Abstract

Trapped vortex combustor has been widely used in many aero-engines due to its ability to achieve low emission and low total pressure loss. The swirler also has a wide application since it can produce the effects of stabilizing the combustion. However, the numerical study regarding the combination of them has not been well investigated. In the current work, the availability of using the swirler on the trapped vortex combustor is numerically studied and the superiority is verified. Besides, the effects of the position of the combustor cavity and the swirl number are studied. The results indicate that the flow field of the proposed combustor can be stable in a wide inlet velocity range and the combustion efficiency can be remarkably improved. Then, the outlet temperature distribution gets more uniform and the total pressure loss can keep in an acceptable range. Also, the NOx emission is lower when operating in a high-speed working condition. In addition, the optimum position of the cavity is determined, which is that the distance between the inlet and the cavity is 10 mm. Finally, it is found that the swirl number mainly affects the flow field and temperature distribution. Therefore, a blade installation angle of 45° should be a reasonable value.

Similar content being viewed by others

Data availability

All data included in this study are available upon request by contact with the corresponding author.

Abbreviations

- c :

-

Mass fraction of the species (%)

- c p :

-

Specific heat at constant pressure (J/(kg·K)

- CFD :

-

Computational fluid dynamics

- CH 4 :

-

Methane

- D :

-

Diffusion coefficient (m2/s)

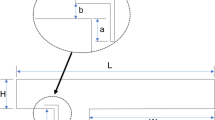

- D 1 :

-

Swirler inner diameter (m)

- D 2 :

-

Swirler outer diameter (m)

- D 3 :

-

Cavity diameter (m)

- D 4 :

-

Combustion chamber diameter (m)

- E :

-

Energy density (J/m3)

- Hf :

-

Height (m)

- k :

-

Turbulent kinetic energy (J)

- K :

-

Thermal conductivity (W/(m·K))

- L 1 :

-

Swirler length (m)

- L 2 :

-

Combustion chamber length (m)

- L 3 :

-

Distance between swirler and cavity (m)

- L 4 :

-

Cavity length (m)

- N-S :

-

Navier-Stokes

- p :

-

Static pressure (Pa)

- P 1 * :

-

Total pressure at the inlet (Pa)

- P 2 * :

-

Total pressure at the outlet (Pa)

- S :

-

Swirl number

- S T :

-

Viscous dissipation

- T :

-

Temperature (K)

- TVC :

-

Trapped vortex combustor

- u :

-

Velocity components in the x direction (m/s)

- v :

-

Velocity components in the y direction (m/s)

- Y in :

-

CH4 mass fraction at the inlet (%)

- Y out :

-

CH4 mass fraction at the outlet (%)

- β :

-

Angle between axial direction and vane (°)

- δ * :

-

Total pressure loss (%)

- ε :

-

Turbulent dissipation rate (%)

- η :

-

Combustion efficiency (%)

- ρ :

-

Density of gas mixture (kg/m3)

- τ :

-

Stress tensor (N/m2)

- \(\dot{\omega_k}\) :

-

Chemical reaction rate (kg/(m3·s))

References

Borisov I, Khalatov A et al (2022) The biomass fueled micro-scale CHP unit with stirling engine and two-stage vortex combustion chamber. Heat Mass Transfer 58:1091–1103. https://doi.org/10.1007/s00231-021-03165-z

Kumar P, Mishra D (2012) Numerical investigation of the flow and flame structure in an axisymmetric trapped vortex combustor. Fuel 102:78–84. https://doi.org/10.1016/j.fuel.2012.06.056

Ping J, He X (2020) Ignition characteristics of a novel mixed-flow trapped vortex combustor for turboshaft engine. Fuel 261:116430. https://doi.org/10.1016/j.fuel.2019.116430

Zhu Z, Huang Y et al (2021) Combustion performance in a cavity-based combustor under subatmospheric pressure. Fuel 302:121115. https://doi.org/10.1016/j.fuel.2021.121115

Singhal A, Ravikrishna R (2011) Single cavity trapped vortex combustor dynamics – Part-2: Simulations. Int J Spray Combust Dyn 3:45–62. https://doi.org/10.1260/1756-8277.3.1.45

Fei X, Wang P, Shuai Z et al (2012) Experiment and simulation study on lean blow-out of trapped vortex combustor with various aspect ratios. Aerosp Sci Technol 18:48–55. https://doi.org/10.1016/j.ast.2011.03.010

Ghenai C, Zbeeb K, Janajreh I (2013) Combustion of alternative fuels in vortex trapped combustor. Energy Convers Manag 65:819–828. https://doi.org/10.1016/j.enconman.2012.03.012

Wang Z, Zeng Z, Kai L et al (2015) Effect of structure parameters of the flow guide vane on cold flow characteristics in trapped vortex combustor. J Hydrodyn 27:730–737. https://doi.org/10.1016/S1001-6058(15)60535-2

Jin Y, Li Y, He X et al (2014) Experimental investigations on flow field and combustion characteristics of a model trapped vortex combustor. Appl Energy 134:257–269. https://doi.org/10.1016/j.apenergy.2014.08.029

Zhang R, Fan W, Qiang S et al (2014) Structural design and performance experiment of a single vortex combustor with single-cavity and air blast atomizers. Aerosp Sci Technol 39:95–108. https://doi.org/10.1016/j.ast.2014.08.017

Zhang R, Fan W, Shi Q et al (2014) Combustion and emissions characteristics of dual-channel double-vortex combustion for gas turbine engines. Appl Energy 130:314–325. https://doi.org/10.1016/j.apenergy.2014.05.059

Zeng Z, Ren J, Liu X et al (2015) The unsteady turbulence flow of cold and combustion case in different trapped vortex combustor. Appl Therm Eng 90:722–732. https://doi.org/10.1016/j.applthermaleng.2015.07.041

Jiang B, Jin Y, Liu D et al (2016) Effects of multi-orifice configurations of the quench plate on mixing characteristics of the quench zone in an RQL-TVC model. Exp Therm Fluid Sci 83:57–68. https://doi.org/10.1016/j.expthermflusci.2016.12.011

Li M, He X, Zhao Y et al (2017) Dome structure effects on combustion performance of a trapped vortex combustor. Appl Energy 208:72–82. https://doi.org/10.1016/j.apenergy.2017.10.029

Zhang R, Hao F, Fan W (2018) Combustion and stability characteristics of ultra-compact combustor using cavity for gas turbines. Appl Energy 225:940–954. https://doi.org/10.1016/j.apenergy.2018.05.084

Chen S, Zhao D (2018) Numerical study of guide vane effects on reacting flow characteristics in a trapped vortex combustor. Combust Sci Technol 190:2111–2133. https://doi.org/10.1080/00102202.2018.1492568

Zhao Y, He X, Xiao J et al (2020) Effect of cavity-air injection mode on the performance of a trapped vortex combustor. Aerosp Sci Technol 106:106083. https://doi.org/10.1016/j.ast.2020.106183

Sharifzadeh R, Afshari A (2020) Numerical investigation of flow field effects on fuel-air mixing in a non-reacting trapped vortex combustor with different injection arrangements. Eur J Mech B-Fluid 82:106–122. https://doi.org/10.1016/j.euromechflu.2020.03.005

Khalil A, Gupta A (2011) Distributed swirl combustion for gas turbine application. Appl Energy 88:4898–4907. https://doi.org/10.1016/j.apenergy.2011.06.051

Khalil A, Arghode V, Gupta A et al (2012) Low calorific value fuelled distributed combustion with swirl for gas turbine applications. Appl Energy 98:69–78. https://doi.org/10.1016/j.apenergy.2012.02.074

Khalil A, Gupta A (2013) Fuel flexible distributed combustion for efficient and clean gas turbine engines. Appl Energy 109:267–274. https://doi.org/10.1016/j.apenergy.2013.04.052

Kim M, Yoon J, Park S et al (2013) Effects of unstable flame structure and recirculation zones in a swirl-stabilized dump combustor. Appl Therm Eng 58:125–135. https://doi.org/10.1016/j.applthermaleng.2013.04.019

Zhang R, Xu Q, Fan W (2018) Effect of swirl field on the fuel concentration distribution and combustion characteristics in gas turbine combustor with cavity. Energy 162:83–98. https://doi.org/10.1016/j.energy.2018.07.170

Runyon J, Marsh R, Bowen P et al (2018) Lean methane flame stability in a premixed generic swirl burner: Isothermal flow and atmospheric combustion characterization. Exp Therm Fluid Sci 92:125–140. https://doi.org/10.1016/j.expthermflusci.2017.11.019

Yang X, He Z, Niu Q et al (2019) Numerical analysis of turbulence radiation interaction effect on radiative heat transfer in a swirling oxyfuel furnace. Int J Heat Mass Transfer 141:1227–1237. https://doi.org/10.1016/j.ijheatmasstransfer.2019.07.060

Yang X, He Z, Cha S et al (2020) Parametric analysis on the combustion and thermal performance of a swirl micro-combustor for micro thermophotovoltaic system. Energy 198:117312. https://doi.org/10.1016/j.energy.2020.117312

Bazooyar B, Darabkhani H (2020) Design, manufacture and test of a micro-turbine renewable energy combustor. Energy Convers Manag 213:112782. https://doi.org/10.1016/j.enconman.2020.112782

Yang X, Yang W, Dong S et al (2020) Flame stability analysis of premixed hydrogen/air mixtures in a swirl micro-combustor. Energy 209:118495. https://doi.org/10.1016/j.energy.2020.118495

Fan B, Pan J, Yang W et al (2017) Numerical investigation of the effect of injection strategy on mixture formation and combustion process in a port injection natural gas rotary engine. Energy Convers Manag 133:511–523. https://doi.org/10.1016/j.enconman.2016.10.070

Xie J, Zhu Y (2019) Characteristics study on a modified advanced vortex combustor. Energy 193:116805. https://doi.org/10.1016/j.energy.2019.116805

Mucci A, Kholi F, Sibilli T et al (2021) Numerical analysis of secondary airflow in a rotating cavity of a gas-turbine at high operating points with vortex reducer implementation. Heat Mass Transfer 57:1363–1378. https://doi.org/10.1007/s00231-021-03029-6

Lucca-Negro O, O’Doherty T (2001) Vortex breakdown: a review. Prog Energy Combust Sci 27:431–481. https://doi.org/10.1016/S0360-1285(00)00022-8

Tangermann E, Pfitzner M (2008) Numerical investigation of flame flashback into swirling flow. Asme Turbo Expo: Power Land, Sea, Air. https://doi.org/10.1115/GT2008-51081

Tangermann E, Pfitzner M (2009) Evaluation of combustion models for combustion-induced vortex breakdown. J Turbul 10(10). https://doi.org/10.1080/14685240802592423

Hsu K, Goss L, Roquemore W (1998) Characteristics of a trapped-vortex combustor. J Propuls Power 14:57–65. https://doi.org/10.2514/2.5266

Guo Y, He X, Gong C et al (2022) Performance of a novel swirling-flow single trapped vortex combustor. Aerosp Sci Technol 127:107674. https://doi.org/10.1016/j.ast.2022.107674

Zhang Y, Li J, Xie J (2022) Effects of lateral cooling hole configuration on a swirl-stabilized combustor. Energy 259:125002. https://doi.org/10.1016/j.energy.2022.125002

Acknowledgements

The authors did not receive support from any organization for the submitted work. In addition, Jin Xie asked his girlfriend to marry him in [37], and the answer from Ms. Yan Huang is: “Yes, I will”. Best wishes for them.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zheng, B., Zhang, Y. & Xie, J. Investigation of performance in a cylindrical trapped vortex combustor with swirler. Heat Mass Transfer 59, 1121–1137 (2023). https://doi.org/10.1007/s00231-022-03319-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-022-03319-7