Abstract

Experimental studies on heat transfer enhancement and friction factor characteristics of water flowing in Laminar flow regime through a square duct, fitted with full-length helical inserts of varying twist ratio have been reported in the present paper. The test liquid flows in the laminar flow through a square duct and in counter current manner a hot water at very high flow rate is directed though the annulus to ensure a constant wall temperature conditions. A plain duct fitted with helical inserts provides higher friction factor and Nusselt number than that of empty duct. The heat transfer and pressure loss were observed to be higher at minimum twist ratio. The thermo hydraulic performance ratio on constant pumping power of the duct induced by helical inserts at different twist of 1.44, 2.55, 3.66, 4.66 were found to be 5.20, 4.44, 4.01, and 3.50 times higher than the plain duct.

Similar content being viewed by others

Data availability

The datasets of experimental runs analysed during the present study is not openly available, but are made available from the corresponding author on reasonable request with valid reasons.

Abbreviations

- A i :

-

Area of heat transfer, m2

- A o :

-

Flow cross sectional area of plain duct, ([Inline Image Removed]), m2

- C p :

-

Specific heat of water at constant pressure, J/kg K

- D :

-

Diameter of duct, m

- D e :

-

Equivalent diameter of Square duct, De = [Inline Image Removed], m

- D t :

-

Diameter of helical tape, m

- D 1 :

-

Inner diameter of outer circular tube, m

- D 2 :

-

Outer diameter of circular tube, m

- \(f\) :

-

Fanning friction factor, dimensionless

- \(g\) :

-

Acceleration due to gravity, m/s2

- \({h}_{i}\) :

-

Average heat transfer coefficient, W/m2 K

- \(\Delta h\) :

-

Differential height of vertical manometer, m

- K :

-

Thermal conductivity of the water, W/m K

- L :

-

Length of test section, m

- \(m\) :

-

Mass flow rate of water, kg/s

- \(N\) :

-

Number of square tubes

- \(Nu\) :

-

Nusselt number (defination on the basis of equivalent diameter), \(Nu={h}_{\mathrm{i}}{D}_{\mathrm{e}}/k\), dimensionless

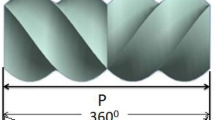

- \(P\) :

-

Pumping power, kW

- Pr :

-

Prandlt number, Pr = \({C}_{\mathrm{p}}\mu /k\), dimensionless

- \(Q\) :

-

Average heat transfer rate, kW

- RTD :

-

Resistance temperature detector

- \(Re\) :

-

Reynolds number (defination on the basis of equivalent diameter), \(Re={D}_{e}v\rho /\mu\), dimensionless

- R 1 :

-

Thermohydraulic performance ratio, \(\left(N{u}_{\mathrm{a}}/N{u}_{\mathrm{o}}\right)\), on the basis of constant mass flow rate, dimensionless.

- R 3 :

-

Thermohydraulic performance ratio, \(\left(N{u}_{\mathrm{a}}/N{u}_{\mathrm{o}}\right)\), on the basis of constant pumping power, dimensionless.

- T :

-

Temperature, K

- ∆T :

-

Temperature difference of water, K

- v :

-

Average velocity of water, m/s

- y :

-

Twist ratio of helical tape (length of 3600 rotation of the tape to the equivalent diameter of the duct), dimensionless.

- W :

-

Width of duct, as well as helical tape, m

- δ :

-

Thickness of a square duct and helical tape, m

- \({\rho }_{m}\) :

-

Density of manometer fluid, kg/m3

- \(\rho\) :

-

Density of water, kg/m3

- \(\mu\) :

-

Viscosity of water, kg/ms

- \(\Delta P\) :

-

Pressure drop across duct section, \(\Delta P=\Delta h\left({\rho }_{m}-\rho \right)g\), N/m2

- a:

-

Augmented

- b:

-

Mean bulk condition

- c:

-

Cold fluid

- e:

-

Based on equivalent diameter, De

- h:

-

Hot fluid

- m:

-

Manometer fluid

- ln:

-

Logarithmic mean

- o:

-

Equivalent plain square duct dimensionless number, Nuo, Reo

- w:

-

Wall conditions

- 1,2:

-

Inlet and outlet conditions of cold fluid

- 3,4:

-

Inlet and outlet conditions of hot fluid

References

Patil SV, Vijay Babu PV (2011) Heat Transfer Augmentation in a Circular tube and Square duct Fitted with Swirl Flow Generators: A Review. Int J Chem Eng Appl 2:326–331

Date AW (1974) Prediction of Fully developed Flow in a Tube containing a Twisted Tape. Int J Heat and Mass Transf 17:845–859

Smithberg E, Landis F (1964) Friction and Forced Convection Heat Transfer Characteristics in Tubes Fitted with Twisted Tape Swirl Generators. ASME J Heat Transf 2:39–49

Date AW, Singham JR (1972) Numerical Prediction of Friction Factor and Heat Transfer Characteristics of Fully developed Laminar flow in Tubes containing Twisted Tapes ASME. J Heat Transf 72:17–22

Hong SW, Bergles AE (1976) Augmentation of Laminar Flow Heat Transfer in Tubes by means of Twisted-Tape inserts, ASME. J Heat Transf 98:251–256

Manglik RM, Bergles AE (1993) Heat Transfer and Pressure drop Correlations for Twisted-Tape inserts in Isothermal Tubes, Part I Laminar flows. ASME J Heat Transf 115(4):881–889

Vijay Babu PV, Raja Rao M (1991) Heat Transfer Correlations for Laminar non- Newtonian flow in Tubes with Twisted-Tape inserts. ASME HTD 174:59–64

Agarwal SK, Raja Rao M (1996) Heat Transfer Augmentation for the Flow of a Viscous liquid in Circular tubes using Twisted tape inserts. Int J Heat Mass Transf 39:3547–3557

Shivkumar, Raja Rao M(1988) Studies on Compound Augmentation of Laminar Flow Heat Transfer to Generalized power law fluids in Spirally Corrugated Tubes by means of Twisted Tape inserts. ASME HTD 96:685–692

Patil AG (2000) Laminar flow Heat Transfer and Pressure Drop Characteristics of Power-law fluids inside Tubes with varying Width Twisted tape inserts. ASME J Heat Transf 22(1):143–149

Al-Fahed S, Chamra LM, Charoun W (1999) Pressure Drop and Heat Transfer Comparison for both Micro tube and Twisted tape inserts in Laminar flow. Exp Thermal Fluid Sci 18:323–333

Saha SK, Dutta A, Dhal SK (2001) Friction and Heat Transfer Characteristics of Laminar Swirl flow through a Circular tube fitted with Regularly Spaced Twisted- tape elements. Int J Heat Mass Transf 44:4211–4223

Sivashanmugam P, Suresh S (2007) Experimental Studies on Heat Transfer and Friction factor Characteristics in Turbulent flow through a Circular tube fitted with Regularly Spaced Helical Screw-tape inserts. J Appl Thermal Eng 27:1311–1319

Lokanath MS (1997) Performance Evaluation of Full length and Half-length Twisted tape inserts on Laminar Flow Heat transfer in Tubes, Proc. of the 14th National Heat and Mass Transfer Confer and Third ISHMT–ASME Joint Heat and Mass Transfer Confrere., IIT Kanpur, India HMT-97–031. 319–324

Sivashanmugam P, Suresh S (2006) Experimental Studies on Heat Transfer and Friction factor Characteristics in Laminar flow through a Circular Tube fitted with Helical Screw-tape inserts. J Applied Thermal Eng 26:1990–1997

Eiamsa-ard S, Pongjet P (2005) Enhancement of Heat Transfer in a Tube with Regularly-Spaced Helical tape Swirl Generators. Sol Energy 78:483–494

Sivashanmugam P, Suresh S (2007) Experimental Studies on Heat Transfer and Friction factor Characteristics in Laminar Flow through a Circular tube fitted with Regularly Spaced Helical Screw-tape inserts. Exp Therm Fluid Sci 32:301–308

Sivashanmugam P, Suresh S (2007) Experimental Studies on Heat Transfer and Friction factor Characteristics in Turbulent flow through a Circular tube fitted with Helical Screw-tape inserts. Chem Engr Process 46:1292–1298

Sivashanmugam P, Nagarajan PK (2007) Experimental Studies on Heat Transfer and Friction factor Characteristics in Laminar Flow through a Circular Tube fitted with Right-Left Helical Screw-tape inserts. Exp Thermal Fluid Sci 32(1):192–197

Patil SV, Vijay Babu PV (2013) Heat transfer enhancement for laminar flow of ethylene glycol through a square duct fitted with increasing and decreasing orders of twisted tape. Heat Trans Asian Res 41(3):227–240

Patil SV, Vijay Babu PV (2014) Heat transfer and pressure drop studies through a square duct fitted with increasing and decreasing order of twisted tape. Heat Trans Eng 35(14–15):1380–1387

S Ray, Date AW(2003) Friction and Heat Transfer Characteristics of Flow through Square Duct with Twisted tape insert. Int J Heat Mass Transf 46:889–902

Saha SK, Mallick DN (2005) Heat Transfer and Pressure Drop Characteristics of Laminar Flow in Rectangular and Square Plain Ducts and Ducts with Twisted-Tape Inserts. Tran ASME J Heat Transf 127:966–977

Pramanik D, Saha SK (2006) Thermohydraulics of Laminar flow through Rectangular and Square Ducts with Transverse ribs and twisted tapes. Tran ASME J Heat Transf 128:1070–1080

Patil SV (2014) P Vijay Babu, Experimental heat transfer and friction factor studies through a square duct fitted with helical screw tapes, The. Can J Chem Eng 92(4):663–670

Patil SV, Vijay Babu PV(2012) Heat transfer enhancement through a square duct fitted with twisted tape inserts. Heat Mass Transf 48(10):1803–1811

Patil SV, Vijay Babu PV (2014) Laminar heat transfer augmentation through a square duct and circular tube fitted with twisted tapes. Exp Heat Transfer 27(2):124–143

Kline SJ, McClintock FA (1953) Describing Uncertainties in Single Sample Experiments. Mech Eng (Am Soc Mech Eng) 75(1):3–8

Steele WG, Coleman HW (1989) Experimental and Uncertainty Analysis for Engineers. Wiley, New York

Sieder EN, Tate GE (1936) Heat Transfer and Pressure drop of liquids in Tubes. Ind Eng Chem 28:1429–1435

Bergles AE (1985) Techniques to augment heat transfer. In: Rohsenow WM, Hartnett JP, Ganie E (eds) Handbook of Heat Transfer Application, first ed. McGraw-Hill, New York

Acknowledgements

The Authors pay sincere thanks to the authorities of Dr. BATU, for their continuous help to carrying out current experimental investigations.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

With reference to publication of present paper, authors hereby state that no sort of conflict of interest associated to this work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Patil, S.V., Babu, P.V.V. & Bhole, K.S. Experimental studies on heat transfer augmentation and friction factor characteristics for laminar flow of water in a square duct induced by full-length helical tapes. Heat Mass Transfer 59, 1565–1573 (2023). https://doi.org/10.1007/s00231-023-03351-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-023-03351-1