Abstract

Prenylation plays a pivotal role in the diversification and biological activities of natural products. This study presents the functional characterization of TolF, a multiple prenyltransferase from Tolypocladium inflatum. The heterologous expression of tolF in Aspergillus oryzae, coupled with feeding the transformed strain with paxilline, resulted in the production of 20- and 22-prenylpaxilline. Additionally, TolF demonstrated the ability to prenylated the reduced form of paxilline, β-paxitriol. A related prenyltransferase TerF from Chaunopycnis alba, exhibited similar substrate tolerance and regioselectivity. In vitro enzyme assays using purified recombinant enzymes TolF and TerF confirmed their capacity to catalyze prenylation of paxilline, β-paxitriol, and terpendole I. Based on previous reports, terpendole I should be considered a native substrate. This work not only enhances our understanding of the molecular basis and product diversity of prenylation reactions in indole diterpene biosynthesis, but also provides insights into the potential of fungal indole diterpene prenyltransferase to alter their position specificities for prenylation. This could be applicable for the synthesis of industrially useful compounds, including bioactive compounds, thereby opening up new avenues for the development of novel biosynthetic strategies and pharmaceuticals.

Key points

• The study characterizes TolF as a multiple prenyltransferase from Tolypocladium inflatum.

• TerF from Chaunopycnis alba shows similar substrate tolerance and regioselectivity compared to TolF.

• The research offers insights into the potential applications of fungal indole diterpene prenyltransferases.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Indole diterpenes (IDTs) constitute a class of structurally unique natural products derived from fungi. Their distinguishing characteristic involves the attachment of a C20 long-chain geranyl–geranyl diphosphate (GGPP) to the indole ring, followed by subsequent modifications, including cyclization, oxidation, prenylation, and other modifications, resulting in structurally complex compounds (Ozaki et al. 2023). These compounds are primarily derived from fungal species such as Penicillium sp., Aspergillus sp., and Claviceps sp., among others (Reddy et al. 2019). Based on their structural features, IDTs can be broadly classified into two major types: paspaline and non-paspaline, because paspaline is characterized by the presence of six rings, therefor, starting from the indole ring side, these six rings are sequentially named from A to F (Niu et al. 2023; Saikia et al. 2008). To date, over 200 IDT compounds have been reported, with paspaline-type IDTs accounting for more than 70% of the total (Niu et al. 2023).

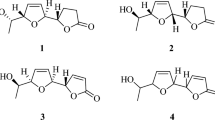

Prenylation is one of the major factors contributing to the diversity of IDT compounds, including modifications on the A-ring and F-ring. The diversity is further reflected in the different forms of attachments, such as regular and reverse, the positions and number of attachments. These modifications greatly enhance the structural diversity of IDTs (Hibbard et al. 2023; Oikawa et al. 2016; Richardson et al. 2022; Van de Bittner et al. 2018). The first characterization of the extracellular enzymatic activity of IDT prenyltransferase (PT) was performed on PaxD, which was shown to catalyze the regular addition of prenyl groups at positions 21 and 22 of paxilline (1) to give 21,22-diprenylpaxilline (2) (Liu et al. 2014a). Subsequent studies showed that JanD had the same activity (Liu et al. 2016), however, LtmE, SpdE and AmyD reacted at positions 20 and 21 of the 1 to produce 20, 21-diprenylpaxilline (3) (Jiang et al. 2020; Kudo et al. 2018; Liu et al. 2014b). For the same substrates, the product of the AtmD was reversely-20-prenylpaxilline (4) (Liu et al. 2013), and the activity of PtmD catalyzes the production of 20-prenylpaxilline (5) is very weak (Fig. 1A) (Liu et al. 2015). In addition to A-ring modifications, the F-ring also undergoes prenylation, such as in terpendole C (6), lolitrem B (7), tolypocladin I (8), and tolypocladin J (9) (Fig. 1B). Recently, a series of compounds named tolypocladin A-L (Fig. S1) was identified in fungus Tolypocladium sp., featuring prenylation modifications in the A and F rings (Xu et al. 2019a, 2019b). However, the genes and enzymes involved in the biosynthesis of tolypocladins and their precise functions remain unknown.

Through genomic informatics analysis, we discovered a gene cluster in Tolypocladium sp. sharing approximately 70% similarity with the ter gene cluster, a known terpendole biosynthetic gene cluster (Motoyama et al. 2012). We conducted functional analysis of PT for TolF within this cluster. When tolF was expressed in A. oryzae and feeding with substrate 1, two new compounds were generated. Through nuclear magnetic resonance (NMR) and mass spectrometry analysis, these compounds were identified as 20- and 22-prenylpaxilline (5, 10). Consistent results were obtained through in vitro enzyme assays. When terpendole I (11) was used as the substrate, both in vivo feeding and in vitro enzyme reactions yielded a single product, with a molecular weight matching that of terpendole J (12). We confirmed that TerF also produces the same compounds when reacting with 1. These results indicate that the native substrate for both enzymes is likely to be 11. We also synthesized the reduced product of 1, β-paxitriol (13), and both in vivo and in vitro experiments demonstrated that TolF and TerF can introduce prenyl group at either the 20 or 22 positions of β-paxitriol (14, 15); they exhibit broad substrate tolerance. These outcomes illustrate the broad substrate selectivity of PT, contributing to a deeper understanding of the versatility of IDTs.

Material and methods

General methods

All reagents used in this study were purchased from the commercially available. Oligonucleotides required for polymerase chain reaction (PCR) were procured from Tsingke Biotechnology Co., Ltd.

The Diode array detector (DAD) on Agilent 1260 Infinity II (Agilent Technologies, USA) was used for High-performance liquid chromatography (HPLC) analysis. Liquid Chromatography-Mass Spectrometry (LC–MS) data were acquired with an AB SCIEX Triple TOF 6600 instrument. Proton and carbon nuclear magnetic resonance (NMR) spectra were obtained using a Bruker AVANCE III HD 500 spectrometer. The chemical shifts were reported in ppm on the δ scale, using CDCl3 as an internal reference (1H NMR = 7.26 ppm, 13C NMR = 77.16 ppm).

Microbial strains and culture conditions

The strain T. inflatum CICC-2598, sourced from the China Center of Industrial Culture Collection, which was propagated in a liquid medium of potato dextrose broth (PDB) at a temperature setting of 25℃ and an agitation speed of 170 rpm over a week. Then, the genome was extracted for the cloning of the tolF gene. The A. oryzae NSAR1 (Jin et al. 2004) strain was utilized as the heterologous expression host, and was grown in a DPY medium (containing 2% dextrin, 1% polypeptone, and 0.5% yeast extract in a 100 mL solution) enriched with suitable nutrients, at a temperature of 30℃ and a rotation speed of 200 rpm (Tagami et al. 2013). Conventional DNA engineering was executed with E. coli DH5α, while protein expression was facilitated using E. coli BL21. All E. coli strains were cultured at a temperature of 37℃, whereas protein expression was performed at 16℃.

Isolation of genomic DNA and assembly of plasmid

The genomic DNA of T. inflatum were performed as described previously (Tagami et al. 2013). The tolF gene (GenBank: OR966868) was amplified from the T. inflatum genome using gene-specific primers (Table S3). The amplified gene was then incorporated into the pUARA2 vector, resulting in the creation of the pUARA2-tolF expression plasmid. Similarly, the terF gene (GenBank: AB725916) was synthesized by Tsingke Biotechnology Co., Ltd., and was also inserted into the pUARA2 vector using the same method, leading to the formation of the pUARA2-terF plasmid.

Transformation of A. oryzae

The A. oryzae transformation was conducted using the protoplast-polyethylene glycol technique, as outlined in the work of Tagami et al. (Tagami et al. 2013). The transformation process employed the plasmids pUARA2-tolF and pUARA2-terF, leading to the creation of AO-tolF and AO-terF, respectively.

Biotransformation of A. oryzae transformants

The transformant AO-tolF or AO-terF were introduced into a nutrient-rich MPY medium (comprising 3% malotose, 0.5% yeast extract and 1% polypeptone) and added the appropriate nutrients (2 mL) in a 10 mL test tube. A methanol solution of the substrate (20 μg) was subsequently added to the culture medium. The culture was then incubated for an additional three days at 30℃, under a rotation speed of 200 rpm. Following incubation, the fermentation broth was immersed in acetone and left overnight at ambient temperature. The mixture was then filtered, and the filtrate was concentrated under vacuum. The residual water by extracted with ethyl acetate, and the organic layers were also concentrated under vacuum. Finally, the samples were analyzed using HPLC and LC–MS.

Cloning, overexpression, and purification of TolF and TerF

Total RNA was extracted from AO-tolF mycelium sample using TRIzol reagent (Invitrogen) according to the manufacturer’s instructions. The first strand cDNA was then synthesized using the PrimeScript™ II First Strand cDNA Synthesis Kit (TAKARA) according to the manufacturer's instructions. Intron less DNA clones of tolF were amplified from the cDNA of AO-tolF and inserted into BamHI-digested pMAL-c5x to construct the pMal-c5x-tolF expression plasmid. The pMal-c5x-tolF plasmid was then transformed into E. coli BL21 for overexpression. The transformants were incubated in LB medium (200 mL) supplemented with 100 μg/mL ampicillin grown at 37℃ and 200 rpm to an optical density of 0.6 at 600 nm, then cooled to 16℃. Protein expression was induced by adding isopropyl-β-D-thiogalactopyranoside (IPTG) to a final concentration of 0.2 mM, followed by further incubation for about 20 h at 16℃ and 200 rpm. The cells containing were harvested and treated as follows. The cells of TolF were resuspended in 4 mL buffer A (50 mM Tris–HCl, 500 mM NaCl, 10% glycerol, pH 7.5) and were lysed by sonication on ice. Cellular debris was removed by centrifugation at 15,000 rpm, at 4℃, for 10 min and purified using MBPTrap HP columns. The purified enzymes were checked by SDS-PAGE. Finally, the purified protein was quickly frozen in liquid nitrogen and saved at -80℃. The cloning, overexpression, purification, and storage methods for TerF are the same as those described above.

In vitro assay of TolF and TerF

The enzymatic reaction of TolF or TerF with 1, 11, and 13 was performed in 100 μL of reaction mixtures containing 50 mM Tris–HCl buffer (pH 7.0), 1 mM of substrates, 1 mM DMAPP, 5 mM MgCl2, and 5 μg enzyme at 30℃ overnight. The reaction was terminated by adding 100 μL of methanol and vortex mixing. The supernatant obtained after centrifugation was analyzed by HPLC and LC–MS.

Analysis of the metabolites

The metabolites were examined using an HPLC system equipped with an Agilent TC-C18 column (250 mm × 4.6 mm). The conditions were as follows: from 0 to 5 min, 60% of solvent B was used; from 5 to 25 min, a linear gradient from 60 to 100% of solvent B was applied; and from 25 to 30 min, 100% of solvent B was used. The mobile phase consisted of solvent A (H2O) and solvent B (CH3OH), with a flow rate of 1 mL/min. The samples were further analyzed using a TripleTOF 6600 mass spectrometer (AB/SCIEX, Milford, MA) in conjunction with an HPLC system (AB/SCIEX). Chromatographic separation was achieved using a Kinetex C18 100A column (Phenomenex) with dimensions of 150 mm × 4.6 mm and a particle size of 2.6 μm. The conditions were as follows: from 0 to 10 min, a gradient from 5 to 100% of solvent B was applied; and from 10 to 15 min, 100% of solvent B was used. The mobile phase consisted of solvent A (H2O + 0.1% formic acid) and solvent B (CH3CN + 0.1% formic acid), with a flow rate of 0.6 mL/min.

Isolation and purification of metabolite

The transformant AO-tolF was inoculated into a MPY medium, supplemented with the necessary nutrients, and a total of 2 L. Subsequently, 2 mg of Substrate 1 or 13, dissolved in methanol, was added to the 100 mL MPY medium. The mixture was then incubated for an additional 3 days at 30℃, under a rotation speed of 200 rpm. The mycelium was obtained by filtration and extracted by acetone. The mycelium was obtained by filtration and extracted by acetone to obtain the bold substance. The crude extract was re-extracted by ethyl acetate. The ethyl acetate layer was separated using silica gel column chromatography, with a hexane to ethyl acetate ratio ranging from 6:1 to 2:1. The compounds isolated from this process were further purified using semi-preparative HPLC.

Results

Identifying the tol gene cluster in T. inflatum

In 2018, genomic data of T. inflatum was publicly disclosed (Bushley et al. 2013). In this study, we acquired a strain from the China Center of Industrial Culture Collection (No. CICC-2598). Initially, we conducted tests to confirm its ability to produce IDT compounds. The fungal strain was cultivated on a rice-based medium, followed by extraction using ethyl acetate. Subsequently, LC–MS analysis was performed to detect and characterize the compound. The results of the molecular network analysis revealed the detection of compounds with molecular weights of 504, 522, and 588 (Fig. S2), characteristic of IDTs. This observation provides evidence for the IDT-producing potential of the CICC-2598 strain, indicating that this strain contains a gene cluster for the synthesis of IDT.

Through genome informatics analysis, we identified a tol gene cluster in T. inflatum, which display similarities with the ter gene cluster, a known terpendole biosynthetic gene cluster (Fig. 2A). The tol gene cluster contains seven genes, of which tolCMB has at least 58% identity with its homologous gene sequence (terCMB) (Fig. 2B), which is responsible for the core synthesis of paspaline (16) (Motoyama et al. 2012). Two P450 genes, named tolPQ, exhibit 80% and 73% identity with terPQ, respectively. The PT of TolF shares 74% identity with TerF, indicating a high level of similarity between these two related enzymes.

The structures of tolypocladin IDTs differ from those of terpendoles. Notably, the former has a single prenyl group on the A-ring in addition to prenylation at the OH (F-ring) side. While TerF from the ter gene cluster is responsible for prenylation of the F-ring alone (Jiang et al. 2020; Motoyama et al. 2012). However, there is only one PT transferase in the tol gene cluster. Therefore, it remains to be determined whether TolF is capable of prenylation of both the A- and F-ring and adding PT modification simultaneously, which requires further investigation.

Functional analysis of TolF

To analyze the functions of PT for TolF within tol cluster, the gene was amplified from T. inflatum genomic DNA, the purified PCR fragment was cloned into pUARA2 under the control of promoter amyB, then transferred to the heterologous expression host A. oryzae NSAR1 to form AO-tolF transformants (Tagami et al. 2013). The ethyl acetate extract of the transformed mycelium was analyzed by HPLC. Two new peaks were observed in the AO-tolF strain when fermented in MPY medium with feeding 1. By contrast, these peaks were absent in the wild-type (WT) strain (Fig. 3, trace iii).

Through high-resolution electrospray ionization mass spectrometry (HR-ESI–MS) analysis, the molecular mass of these two new peaks were determined to be C32H41NO4 (m/z 504.3105 and 504.3106 [M + H]+), respectively (Fig. S3). Because the molecular weights of both two compounds are 68 Da greater than that of 1 with an [M + H]+ ion at m/z 436, this data strongly suggested that these two products were mono-prenylated 1. To determine the structures of these two new compounds, the mycelial ethyl acetate extract of AO-tolF with 1 was obtained from a scaled-up fermentation. The crude extract was purified with silica gel column chromatography and partitioned with hexane–ethyl acetate.

Compound 5 of 1H-NMR spectra exhibited new signals for regular prenyl moieties at δ = 5.41 (t, J = 7.9 Hz, 1H), and δ = 3.61 (d, J = 7.0 Hz, 2H), Compound 10 of 1H-NMR spectra exhibited at δ = 5.36 (t, J = 7.2 Hz, 1H), and δ = 3.41 (d, J = 7.2 Hz, 2H). Finally, thorough NMR data analysis, encompassing 1H-NMR, 13C-NMR, COSY (Correlation Spectroscopy), HSQC (Heteronuclear Single Quantum Coherence), HMBC (Heteronuclear Multiple Quantum Coherence), and NOESY (Nuclear Overhauser Effect Spectroscopy), confirmed the structure as 20- and 22-prenylated 1 (Table S1, Fig. S9-S20).

PT transferases often display a broad range of substrate promiscuity, as exemplified by enzymes such as PaxD and AtmD, exhibiting enzymatic activity towards intermediates of various biosynthetic pathways (Liu et al. 2013). Accordingly, we conducted a study on the substrate promiscuity of TolF. Specifically, we synthesized the reduced product of 1, known β-paxitriol as 13 (Fig. S21) (Miles et al. 1992). When feeding this compound into the AO-tolF strain, two distinct products were observed through HPLC analysis (Fig. 3, trace v). HR-ESI–MS analysis determined the molecular weight [M + H]+ 506.3264 and 506.3262 of those two compounds, with the presumed molecular formula of C32H43NO4 (calculated as [M + H]+ 506.32655). Moreover, a specific fragment of 198.13 was detected by LC–MS analysis (Fig. S4). This fragment is the characteristic peak of the A-ring mono-prenylated form of IDT (Uhlig et al. 2009). Next, we scaled up fed 13 to the AO-tolF strain and performed purification of these two compounds using HPLC. One of the compounds exhibited 1H data (Fig. S22) that matched with the previously reported 20-prenylpaxitriol (14) (Liu et al. 2015). Based on the 1H NMR data (Fig. S23), and identification results mentioned earlier, we conclude that the structure of the other compound was 22-prenylpaxitriol (15).

Functional analysis of TerF

As observed in the previous studies, the function of TerF introduced the prenyl group at the OH position of the F-ring in 11 (Jiang et al. 2020; Motoyama et al. 2012). In this study, we constructed a strain of A. oryzae expressing terF. Because the producing strain was unavailable, we synthesized the gene fragment and constructed the expression plasmid pUARA2-terF, which was then introduced into A. oryzae to establish the AO-terF strain. When this transformed strain was feeding with 11, a single product (Fig. 4B trace ii) with a molecular weight consistent with the introduction of a prenyl group was detected (Fig. S5). Based on previous reports (Jiang et al. 2020; Motoyama et al. 2012), this compound is 12. However, when AO-terF was co-cultured with 1, two compounds identical to those produced by TolF were observed, with identical retention times and LC-MS patterns to 5 and 10 (Fig. S6).

Additionally, we conducted experiments feeding 11 to the AO-tolF strain, and similarly observed only a single product (Fig. 4B trace iii). These results indicate that 11 is the native substrate of TerF and TolF. Furthermore, both TolF and TerF exhibit similar functions and broad substrate specificity. However, within the tol biosynthetic gene cluster, only one PT might be responsible for the reaction with multiple substrates.

In vitro characterization of TolF and TerF

To elucidate the specific roles of TolF, we aimed to employ recombinant TolF for in vitro assays. The predicted gene product consists of a sequence of 433 amino acids (Table S2). The open reading frame of tolF was amplified using cDNA as a template, and subsequently cloned into the pCold I, pQE30, and pET28a expression vector, however, no soluble proteins were obtained. As a potential solution, we endeavored to optimize the codon usage of the gene, to achieve a soluble protein after overexpression. Unfortunately, despite these efforts, obtaining soluble protein was still unattainable.

In a previous study conducted by our research in 2014, we successfully expressed and purified AmyD, a fungal prenyltransferase that catalyzes the regular diprenylation of paxilline sites 20 and 21, achieved using the maltose-labeled expression vector pMAL-c5x (Liu et al. 2014b). Therefore, our focus shifted toward constructing the TolF gene in the pMAL-c5x vector. Remarkably, subsequent overexpression resulted in the successful production of soluble protein. The homogeneity of the protein was ensured through purification using a one-step MBPTrap HP chromatography process. The obtained recombinant TolF, with a calculated molecular mass of 47 kDa, was further validated for its molecular size and purity through SDS-PAGE analysis (Fig. S7). We also expressed the synthesized terF gene in E. coli and purified the TerF enzyme for in vitro enzymatic reactions.

Subsequently, we analyzed the catalytic activity of the purified recombinant enzyme products using HPLC and LC–MS. As expected, the formation of 5 and 10 was observed when TolF or TerF was incubated with 1 and DMAPP (Fig. 5, traces ii and iii), and two compounds 14 and 15 were detected when 13 was used as a substrate (Fig. S8), while controls without the enzyme did not lead to the formation of these compounds. However, when 11 was used as the prenyl acceptor, only a single product 12 was observed (Fig. 5, trace v and vi).

Discussion

In this study, we identified a putative indole diterpene biosynthetic gene cluster tol consisting of seven genes in the genome of T. inflatum. Within this gene cluster, a multiple PT was identified, named TolF, which shares 74% amino acid identity with the known enzyme TerF involved in the F-ring modification of IDTs (Motoyama et al. 2012). Detailed analysis of both enzymes was conducted through heterologous expression in A. oryzae and in vitro enzymatic assays. Experimental results revealed that TolF and TerF could catalyze the production of 20- and 22-position prenylated products of 1, respectively. In order to investigate the broad substrate specificity of these two enzymes, the reduced product of 1, the compound 13 was synthesized. When 13 as substrate both in vivo and in vitro experimental analyses detected two new products. By LC–MS analysis, both compounds have a specific fragment 198.13, which is produced by C-ring cleavage of mono-prenylated paxilline (Liu et al. 2014a). In combination with the 1H NMR data and TolF catalyzed 1 production of 5 and 10, these two new compounds should be catalyzed in the same position generated to 14 and 15. However, when compound 11 was used as a substrate, only one product was produced, which is consistent with previous reports. In 2012, Motoyama et al. proposed that TerF function is to modify the hydroxyl group on the F-ring by knocking out the gene in the strain Chaunopycnis alba (Motoyama et al. 2012). In 2020, we used heterologous expression in A. oryzae and produced terpendole C when the terFK genes were introduced into a strain producing compound 11, this result showed that compound 12 was definitively identified as an intermediate (Jiang et al. 2020). In the present study, our experimental results further support this conclusion. Although both enzymes exhibit broad substrate specificity, we found that under the same substrate concentration and reaction time conditions, those two enzymes by in vitro, when reacting with compound 11 the substrate was completely consumed, while when reacting with compounds 1 and 13, the substrate there was still some residual substrate, the result indicating that the native substrate in the cell was 11.

These findings expand the substrate promiscuity of PT transferases and the diversity of IDT compounds, providing insights into the biosynthetic pathway of tolypocladins compounds. The broad substrate tolerance of these enzymes introduces the potential for their application in combinatorial biosynthesis strategies. By integrating these enzymes with various pathways or engineering enzymes with new catalytic activities, it becomes feasible to generate unique compounds with potential beneficial properties. This approach could lead to the discovery of new bioactive molecules, expanding the repertoire of available natural products and potentially contributing to the development of new therapeutic agents.

Data availability

All data generated during this study are included in this published article and its supplementary information file.

References

Bushley KE, Raja R, Jaiswal P, Cumbie JS, Nonogaki M, Boyd AE, Owensby CA, Knaus BJ, Elser J, Miller D, Di Y, McPhail KL, Spatafora JW (2013) The genome of Tolypocladium inflatum: evolution, organization, and expression of the cyclosporin biosynthetic gene cluster. PLoS Genet 9(6):e1003496. https://doi.org/10.1371/journal.pgen.1003496

Hibbard TR, McLellan RM, Stevenson LJ, Richardson AT, Nicholson MJ, Parker EJ (2023) Functional crosstalk between discrete indole terpenoid gene clusters in Tolypocladium album. Org Lett 25(41):7470–7475. https://doi.org/10.1021/acs.orglett.3c02412

Jiang Y, Ozaki T, Harada M, Miyasaka T, Sato H, Miyamoto K, Kanazawa J, Liu C, Maruyama J-I, Adachi M, Nakazaki A, Nishikawa T, Uchiyama M, Minami A, Oikawa H (2020) Biosynthesis of indole diterpene lolitrems: radical-induced cyclization of an epoxyalcohol affording a characteristic lolitremane skeleton. Angew Chem Int Ed 59(41):17996–18002. https://doi.org/10.1002/anie.202007280

Jin FJ, Maruyama J-i, Juvvadi PR, Arioka M, Kitamoto K (2004) Development of a novel quadruple auxotrophic host transformation system by argB gene disruption using adeA gene and exploiting adenine auxotrophy in Aspergillus oryzae. FEMS Microbiol Lett 239(1):79–85. https://doi.org/10.1016/j.femsle.2004.08.025

Kudo K, Liu C, Matsumoto T, Minami A, Ozaki T, Toshima H, Gomi K, Oikawa H (2018) Heterologous biosynthesis of fungal indole sesquiterpene sespendole. ChemBioChem 19(14):1492–1497. https://doi.org/10.1002/cbic.201800187

Liu C, Minami A, Noike M, Toshima H, Oikawa H, Dairi T (2013) Regiospecificities and prenylation mode specificities of the fungal indole diterpene prenyltransferases AtmD and PaxD. Appl Environ Microbiol 79(23):7298–7304. https://doi.org/10.1128/AEM.02496-13

Liu C, Noike M, Minami A, Oikawa H, Dairi T (2014a) Functional analysis of a prenyltransferase gene (paxD) in the paxilline biosynthetic gene cluster. Appl Microbiol and Biotechnol 98(1):199–206. https://doi.org/10.1007/s00253-013-4834-9

Liu C, Noike M, Minami A, Oikawa H, Dairi T (2014b) A fungal prenyltransferase catalyzes the regular di-prenylation at positions 20 and 21 of paxilline. Biosci Biotechnol Biochem 78(3):448–454. https://doi.org/10.1080/09168451.2014.882759

Liu C, Tagami K, Minami A, Matsumoto T, Frisvad JC, Suzuki H, Ishikawa J, Gomi K, Oikawa H (2015) Reconstitution of biosynthetic machinery for the synthesis of the highly elaborated indole diterpene penitrem. Angew Chem Int Ed 54(19):5748–5752. https://doi.org/10.1002/anie.201501072

Liu C, Minami A, Dairi T, Gomi K, Scott B, Oikawa H (2016) Biosynthesis of shearinine: diversification of a tandem prenyl moiety of fungal indole diterpenes. Org Lett 18(19):5026–5029. https://doi.org/10.1021/acs.orglett.6b02482

Miles CO, Wilkins AL, Gallagher RT, Hawkes AD, Munday SC, Towers NR (1992) Synthesis and tremorgenicity of paxitriols and lolitriol: possible biosynthetic precursors of lolitrem B. J Agric Food Chem 40(2):234–238. https://doi.org/10.1021/jf00014a013

Motoyama T, Hayashi T, Hirota H, Ueki M, Osada H (2012) Terpendole E, a kinesin Eg5 inhibitor, is a key biosynthetic intermediate of indole-diterpenes in the producing fungus Chaunopycnis alba. Chem Biol 19(12):1611–1619. https://doi.org/10.1016/j.chembiol.2012.10.010

Niu J, Qi J, Wang P, Liu C, Gao J-m (2023) The chemical structures and biological activities of indole diterpenoids. Nat Prod Bioprospect 13(1):3. https://doi.org/10.1007/s13659-022-00368-7

Oikawa H, Minami A, Liu C (2016) Total Biosynthesis of fungal indole diterpenes using cell factories. Heterocycles 92. https://doi.org/10.3987/REV-15-830

Ozaki T, Minami A, Oikawa H (2023) Biosynthesis of indole diterpenes: a reconstitution approach in a heterologous host. Nat Prod Rep 40(1):202–213. https://doi.org/10.1039/d2np00031h

Reddy P, Guthridge K, Vassiliadis S, Hemsworth J, Hettiarachchige I, Spangenberg G, Rochfort S (2019) Tremorgenic mycotoxins: structure diversity and biological activity toxins 11(5):E302. https://doi.org/10.3390/toxins11050302

Richardson AT, Cameron RC, Stevenson LJ, Singh AJ, Lukito Y, Berry D, Nicholson MJ, Parker EJ (2022) Biosynthesis of Nodulisporic Acids: A multifunctional monooxygenase delivers a complex and highly branched array. Angew Chem Int Ed 61(49):e202213364. https://doi.org/10.1002/anie.202213364

Saikia S, Nicholson MJ, Young C, Parker EJ, Scott B (2008) The genetic basis for indole-diterpene chemical diversity in filamentous fungi. Mycol Res 112(2):184–199. https://doi.org/10.1016/j.mycres.2007.06.015

Tagami K, Liu C, Minami A, Noike M, Isaka T, Fueki S, Shichijo Y, Toshima H, Gomi K, Dairi T, Oikawa H (2013) Reconstitution of biosynthetic machinery for indole-diterpene paxilline in Aspergillus oryzae. J Am Chem Soc 135(4):1260–1263. https://doi.org/10.1021/ja3116636

Uhlig S, Botha CJ, Vrålstad T, Rolén E, Miles CO (2009) Indole−diterpenes and ergot alkaloids in Cynodon dactylon (Bermuda Grass) infected with Claviceps cynodontis from an outbreak of tremors in cattle. J Agric Food Chem 57(23):11112–11119. https://doi.org/10.1021/jf902208w

Van de Bittner KC, Nicholson MJ, Bustamante LY, Kessans SA, Ram A, van Dolleweerd CJ, Scott B, Parker EJ (2018) Heterologous biosynthesis of nodulisporic acid F. J Am Chem Soc 140(2):582–585. https://doi.org/10.1021/jacs.7b10909

Xu L-L, Hai P, Zhang S-B, Xiao J-F, Gao Y, Ma B-J, Fu H-Y, Chen Y-M, Yang X-L (2019a) Prenylated indole diterpene alkaloids from a mine-soil-derived Tolypocladium sp. J Nat Prod 82(2):221–231. https://doi.org/10.1021/acs.jnatprod.8b00589

Xu LL, Pang X-J, Shi Q, Xian P-J, Tao Y-D, Yang X-L (2019b) Two new prenylated indole diterpenoids from Tolypocladium sp. and their antimicrobial activities. Chem Biodivers 16(6):e1900116. https://doi.org/10.1002/cbdv.201900116

Acknowledgements

We are grateful to Prof. Hideaki Oikawa (Hokkaido University) for the gift of A. oryzae NSAR1, the expression vectors pUARA2, and compound terpendole I; we are also grateful to Dr. Shengnan Tan and Dan Sui, Instrumental analysis center in Northeast Forestry University for supplying LC-MS and NMR analysis.

Funding

This work was supported by grants from the Natural Science Foundation of Heilongjiang Province of China (No. LH2023C035), the National Natural Science Foundation of China (No. 32370069, U22A20369, and 31800031) and the Fundamental Research Funds for the Central Universities (No. 2572022BD03).

Author information

Authors and Affiliations

Contributions

L. C., Q. J., W. P., and H. H. conceived and planned the experiments. H. H. carried out the experiments. P. S., W.Q., W. H., and L. C. analyzed data. L. C. and H. H. wrote the manuscript. All authors read and approved the final version of the manuscript.

Corresponding authors

Ethics declarations

Ethics approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Conflict of interest

The author declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Han, H., Peng, S., Wang, Q. et al. Biochemical characterization of a multiple prenyltransferase from Tolypocladium inflatum. Appl Microbiol Biotechnol 108, 275 (2024). https://doi.org/10.1007/s00253-024-13113-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00253-024-13113-6