Abstract

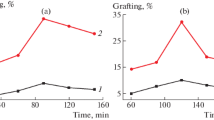

Coir fibers were modified with 2-hydroxyethyl methacrylate (HEMA), methyl methacrylate (MMA) and 2-hydroxyethyl acrylate (2-HEA) solutions under UV radiation. Monomer concentration and radiation dose were optimized in terms of grafting and tensile properties. It was found that 20 % HEMA at 20th UV pass, 30 % MMA at 15th UV pass and 25 % 2-HEA at 20th UV pass of radiation produced higher tensile properties over untreated sample. Urea of different concentrations (0.5–2 %) were incorporated into optimized solutions and 1 % urea showed the best properties of the fiber. Water uptake behavior and simulating weathering degradation properties were also performed.

Similar content being viewed by others

References

Ashori A (2006) Non-wood fibers—a potential source of raw material in papermaking. Polym Plast Technol Eng 45(10):1133–1136

Ashori A (2013) Effects of nanoparticles on the mechanical properties of rice straw/polypropylene composites. J Comp Mater 47(2):149–154

Bullions TA, Gillespie RA, Price-O’Brien J, Loos AC (2004) The effect of maleic anhydride modified polypropylene on the mechanical properties of feather fiber, kraft pulp, polypropylene composites. J Appl Polym Sci 92:3771–3783

Mohanty AK, Misra M, Hinrichsen G (2000) Biofibers, biodegradable polymer and biocomposites: an overview. Macromol Mater Eng 276:1–24

Joseph PV, Joseph K, Thomas S (2002) Short sisal fiber reinforced polypropylene composites: the role of interface modification on ultimate properties. Compos Interfaces 9(2):171–205

Cantero G, Arbelaiz A, Llano-Ponte R, Mondragon I (2003) Effects of fiber treatment on wettability and mechanical behavior of flax/polypropylene composites. Compos Sci Technol 63:1247–1254

Oksman Kristina et al (2000) Third International Symposium on Natural Polymers and Composites: ISNaPol/2000. Sao Pedro, SP 355

Ashori A, Sheshmani S, Farhani F (2013) Preparation and characterization of bagasse/high density polyethylene composite using multi-walled carbon nanotubes. Carbohydr Polym 92(1):865–871

Cantero G, Arbelaiz A, Llano-Ponte R, Mondragon I (2003) Effects of fiber treatment on wettability and mechanical behavior of flax/polypropylene composites. Compos Sci Technol 9(63):1247–1258

Geethamma VG, Mathew KT, Lakshminarayanan R, Thomas S (1998) Composite of short coir fibers and natural rubber: effect of chemical modification, loading and orientation of fiber. Polymer 39(6):1483–1491

Daniel Z, Maria H (2000) Domestication of plants in the old world, 3rd edn. Oxford University Press, Oxfordshire

Duke JA (1989) Handbook of nuts. CRC Press, London

Bledzki AK, Reihmane S, Gassan J (1996) Properties and modification methods for vegetable fibers for natural fiber composites. J Appl Polym Sci 59:1329–1336

Varma DS, Varma M, Varma IK (1984) Coir fibers, part 1: effect of physical and chemical treatment on properties. J Text Inst 54(12):821–832

Hua L, Zadorecki P, Flodin P (1987) Cellulose fiber-polyester composites with reduced water sensitivity (1)—chemical treatment and mechanical properties. Polym Comps 8:199–202

Ali KMI, Khan MA, Ali MA (1997) Study on jute materials with urethane acrylate by UV curing. Radiat Phys Chem 49(3):383–388

Khan MA, Haque N, Kafi AA, Alam MN, Abedin MZ (2006) Jute reinforced polymer composite by gamma radiation: effect of surface treatment with UV radiation. Polym Plast Technol Eng 45(50):607–613

Zaman HU, Khan MA, Khan RA (2011) Surface modification of jute fabrics using acrylic monomers: effect of additives. Int J Polym Mater 60:754–765

Khan MA, Islam MN, Ali KMI (1996) Graft co-polymerization of urethane acrylate on hessian cloth (jute) by ultraviolet radiation. Polym Plast Technol Eng 35(2):229–315

Khan MA, Hossian MM, Hossian MA, Ali KMI (1997) Improvement of jute yarn through in situ co-polymerization by UV radiation. Polym Plast Technol Eng 36(2):85–296

Uddin MK, Khan MA, Ali KMI (1995) Modification of jute yarn by graft co-polymerization with UV radiation. Radiat Phys Chem 48(4):511–517

Patra CM, Singh BE (1994) Influence of N-acetylglycine on the kinetics of the ceric ion-initiated graft copolymerization of acrylonitrile and methyl methacrylate onto jute fibers. J Appl Polym Sci 52(11):1557–1568

ASTM D3800-79 (1990) Standard test method for density of high-modulus fibers. Philadelphia, PA: American Society for Testing and Methods

ASTM Standard D638- 01(2002) Standard test methods for tensile properties of plastics, Annual Book of ASTM Standard, ASTM International, Pennsylvania, USA, vol. 08.03.2002

Dworjanyn PA, Granett JL (1992) Radiation grafting on monomers on plastic fibers. In: Progress in Polymer Processing, Radiation Processing of Polymer; Shing A, Silvernmaan J (eds); Hanser: Munich, Chap. 6, 93

Datta SK, Chaki TK, Bhowmick AK (1996) Structure property relationship of ethylene vinyl acetate copolymer grafted with triallyl cyanurate by electron beam radiation. Radiat Phys Chem 47:913–926

Uddin MK, Khan MA, Ali KMI (1997) Degradable jute plastic composites. Polym Degrad Stab 55(1):1–7

Miah MJ, Khan MA, Khan RA (2011) Fabrication and characterization of jute fiber reinforced low density polyethylene based composites: effects of chemical treatment. J Sci Res 3(2):249–259

Mohanty AK, Khan MA, Hinrichsen G (2000) Surface modification of jute and its influence on performance of biodegradable jute-fabric/Biopol composites. Comp Sci Technol 60(7):1115–1124

Ali KMI, Khan MA, Husain MM (1994) Study of wood plastic composites in presence of nitrogen containing additives. Radiat Phys Chem 44(4):427–429

Khan MA, Hassan MM, Taslima R, Mustafa AI (2006) Role of pretreatment with potassium permanganate and urea on mechanical and degradable properties of photocured coir (Cocos nucifera) fiber with 1,6-hexanediol diacrylate. J Appli Polym Sci 100:4361–4367

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zaman, H.U., Khan, R.A., Khan, M.A. et al. Physico-mechanical and degradation properties of biodegradable photografted coir fiber with acrylic monomers. Polym. Bull. 70, 2277–2290 (2013). https://doi.org/10.1007/s00289-013-0950-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-013-0950-z