Abstract

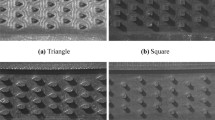

In order to explore the mechanism of boiling heat transfer in microchannels and the appearance of CHF and ONB under different conditions, a visualized experimental research has been conducted on the flow and heat transfer characteristics in microchannels. Combined with the behaviour of bubbles, the occurrence of ONB and CHF in the microchannels with different shapes, different flow velocities and different inflow directions has been compared and analyzed. Results indicate that, after the heat flux exceeds 20 W/cm2, the four microchannels all enter the nucleate boiling stage (ONB), with little difference in order. The appearance of ONB for the droplet pin fin is the earliest (qe = 41.51 W/cm2), with non-closed pin fin with flow direction B (qe = 56.65 W/cm2) as the latest. Accordingly, the channel with droplet fin (qe = 106.2 W/cm2) pin fins appear CHF first, and the non-closed droplet shape (flow direction A: qe = 141.6 W/cm2; flow direction B: no CHF) is the latest. While for the same channel, with the increase of mass flow, the convective heat transfer coefficient becomes higher and ONB and CHF will be delayed. For the different layout, the more favorable flow arrangement (flow direction B) is helpful to delay ONB and CHF. A comprehensive factors η is introduced to evaluate the boiling flow and heat transfer performance of the microchannels with different situations. At higher heat flux density (58 W/cm2-150 W/cm2), flow direction B perform best. Under the discussed condition, the heat flux value as 109.91 W/cm2, 106.22 W/cm2, and 143.05 W/cm2 are the limit values for the CHF, in the square, droplet and non-closed droplet A pin fin arrays. Where, the CHF has not appeared in non-closed droplet B, whose limit value is more than 145 W/cm2. In general, the results illustrate that the opening structure is helpful for boiling heat transfer. The novel design can prolong the duration of bubble flow in nucleate boiling, which plays a key role in delaying CHF.

Similar content being viewed by others

Data availability

The data are available from the corresponding author on reasonable request.

Abbreviations

- a :

-

Long axis of micro pin fin (mm)

- A :

-

Cross-sectional area of pin fin (m2)

- b :

-

Short axis of micro pin fin (mm)

- G :

-

Mass flow rate (kg/h)

- h :

-

The average heat transfer coefficient (W/(m2⋅K))

- H :

-

Height of micro pin fins channel (mm)

- L 0 :

-

Microchannel length(mm)

- L 1 :

-

Length of micro pin fins channel (mm)

- N t :

-

Number of micro pin fins

- P 1 :

-

The inlet pressure of micro pin fins channel (Pa)

- P 2 :

-

The outlet pressure of micro pin fins channel (Pa)

- P s :

-

Wetted perimeter of cross section of micro pin fin (m)

- q :

-

Density of heat flow rate(W/m2)

- Q :

-

Boiling heat transfer(W)

- Re :

-

Reynolds number

- r :

-

Latent heat of vaporization(kJ/kg)

- S :

-

Heat transfer area (m2)

- S D :

-

Diagonal spacing of micro pin fins(mm)

- S L :

-

Longitudinal spacing of micro Pin fins(mm)

- S T :

-

Transverse spacing of micro Pin fins(mm)

- t :

-

Time (s)

- T f :

-

Qualitative temperature of working fluid (℃)

- T i (i = 1,2,3…):

-

Measuring point temperature of microchannel bottom plate (℃)

- T in :

-

The inlet temperature (℃)

- T out :

-

The outlet temperature (℃)

- T surf :

-

The bottom temperature (℃)

- u :

-

Velocity of fluid (m/s)

- W :

-

Width of micro pin fins channel (mm)

- ΔP :

-

Pressure drop between inlet and outlet of micro pin fins channel (Pa)

- v :

-

Viscosity of the working fluid (m2⋅s)

- λ :

-

Thermal conductivity(W/(m ⋅K))

- η :

-

Comprehensive factor

- min:

-

min minimum

- max:

-

max maximum

References

Tuckerman DB, Pease RFW (1981) High-performance heat sinking for VLSI. IEEE Electron Device Lett 2(5):126–129

Zhang F, Wu B, Du B (2022) Heat transfer optimization based on finned microchannel heat sink. Int J Therm Sci 172:107357

Vishwjeet K, Manoj KP (2019) Anil, Experimental investigation of enhanced perfor-mance of pin fin heat sink with wings. Appl Therm Eng 155:546–562

Yang D, Wang Y (2017) Numerical and experimental analysis of cooling performance of single-phase array microchannel heat sinks with different pin-fin configurations. Appl Therm Eng 112:1547–1556

Ambreen T, Saleem A, Park CW (2019) Pin-fin shape-dependent heat transfer and fluid flow characteristics of water and nanofluid-cooled micropin-fin heat sinks: Square, circular and triangular fin cross-sections. Appl Therm Eng 158:113781

Arshad HM, Ali S, Khushnood M (2018) Jabbal, Experimental investigation of PCM based round pin-fin heat sinks for thermal management of electronics: Effect of pin-fin diameter. Int J Heat Mass Transf 117:861–872

Ateş A, Benam BP, Yağcı V, Malyemez MÇ, Parlak M, Sadaghiani AK, Koşar A (2022) On the effect of elliptical pin Fins, distribution pin Fins, and tip clearance on the performance of heat sinks in flow boiling. Appl Therm Eng 212:118648

Sivashankar M, Selvam C (2022) Experimental investigation on the thermal performance of low-concentrated photovoltaic module using various pin-fin configurations of heat sink with phase change materials. J Energy Storage 55:105575

Hua JY, Li G, Zhao XB, Li QH (2017) Experimental study on thermal performance of micro pin-fin heat sinks with various shapes. Heat Mass Transf 53(3):1093–1104

Sun RR, Hua JY, Zhang XQ, Zhao XB (2021) Experimental study on the effect of shape on the boiling flow and heat transfer characteristics of different pin-fin microchannels. Heat Mass Transf 57:2081–2095

Hua JY, Zhang ST, Zhang J (2023) The experimental analysis on the influence of Non-closed droplet shape and location on Thermal/Flow performance of pin fin heat sinks. App Therm Eng 224:120132

Jia Y, Xia G, Li Y, Ma D, Cai B (2018) Heat transfer and fluid flow characteristics of combined microchannel with cone-shaped micro pin fins. Int Commun Heat Mass Transfer 92:78–89

Hithaish D, Saravanan V, Umesh C, Seetharamu K (2022) Thermal management of electronics: Numerical investigation of triangular finned heat sink. Therm Sci Eng Prog 30:101246

Park JE, Thome JR (2010) Critical heat flux in multi-microchannel copper elements with low pressure refrigerants. Int J Heat Mass Transf 53:110–122

Kharangate CR, O’Neill LE, Mudawar I, Hasan MM, Nahra HK et al (2015) Effects of subcooling and two-phase inlet on flow boiling heat transfer and critical heat flux in a horizontal channel with one-sided and double-sided heating. Int J Heat Mass Transf 91:1187–1205

Deng DX, Wan W, Qin Y et al (2017) Flow boiling enhancement of structured microchannels with micro pin fins. Int J Heat Mass Trans 105:338–349

Ma X, Ji XY et al (2022) Flow boiling heat transfer characteristics on micro-pin-finned surfaces in a horizontal narrow microchannel. Int J Heat Mass Tran 194:12307

Lie YM, Ke JH, Chang WR, Cheng TC, Lin TF (2007) Saturated flow boiling heat transfer and associated bubble characteristics of FC-72 on a heated micro-pin-finned silicon chip. Int J Heat Mass Tran 50(19):3862–3876

Chang WR, Chen CA, Ke JH, Lin TF (2010) Subcooled flow boiling heat transfer and associated bubble characteristics of FC-72 on a heated micro-pin-finned silicon chip. Int J Heat Mass Tran 53(23–24):5605–5621

Ma A, Wei J, Yuan M, Fang J (2009) Enhanced flow boiling heat transfer of FC-72 on micro-pin-finned surfaces. Int J Heat Mass Tran 52(13–14):2925–2931

Yuan M, Wei J, Xue Y, Fang J (2009) Subcooled flow boiling heat transfer of FC-72 from silicon chips fabricated with micro-pin-fins. Int J Therm Sci 48(7):1416–1422

Li J, Cheng P (2004) Bubble cavitation in a microchannel. Int J Heat Mass Tran 47(12–13):2689–2698

Wu Z, Sundén B (2014) On further enhancement of single-phase and flow boiling heat transfer in micro/minichannels. Renew Sustain Energy Rev 40:11–27

Zhang J, Hua JY et al (2022) Visualized experimental study on the dynamic behavior of boiling bubbles in the square micro pin-fins on different hydrophobic surfaces. Heat Mass Tran 59(4):741–761

Qin LW, Zhang XQ, Hua JY et al (2022) Flow boiling performance and bubble behaviors of non-closed droplet micro pin-fin arrays. Int Commun Heat Mass 133:105918

Funding

This work is supported by the Nature Science Foundation Programs of Jiangsu Province Colleges and Universities (21KJB470005).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We wish to confirm that there are no known conflicts of interest associated with this publication and there has been no significant financial support for this work that could have influenced its outcome. We confirm that the manuscript has been read and approved by all named authors and that there are no other persons who satisfied the criteria for authorship but are not listed. We further confirm that the order of authors listed in the manuscript has been approved by all of us. We confirm that we have given due consideration to the protection of intellectual property associated with this work and that there are no impediments to publication, including the timing of publication, with respect to intellectual property. In so doing we confirm that we have followed the regulations of our institutions concerning intellectual property.We understand that the Corresponding Author is the sole contact for the Editorial process (including Editorial Manager and direct communications with the office). She is responsible for communicating with the other authors about progress, submissions of revisions and final approval of proofs. We confirm that we have provided a current, correct email address which is accessible by the Corresponding Author and which has been configured to accept email from (yepiaoluo.101@163.com).

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, X., Hua, J., Lan, H. et al. The experimental analysis on the influence of different conditions in microchannel on critical heat flux and boiling starting point. Heat Mass Transfer 59, 2087–2103 (2023). https://doi.org/10.1007/s00231-023-03400-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-023-03400-9