Abstract

Thermal contact conductance (TCC) plays a vital role in improving the performance and the service life the electronic devices. As, the solid conduction paths through which the heat as to be dissipated includes multiple metal-metal and metal-dielectric contacts, which offers significant resistance to the rate of heat transfer. There exists a strong need for the estimation of TCC at the interface of metal-metal as well as metal-dielectric contacts. Majority of the studies relies upon experimental estimation, which is found to be expensive and challenging to perform in numerous electronics areas. The present work provides the 3D, finite element based micro contact thermo-mechanical simulation approach for the estimation of TCC between metal-metal and metal-dielectric contacts. The approach is compared against the steady-state experimental results and shows satisfactory agreement. The study has been extended further to analyse the effect of thermal interfacial materials (TIMs), the conductivity of TIMs, the thickness of TIM and load on contact heat transfer rate and TCC of metal-dielectric contacts. Present results have shown, the highest enhancements in contact heat transfer rates and TCC for TIMs with higher thermal conductivity and when the entire mean plane separation is filled with TIM of higher thermal conductivity. Finally, a model of TCC for metal-dielectric contacts has been established. Based on the methodology presented in this work, the design engineer can analyse the thermo-mechanical behaviour of specific pressed contacts under real operating conditions involving varying load, temperature as well as the interstitial materials at the junction.

Similar content being viewed by others

Abbreviations

- A:

-

nominal contact area

- A r :

-

real contact area

- D sum :

-

summit or peak density

- d :

-

mean plane separation distance

- E:

-

modulus of elasticity

- E ' :

-

effective modulus of elasticity \( {E}^{\hbox{'}}={\left[\left(\left(1-{\nu}_1^2\right)/{E}_1\right)+\left(\left(1-{\nu}_2^2\right)/{E}_2\right)\right]}^{-1} \)

- \( H \) :

-

Vickers hardness

- H:

-

Height

- h :

-

overall thermal contact conductance

- h s :

-

solid spot conductance

- h g :

-

gap conductance

- k :

-

thermal conductivity

- L:

-

sampling length

- n:

-

Number of contact spots

- P :

-

nominal pressure

- P mean :

-

mean contact pressure

- q :

-

average interfacial heat flux

- Smises :

-

Von-Mises equivalent stress

- R a :

-

arithmetic mean roughness

- R q :

-

root mean square roughness

- t :

-

thickness of thermal interfacial material

- ΔT :

-

interfacial temperature drop

- U:

-

displacement

- [K]:

-

structural stiffness matrix

- {F}:

-

load vector

- [Kt]:

-

thermal conductivity matrix

- {Q}:

-

heat flux vector

- {T}:

-

Temperature vector

- {u}:

-

displacement vector

- ψ :

-

plasticity index

- σ :

-

standard deviation of surface heights

- σ eff :

-

effective root mean square roughness \( {\sigma}_{eff}=\sqrt{\left({\sigma}_1^2+{\sigma}_2^2\right)} \)

- η :

-

asperity density

- ρ :

-

mean summit radius

- α :

-

bandwidth parameter

- ν :

-

Poisson's ratio

- μ :

-

mean of the surface height distribution

- 1, 2:

-

upper and lower body

- x, y, z:

-

axes in cartesian coordinate system

- c, t:

-

contact source and target

- TCC:

-

thermal contact conductance

- TCR:

-

thermal contact resistance

- 2D,3D:

-

two and three dimensional

- FKN:

-

normal stiffness factor

- FTOLN:

-

penetration tolerance limit

- PDF:

-

probability density function

- SD:

-

simple derivative

- FCD:

-

finite central difference

- TIM:

-

Thermal interface material

References

Yovanovich MM (2005) Four decades of research on thermal contact, gap, and joint resistance in microelectronics. IEEE Transactions on Components and Packaging Technologies 28(2):182–206. https://doi.org/10.1109/TCAPT.2005.848483

Donovan BF, Szwejkowski CJ, Duda JC, Cheaito R, Gaskins JT, Peter Yang CY, Constantin C, Jones RE, Hopkins PE (2014) Thermal boundary conductance across metal-gallium nitride interfaces from 80 to 450 K. Appl Phys Lett 105(20):203502. https://doi.org/10.1063/1.4902233

Andresen M, Ma K, Buticchi G, Falck J, Blaabjerg F, Liserre M (2018) Junction temperature control for more reliable power electronics. IEEE Trans Power Electron 33(1):765–776. https://doi.org/10.1109/TPEL.2017.2665697

Wang A, Zhao J (2010) Review of prediction for thermal contact resistance. Science China Technol Sci 53(7):1798–1808. https://doi.org/10.1007/s11431-009-3190-6

Xian Y, Zhang P, Zhai S, Yuan P, Yang D (2018) Experimental characterization methods for thermal contact resistance: a review. Appl Therm Eng 130:1530–1548. https://doi.org/10.1016/j.applthermaleng.2017.10.163

Kumar S, Tariq A (2017) Steady state experimental investigation of thermal contact conductance between curvilinear contacts using liquid crystal thermography. Int J Therm Sci 118:53–68. https://doi.org/10.1016/j.ijthermalsci.2017.04.014

Kumar S, Tariq A (2019) Effects of contact-nature on transient thermal contact conductance. Int J Therm Sci 137:299–312. https://doi.org/10.1016/j.ijthermalsci.2018.11.029

Kumar S, Tariq A (2017) Determination of thermal contact conductance of flat and curvilinear contacts by transient approach. Exp Thermal Fluid Sci 88:261–276. https://doi.org/10.1016/j.expthermflusci.2017.06.004

Tariq A, Asif M (2016) Experimental investigation of thermal contact conductance for nominally flat metallic contact. Heat Mass Transf 52(2):291–307. https://doi.org/10.1007/s00231-015-1551-1

Frekers Y, Helmig T, Burghold EM, Kneer R (2017) A numerical approach for investigating thermal contact conductance. Int J Therm Sci 121:45–54. https://doi.org/10.1016/j.ijthermalsci.2017.06.026

Greenwood JA (1966) Constriction resistance and the real area of contact. Br J Appl Phys 17(12):1621

Cooper MG, Mikic BB, Yovanovich MM (1969) Thermal contact conductance. Int J Heat Mass Transf 12(3):279–300. https://doi.org/10.1016/0017-9310(69)90011-8

Mikić BB (1974) Thermal contact conductance; theoretical considerations. Int J Heat Mass Transf 17(2):205–214. https://doi.org/10.1016/0017-9310(74)90082-9

Yovanovich M (1981). Thermal contact correlations. In: 16th Thermophysics conference. Fluid dynamics and co-located conferences. American Institute of Aeronautics and Astronautics. https://doi.org/10.2514/6.1981-1164

Asif M, Tariq A, Singh KM (2019) Estimation of thermal contact conductance using transient approach with inverse heat conduction problem. Heat Mass Transf 55(11):3243–3264. https://doi.org/10.1007/s00231-019-02617-x

Gou J-J, Ren X-J, Dai Y-J, Li S, Tao W-Q (2018) Study of thermal contact resistance of rough surfaces based on the practical topography. Comput Fluids 164:2–11. https://doi.org/10.1016/j.compfluid.2016.09.018

Murashov MV, Panin SD (2015) Numerical modelling of contact heat transfer problem with work hardened rough surfaces. Int J Heat Mass Transf 90:72–80. https://doi.org/10.1016/j.ijheatmasstransfer.2015.06.024

Verma NN, Mazumder S (2016) Extraction of thermal contact conductance of metal–metal contacts from scale-resolved direct numerical simulation. Int J Heat Mass Transf 94:164–173. https://doi.org/10.1016/j.ijheatmasstransfer.2015.11.026

Sadowski P, Stupkiewicz S (2010) A model of thermal contact conductance at high real contact area fractions. Wear 268(1):77–85. https://doi.org/10.1016/j.wear.2009.06.040

Cui T, Li Q, Xuan Y (2014) Characterization and application of engineered regular rough surfaces in thermal contact resistance. Appl Therm Eng 71(1):400–409. https://doi.org/10.1016/j.applthermaleng.2014.07.020

Greenwood JA (1984) Unified theory of surface roughness. Proceedings of the Royal Society 393 133–157

Nayak PR (1971) Random process model of rough surfaces. J Lubr Technol 93(3):398–407. https://doi.org/10.1115/1.3451608

Pogačnik A, Kalin M (2013) How to determine the number of asperity peaks, their radii and their heights for engineering surfaces: a critical appraisal. Wear 300(1–2):143–154. https://doi.org/10.1016/j.wear.2013.01.105

Zhao J-F, Wang A-L, Yang C-X (2005) Prediction of thermal contact conductance based on the statistics of the roughness profile characteristics. Int J Heat Mass Transf 48(5):974–985. https://doi.org/10.1016/j.ijheatmasstransfer.2004.07.021

Murashov MV, Panin SD (2010). Modeling of thermal contact conductance. In: Proceedings of the 14th International Heat Transfer Conference, Washington, DC, USA, August 8–13, 2010 2010. pp 387–392. https://doi.org/10.1115/IHTC14-22616

Xian Y, Zhang P, Zhai S, Yang P, Zheng Z (2019) Re-estimation of thermal contact resistance considering near-field thermal radiation effect. Appl Therm Eng 157:113601. https://doi.org/10.1016/j.applthermaleng.2019.04.011

Jackson RL, Bhavnani SH, Ferguson TP (2008) A multiscale model of thermal contact resistance between rough surfaces. Journal of heat transfer 130(8):081301–081308. https://doi.org/10.1115/1.2927403

Dai Y-J, Gou J-J, Ren X-J, Bai F, Fang W-Z, Tao W-Q (2018) A test-validated prediction model of thermal contact resistance for Ti-6Al-4V alloy. Appl Energy 228:1601–1617. https://doi.org/10.1016/j.apenergy.2018.06.134

Tang G, Tc C, Zhang X (2019) Thermal optimization and characterization of SiC-based high power electronics packages with advanced thermal design. IEEE Trans Compon Packag Manuf Technol 9(5):854–863. https://doi.org/10.1109/TCPMT.2018.2860998

Bhushan B (2013). Introduction to tribology. Tribolgy series, 2 edn. Wiley, New York

Greenwood JA, Williamson JBP (1966) Contact of nominally flat surfaces. Proceedings of the Royal Society of London Series A, Mathematical and Physical Sciences 295(1442):300–319

ANSYS n.d.. 15.0 help

Thompson MK (2006). Methods for generating rough surfaces in ANSYS in: International ANSYS Users Conference & Exhibition

Siddappa PG, Tariq A (2017). Numerical modeling of thermal contact conductance of pressed metallic contacts In: Proceedings of the 24th National and 2nd International ISHMT-ASTFE Heat and Mass Transfer Conference (IHMTC-2017), BITS Pilani, Hyderabad, India, 2017, December 27–30 2017. pp 765–772. https://doi.org/10.1615/IHMTC-2017.1080

Summers PT, Chen Y, Rippe CM, Allen B, Mouritz AP, Case SW, Lattimer BY (2015) Overview of aluminum alloy mechanical properties during and after fires. Fire Science Reviews 4(1). https://doi.org/10.1186/s40038-015-0007-5

Wang TB, Jin CC, Yang J, Hu CF, Qiu T (2014) Physical and mechanical properties of hexagonal boron nitride ceramic fabricated by pressureless sintering without additive. Adv Appl Ceram 114(5):273–276. https://doi.org/10.1179/1743676114y.0000000226

Burzo MG, Raad PE, Komarov PL, Wicaksono C, Choi TY (2013). Measurement of thermal conductivity of nanofluids and thermal interface materials using the laser-based transient thermoreflectance method. In: 29th IEEE Semiconductor Thermal Measurement and Management Symposium, 17–21 March 2013. pp 194–199. https://doi.org/10.1109/SEMI-THERM.2013.6526828

Amils RI, Gallego JD, Sebastián JL, Muñoz S, Martín A, Leuther A (2016) Thermal conductivity of silver loaded conductive epoxy from cryogenic to ambient temperature and its application for precision cryogenic noise measurements. Cryogenics 76:23–28. https://doi.org/10.1016/j.cryogenics.2016.03.001

Apiezon® (January 2018). Cryogenic high vacuum grease. https://static.mimaterials.com/apiezon/DocumentLibrary/TechnicalDatasheets/Apiezo n_N_Cryogenic_High_Vacuum_Grease_Datasheet.pdf

Acknowledgements

The author acknowledges the financial support of the Bhabha Atomic Research Centre (BARC), India for enriching the thermal contact conductance research facility in Mechanical & Industrial Engineering Department at Indian Institute of Technology Roorkee, India (Grant Code: no. DAE-526 -MID & DAE-855-MID).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

APPENDIX-A

APPENDIX-A

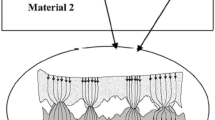

The schematic visualisation of the contacting surfaces with relevant surface topography descriptors is shown in Fig. 21. The arithmetic mean roughness (Ra), also known as centreline average of a surface profilez(x) sampled over a length L is defined as the arithmetic mean of the absolute values of the roughness profile ordinates and is given by

The root mean square roughness (RMS) (σ or Rq) of a surface profile z(x) is given by

Rights and permissions

About this article

Cite this article

Siddappa, P.G., Tariq, A. Metal and dielectric contact heat transfer and enhancement study using finite element approach. Heat Mass Transfer 56, 2893–2908 (2020). https://doi.org/10.1007/s00231-020-02910-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-020-02910-0