Abstract

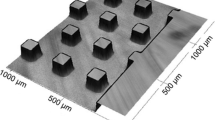

The boiling flow and heat transfer performance of four different pin-fins in microchannels are investigated through visualization experiment research. Flow boiling visualization results have been conducted by using deionized water as working fluid with circulating under flow rates in the range of 0.25~9kg/h, with the inlet temperature as 30 ℃ and heating power as 126W. The experimental results show that the flow patterns in the channel are mist flow, annular flow, isolated bubble and no bubble. And the flow pattern corresponds to the pressure change. With the increase of Re, the pressure drop in the microchannel first increases rapidly, then decreases, and finally increases again. The change process of pressure drop corresponds to the bubble heat transfer process. The corresponding heat transfer processes include film boiling、transition from film boiling to nucleation boiling、nucleation boiling and single-phase convection. At the same time, the state of bubbles in the channel can correspond to the intensity and mode of heat transfer. The average surface temperature of the bottom plate decreases with the increase of Re. The average convective heat transfer coefficient increases, then decreases and increases again with the increase of Re. The twice increases are mainly due to liquid film evaporation and single-phase flow transition. The average convective heat transfer coefficient increases with the increase of heat flux. And in four different micro-fin shapes, the heat transfer effect of triangle fin array is the best, because the disturbance of triangle to fluid is the most intense. While in the nucleation boiling region, the convective heat transfer coefficient of triangle micro-fin arrays is the largest. At that stage, the bubbles in triangle micro fin array grow and separate more easily.When the Re is less than 130, the number of bubbles in the triangle micro array is great than that in the ellipse micro array, and the bubble departure diameter is the largest, as well. And the bubble growth time and bubble waiting time are the shortest. When Re is greater than 130, the number of bubbles in the channel is relatively small, and the nucleation boiling intensity decreases. When the Re continues to increase, there are few or no bubbles in the channel, which is close to the single-phase convection. Moreover, the pressure drop, bottom temperature and convective heat transfer coefficient of triangle micro fin array change most obviously. The results show that when Re increases from 30 to 125, the bottom temperature decreases by 41 ℃, the maximum convective heat transfer coefficient reaches 16800 w / m2 · ℃, and the maximum Nu is 10.

Similar content being viewed by others

Abbreviations

- a :

-

long axis of micro pin-fin(m)

- A :

-

whole heat transfer area (m2)

- A b :

-

heat transfer area of microchannel without micro pin-fin (m2)

- A fin :

-

heat transfer area of micro pin-fin (m2)

- b :

-

short axis of micro pin-fin(m)

- d w :

-

the bubble departure diameter(m)

- D :

-

equivalent diameter (m)

- h av :

-

the average heat transfer coefficient (W/(m2·K))

- H :

-

height of micro pin-fin heat sink (m)

- L :

-

length of micro pin-fin heat sink (m)

- L 1 :

-

length of the area occupied by the pin-fin in the heat sink (m)

- Nu :

-

Nusselt number

- P sL :

-

wetted perimeter of cross section of microchannel(m)

- ΔP :

-

pressure drop between inlet and outlet of micro pin-fin arrays (Pa)

- Q :

-

volume flow rate (m3/s)

- Re :

-

Reynolds number

- S D :

-

oblique distance of pin-fin (m)

- S L :

-

longitudinal distance of pin-fin (m)

- S T :

-

transverse distance of pin-fin (m)

- t g :

-

the bubble growth time(s)

- t w :

-

the bubble waiting time(s)

- T surf :

-

temperature of surface (℃)

- T f :

-

temperature of working fluid (℃)

- u :

-

velocity of fluid (m/s)

- W :

-

width of micro pin-fin heat sink (m)

- Λ :

-

coefficient of thermal conductivity (W/m·K )

- η :

-

efficiency of micro pin-fin

- Φ :

-

heat flux (kW/m2)

- υ :

-

viscosity of the working fluid (m2·s)

- b:

-

sidewall which not occupied by micro pin-fin arrays

- fin:

-

micro pin-fin array

- m:

-

mass

- max:

-

maximum

- min:

-

minimum

References

Dey R, Das T, Chakraborty S (2012) Frictional and Heat Transfer Characteristics of Single-Phase Microchannel Liquid Flows [J]. Heat Transfer Eng 33:(4–5)

Abdollahi A, Norris SE, Sharma RN (2019) Heat transfer measurement techniques in microchannels for single and two-phase Taylor flow [J]. Appl Therm Eng 162

Yang X, Weldetsadik NT, Hayat Z et al (2019) Pressure drop of single phase flow in microchannels and its application in characterizing the apparent rheological property of fluids [J]. Microfluid Nanofluid 23:(5)

Gorasiya A, Saha SK (2019) Single phase laminar fluid flow and heat transfer in microchannel with cylindrical and parallelepiped micro-fins [J]. Anil Gorasiya; Sandip K. Saha 55:(3)

Dalkılıç AS, Mahian O, Yılmaz S et al (2017) Experimental investigation of single-phase turbulent flow of R-134a in a multiport microchannel heat sink [J]. Int Commun Heat Mass Transfer 89

Abdoli A, Jimenez G, Dulikravich GS (2015) Thermo-fluid analysis of micro pin-fin array cooling configurations for high heat fluxes with a hot spot [J]. Int J Therm Sci 90

Moshtagh M, Jamekhorshid A, Azari A et al (2020) Experimental and numerical investigation of microencapsulated phase change material slurry heat transfer inside a tube with butterfly tube inserts [J]. Appl Therm Eng 174

Shafeie H, Abouali O, Jafarpur K et al (2013) Numerical study of heat transfer performance of single-phase heat sinks with micro pin-fin structures [J]. Appl Therm Eng 58:(1-2)

Mei D, Liang L, Qian M et al (2013) Modeling and analysis of flow distribution in an A-type microchannel reactor [J]. Int J Hydrog Energy 38:(35)

Croce G, D’Agaro P (2003) Numerical analysis of roughness effect on microtube heat transfer [J]. Superlattice Microst 35:(3)

Lu H, Xu M, Gong L et al (2020) Effects of surface roughness in microchannel with passive heat transfer enhancement structures [J]. Int J Heat Mass Transfer 148

Zhang X, Zhao T, Wu S et al (2019) Experimental Study on Liquid Flow and Heat Transfer in Rough Microchannels [J]. Adv Condens Matter Phys

Vinoth R, Kumar DS (2018) Experimental investigation on heat transfer characteristics of an oblique finned microchannel heat sink with different channel cross sections[J]. Heat Mass Transfer 54(12):3809–3817

Chakravarthii DMK, Devarajan M, Subramani S (2017) Experimental and numerical investigation of pressure drop and heat transfer coeffcient in converging–diverging microchannel heat sink [J]. Heat Mass Transfer 53(7):2265–2277

Sahar AM, Wissink J, Mahmoud MM et al (2017) Effect of hydraulic diameter and aspect ratio on single phase flow and heat transfer in a rectangular microchannel [J]. Appl Therm Eng 115

Guo B, Baozhou D, Liu Z et al (2017) Study on two phase friction pressure drop characteristics of flow boiling in micro column group channel [J]. Shandong Sci 030(006):50–57

Guo B (2017) Study on pressure drop and heat transfer characteristics of flow boiling in microchannels [D]. North China Electric Power University

Li H, Guo B, Baozhou D et al (2018) Experimental study on saturated boiling heat transfer in microchannels [J]. Acta Refrig Sinica 181(03):47–53

Wan W, Deng D, Huang Q et al (2017) Experimental study and optimization of pin fin shapes in flow boiling of micro pin fin heat sinks [J]. Appl Therm Eng 114

Chien LH, Liao WR, Ghalambaz M et al (2019) Experimental study on convective boiling of micro-pin-finned channels with parallel arrangement fins for FC-72 dielectric fluid [J]. Int J Heat Mass Transfer 138:390–400

Xie M, Luo X, Liqin H (2016) Pressure drop characteristics of R22 refrigerant flow boiling in microchannels [J]. Chem Eng 1:38–42

Liao WR, Chien LH, Ghalambaz M, Yan WM (2019) Experimental study of boiling heat transfer in a microchannel with nucleated-shape columnar micro-pin-fins [J]. Int Commun Heat Mass Transfer 108:104277

Yin L, Jiang P, Xu R et al (2019) Heat transfer and pressure drop characteristics of water flow boiling in open microchannels [J]. Int J Heat Mass Transfer 137

Huang Q, Jia L, Dang C et al (2018) Experimental Study on Flow Boiling of Deionized Water in a Horizontal Long Small Channel [J]. J Therm Sci 27(2):157–166

Yin L, Jiang P, Ruina X et al (2017) Visualization of flow patterns and bubble behavior during flow boiling in open microchannels [J]. Int Commun Heat Mass Transfer 85:131–138

Qin L, Hua J, Zhao X et al (2019) Micro-PIV and numerical study on influence of vortex on flow and heat transfer performance in micro arrays [J]. Appl Therm Eng 161

Zhang X (2019) Experimental study on heat exchanger characteristics of boiling flow in different Shape and hydrophobic microchannels [D]. Nanjing Norm Univ

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, R., Hua, J., Zhang, X. et al. Experimental study on the effect of shape on the boiling flow and heat transfer characteristics of different pin-fin microchannels. Heat Mass Transfer 57, 2081–2095 (2021). https://doi.org/10.1007/s00231-021-03092-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-021-03092-z