Abstract

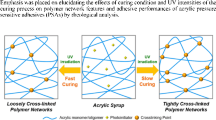

UV-initiated crosslinking technology is well established in the market and allows the production of a wide range of ultraviolet (UV)-crosslinkable pressure-sensitive adhesives (PSA) with interesting features. The balance between such properties as adhesive and cohesive strengths within the crosslinked self-adhesive coatings is critical for their performance. The UV crosslinking of acrylic PSA, especially for following properties: tack, peel adhesion, and shear strength of self-adhesive polymer layers, has been investigated using UV excimer-laser and UV lamp as UV sources. It was observed that after UV crosslinking of acrylic PSA using excimer-laser in comparison with typical UV lamp, high-quality PSA products with excellent properties, such as tack, peel adhesion, shear strength, and shrinkage were received.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Since their introduction half century ago, acrylic pressure-sensitive adhesive (PSA) have been successfully applied in many fields.

They are used in self-adhesive tapes, splicing tapes, labels, protective films, sign, and marking films as well as in dermal dosage systems for pharmaceutical applications and in biomedical electrodes [1].

Three properties which are useful in characterizing the nature of PSA are tack, peel (adhesion), and shear (cohesion). The first measures the adhesive’s ability to adhere quickly, the second its ability to resist removal by peeling, and the third its ability to hold in position when shearing forces are exerted. Generally speaking, the first two are directly related to each other but are inversely related to the third [2].

The performance of acrylic PSA, such as tack, peel adhesion, shear strength, and shrinkage are to a large degree determined by the molecular weight of acrylic copolymer, polymerization method, and especially by the type and quantity of the crosslinking agents added to the PSA, in the case of photoreactive acrylic PSA by photoinitiator type and concentration and by UV-crosslinking process [3].

Industrial applications of UV-crosslinkable materials have grown tremendously in the last 10 years in the field of adhesive, self-adhesive, and other coatings. The growing success of UV-crosslinking technologies in a wide variety of industrial products and processes can be attributed to the high productivity, improved properties of UV-crosslinked coatings, low energy consumption, and environmental benefits. UV lamps as light sources emit spectral radiation in the UV region between 200 and 400 nm [4].

The word light amplification by stimulated emission of radiation (LASER) reveals a technology existing for about 45 years. UV laser is a high energy, monochromatic light source, whose use within curing is known from stereolithography. Regarding the PSA technology, the excimer-laser has the highest chance to be used [5–13]. The radiation emitted by a laser has a number of unusual properties that distinguish it from radiation emitted by conventional radiation sources. Laser radiation is highly monochromatic. It has a very narrow spectral line-width. This line-width is not zero, but typically it is much less than that of conventional radiation sources. Laser radiation is coherent. Coherence implies a regular, orderly progression of the vibration of the electromagnetic radiation.

The aim of this study was to manufacture photoreactive solvent-borne acrylic PSA with high application performances, such as tack, peel adhesion, shear strength, and shrinkage by using excimer-laser as UV radiation source in comparison with typical UV lamp for UV-initiated crosslinking reaction.

Experimental

Synthesis of photoreactive acrylic PSA

The investigated solvent-borne acrylic PSA were synthesized in ethyl acetate with 50 wt% polymer content, 2 h dosage time of monomers mixture, and 5 h post-reaction time in the presence of 0.1 wt% radical starter AIBN at temperature of 78 °C (boiling point of ethyl acetate). The monomers mixture comprises between 93.0 and 94.9 wt% of 2-ethylhexyl acrylate, 5 wt% of acrylic acid, and between 0.1 and 2.0 (exactly: 0.1, 0.3, 0.5, 1, 1.5, and 2 wt%) of unsaturated copolymerizable photoinitiator (Table 1). All monomers, ethyl acetate, and AIBN were available from BASF (Germany). The copolymerizable photoinitiators mentioned in Table 1 were available from Poly-Chem (Germany).

UV crosslinking of synthesized acrylic PSA

The UV-crosslinking experiments using UV excimer-laser (LPX 210 from Lambda Physik Company) and using conventional UV lamp (Aktiprint mini 18-2 from Technigraf) were conducted using synthesized acrylic PSA containing the tested unsaturated copolymerizable hydrogen abstraction type photoinitiator, 4-acryloyloxy benzophenone (ABP), 4-acryloyloxyethoxy carbonyl-4′-chlorobenzophenone (ACCP), and benzoine acrylate (BA) which are incorporated during polymerization into the polymer chain of acrylic PSA as photoreactive-crosslinking centers.

The solvent-borne UV-crosslinkable acrylic PSA containing the above illustrated photoinitiators were coated directly with 60 g/m2 on a polyester film and after drying for 10 min at 105 °C crosslinked 20 s by use of an UV excimer-laser LPX 210 from Lambda Physik Company (Germany) with a wavelength of 351 nm with the following characteristics of emitted radiation:

Emitted pulse UV energy | 200 mJ |

Pulse durations | 30 ns |

Frequency of pulses | 10 Hz |

Number of pulses | 200 |

UV dose | 5.4 mJ/cm2 |

The same samples were crosslinked 20 s with UV dose of 600 mJ/cm² using UV lamp Aktiprint mini 18-2. In the case of shrinkage determination, acrylic PSA is coated on silicon paper, dried in drying canal, and then transferred on PVC film.

Determination of UV radiation intensity

The UV exposure was measured using an integrating radiometer Dynachem™ Model 500, available from Dynachem Corporation, 2631 Michelle Drive, Tustin, CA 92680.

Evaluation of tack, peel adhesion, shear strength, and shrinkage

The mentioned properties were determined by standard Association des Fabricants Europeens de Rubans Auto-Adhesifs (A.F.E.R.A.) procedures. Exact details can be found in AFERA 4015 (tack), AFERA 4001 (peel adhesion), and AFERA 4012 (shear strength). Administrative address: 60, rue Auber-94408 Vitry Sur Seine Cedex, France. Those tests were conducted with the use of testing machine Zwick/Roell Z-25.

The loop tack method according to AFERA 4015 is relatively simple and may be carried out using common tensile strength test machines. A sample of PSA-coated material 1-inch (about 2.5 cm) wide and about 7-inch (about 17.5 cm) long is bonded to a vertical of a clean steel test plate for at least 10 lineal centimeters in firm contact. The vertical steel test plate is clamped in the jaws of a Zwick tensile testing machine. The scale reading in Newtons is recorded as the tape is peeled from the steel surface with a constant rate of 100 mm per minute. Loop tack has the advantage of allowing tack to be measured on a wide range of substrates, such as stainless steel, glass, PE, PP, etc.

The peel adhesion according to AFERA 4001 is the force required to remove a coated flexible PSA sheet material from a test panel measured at a specific angle of 180° and rate of removal. A sample of PSA-coated material 1-inch (about 2.5 cm) wide and about 5-inch (about 12.7 cm) long is bonded to a horizontal target substrate surface of a clean steel test plate at least 12.7 cm in firm contact. A 2 kg hard rubber roller is used to apply the strip. The free end of the coated strip is doubled back nearly touching itself so the angle of removal will be 180°. The free end is attached to the adhesion tester scale. The steel test plate is clamped in the jaws of a tensile testing machine Zwick, which is capable of moving the plate away from the scale at a constant rate of 300 mm per minute. The scale reading in Newtons is recorded as the tape is peeled from the steel surface. The data are reported as the average of the range of numbers observed during the test. The peel adhesion test of PSA was conducted with three identical samples. The given result is an arithmetic average from the available peel adhesion results.

The shear strength is a measure of the cohesiveness or internal strength of an adhesive. It is based upon the value of force required to pull an adhesive strip from a standard flat surface in a direction parallel to the surface to which it has been affixed with a definite pressure, according to AFERA 4012, at room temperature and at 70 °C. Shear strength is the adhesive’s ability to maintain its position when shearing forces are applied. Each test is conducted on an adhesive-coated strip applied to a standard stainless steel panel in a manner such that a 1-inch × 1-inch (about 2.5 cm × 2.5 cm) portion of the strip is in fixed contact with the panel with one end of the strip being free. The steel panel with the coated strip attached is held in a rack such that the panel forms an angle of 178°–180° with the free end tape extended; the latter then is loaded with a force of different hanging weights in gram or kilogram applied from the free end of the test strip.

Shrinkage was tested as the percentage or millimeter change of dimensions of the PVC foil covered with PSA after PSA crosslinking and attached to the glass after keeping it 4 weeks at temperature of 60 °C. With shrinkage greater than 0.5 % or greater than 0.5 mm, other properties such as tack, peel adhesion, shear strength, and shrinkage were neglected.

Results and discussion

In the graphs shown in Figs. 1 and 2, the influence of the investigated unsaturated photoinitiators, as a function of their concentration, on the tested acrylic PSA tack by the use of UV source excimer-laser (Fig. 1) and after UV crosslinking using UV lamp (Fig. 2) are described.

As can be seen in Fig. 1, for all the acrylic PSA containing tested copolymerizable photoinitiators, a continuous tack drop after UV crosslinking using excimer-laser and UV lamp was observed. The tack of UV-crosslinked acrylic PSA is very sensitive to the variations of the crosslinking time and the variations of photoinitiator concentration. In general, the surface of the adhesive suffers decrease of tack with an increase of yielded free radicals. The most striking tack drop was observed for relatively small photoinitiator concentrations ranging about 0.3 wt%. The best tack results were observed by using copolymerizable photoinitiator ABP.

The peel adhesion results obtained for all the tested unsaturated photoinitiators show an influence of the type of photoinitiators and their concentration on the synthesized acrylic PSA. UV-initiated crosslinking of acrylic PSA containing ABP preceded quickly, when an UV excimer-laser was used (Fig. 3). By an application of UV lamp, the lower peel adhesion level was noticed (Fig. 4). The highest peel adhesion value of 23.1 N was measured for 0.1 wt% of unsaturated H-abstractor ABP (Fig. 3).

The highest shear strength values, measured at 20 °C after UV crosslinking during excimer-laser exposure, were obtained with all acrylic PSA containing investigated copolymerizable photoinitiators (Fig. 5). Using UV radiation from UV lamp resulted in shear strength under level of with excimer-laser-crosslinked acrylic PSA. A faster and more complete crosslinking was achieved by setting the photoinitiator amounts above 0.1 wt% of 4-acryloylooxy benzophenone (ABP), above 0.5 wt% of ACCP, and above 1.5 wt% of BA. The observed shear strength results at 70 °C have proven the maximal measured values for similar photoinitiator contents (Fig. 5).

Incorporation of unsaturated photoinitiators into acrylic polymer structure strongly influences the shear strength properties of the UV-crosslinked PSA after UV exposure from UV lamp (Fig. 6). After UV exposure, an increase of the concentration of investigated photoinitiators produces a higher network density, leading to higher cohesion in comparison with classical conventional photoinitiator systems. The highest shear strength results were observed for about 0.3 wt% of ABP, 1.0 wt% of ACCP, and 1.5 wt% of PAC also, at 20 and at 70 °C (Fig. 6). The best results of cohesion increasing were evaluated using excimer-laser.

In the investigated solvent-borne acrylic PSA containing tested photoreactive copolymerizable photoinitiators, the best optimal pressure-sensitive performances by evaluation of UV excimer-laser radiation-crosslinked adhesives, which is the balanced values of tack, peel adhesion, and shear resistance for the aimed application, were observed for photoinitiator ABP.

Figures 7 and 8 show the effect on shrinkage of acrylic PSA containing varying amounts of investigated copolymerizable photoinitiators: ABP, ACCP, and BA after UV-crosslinking reaction using excimer-laser and UV lamp.

Generally speaking, it has been concluded that all tested copolymerizable photoinitiators tend to generate the overall best shrinkage resistance. It is interesting to note that the shrinkage of acrylic PSA after UV exposure tremendously decreases, suggesting continued crosslinking activity under UV exposure by application of excimer-laser. Excellent shrinkage values of 0.2 mm were noticed in the case of ABP for 1.0 wt%. Above 0.3 wt% of ABP and 0.3 wt% of ACCP, the shrinkage values correspond to less than 0.35 and 0.5 mm, respectively. This has shown that photoinitiator ABP is good alternative to the other unsaturated photoinitiators. Its only real weakness is still again, when exposed to UV crosslinking, while ABP will offer higher shrinkage resistance. The best copolymerizable photoinitiator, referring to very low shrinkage of UV-crosslinked acrylic PSAs was ABP. At already 0.1 wt% of ABP content, an acceptable shrinkage of 0.45 mm of UV-crosslinked self-adhesive layer by using excimer-laser was achieved.

Conclusions

From the investigated copolymerizable photoinitiators incorporated into polymer chain during the synthesis of solvent-borne acrylic PSA, the best results for relevant properties of PSA, such as tack, peel adhesion, shear strength, and shrinkage were observed by application of ABP. The highest values of peel adhesion were observed for 0.3 wt% of ABP and the excellent high cohesion were observed at concentration of about 0.1 wt% of ABP. 0.3 wt% of ABP quarantines have low acceptable shrinkage of 0.3 mm. The unsaturated ABP produces a higher level of radicals immediately after the UV curing process, as well as after prolonged exposure to UV, than most of the common photoinitiators. After passing of about 5.4 mJ/cm2, the tack drop is very slow. The relatively short organic spacer between ester group and benzophenone group contributes to a greater possibility of free radical transfer onto the organic spacer by which de facto the shear strength of solvent-borne acrylic PSA increases. The exceptionally high efficiency of ABP as copolymerizable photoinitiator in comparison with the other tested unsaturated photoinitiators BA and ACCP is attributed among others to a short molecule of ABP and with a short distance between both crosslinked polymer chains after UV radiation. The photoreactivity of ACCP, comparable with ABP is lower, because the chlorine atom shortens the radicals “living time” by the so-called heavy atom effect. The investigated photoreactive solvent-borne UV excimer-laser-crosslinkable acrylic PSA can be used for the manufacturing of high performance self-adhesive materials such as mounting tapes, labels, masking tapes or sign, and marking films. The UV crosslinking using excimer-laser is most preferable than the UV-crosslinking process by application of typical UV lamp. The very important limiting factor for wide use of excimer-laser in the UV PSA technology is at the moment their high price.

References

Czech Z, Wesołowska M (2007) Novel azo-peresters radical initiators used for the synthesis of acrylic pressure-sensitive adhesives. Eur Polym J 43:3604–3612

Everaerts A, Malmer J (1992) Removable, low melt viscosity acrylic pressure sensitive adhesives. WO 93/13148

Czech Z (2007) Synthesis and cross-linking of acrylic PSA systems. J Adhes Sci Technol 21:625–635

Czech Z (2007) New generation of crosslinking agents based on multifunctional methylaziridines. Int J Adhes Adhes 27:49–58

Czech Z (1996) Application of laser in PSA technology, Swiss Bonding`96. Rapperswill, Switzerland, pp 200–205

Kabatc J (2011) The photochemistry of novel electron-transfer three-component visible light photoinitiating systems. In: Maes KJ, Willems JM (eds) Photochemistry: UV/VIS spectroscopy, photochemical reations and photosynthesis, chap 1. Nova Science Publishers, Inc., Hauppauge

Czech Z, Blum W, Herrmann F (1993) WO 94/14853

Kabatc J, Czech Z, Kowalczyk A (2011) The application of halomethyl 1,3,5-triazine as a photoinitiator or co-initiator for acrylate monomer polymerization. J Photochem Photobiol A 219:6–25

Czech Z, Blum W, Herrmann F (1992) DE 42 43 270

Czech Z (2003) Influence of the unsaturated benzophenone photoinitiators on shrinkage of acrylic pressure-sensitive adhesives. Polimery XLVIII:375–377

Czech Z, Butwin A (2010) UV-initiated crosslinking of acrylic pressure-sensitive adhesives using ultraviolet excimer-laser. Rev Adv Mater Sci 23:32–36

Tcheng JE, Volkert-Noethen AA (2001) Current multicentre studies with the excimer laser: design and aims. Lasers Med Sci 16:122–129

Shinozakia T, Ooiea T, Yanoa T, Zhaoa JP, Chena ZY, Yonedaa M (2002) Laser-induced optical emission of carbon plume by excimer and Nd:YAG laser irradiation. Appl Surf Sci 197–198:263–267

Open Access

This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Czech, Z., Kowalczyk, A., Kabatc, J. et al. UV-initiated crosslinking of photoreactive acrylic pressure-sensitive adhesives using excimer-laser. Polym. Bull. 70, 479–488 (2013). https://doi.org/10.1007/s00289-012-0818-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-012-0818-7