Abstract

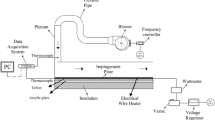

This study reports the findings of research into the effect of impinging air jet performance caused by flow-blocking elements situated near the orifice exit. The main goal is to figure out how heat transfer performance can be improved with less pumping power. Three distinct types of orifice plates are used to achieve this result. One of these three lacks flow-blocking components altogether, while the other two have variants on this theme. Each of the two orifice plates with flow-blocking components consists of either (i) a wire screen mesh at the orifice exit plane or (ii) distributed orifice (a number of smaller orifices spaced evenly apart). Experiments are performed to cool a flat plate (1.5 mm in thickness) heated electrically by impinging square jets of air at ambient temperature. Three distinct comparison criteria are used to examine the fluid flow, hydrodynamics, and heat transfer properties of the jets emerging from these orifices. For all three jet configurations, these criteria consist of (i) a constant mass flow rate of the fluid, (ii) a constant pumping power consumption of the jet over the orifice plate, and (iii) a constant Nusselt number on the impingement surface. It is seen that by using flow-blocking components at the orifice exit plane improves the heat transfer performance of an impinging air jet. When comparing the two flow blockage designs (distributed orifice vs. orifice with mesh), the distributed orifice configuration performs better.

Similar content being viewed by others

Abbreviations

- B :

-

width of the orifice without any flow blockage element, mm

- I :

-

current, A

- k :

-

thermal conductivity of air, W/m-\(^\circ\)C

- L :

-

width of the impingement plate, mm

- \(\dot{m}\) :

-

mass flow rate, kg/s

- Nu :

-

local Nusselt number

- \(Nu_{0}\) :

-

stagnation Nusselt number

- P :

-

pumping power, W

- q :

-

heat flux, W/\(m^{2}\)

- \(\dot{Q}\) :

-

volumetric flow rate, lit/min

- \(Q_{supp}\) :

-

heat supplied, W

- \(Q_{loss}\) :

-

heat loss, W

- \(Q_{net}\) :

-

net heat supplied, W

- Re :

-

Reynolds number

- T :

-

local temperature, \(^\circ\)C

- TI :

-

turbulence intensity, %

- \(T_{0}\) :

-

stagnation temperature, \(^\circ\)C

- \(T_{j}\) :

-

jet temperature at the nozzle exit, \(^\circ\)C

- \(U_{c}\) :

-

jet centerline velocity, m/s

- \(U_{e}\) :

-

jet exit velocity, m/s

- \(U_{c}/U_{e}\) :

-

normalized jet centerline velocity

- V :

-

voltage supplied to the heater, V

- X :

-

lateral distance from the stagnation point on the impingement plate, mm

- X/B :

-

non-dimensional lateral distance on the impingement plate

- Z :

-

jet-to-plate distance, mm

- Z/B :

-

non-dimensional jet-to-plate distance

- \(\mu\) :

-

dynamic viscosity of air, kg/m-s

- \(\rho\) :

-

density of air, kg/\(m^3\)

- \(\phi\) :

-

flow area ratio

- \(\Delta p\) :

-

pressure drop, Pa

References

Hosain ML, Fdhila RB, Daneryd A (2014) Multi-jet impingement cooling of a hot flat steel plate. Proceedings of the 6th International Conference on Applied Energy 61:1835–1839

Han B, Goldstein RJ (2001) Jet-impingement heat transfer in gas turbine systems. Ann N Y Acad Sci 934:147–161

Sarkar A, Nitin N, Karwe MV, Singh RP (2004) Fluid flow and heat transfer in air jet impingement in food processing. J Food Sci 127:CRH113–122

Kwon B, Foulkes T, Yang T, Miljkovic N, King WP (2020) Air jet impingement cooling of electronic devices using additively manufactured nozzles. IEEE Trans Compon Packag Manuf Technol 10(2):220–229

Matteo F, Shanjuan J, Vijay KD (2005) A comparative study of cooling of high power density electronics using sprays and microjets. ASME J Heat Transfer 127:38–48

Carlomagno GM, Ianiro A (2014) Thermo-fluid-dynamics of submerged jets impinging at short nozzle-to-plate distance : A review. Exp Thermal Fluid Sci 58:15–35

Dewan A, Dutta R, Srinivasan B (2012) Recent trends in computation of turbulent jet impingement heat transfer. Heat Transf Eng 33(4–5):447–460

Ekkad SV, Singh P (2021) A modern review on jet impingement heat transfer methods. ASME J Heat Transfer 143(6)

Nawani S, Subhash M (2021) A review on multiple liquid jet impingement onto flat plate. Mater Today Proceed 46:11190–11197

Prevost T, Battagliolia S, Jenkins R, J RA, (2022) Enhancing Jet Array Heat Transfer: Review of Geometric Features of Nozzle and Target Plates. Int J Thermofluids 16:100203

Weigand B, Spring S (2011) Multiple Jet Impingement - A Review. Heat Transfer Research 42:101–142

Zhou DW, Lee SJ (2004) Heat transfer enhancement of impinging jets using mesh screens. Int J Heat Mass Transf 47:2097–2108

Zhou DW, Lee SJ (2005) Effect of mesh screen on heat transfer enhancement of impinging jet. Journal of Enhanced Heat Transfer 12(1):101–120

Zhou DW, Lee SJ, Ma CF, Bergles AE (2006) Optimization of mesh screen for enhancing jet impingement heat transfer. Heat Mass Transf 42:501–510

Gori F, Petracci I (2012) Influence of turbulence on heat transfer upon a cylinder impinged by a slot jet of air. Appl Therm Eng 49:106–117

Gori F, Petracci I (2015) Influence of screen solidity ratio on heat transfer upon a cylinder impinged by a rectangular jet. Int J Heat Mass Transf 81:19–27

Cafiero G, Discetti S, Astarita T (2014) Heat transfer enhancement of impinging jets with fractal-generated turbulence. Int J Heat Mass Transf 75:173–183

Cafiero G, Discetti S, Astarita T, Cafiero G, Discetti S, Astarita T (2015) Flow field topology of submerged jets with fractal generated turbulence Flow field topology of submerged jets with fractal generated turbulence. Phys Fluids 27(115103):1–18

Cafiero G, Salvatore C, Astarita T, Discetti S (2016) Flow field features of fractal impinging jets at short nozzle to plate distances. Exp Thermal Fluid Sci 78:334–344

Muvvala P, Balaji C, Venkateshan SP (2017) Experimental investigation on the effect of wire mesh at the nozzle exit on heat transfer from impinging square jets. Exp Thermal Fluid Sci 84:78–89

Lee DH, Lee YM, Kim YT, Won SY, Chung YS (2002) Heat transfer enhancement by the perforated plate installed between an impinging jet and the target plate. Int J Heat Mass Transf 45:213–217

Muvvala P, Balaji C, Venkateshan SP (2017) Experimental investigation on heat transfer from square jets issuing from perforated nozzles. Heat Mass Transf 53:2363–2375

Kaewkaikrong B, Makatar Wh, Theerayut L, Chayut N (2012) Study on heat transfer characteristics of impinging jet with delta tabs attachment at pipe exit. In: the 10th International PSU Engineering Conference

Nanan K, Wongcharee K, Nuntadusit C, Eiamsa-ard S (2012) Forced convective heat transfer by swirling impinging jets issuing from nozzles equipped with twisted tapes. Int Commun Heat Mass Transfer 39:844–852

Vinze R, Chandel S, Limaye MD, Prabhu SV (2016) Local heat transfer distribution between smooth flat surface and impinging incompressible air jet from a chevron nozzle. Exp Thermal Fluid Sci 78:124–136

Wongcharee K, Kunnarak K, Chuwattanakul V, Eiamsa-ard S (2020) Heat transfer rate of swirling impinging jets issuing from a twisted tetra-lobed nozzle. Case Stud Therm Eng 22

YuanWei L, JingZhou Z, BoYan W, XiaoMing T (2020) Convective heat transfer on flat and concave surfaces subjected to an impinging jet form lobed nozzle. Science China Technol Sci 63:116–127

Liang X, Yang T, Sun Y, Xi L, Gao J, Li Y, Li J (2021) Flow and heat transfer characteristics of a swirling impinging jet issuing from a threaded nozzle. Case Studies in Thermal Engineering 25

Hamid N, Eftekhari Mohammad ML, Arash Yazdiand (2022) Heat transfer and fluid flow of swirling impinging jets ejected from nozzles with different twisted tapes. J Braz Soc Mech Sci Eng 44:498

Venkateshan SP (2015) Mechanical Measurements. Athena Academic and Wiley

Zhou DW, Lee SJ (2007) Forced convective heat transfer with impinging rectangular jets. Int J Heat Mass Transf 50:1916–1926

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

The first author Pullarao Muvvala contributed to the study conception and design. Material preparation, data collection and analysis were performed and the first draft of the manuscript was written by Pullarao Muvvala. The second author Din Bandhu commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflicts of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Muvvala, P., Bandhu, D. The influence of flow blockage elements at the orifice exit on the hydrodynamic and thermal performances of impinging square jets - an experimental investigation. Heat Mass Transfer 59, 1821–1836 (2023). https://doi.org/10.1007/s00231-023-03371-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-023-03371-x