Abstract

Consumer safety and product quality are of high priority in the food industry. Strongly adhering deposits are formed in processing equipment such as plate heat exchangers, which demand large quantities of water, chemicals, energy and time for cleaning. This study presents an approach to characterize soil properties and to link them to the cleaning behavior to generate a basis for soil-specific cleaning. Six starch soils were rheologically analyzed during swelling, pull-off forces were measured with a micromanipulation device, and swelling progression was determined with a camera. Cleaning experiments were conducted in a plane channel setup. A reptation time without cleaning and a subsequent constant cleaning rate defined the cleaning behavior. The observed cleaning mechanisms were considered as well. Multivariate statistics revealed significant interrelationships between soil properties and cleaning behavior. The complex reasons for the overall cleaning behavior remain unknown, but certain aspects could be explained by the measured soil properties.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Cleaning of strongly adhering deposits is a challenging but crucial task in the food industry as product quality and consumer safety highly depend on safe cleaning processes. Following the latest market trends, food producers strive to individualize their products and reduce batch sizes. This leads to an increasing number of product changes and the necessity of frequent cleaning [1]. However, product-specific cleaning requirements are often not fully known. Since these cleaning processes are not optimally adapted to the respective soil, the use of water, chemicals, energy and time is oversized in many cases. Consequently, knowledge of the individual physicochemical properties of a soil is essential to ensure environmentally friendly cleaning [2,3,4].

As regards the cleaning behavior of different soils, four cleaning mechanisms can be distinguished. Viscous shifting occurs in viscous deposits. Diffusive dissolution requires the solubility of soil components, while cohesive separation involves breaking up cohesive bonds within the soil layer and removal of larger fragments. Adhesive detachment refers to the debonding of the soil from the substrate [2, 5,6,7]). The composition and structure of the soils, which also depend on drying and ageing, and the cleaning fluid largely define the cleaning mechanism. Furthermore, the mechanical properties of food soils may change during cleaning [2]. Polymeric networks such as proteins or long-chain carbohydrates swell during contact with the cleaning fluid. Cleaning starts after a short time, called reptation time, when molecular chains disengage into the fluid or when the fluid deforms and displaces the soil layer [8,9,10].

Numerous studies investigated the mechanical properties of soils and attempted to relate them to cleaning behavior. Comparatively often, relations between the cleaning behavior and rheological properties of soil layers were found [11,12,13,14,15,16]. Xin et al. [11] were the first who linked the cleaning rate of whey protein concentrate deposits to their mechanical properties determined by oscillatory rheometry and indentation tests. The oscillatory shear rheometry method reflects mechanical properties at small strains. In Contrast, rotational rheometry examines rheological properties at larger deformations [14, 15]. Wilson et al. [14] highlighted that the effect of temperature on the cleaning rate during impinging jet cleaning of petroleum jelly was directly related to the effect of temperature on critical shear stress. Using rotational and oscillatory rheometry, Palabiyik et al. [15] identified a linear relationship between a dimensionless cleaning time and the ratio of critical shear stress to surface shear stress for viscoplastic fluids.

However, rheological studies were usually performed on homogenous soil films or pastes placed between roughened parallel plates. In contrast, Helbig et al. [6] applied and dried egg yolk deposits on the bottom plate of a rheometer. The rheological properties of the soil layers were investigated in different cleaning fluids during swelling.

Micro- or millimanipulation devices examine adhesive and cohesive interactions at large deformations [7, 17, 18]. Tsai et al. [19] and Fernandes et al. [20] used a micromanipulation device to estimate the critical shear stress of viscoplastic soils in contact with the cleaning fluid and related it to the cleaning behavior. Köhler et al. [7] used micromanipulation to link the measured adhesive strength to the water mass fraction at the soil-substrate interface and coupled this to the cleaning time of ketchup soil layers.

Fluid dynamic gauging (FDG) is a method to study the thickness of swelling soil layers immersed in a cleaning fluid [21,22,23]. Thereby, the suction force or pressure can be used to measure the strength of soft soil layers [24, 25].

However, only few studies consider that the rheological properties of soils change during swelling. Regardless of the soil, various authors indicated that cohesive and adhesive strengths decrease with swelling time [6, 16, 18, 26].

Starch is widely used in the food industry as thickener, stabilizer, and gelling agent. Since products containing starch often adhere strongly at the inner surface of pipes and accessories, different cleaning parameters such as temperature, chemistry of the cleaning fluid and methods to analyze the removal of dried starch layers were investigated [10, 27,28,29,30]. The swelling and cleaning behavior of starch soils is affected by the chemical composition and the starch structure, which can result from different botanical origins. Furthermore, varying cleaning mechanisms were observed depending on alkaline concentration and temperature of the cleaning fluid. However, the cleaning behavior of different starches could not be fully explained with the determined swelling properties [10].

This study aims to analyze the influence of strength and elasticity of swelling soil layers on the cleaning behavior of four native and two modified starches. Soil layer thickness measurements were used to obtain information on the swelling progress which supported the interpretation of rheological measurements and pull-off properties obtained from micromanipulation measurements in conjunction with cleaning experiments.

2 Materials and methods

2.1 Investigated soils and cleaning fluids

Four native starches from different botanical sources (waxy maize (WMS), Cargill Deutschland GmbH, Hamburg-Rothenburgsort, Germany; potato (PS), wheat (WS), AGRANA Beteiligungs-AG, Tulln, Austria; rice (RS), BENEO GmbH, Mannheim, Germany), a modified waxy maize starch (acetylated distarch adipate (ADA-S), Cargill Deutschland GmbH, Hamburg-Rothenburgsort, Germany) and a modified potato starch (hydroxypropyl distarch phosphate (HDP-S), Unilever Deutschland GmbH, Auerbach, Germany) were investigated. Soil layers were prepared as described by Kricke et al. [10]. The concentration of each starch was adjusted in a way that, after gelatinization at 95 °C for 45 min with stirring at 1000 rpm, the viscosity of the starch pastes enabled homogenous application using a pipette: WMS and WS, 3.5 g/100 g; PS, 2.5 g/100 g; RS, ADA-S and HDP-S, 3.0 g/100 g. Luminescent, stabilized strontium aluminate crystals (0.0267 g/g dry starch) were added to ensure UV detectability of soil layers during the cleaning tests. Stainless steel substrates (AISI 304; 2B finish; Rz ≤ 1 µm) measuring 40 × 20 mm2 were soiled for micromanipulation and swelling experiments, and 150 × 80 mm2 substrates were used for cleaning experiments. The dried soil mass coverage \({m}_{\mathrm{s},0}^{\prime \prime}\) of the samples was set to 50 ± 5 g/m2 by applying an appropriate mass of gelatinized starch paste and drying at standard climate (23 °C, 50% relative humidity) for 18 h. For the rheological measurements, the concentration of the starch pastes was adjusted to obtain thicker, plane soil layers: WMS, 10.0 g/100 g; WS and RS, 7.5 g/100 g; PS, 4.5 g/100 g; ADA-S, 3.5 g/100 g; HDP-S, 6.0 g/100 g.

All experiments were carried out at five test conditions: with deionized water at 25 °C or 55 °C, using sodium hydroxide with a concentration of 1.0 g/100 g at 40 °C, as well as with 2.0 g/100 g sodium hydroxide at 25 °C or 55 °C (abbrev. T25H2O, T55H2O, T40N10, T25N20, T55N20).

2.2 Rheological analyses

To measure the rheological properties of the starch layers during swelling, a MCR 300 rheometer (Anton Paar GmbH, Ostfildern, Germany) with plate-plate geometry (diameter 50 mm) and Peltier temperature control was used. Dynamic experiments were carried out based on Helbig et al. [6] with the following adjustments. The soil layer was applied using an acrylic ring with an inner diameter of 60 mm and a thickness of 2 mm. To dry the starch paste, the lower plate was heated to 55 °C for 60 min, followed by an adjustment to the test condition temperature within 5 min. The tempered test fluid was spread by a pipette, and soaking was stopped after 1 min by lowering the upper plate until a normal force of 15 N was reached. An anti-evaporation cover was fitted. A dynamic time sweep (1% strain, 1 rad/s) was applied for 15 min to determine the absolute value of the complex modulus |G*| as well as the loss factor tan δ. The total soaking time was 200 s until the first measured data point. The measurements were repeated for at least three times.

2.3 Micromanipulation experiments

A micromanipulation device described by Helbig et al. [6] was used to determine the strength of the soil layers, which includes adhesive and cohesive binding forces that need to break during deformation and displacement of the soil layer [17, 19]). After defined soaking times tsoak of 60 s or 300 s, the soiled substrate was positioned at a gap distance of 100 ± 10 µm between the substrate surface and the lower edge of the blade. The force required to pull off the soil at a constant scraper blade speed of 2.6 mm/s was measured at a frequency of 100 Hz with a force sensor (KD40s, 2 N, ME-Meßsysteme GmbH, Hennigsdorf, Germany).

The pull-off forces were normalized with respect to substrate width B of 20 mm to obtain the normalized pull-off force (\(F\text{/}{\text{B}}\)). Averaging these pull-off forces (\(\stackrel{\mathrm{-}}{\text{F}}\text{/}{\text{B}}\)) over substrate length L of 40 mm, as described by Köhler et al. [7], made it possible to compare the results of the different soils and fluids by one characteristic scalar value.

2.4 Soil layer thickness measurements during swelling

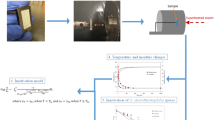

The growing thickness of the starch layers was investigated in a swelling test setup [7]. The probe was placed horizontally in a heatable and transparent tank and monitored with a camera and zoom lens (Zoom 70 XL, TV-Tube 1.0X, Opto GmbH, Gräfelfing, Germany) during soaking for 1800s. Snap shots of a representative swelling experiment are shown in Fig. 1. The thickness increase Δh(t) = h(t)—h(t = 0) was captured time-resolved for the whole swelling process using a contrast based evaluation script.

2.5 Cleaning experiments

The cleaning behavior of the starch soils was investigated in a plane channel flow test setup as depicted and thoroughly described by Joppa et al. [5]. The 150 × 80 mm2 samples were inserted in a 78 × 5 mm2 cross-sectional plane flow area. Cleaning was carried out for 1800s at a bulk velocity of 1 m/s, resulting in turbulent flow with Reynolds numbers ranging from 10,300 to 18,500 depending on the temperature of the fluid. The fluorescent tracer embedded in the soil layer was excited by UV lamps through a transparent PMMA cover and allowed the cleaning observation by a monochrome camera. The gray values were measured over time and averaged within a centered 40 × 40 mm2 range of interest. The intensity Iraw(t) was normalized with respect to initial intensity Iraw(t = 0) to ensure comparability of the different cleaning measurements.

Joppa et al. [31] already introduced a method to distinguish the swelling induced intensity increase from the actual cleaning progress. Relevant swelling experiments were carried out within the cleaning test setup. The reptation time trep, during which no cleaning occurs, and mean cleaning rate \({\overline{\dot{m}} }_{\mathrm{s}}^{\prime \prime}\) were determined from the intensity plots [10]. The cleaning mechanism was additionally documented from visual inspection for all cleaning experiments as introduced by Köhler et al. [32]. Diffusive dissolution and cohesive separation could not be differentiated from macroscopic observations. Therefore, cohesive separation, viscous shifting and adhesive detachment were used to describe the observations.

2.6 Statistical analyses

The statistical analyses were carried out with SPSS 27.0 (SPSS Inc., Chicago, USA). Significant differences between mean values were identified by one-way analysis of variance followed by a Tukey-B post-hoc test at P ≤ 0.05. Relationships between rheological, pull-off, swelling, and cleaning properties were identified using nominal or, in case of |G*|, logarithmic data by applying principal component analysis (PCA).

3 Results and discussion

3.1 Rheological properties

Dynamic shear rheometry is able to provide information about the viscoelastic behavior of materials. The complex modulus G* describes the entire deformation resistance of a material and includes the storage modulus G´ and the loss modulus G´´ as real and imaginary part of a complex variable. The loss factor tan δ represents the ratio of viscous to elastic contributions.

For most starches, the complex modulus and loss factor slightly changed within the first three minutes of measurement and thereafter reached a stable level (data not shown). The complex modulus mostly showed an initial increase in T25H2O and an initial decrease in T55N20. ADA-S showed a steady decrease of the complex modulus and increase of the loss factor in all cleaning fluids throughout the whole measurement period. The branched network of solid bonds in the acetylated distarch adipate is less susceptible to swelling than the network of native starches [33]. Unfortunately, the rapid change in rheological properties of native starch soil layers were only recorded to a limited extend caused by the method-related 200 s time delay after soaking started.

The complex modulus and loss factor depended on the type of starch as well as on temperature and sodium hydroxide concentration of the fluid (Fig. 2). WS had the highest complex modulus and lowest loss factor of all analyzed starches, therefore it had a higher deformation resistance with a more elastic behavior. On the other hand, the soil layers of WMS were more viscous with the highest loss factor and less deformation resistant. The high loss factor of WMS might result from a high water solubility of WMS in comparison with other starches [34]. During swelling in heated water, the WMS layer became more viscous, while the ADA-S soil layer was most elastic. In contrast, NaOH in both concentrations weakened the soil network of ADA-S but increased the loss factor during swelling at all temperatures. The loss factor of PS was low in water or T40N10, but twice as high when in contact with high concentrated sodium hydroxide (2.0 g/100 g). Nor Nadiha et al. [35] assumed that the high polymerized amylose of potato starch is less vulnerable to low concentrations of sodium hydroxide but tends to alkaline hydrolysis when a critical concentration is exceeded. During alkaline hydrolysis, monomers of PS split off, resulting in a high water solubility [34] and therefore a loss of elastic bindings.

Rheological properties a complex modulus |G*| and b loss factor tan δ of all investigated starches and fluid properties after soaking for 200 s. Error bars represent standard deviation of three replicate measurements. Mean values with different letters within a starch type show significant difference at P ≤ 0.05

3.2 Pull-off properties from micromanipulation experiments

Three representative types of force plots were determined in the micromanipulation experiments (Fig. 3). Caused by a larger surface area, fluid penetration was obviously pronounced at the edges of the soil layer, resulting in reduced pull-off forces at the beginning and the end of the measurement. Depending on the fluid used, the rate of penetration varied. The cohesive binding forces in the center of the soil layer remained resistant to deformation for a longer time, e.g., after soaking of PS in T25H2O for 60 s. In contrast to the continuously increasing and decreasing pull-off force after soaking of PS in T25H2O, the forces after soaking of PS in T40N10 for 300 s were comparably low at the beginning and at the end of the force measurement. Higher forces were only measured in a small central part of the soil layer. Once the fluid completely penetrated the soil, the pull-off forces decreased over the entire length, as demonstrated by the graph of \(F\)/B after soaking of PS in T55N20 for 300 s.

The averaged pull-off forces are shown in Fig. 4 for all starches and fluid conditions after soaking for 60 s. The same tendencies, but at lower magnitudes, were observed after soaking for 300 s (data not shown). All starches showed the highest averaged pull-off forces after soaking in T25H2O for 60 s. The averaged pull-off forces were reduced when the temperature was increased to 55 °C. Comparable to this, lower pull-off forces were observed with increasing temperature after soaking in sodium hydroxide (2.0 g/100 g) with exception of WS. For all investigated starches, soaking of the layers in T40N10 led to pull-off forces similar to that in T55N20.

High standard deviations appeared for several test conditions, e.g., native and modified potato starch (PS, HDP-S) after soaking in T25H2O. In these cases, continuously increasing and subsequently decreasing pull-off forces were observed.

3.3 Swelling properties

As shown in Fig. 5, the soil layer grew steadily over time with a pronounced increase at the beginning. Subsequently, the growth continued at a lower rate until the swelling experiment was stopped after 1800s. These thickness increases depended on the individual starch and the used fluid. Some starch layers detached from the substrate after swelling in certain fluids probably due to lowered adhesive forces and a strong multidirectional volume increase. The earliest detachment was observed around tsoak = 300 s. Kricke et al. [10] showed that the initial swelling rate had an important influence on the cleaning behavior of starch soils. The current data of the thickness increase Δh at tsoak = 60 s gave a measure for the initial swelling rate. Therefore, and since defined scalar values were required for further statistical analysis, Δh at 60 s was taken as indicator for describing the swelling behavior.

The thickness increase showed a strong dependency on the fluid after soaking for 60 s (Fig. 6). These tendencies were similar for all starches. The thickness increased just slightly in T25H2O. A stronger thickness increase was observed in T55H2O. Within sodium hydroxide, the thickness increase was even more pronounced at the respective temperature compared to deionized water.

3.4 Cleaning behavior

The reptation time and mean cleaning rate obtained from the cleaning experiments are shown in Fig. 7. The reptation time was set to 1800s and the mean cleaning rate equals zero for the test points where no cleaning occurred.

a Reptation time trep and b mean cleaning rate \({\overline{\dot{m}} }_{s}^{\prime \prime}\) of all investigated starches and fluid properties. trep was set to 1800s and \({\overline{\dot{m}} }_{s}^{\prime \prime}\) to zero when no cleaning occurred. Error bars represent standard deviation of three replicate measurements. Mean values with different letters within a starch type show significant difference at P ≤ 0.05

For all starches, the reptation time depended on temperature and sodium hydroxide concentration of the cleaning fluid. None of the starches was cleaned by T25H2O except modified potato starch (HDP-S). A temperature increase to 55 °C initiated the cleaning process for most starches, except WS and RS. Once sodium hydroxide was used as cleaning fluid, all starches were removed from the surface. The cleaning process was initiated after a comparably long reptation time at T25N20 for most starches. Interestingly, the reptation time showed equally low values for T40N10 and T55N20 for most starches, except WS.

The mean cleaning rate showed opposite dependencies on the cleaning fluid, since an effective cleaning process is marked by a low reptation time on the one side, and a high cleaning rate on the other. Noticeably, the mean cleaning rate was highest for PS at T40N10 and T55N20 as well as for RS at T40N10. At these test points, an adhesive detachment of the soil layers was observed as cleaning mechanism, and the soil layer was teared off in large cohering parts as depicted in Fig. 8b. Adhesive detachment was also observed as dominant cleaning mechanism for PS at T25N20 as well as for WS at T55N20. Slightly smaller cohering parts were removed and the detachment of the complete soil layer took longer at these test points. WMS was cleaned at a comparably high cleaning rate. Here, partial viscous shifting was observed as dominant cleaning mechanism when T40N10 and T55N20 were used as fluid (Fig. 8c). The soil layer formed a wavy surface at T55H2O and T25N20 (Fig. 8d). Cohesive separation was identified as dominant cleaning mechanism for all other starches and test points (Fig. 8a).

3.5 Statistical correlations and interdependencies

Figure 9 presents the result of the principal component analysis considering the rheological, pull-off, and swelling properties as well as the cleaning behavior. Overall, 30 objects, representing the six different starches at five test conditions, were included. It is clearly visible that most of the variables loaded on the first principal component (PC 1) which explained 50.8% of the overall variance. The second (PC 2) and third (PC 3) principal component explained 17.1% and 13.7% of the overall variance and should be considered to uncover the underlying interdependencies. Table 1 illustrates bicorrelations between rheological, pull-off, swelling, and cleaning properties.

The complex modulus |G*| and the averaged pull-off force \(\overline{F }/B\) as well as the reptation time trep loaded strongly positive on PC 1, and slightly positive on PC 2. In contrast, the loss factor tan δ loaded negative on PC 1 and PC 2. This indicates correlations between rheological and pull-off properties. The factors representing cleaning behavior (\({\overline{\dot{m}} }_{\mathrm{s}}^{\prime \prime}\), trep) loaded in the opposite direction of each other, which is consistent with previous findings [10]. The thickness increase Δh loaded in the same direction as the cleaning rate \({\overline{\dot{m}} }_{\mathrm{s}}^{\prime \prime}\).

As presented in Table 1, bicorrelations were revealed between the rheological properties and the averaged pull-off force. This substantiates the assumption that the averaged pull-off force highly depended on the rheological properties of the swollen soil layer. On the one hand, a high complex modulus increased the pull-off resistance of the soil layer. On the other hand, an increasing loss factor represents a rising viscous condition of the soil layer, which led to a decreasing pull-off resistance in return. Furthermore, the complex modulus and especially the averaged pull-off force were negatively correlated to the thickness increase during swelling, substantiating that the inner strength of the soil layer was strongly influenced by the rapid swelling process.

Turning to the cleaning properties presented in Table 1, the reptation time correlated positive with the complex modulus and negative with the loss factor and the thickness increase. The results also showed that none of the investigated properties alone was responsible for a longer or a shorter reptation times. Only slight relations, but non-significant correlations between the cleaning rate and the rheological and swelling properties were revealed. The correlation between the thickness increase during swelling and the cleaning rate, as indicated by PCA, was not confirmed in bicorrelation, since both were oppositely loaded on PC 3 (data not shown) indicating another influencing factor. Different cleaning mechanisms observed during the cleaning experiments might explain these findings.

The influence of temperature und sodium hydroxide concentration of the fluid on the different properties and cleaning behavior varied starch-specifically. Therefore, two radar plots for a) waxy maize starch and b) acetylated waxy maize starch are given in Fig. 10, presenting the rheological, pull-off, swelling and cleaning properties at the different test conditions.

For WMS, no cleaning occurred in T25H2O. The use of deionized water at 55 °C or sodium hydroxide evoked the cleaning process and a decline of the reptation time. Higher temperature of the cleaning fluid led to a strong increase of the cleaning rate along with a rising thickness increase during swelling as well as a decreasing elasticity and strength of the starch soil layer, indicated by the increasing loss factor and decreasing averaged pull-off force. Wavy soil surfaces were formed during cleaning with T55H2O and T25N20. With T40N10 and T55N20, viscous shifting was observed as dominant cleaning mechanism, which provoked a high cleaning rate. It is assumed that the formation of these wavy soil surfaces and viscous shifting were caused by the viscous behavior of the soil layer.

No cleaning occurred for ADA-S in T25H2O either. A decrease of the reptation time was observed when the fluid temperature was raised, or when sodium hydroxide was used. Contrary to WMS, the highest cleaning rate was achieved using T55H2O. The loss factor was lowest at this test point, and complex modulus and averaged pull-off force showed high values. Therefore, the soil layer was characterized by a high strength and elasticity, and cohesive separation was observed as cleaning mechanism at this test point. Once sodium hydroxide solution was used as soaking fluid, the loss factor increased strongly, indicating a more viscous behavior of the soil layer. The swelling thickness increased as well, but furthermore, low values of the complex modulus and averaged pull-off force indicated a decreased inner strength.

4 Conclusion

This study identified starch-specific interdependencies between rheological, pull-off and swelling properties of food soils and their cleaning behavior. The presented set of methods is a useful basis to characterize soils with regard to their cleaning properties. It should be emphasized that relations between the loss factor and the viscous behavior during cleaning were identified by principal component analysis. However, the soil properties change strongly time-dependent during cleaning. It is crucial but challenging to identify and extract representative scalar values for statistical analysis. Distinct dependencies can be expected when the cleaning mechanism is included in the analysis. Further research should be undertaken to explain the complex reasons for soil-specific cleaning behavior. The focus should be on intra- and intermolecular attractive forces that strengthen or weaken the soil layers.

Abbreviations

- ADA-S:

-

Acetylated distarch adipate

- HDP-S:

-

Hydroxypropyl distarch phosphate

- PC:

-

Principal component

- PCA:

-

Principal components analysis

- RS:

-

Rice starch

- PS:

-

Potato starch

- T25H2O:

-

T = 25 °C, deionized water

- T55H2O:

-

T = 55 °C, deionized water

- T40N10:

-

T = 40 °C, cNaOH = 1.0 g/100 g

- T25N20:

-

T = 25 °C, cNaOH = 2.0 g/100 g

- T55N20:

-

T = 55 °C, cNaOH = 2.0 g/100 g

- WMS:

-

Waxy maize starch

- WS:

-

Wheat starch

- A :

-

Area, m2

- B :

-

Width, m

- c :

-

Concentration, g/100 g

- G’ :

-

Storage modulus, Pa

- G´´:

-

Loss modulus, Pa

- G*:

-

Complex modulus, Pa

- D hyd :

-

Hydraulic diameter, Dhyd = 4A/p, m

- F :

-

Force, N

- h :

-

Height, m

- I :

-

Intensity, -

- KMO :

-

Kaiser-Meyer-Olkin criterion, -

- L :

-

Length, m

- m :

-

Mass, \({\text{g}}\)

- \({m}_{\mathrm{s}}^{\prime \prime}\) :

-

Soil mass per area, g/m2

- \({\overline{\dot{m}} }_{\mathrm{s}}^{\prime \prime}\) :

-

Mean cleaning rate per area, g/(s\(\cdot\)m2)

- p :

-

Wetted perimeter, m

- P :

-

P-value, -

- R z :

-

Average surface roughness, µm

- Re :

-

Reynolds number, Re = ubDhyd/ν, -

- t :

-

Time, s

- T :

-

Temperature, °C

- u :

-

Velocity, m/s

- tan δ :

-

Loss factor, -

- ν :

-

Kinematic viscosity, m2/s

- 0:

-

Initial

- b:

-

Bulk

- hyd:

-

Hydraulic

- raw:

-

Original

- rep:

-

Reptation

- s:

-

Soil

- soak:

-

Soaking

References

Claassen GDH, Hendrix EMT (2014) On Modelling Approaches for Planning and Scheduling in Food Processing Industry. In: Murgante B et al. (eds) Computational Science and Its Applications – ICCSA 2014. ICCSA 2014. Lect Notes Comput Sci 8580. Springer, Cham. https://doi.org/10.1007/978-3-319-09129-7_4

Fryer PJ, Asteriadou K (2009) A prototype cleaning map: A classification of industrial cleaning processes. Trends Food Sci Technol 20:255–262

Herrera-Márquez O, Serrano-Haro M, Vicaria JM, Jurado E, Fraatz-Leál AR, Zhang ZJ, Fryer PJ, Avila-Sierra A (2020) Cleaning maps: A multi length-scale strategy to approach the cleaning of complex food deposits. J Clean Prod 261:121254

Agüeria DA, Libonatti C, Civit D (2021) Cleaning and disinfection programmes in food establishments: a literature review on verification procedures. J Appl Microbiol 131:23–35

Joppa M, Köhler H, Rüdiger F, Majschak J-P, Fröhlich J (2017) Experiments and Simulations on the Cleaning of a Swellable Soil in Plane Channel Flow. Heat Transf Eng 38:786–795

Helbig M, Zahn S, Böttcher K, Rohm H, Majschak J-P (2019) Laboratory methods to predict the cleaning behaviour of egg yolk layers in a flow channel. Food Bioprod Process 113:108–117

Köhler H, Liebmann V, Golla C, Fröhlich J, Rüdiger F (2021) Modeling and CFD-simulation of cleaning process for adhesively detaching film-like soils with respect to industrial application. Food Bioprod Process 129:157–167. https://doi.org/10.1016/j.fbp.2021.08.002

Devotta I, Ambeskar D, Mandhare AB, Mashelkar RA (1994) The life time of a dissolving polymeric particle. Chem Eng Sci 49:645–654

Xin H, Chen XD, Özkan N (2004) Removal of a model protein foulant from metal surfaces. AIChE J 50:1961–1973

Kricke S, Böttcher K, Zahn S, Majschak J-P, Rohm H (2021) Effect of Physicochemical Properties of Native Starches on Cleaning in Falling Film and Plane Channel Flow Experiments. Heat Transfer Eng. https://doi.org/10.1080/01457632.2021.1963559

Xin H, Chen XD, Özkan N (2002) Whey Protein-Based Gel as a Model Material for Studying Initial Cleaning Mechanisms of Milk Fouling. J Food Sci 67:2702–2711

Othman AM, Asteriadou K, Fryer P (2009) Removal force measurement and rheological characterization of sweetened condensed milk deposits : A preliminary study, in: Müller-Steinhagen H, Malayeri MR, Watkinson AP (eds) Proceedings of International Conference on Heat Exchanger Fouling and Cleaning VIII. Presented at the International Conference on Heat Exchanger Fouling and Cleaning VIII, Austria

Goode KR, Asteriadou K, Fryer PJ, Picksley M, Robbins PT (2010) Characterising the cleaning mechanisms of yeast and the implications for Cleaning In Place (CIP). Food Bioprod. Process. Spec Issue Fouling Clean Food Process 2010 88:365–374

Wilson DI, Atkinson P, Köhler H, Mauermann M, Stoye H, Suddaby K, Wang T, Davidson JF, Majschak J-P (2014) Cleaning of soft-solid soil layers on vertical and horizontal surfaces by stationary coherent impinging liquid jets. Chem Eng Sci 109:183–196

Palabiyik I, Lopez-Quiroga E, Robbins PT, Goode KR, Fryer PJ (2018) Removal of yield-stress fluids from pipework using water. AIChE J 64:1517–1527

Yang J, Bhagat RK, Fernandes RR, Nordkvist M, Gernaey KV, Krühne U, Wilson DI (2019) Cleaning of toothpaste from vessel walls by impinging liquid jets and their falling films: Quantitative modelling of soaking effects. Chem Eng Sci 208:115148

Ali A, de’Ath D, Gibson D, Parkin J, Alam Z, Ward G, Wilson DI (2015) Development of a “Milimanipulation” device to study the removal of soft solid fouling layers from solid substrates and its application to cooked lard deposits. Food Bioprod Process 93:256–268

Cuckston GL, Alam Z, Goodwin J, Ward G, Wilson DI (2019) Quantifying the effect of solution formulation on the removal of soft solid food deposits from stainless steel substrates. J Food Eng 243:22–32

Tsai J-H, Fernandes RR, Wilson DI (2020) Measurements and modelling of the ‘millimanipulation’ device to study the removal of soft solid layers from solid substrates. J Food Eng 285:110086

Fernandes RR, Suleiman N, Wilson DI (2021) In-situ measurement of the critical stress of viscoplastic soil layers. J Food Eng 303:110568

Tuladhar TR, Paterson WR, Wilson DI (2002) Investigation of Alkaline Cleaning-in-Place of Whey Protein Deposits Using Dynamic Gauging. Food Bioprod Process 80:199–214

Wang S, Wilson DI (2015) Zero-Discharge Fluid-Dynamic Gauging for Studying the Swelling of Soft Solid Layers. Ind Eng Chem Res 54

Pérez-Mohedano R, Letzelter N, Bakalis S (2016) Swelling and hydration studies on egg yolk samples via scanning fluid dynamic gauge and gravimetric tests. J Food Eng 169:101–113

Chew JYM, Paterson WR, Wilson DI (2004) Fluid dynamic gauging for measuring the strength of soft deposits. J Food Eng 65:175–187

Hooper RJ, Liu W, Fryer PJ, Paterson WR, Wilson DI, Zhang Z (2006) Comparative Studies of Fluid Dynamic Gauging and a Micromanipulation Probe for Strength Measurements. Food Bioprod Process 84:353–358. https://doi.org/10.1205/fbp06038

Liu W, Christian GK, Zhang Z, Fryer PJ (2006) Direct measurement of the force required to disrupt and remove fouling deposits of whey protein concentrate. Int Dairy J 16:164–172

Jurado-Alameda E, Herrera-Márquez O, Martínez-Gallegos JF, Vicaria JM (2015) Starch-soiled stainless steel cleaning using surfactants and α-amylase. J Food Eng 160:56–64

Otto C, Zahn S, Hauschild M, Babick F, Rohm H (2016) Comparative cleaning tests with modified protein and starch residues. J Food Eng 178:145–150

Vicaria JM, Jurado-Alameda E, Herrera-Márquez O, Olivares-Arias V, Ávila-Sierra A (2017) Analysis of different protocols for the cleaning of corn starch adhering to stainless steel. J Clean Prod 168:87–96

Sauk T, Föste H, Augustin W, Scholl S (2018) A new online-method for the characterization of detached particles while cleaning starch fouling layers. Food Control 91:26–31

Joppa M, Köhler H, Rüdiger F, Majschak J-P, Fröhlich J (2020) Prediction of Cleaning by Means of Computational Fluid Dynamics: Implication of the Pre-wetting of a Swellable Soil. Heat Transf Eng 41:178–188

Köhler H, Liebmann V, Joppa M, Fröhlich J, Majschak J-P, Rüdiger F (2019) On the Concept of CFD-based Prediction of Cleaning for Film-like Soils, in: Zettler HU (ed) Proceedings of International Conference on Heat Exchanger Fouling and Cleaning XIII, Poland

Leach HW, McCowen LD, Schoch TJ (1959) Structure of the starch granule. I Swelling and solubility patterns of various starches. Cereal Chem 36:534–544

Schmidt C, Brunner M, Berger C, Zahn S, Rohm H (2022) Solubility and swelling of soils from native starch. Int J Food Sci Technol. https://doi.org/10.1111/ijfs.15911

Nor Nadiha MZ, Fazilah A, Bhat R, Karim AA (2010) Comparative susceptibilities of sago, potato and corn starches to alkali treatment. Food Chem 121:1053–1059

Acknowledgements

The authors gratefully acknowledge the support of Robert Dienst and Steffen Sackmaier, Chair of Processing Machines/Processing Technologies, as well as Laura Frank, Karoline Reinelt and Lucia Rataj, Chair of Food Engineering, Technische Universität Dresden, by supporting the measurements. This research project is supported by the Industrievereinigung für Lebensmitteltechnologie und Verpackung e.V. (IVLV), the Arbeitsgemeinschaft industrieller Forschungsvereinigungen‚ Otto von Guericke‘ e.V. (AiF) and the Federal Ministry of Economic Affairs and Climate Action (AiF Project IGF 20861 BR).

Funding

Open Access funding enabled and organized by Projekt DEAL. This research project is supported by the Industrievereinigung für Lebensmitteltechnologie und Verpackung e.V. (IVLV), the Arbeitsgemeinschaft industrieller Forschungsvereinigungen‚ Otto von Guericke ‘ e.V. (AiF) and the Federal Ministry of Economic Affairs and Climate Action (AiF Project IGF 20861 BR).

Author information

Authors and Affiliations

Contributions

Sebastian Kricke: Conceptualization, Methodology, Formal analysis, Investigation, Writing – Original Draft, Writing – Review & Editing, Funding acquisition; Christiane Berger: Methodology, Investigation, Writing – Original Draft; Susann Zahn: Conceptualization, Methodology, Formal analysis, Writing – Original Draft, Writing – Review & Editing, Supervision, Funding acquisition; Hannes Köhler: Conceptualization, Software, Writing – Review & Editing, Supervision, Funding acquisition; Harald Rohm: Writing – Review & Editing, Supervision, Funding acquisition; Jens-Peter Majschak: Writing – Review & Editing, Supervision, Funding acquisition.

Corresponding author

Ethics declarations

Competing Interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kricke, S., Berger, C., Zahn, S. et al. Influence of rheological properties and pull-off forces of native and modified starches on cleaning in plane channel flow. Heat Mass Transfer 60, 861–870 (2024). https://doi.org/10.1007/s00231-023-03397-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-023-03397-1