Abstract

Silicon oxide (SiO) coated nanostructured surfaces for nucleate pool boiling heat transfer are experimentally studied. The 300 nm thickness SiO nanostructured coating over SiO intermediate layer (100 nm thickness thin film) is evolved with three different azimuthal orientations of 55°, 70° and 85° (vapor incident angle) on three separate copper heating surfaces by Glancing Angle Deposition (GLAD) technique. 300 nm thickness nanostructured coating without intermediate layer is synthesized on another copper heating surface at azimuthal orientation of 85° by applying same technique. Additionally, 300 nm thickness SiO thin film on one copper surface is fabricated with E-beam method and without GLAD technique. The surfaces are characterized by Field Emission - Scanning Electron Microscopy and Atomic Force Microscope measurement to analyze the surface cavity, roughness and effective heating surface area. The pool boiling experiments are performed on these surfaces including uncoated one at saturation temperature of 6º C. Refrigerant R-134a is used as boiling liquid. The SiO nanostructured surface with intermediate layer of TF provides higher heat transfer activities than that of without intermediate layer. The modified surface at 85º GLAD significantly enhanced boiling heat transfer performance compared to 55º GLAD, 70º GLAD and uncoated surface. The studies of Field Emission - Scanning Electron Microscopy confirmed that the successfully and uniformly distributed SiO nanostructure formed via 85º GLAD. The nanofabrication with 85º GLAD over intermediate layer is an approach that provides the ability of producing a well aligned and well separated nanostructure on a surface for enhanced boiling heat transfer. This simple and cost-effective surface modification technique can alter thermodynamic performance of surface, especially in case of energy conversion devices to reduce energy dissipation.

Similar content being viewed by others

Availability of data and materials

The datasets used and/or analysed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- A:

-

Surface area, [m2]

- A1, A2, A3, A4, A5, A6 and AS :

-

Area calculated from vertically oriented heater at Sect. 1, 2, 3, 4, 5, 6 and S, [m2]

- D1, D2, D3, D4, D5, D6and DS :

-

Diameter measured from vertically oriented heater section at point 1, 2, 3, 4, 5, 6 and S, [m]

- h:

-

Heat transfer coefficient, [W.m−2.K−1]

- I:

-

Current, [amp]

- k:

-

Thermal conductivity,[W m−1.K−1]

- M:

-

Molecular weight

- \(\mathrm{P}\) :

-

Pressure

- \({\mathrm{P}}_{\mathrm{c}}\) :

-

Critical pressure

- \({\mathrm{P}}_{\mathrm{r}}\) :

-

Reduced pressure, (P/Pc)

- Q:

-

Power input, [W]

- q:

-

Heat flux, [W.m−2]

- q1, q2, q3, q4, q5, q6 and qS :

-

Heat flux calculated from vertically oriented heater at sectional area A1, A2, A3, A4, A5, A6 and AS, [W.m−2]

- \({\mathrm{R}}_{\mathrm{a}}\) :

-

Arithmetic mean roughness height, [\(\mathrm{\mu m}]\)

- T:

-

Temperature, [\(K\)]

- T1, T2, T3, T4, T5, T6, TS :

-

Temperature measured from heater Section in horizontal direction, [\(\mathrm{K}\)]

- V:

-

Voltage, [volt]

- ∆ :

-

Difference

- α:

-

Evaporation incident angle / Azimuthal orientation

- AFM:

-

Atomic Force Microscope

- DI:

-

Deionized;

- EBE:

-

E-Beam Evaporator

- EBPD:

-

Electron Beam Physical Vapor Deposition

- EPE:

-

Expanded Poly-Ethylene

- FE-SEM:

-

Field Emission - Scanning Electron Microscopy

- GLAD:

-

Glancing Angle Deposition

- HTC:

-

Heat Transfer Coefficient

- nm:

-

Nanometer

- SiO:

-

Silicon oxide

- TF:

-

Thin Film

- b:

-

Boiling

- cu:

-

Copper

- ref:

-

Reference

- s:

-

Surface

- R:

-

Ratio

- sat:

-

Saturation

- w:

-

Wall

- ER:

-

Enhancement Ratio

References

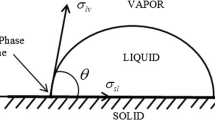

Quéré D (2008) Wetting and roughness. Annu Rev Mater Res 38:71–99

Dhir V, Liaw S (1989) Void fraction measurements during saturated pool boiling of water on partially wetted vertical surfaces. J Heat Transfer 111:731–738

Kandlikar SG (1999) Handbook of phase change: boiling and condensation, CRC Press

Griffith P, Wallis JD (1958) The role of surface conditions in nucleate boiling, in, Cambridge, Mass.: Massachusetts Institute of Technology, Division of Industrial Cooperation

Reeber M, Frieser R (1980) Heat transfer of modified silicon surfaces. IEEE Transactions on Components, Hybrids, and Manufacturing Technology 3:387–391

You S (1995) A painting technique to enhance pool boiling heat transfer in saturated FC-72. J Heat Transfer 117:387

Li C, Peterson G (2007) Parametric study of pool boiling on horizontal highly conductive microporous coated surfaces. J Heat Transfer 129:1465–1475

You S, Pak J (2001) Mechanism of nucleate boiling heat transfer enhancement from microporous surfaces in saturated FC-72. In: Proc. 2001 KSME Kyoto-Seoul-Tsinghua University Thermal Conference pp. 87–94

Phan HT, Caney N, Marty P, Colasson S, Gavillet J (2009) Surface wettability control by nanocoating: the effects on pool boiling heat transfer and nucleation mechanism. Int J Heat Mass Transf 52:5459–5471

Stutz B, Morceli CH, Da Silva MD, Cioulachtjian S, Bonjour J (2011) Influence of nanoparticle surface coating on pool boiling. Exp Therm Fluid Sci 35:1239–1249

Kim H, Kim J, Kim MH (2006) Effect of nanoparticles on CHF enhancement in pool boiling of nano-fluids. Int J Heat Mass Transf 49:5070–5074

Kim S, Bang IC, Buongiorno J, Hu L (2007) Surface wettability change during pool boiling of nanofluids and its effect on critical heat flux. Int J Heat Mass Transf 50:4105–4116

Kim HD, Kim MH (2007) Effect of nanoparticle deposition on capillary wicking that influences the critical heat flux in nanofluids. Appl Phys Lett 91:014104

Yan W, Lin-lin W, Ming-yan L (2007) Antifouling and enhancing pool boiling by TiO2 coating surface in nanometer scale thickness. AIChE J 53:3062–3076

Wu W, Bostanci H, Chow L, Hong Y, Su M, Kizito JP (2010) Nucleate boiling heat transfer enhancement for water and FC-72 on titanium oxide and silicon oxide surfaces. Int J Heat Mass Transf 53(9):1773–1777

Chen Y, Mo D, Zhao H, Ding N, Lu S (2009) Pool boiling on the superhydrophilic surface with TiO2 nanotube arrays. Sci China Ser E: Technol Sci 52(6):1596–1600

Li C, Wang Z, Wang PI, Peles Y, Koratkar N, Peterson G (2008) Nanostructured copper interfaces for enhanced boiling. Small 4(8):1084–1088

Ray M, Deb S, Bhaumik S (2016) Pool boiling heat transfer of refrigerant R-134a on TiO 2 nano wire arrays surface. Appl Therm Eng 107:1294–1303

Taschuk MT, Hawkeye MM, Brett MJ (2010) Glancing angle deposition. Handbook of Deposition Technologies for Films and Coatings 621–678

Schultz R, Cole R (1979) Uncertainty analysis in boiling nucleation. In: AIChE Symposium Series pp. 32–38

Cooper M (1984) Saturation nucleate pool boiling-a simple correlation, in: Inst Chem Eng Symp Ser pp. 785–793

Acknowledgements

The authors gratefully acknowledge to SAIF, IIT Mumbai, India for providing the FE-SEM facility and NIT Agartala, India for preparation of SiO particles coatings along with characterization of the test surfaces by AFM and different experimental works.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

Full contribution of corresponding author.

Corresponding author

Ethics declarations

Competing interests

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Study is primarily focusing on nucleate boiling and performed the boiling experiment at the saturation condition

• Nanostructured film was evolved by 55º, 70º and 85º GLAD azimuthal orientations

• SiO nanostructured film was fabricated with and without SiO intermediate TF layer

• R-134a was boiled on all nanostructured surfaces at pool temperature 6 ºC

• Boiling results show that 85º GLAD surface gives maximum HTC

• Nanostructured film with intermediate layer performed better durability

Rights and permissions

About this article

Cite this article

Ray, M. Effects of the azimuthal orientation on glancing angle deposited nanostructured surfaces for enhanced boiling heat transfer. Heat Mass Transfer 58, 1679–1694 (2022). https://doi.org/10.1007/s00231-022-03208-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-022-03208-z