resin. Polym. Bull. 74, 1283–1298 (2017). https://doi.org/10.1007/s00289-016-1777-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-016-1777-1