Abstract

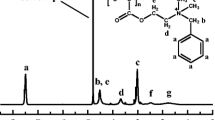

A series of monodispersed (PDI <0.05) butyl acrylate emulsions with different sizes (100–500 nm) and solid contents (22, 17, 12 and 7 wt%) were prepared using a semibatch seeded emulsion polymerization method. Sodium dodecyl sulfate (SDS) was used as an emulsifier and potassium persulfate as an initiator. Surface tensions of the emulsions were investigated and the relationship of the emulsion stability, particle size and solid content was examined. The critical micelle concentration (CMC) of the emulsifier SDS was determined by the intersection of two tangents to surface tension curves. We found that the surface tension at CMC as high as 65.99 mN/m for the emulsion with a solid content of 22 % and a particle size of 115 nm, very close to the value of it for pure water. The surface tension decreased from 65.99 to 54.74 mN/m with an increase in particle size from 115 to 494 nm concomitantly with a decrease in the CMC of SDS from 56.10 to 19.83 mmol/l for the emulsion with a solid content of 22 wt%. As to the emulsions with the same particle size, CMC value was positively correlated with solid content. The minimum value of CMC was 9.12 mmol/l for the emulsion with a solid content of 7 % and a particle size of 494 nm, whereas the maximum CMC was 56.10 mmol/l for the emulsion with a solid content of 22 wt% and a particle size of 115 nm. As a result, an equation describing the relationship between CMC and solid content was deduced. This model yielded the same trends as the experimental results.

Similar content being viewed by others

References

Lee DI (1990) The control of structure in emulsion polymerization. Makromol Chem Macromol Symp 33:117–131

Xia Y, Gates B, Yin Y et al (2000) Monodispersed colloidal spheres: old materials with new applications. Adv Mater 12(10):693–713

Sparks DL (2003) Environmental soil chemistry. UK, pp 150–172

Wang L, Li X, Zhang G, Dong J, Eastoe J (2007) Oil-in-water nanoemulsions for pesticide formulations. J Colloid Interface Sci 314:230–235

El-Din MRN, Al Sabagh AM, Miller R (2010) Preparation of water-in-jet fuel nano-emulsions using a high-energy method. Int J Green Nanotechnol Phys Chem 2(1):20–29

Sole I, Maestro A, Solans C, Jose M (2006) Optimization of nano-emulsion preparation by low-energy methods in an ionic surfactant system. Langmuir 22:8326–8332

Noor El-Din MR (2011) Study on the stability of water-in-kerosene nano-emulsion and their dynamic surface properties. Colloids Surf A Physicochem Eng Aspects B90:189–198

Solans C, Izquierdo P, Nolla J, Azemar N, Garcia-Celma MJ (2005) Nano-emulsions. J Colloid Interface Sci 10(3):102–110

Fernandez P, André V, Riegger J, Kühnle A (2004) Nano-emulsion formation by emulsion phase inversion. Colloids Surf A Physicochem Eng Aspects 251:53–58

Landfester K, Willert M, Antonietti M (2000) Preparation of polymer particles in non-aqueous direct and inverse miniemulsions. Macromolecules 33(7):2370–2376

Wu H, Ramachandran C, Weiner ND, Roessler BJ (2001) Topical transport of hydrophilic compounds using water-in-oil nanoemulsions. Int J Pharm 220:63–75

Garcia MJ, Solans C (2004) Formation of water-in-oil (w/o) nano-emulsions in a water/mixed non-ionic surfactant/oil system prepared by a low-energy emulsification method. Colloid Surf A Physicochem Eng Aspects 250:415–421

Tadros TF, Izquierdo P, Esquena J, Solans C (2004) Formation and stability of nano-emulsions. Adv Colloid Interface Sci 108–109:303–318

Forgiarini A, Esquena J, Gonzalez C, Solans C (2001) Formation and stability of nano emulsions in mixed non ionic surfactant systems. Prog Colloid Polym Sci 118:184–189

Ruckenstein E, Park JS (1992) Stable concentrated emulsions as precursors for hydrophilic–hydrophobic polymer composites. Polymer 33(2):405–417

Schuler B, Baumstark R, Krisch S, Pfau A, Samdor M, Zosel A (2000) Prog Org Coat 40:1258

Wettig SD, Verrall RE (2001) Studies of the interaction of cationic gemini surfactants with polymers and triblock copolymers in aqueous solution. J Colloid Interface Sci 244(2):377–385

Liu BJ, Zhang MY, Zhou C, Ren L, Cheng HL, Ao YH, Zhang HX (2013) Synthesis of monodisperse, large scale and high solid content latexes of poly(n-butyl acrylate) by a one-step batch emulsion polymerization. Colloid Polym Sci 291:2385–2398

Anton N, Benoit JP, Saulnier P (2008) Design and production of nanoparticles formulated from nano-emulsion templates-a review. J Controlled Release 128(3):185–199

Shinoda K, Kunieda H (1983) Phase properties of emulsions: PIT and HLB. In: Becher P (ed) Encyclopedia of emulsion technology. NY, pp 337–367

Sajjadi S, Brooks BW (2001) Semibatch emulsion polymerization of butyl acrylate. II: effects of emulsifier distribution. J Appl Polym Sci 79:582–597

Acknowledgments

The project was supported by NSFC (51173020, 50800300 and 51003007).

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

When the concentration of emulsifier reaches CMC equilibrium, the total number of emulsifier molecules is the sum of the number of free molecules and adsorbed molecules, that is:

where m is the mass of emulsifier, M 0 is molar mass of emulsifier, a is the number of free molecules, b is the number of adsorbed molecules.

We can solve the value of a and b, respectively, are

where a 0 is the adsorption density, A is the total surface area of particles, \(A = \alpha .\pi .D^{2}\), where α is the number of particles and D is the effective grain size.

Assumes that the experiment uses 100 ml of the emulsion, at CMC point, C = C 0, thus,

So, substituting Eqs. (8) and (9) into (7), we get

Rights and permissions

About this article

Cite this article

Zhang, T., Lu, Q., Lü, Y. et al. Determination of critical micelle concentration of sodium dodecyl sulfate in butyl acrylate emulsions. Polym. Bull. 72, 2215–2225 (2015). https://doi.org/10.1007/s00289-015-1399-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-015-1399-z