Abstract

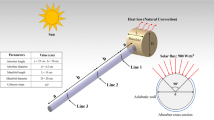

This paper numerically investigates the performance of the EuroTrough-parabolic trough solar collector. The heat flux distribution on the absorber tube is evaluated by the Monte Carlo Ray Tracing (MCRT) method. To enhance the heat transfer, using a dimpled absorber tube instead of a plain absorber tube, and using nanofluid instead of Therminol® VP-1 is recommended. To simulate the radiation, the surface-to-surface model is implemented. Heat transfer, Performance Evaluation Criteria (PEC), and Darcy-Weisbach friction factor evaluate collector performance. Usually, these parameters are calculated when methods of increasing heat transfer are utilized. PEC increases to at most 1.18 if the dimpled absorber tube is used. Also, the results show that the temperature at the bottom of the absorber tube decreases significantly. Moreover, eight vortexes are created within the tube cross-section, which means that the flow is turbulent and mixing of flow occurs. By increasing the depth of the dimple and reducing the pitch of the dimple, these vortices approach each other in pairs and eventually join together. Moreover, turbulent kinetic energy increases with increasing the depth of the dimple and decreasing the pitch of the dimple. Using nanofluid results in the reduction of heat transfer due to intensification of the laminar sublayer.

Similar content being viewed by others

Change history

20 May 2022

A Correction to this paper has been published: https://doi.org/10.1007/s00231-022-03247-6

Abbreviations

- Cp :

-

Specific heat (J/kg K)

- DD:

-

Depth of dimple

- D:

-

Diameter (m)

- D ω :

-

Cross-diffusion term

- FVM:

-

Finite volume method

- f:

-

Darcy-Weisbach friction factor

- G k :

-

Generation of κ

- G ω :

-

Generation of ω

- HTF:

-

Heat transfer flud

- h:

-

Convective heat transfer coefficient (W/m2K)

- k:

-

Thermal conductivity (W/mK)

- LCR:

-

Local concentration ratio

- L:

-

Length (m)

- MCRT:

-

Monte Carlo Ray Tracing

- ṁ :

-

Mass flow rate (kg/s)

- Nu:

-

Nusselt number

- PD:

-

Pitch of dimple

- PEC:

-

Performance Evaluation Criteria

- PTC:

-

Parabolic trough collector

- Pr:

-

Prandtl number

- p:

-

Pressure (Pa)

- Re:

-

Reynolds number

- S2S:

-

Surface-to-surface

- T:

-

Temperature (K)

- V:

-

Velocity (m/s)

- Y k :

-

Dissipation of κ

- Y ω :

-

Dissipation of ω

- Γ k :

-

Effective diffusivity for κ

- Γ ω :

-

Effective diffusivity for ω

- ε :

-

Emmisivity

- θ:

-

Angular coordinate

- κ :

-

Turbulent kinetic energy

- μ:

-

Dynamic viscosity (Ns/m2)

- ρ:

-

Density (kg/m3)

- ϕ:

-

Concentration

- ω:

-

Specific dissipation rate

- amb:

-

Ambient

- f :

-

Fluid

- g :

-

Glass cover

- i:

-

Inlet

- nf:

-

Nanofluid

- p:

-

Particle

- sk:

-

Sky

- w:

-

Wall

- wi:

-

Wind

References

Facão J, Oliveira AC (2005) Modeling laminar heat transfer in a curved rectangular duct with a computational fluid dynamics code. Numeri Heat Transf A Appl 48:165–177

Arun MG, Dilip D, Kumar Ranjith S (2021) Effect of interface curvature on isothermal heat transfer in a hydrophobic microchannel with transverse ribs and cavities. Int J Therm Sci 167:107014

Sacithra A, Manivannan A (2019) Turbulent flow analysis of a flattened tube in- plane curved solar collector using Titanium oxide nanofluid. Heat Mass Transf 55:1783–1799

Rezaei Gorjaei A, Shahidian A (2020) Investigating heat transfer and skin friction using water–CuO nanofluid between eccentric channels. Heat Transfer Eng 41:1485–1498

Waghole DR, Warkhedkar RM, Kulkarni VS, Shrivastva RK (2016) Studies on heat transfer in flow of silver nanofluid through a straight tube with twisted tape inserts. Heat Mass Transf 52:309–313

Rezaei Gorjaei A, Shahidian A (2019) Heat transfer enhancement in a curved tube by using twisted tape insert and turbulent nanofluid flow. J Therm Anal Calorim 137:1059–1068

Eiamsa-ard S, Wongcharee K, Kunnarak K, Kumar M, Chuwattabakul V (2019) Heat transfer enhancement of TiO2-water nanofluid flow in dimpled tube with twisted tape insert. Heat Mass Transf 55:2987–3001

Hwang SD, Kwon HG, Cho HH (2008) Heat transfer with dimple/protrusion arrays in a rectangular duct with a low Reynolds number range. Int J Heat Fluid Flow 29:916–926

Vicente PG, Garcıa A, Viedma A (2002) Heat transfer and pressure drop for low Reynolds turbulent flow in helically dimpled tubes. Int J Heat Mass Transf 45:543–553

Aroonrat K, Wongwises S (2018) Condensation heat transfer and pressure drop characteristics of R-134a flowing through dimpled tubes with different helical and dimpled pitches. Int J Heat Mass Transf 121:620–631

Mahmood GI, Ligrani PM (2002) Heat transfer in a dimpled channel: combined influences of aspect ratio, temperature ratio, Reynolds number, and flow structure. Int J Heat Mass Transf 45:2011–2020

Nascimento IP, Garcia EC (2016) Heat transfer performance enhancement in compact heat exchangers by using shallow square dimples in flat tubes. Appl Therm Eng 96:659–670

Wang Y, He YL, Lei YG, Zhang J (2010) Heat transfer and hydrodynamics analysis of a novel dimpled tube. Exp Therm Fluid Sci 34:1273–1281

Rao Y, Li B, Feng Y (2015) Heat transfer of turbulent flow over surfaces with spherical dimples and teardrop dimples. Exp Therm Fluid Sci 61:201–209

Dagdevir T, Keklikcioglu O, Ozceyhan V (2019) Heat transfer performance and flow characteristic in enhanced tube with the trapezoidal dimples. Int Commun Heat Mass Transf 108:104299

Rezaei Gorjaei A, Rahmani R (2021) Numerical Simulation of Nanofluid Flow in a Channel Using Eulerian-Eulerian Two-Phase Model. Int J Thermophys 42:1–16

Rasheed AH, Alias HB, Salman SD (2021) Experimental and numerical investigations of heat transfer enhancement in shell and helically microtube heat exchanger using nanofluids. Int J Therm Sci 159:106547

Alosious S, Nair AR, Krishnakumar K (2017) Experimental and numerical study on heat transfer enhancement of flat tube radiator using Al2O3 and CuO nanofluids. Heat Mass Transf 53(12):3545–3563

Zheng D, Wang J, Chen ZX, Baleta J, Sundén B (2020) Performance analysis of a plate heat exchanger using various nanofluids. International Journal of Heat and Mass Transfer 158:119993

Siavashi M, Jamali M (2016) Heat transfer and entropy generation analysis of turbulent flow of TiO2-water nanofluid inside annuli with different radius ratios using two-phase mixture model. Appl Therm Eng 100:1149–1160

Ulahannan L, Krishnakumar K, Nair AR, Kumar Ranjith S (2021) An experimental study on the effect of nanoparticle shape on the dynamics of Leidenfrost droplet impingement. Experimental and Computational Multiphase Flow 3:47–58

Zhang L, Mansir IB, Salem M, Mahariq I, Rezaei Gorjaei A (2022) Heat transfer and exergy destruction analyses with ferrofluid in LS-3 solar collector under dipole magnetic field. Sustain Energy Technol Assess 51:101952

Allouhia A, Benzakour Amineb M, Saidurc R, Kousksoue T, Jamil A (2018) Energy and exergy analyses of a parabolic trough collector operated with nanofluids for medium and high temperature applications. Energy Convers Manage 155:201–217

Bortolatoa M, Dugaria S, Agrestic F, Barisonc S, Fedeled L, Sanie E, Col DD (2017) Investigation of a single wall carbon nanohorn-based nanofluid in a fullscale direct absorption parabolic trough solar collector. Energy Convers Manage 150:693–703

Ravi Kumar K, Reddy KS (2012) Effect of porous disc receiver configurations on performance of solar parabolic trough concentrator. Heat Mass Transf 48:555–571

Kaya H, Arslan K (2019) Numerical investigation of efficiency and economic analysis of an evacuated U-tube solar collector with different nanofluids. Heat Mass Transf 55:581–593

Mehrnia V, Haghighi Khoshkhoo R (2014) Solar field thermo-economical optimization of Yazd integrated solar combined cycle (ISCC). Modares Mechanical Engineering 14:117–127

Karami Sadaghiyani O, Boubakran MS, Hassanzadehn A (2018) Energy and exergy analysis of parabolic trough collectors. Int J Heat Technol 36:147–158

Amiri H, Aminy M, Lotfi M, Jafarbeglo B (2021) Energy and exergy analysis of a new solar still composed of parabolic trough collector with built-in solar still. Renewable Energy 163:465–479

Wu Z, Li S, Yuan G, Lei D, Wang Z (2014) Tree-dimensional numerical study of transfer characteristics of parabolic trough receiver. Appl Energy 113:902–911

Norouzi AM, Siavashi M, Khaliji Oskouei MH (2020) Efficiency enhancement of the parabolic trough solar collector using the rotating absorber tube and nanoparticles. Renew Energy 145:569–584

Said Z, Sajid MH, Saidur R, Mahdiraji GA, Rahim NA (2015) Evaluating the Optical Properties of TiO2 Nanofluid for a Direct Absorption Solar Collector. Numerical Heat Transfer, Part A: Applications 67:1010–1027

Qiu Y, Li MJ, He YL, Tao WQ (2017) Thermal performance analysis of a parabolic trough solar collector using supercritical CO2 as heat transfer fluid under non-uniform solar flux. Appl Therm Eng 115:1255–1265

Selvakumar P, Somasundaram P, Thangave P (2014) Performance study on evacuated tube solar collector using therminol D-12 as heat transfer fluid coupled with parabolic trough. Energy Convers Manage 85:505–510

Okonkwo EC, Essien EA, Akhayere E, Abid M, Kavazd D, Ratlamwalac TAH (2018) Thermal performance analysis of a parabolic trough collector using waterbased green-synthesized nanofluids. Sol Energy 170:658–670

Wu SH, Wang M, Xiao L, Chen ZH (2020) Flow and heat transfer characteristics in slip regime for an annulus of evacuated collector tube subjected to non-uniform solar flux boundary condition. Int J Therm Sci 153:106351

Mwesigye A, Bello-Ochende B, Meyer JP (2014) Minimum entropy generation due to heat transfer and fluid friction in a parabolic trough receiver with non-uniform heat flux at different rim angles and concentration ratios. Energy 73:606–617

Mwesigye A, Huan Z, Meyer JP (2016) Thermal performance and entropy generation analysis of a high concentration ratio parabolic trough solar collector with Cu-Therminol® VP-1 nanofluid. Energy Convers Manage 120:449–465

Fuqiang W, Jianyu T, Lanxin M, Chengchao W (2015) Effects of glass cover on heat flux distribution for tube receiver with parabolic trough collector system. Energy Convers Manage 90:47–52

Sokhansefat T, Kasaeian A, Kowsary F (2014) Heat transfer enhancement in parabolic trough collector tube using Al2O3/synthetic oil nanofluid. Renew Sustain Energy Rev 33:636–644

Solutia technical bulletin 7239115C-TherminolVP. Available online at. https://www.therminol.com/products/Therminol-VP1. Accessed 08.09.2015

Rezaei Gorjaei A, Soltani M, Bahiraei M, Kashkooli FM (2018) CFD simulation of nanofluid forced convection inside a three-dimensional annulus by two-phase mixture approach: Heat transfer and entropy generation analyses. Int J Mech Sci 146:396–404

Mwesigye A, Huan Z, Meyer JP (2015) Thermodynamic optimisation of the performance of a parabolic trough receiver using synthetic oil–Al2O3 nanofluid. Appl Energy 156:398–412

Rezaei Gorjaei A, Joda F, Haghighi Khoshkhoo R (2020) Heat transfer and entropy generation of water–Fe3O4 nanofluid under magnetic field by Euler-Lagrange method. J Therm Anal Calorim 139:2023–2034

Faghih Aliabadi MA, Zhang G, Dykas S, Li H (2021) Control of two-phase heat transfer and condensation loss in turbine blade cascade by injection water droplets. Appl Therm Eng 186:116541

Firoozi A, Majidi S, Ameri M (2020) A numerical assessment on heat transfer and flow characteristics of nanofluid in tubes enhanced with a variety of dimple configurations, Thermal Science and Engineering Progress 19:100578

Burkholder F, Kutscher C (2009) Heat loss testing of Schott’s 2008 PTR70 parabolic trough receiver. National Renewable Energy Laboratory 1–58

Webb RL (1981) Performance evaluation criteria for use of enhanced heat transfer surfaces in heat exchanger Design. Int J Heat Mass Transf 24(1981):715–726

Zhang G, Wang X, Dykas S, Faghih Aliabadi MA (2022) Reduction entropy generation and condensation by NaCl particle injection in wet steam supersonic nozzle. Int J Therm Sci 171:107207

Sundar LS, Naik MT, Sharma KV, Singh MK, Reddy SCHT (2012) Experimental investigation of forced convection heat transfer and friction factor in a tube with Fe3O4 magnetic nanofluid. Exp Thermal Fluid Sci 37:65–71

Valizade M, Heyhat MM, Maerefat M (2020) Experimental study of the thermal behavior of direct absorption parabolic trough collector by applying copper metal foam as volumetric solar absorption. Renew Energy 145:261–269

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no confict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised due to incorrect Figure 7.

Rights and permissions

About this article

Cite this article

Rezaei Gorjaei, A., Haghighi Khoshkhoo, R., Joda, F. et al. Thermo-hydraulic analysis of EuroTrough solar collector with dimpled absorber tubes and nanofluid: coupling MCRT and CFD methods. Heat Mass Transfer 58, 1829–1842 (2022). https://doi.org/10.1007/s00231-022-03219-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-022-03219-w