Abstract

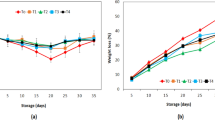

Drying characteristics, color, pH, °Brix, energy, thermal image and micrograph parameters of the whole, half cut and puree black chokeberry samples were analyzed. Experiments were carried out with a freeze dryer at a temperature of −50 °C. The results indicated that drying time was being highest with whole samples, whereas the lowest with puree samples. According to the nine different thin-layer drying models, the Midilli et al. model was the best model to explain the thin-layer freeze drying of black chokeberry. The slope of the puree samples was found steeper in the drying rate. In terms of colorimetric parameters of chroma (C) and total color difference (∆E) has similarly affected by drying methods (P < 0.05). By comparison of pH values, no significant differences found between freeze dried samples (P < 0.05). However, the maximum change of the °Brix value was determined by puree dried samples. In addition, higher energy efficiency was calculated by puree drying. Although the micrographs of half cut and puree dried samples were not distinguishable, the temperature distribution of whole samples was more uniform. As a conclusion, alternative drying methods could be useful in commercial uses such as puree with many advantages.

Similar content being viewed by others

Abbreviations

- db :

-

dry basis

- MR :

-

moisture ratio

- DR :

-

drying rate

- M 0 :

-

initial moisture content

- M t :

-

moisture content at a particular time

- M e :

-

equilibrium moisture content

- Mt + dt :

-

moisture content at t + dt

- t :

-

time

- L* :

-

darkness/lightness

- a* :

-

greenness/redness

- b* :

-

blueness/yellowness

- C :

-

chroma

- α :

-

hue angle

- ΔE :

-

total color difference

- Ec :

-

energy consumption

- SMER :

-

specific moisture extraction rate

- SEC :

-

specific energy consumption

- ƞ en :

-

energy efficiency

- mw :

-

mass of evaporated water

- λ w :

-

latent heat of free water

- λ wp :

-

latent heat of product

- SEM :

-

scanning electron microscope

- LSD :

-

least significant difference

- χ 2 :

-

lowest reduced chi-squared

- RMSE :

-

lowest root mean square error

- R 2 :

-

highest coefficient of determination

- MR exp, i :

-

experimental moisture ratio for test number i

- MR pre, i :

-

predicted moisture ratio for test number i

- N :

-

observation number

- n :

-

number of constants in the drying model

References

Kara C, Doymaz İ (2015) Effective moisture diffusivity determination and mathematical modelling of drying curves of apple pomace. Heat Mass Transf 51:983–989

Ozgen F (2015) Experimental investigation of drying characteristics of cornelian cherry fruits (Cornus mas L.). Heat Mass Transf 51:343–352

Parlak N (2015) Fluidized bed drying characteristics and modeling of ginger (zingiber officinale) slices. Heat Mass Transf 51:1085–1095

Ergün K, Çalışkan G, Dirim SN (2016) Determination of the drying and rehydration kinetics of freeze dried kiwi (Actinidia deliciosa) slices. Heat Mass Transf 52:2697–2705

Khampakool A, Soisungwan S, Park SH (2019) Potential application of infrared assisted freeze drying (IRAFD) for banana snacks: drying kinetics, energy consumption, and texture. LWT-Food Sci Technol. 99:355–363

Duan X, Yang X, Ren G, Pang Y, Liu L, Liu Y (2016) Technical aspects in freeze-drying of foods. Dry Technol 34:1271–1285

Shingisov AU, Alibekov RS (2017) Analysis of the moisture evaporation process during vacuum freeze-drying of koumiss and shubat. Heat Mass Transf 53:1571–1578

Martínez-Navarrete N, Camacho MM, Agudelo C, Salvador A (2019) Sensory characterization of juice obtained via rehydration of freeze-dried and spray-dried grapefruit. J Sci Food Agric 99:244–252

Paul ID, Das M (2018) Effect of freeze, microwave-convective hot air, vacuum and dehumidified air drying on total phenolics content, anthocyanin content and antioxidant activity of jamun (Syzygium cumini L.) pulp. J Food Sci Technol 55:2410–2419

Ancos B, Sánchez-Moreno C, Zacarías L, Rodrigo MJ, Ayerdí SS, Benítez FJB, Avila AD, González-Aguilar GA (2018) Effects of two different drying methods (freeze-drying and hot air-drying) on the phenolic and carotenoid profile of ‘Ataulfo’mango by-products. J Food Meas Charact. 12:1–13

Gomes WF, França FRM, Denadai M, Andrade JKS, da Silva Oliveira EM, de Brito ES, Rodrigues S, Narain N (2018) Effect of freeze-and spray-drying on physico-chemical characteristics, phenolic compounds and antioxidant activity of papaya pulp. J Food Sci Technol 55:2095–2102

Izli N, Izli G, Taskin O (2018) Impact of different drying methods on the drying kinetics, color, total phenolic content and antioxidant capacity of pineapple. Cyta-J Food 16:213–221

Izli N, Izli G, Taskin O (2017) Drying kinetics, colour, total phenolic content and antioxidant capacity properties of kiwi dried by different methods. J Food Meas Charact 11:64–74

Wu T, Grootaert C, Voorspoels S, Jacobs G, Pitart J, Kamiloglu S, Possemiers S, Heinonen M, Kardum N, Glibetic M, Smagghe G, Raes K, Camp JV (2017) Aronia (Aronia melanocarpa) phenolics bioavailability in a combined in vitro digestion/Caco-2 cell model is structure and colon region dependent. J Funct Foods 38:128–139

Calín-Sánchez Á, Kharaghani A, Lech K, Figiel A, Carbonell-Barrachina ÁA, Tsotsas E (2015) Drying kinetics and microstructural and sensory properties of black chokeberry (Aronia melanocarpa) as affected by drying method. Food Bioprocess Tech 8:63–74

Samoticha J, Wojdyło A, Lech K (2016) The influence of different the drying methods on chemical composition and antioxidant activity in chokeberries. LWT-Food Sci Technol 66:484–489

Thi DN, Hwang ES (2016) Effects of different growing regions on quality characteristics, bioactive compound contents, and antioxidant activity of aronia (Aronia melanocarpa) in Korea. Prev Nutr Food Sci 21:255–262

Gawałek J, Domian E, Ryniecki A, Bakier S (2017) Effects of the spray drying conditions of chokeberry (Aronia melanocarpa L.) juice concentrate on the physicochemical properties of powders. Int J Food Sci Tech 52(9):1933–1941

Ruskova MM, Aleksandrov SS, Bakalov IY, Popescu EC, Petrova TV, Gotcheva VG, Penov ND (2016) Osmotic dehydration as a preliminary technological process for the production of dried chokeberry (Aronia melanocarpa). Bulg Chem Commun 48:412–417

Thi DN, Hwang ES (2016) Effects of drying methods on contents of bioactive compounds and antioxidant activities of black chokeberries (Aronia melanocarpa). Food Sci Biotechnol 25:55–61

Lee S, Moon HK, Lee SW, Moon JN, Kim JK (2016) Biological activities in Aronia melanocarpa depending on drying methods. Korean J Food Preserv 23:1018–1025

Darıcı S, Şen S (2015) Experimental investigation of convective drying kinetics of kiwi under different conditions. Heat Mass Transf 51:1167–1176

Kaveh M, Abbaspour-Gilandeh Y, Chayjan RA, Taghinezhad E, Mohammadigol R (2018) Mass transfer, physical, and mechanical characteristics of terebinth fruit (Pistacia atlantica L.) under convective infrared microwave drying. Heat Mass Transf 54:1879–1899

Izli N, Polat A (2019) Freeze and convective drying of quince (Cydonia oblonga miller.): effects on drying kinetics and quality attributes. Heat Mass Transf 55(5):1317–1326

Taşkın O, İzli G, İzli N (2018) Convective drying kinetics and quality parameters of european cranberrybush. Tarım Bilim Derg 24:349–358

Pei F, Yang WJ, Shi Y, Sun Y, Mariga AM, Zhao LY, Fang Y, Ma N, An XX, Hu QH (2014) Comparison of freeze-drying with three different combinations of drying methods and their influence on colour, texture, microstructure and nutrient retention of button mushroom (Agaricus bisporus) slices. Food Bioprocess Tech. 7:702–710

Acar B, Sadikoglu H, Doymaz I (2015) Freeze-drying kinetics and diffusion modeling of saffron (Crocus sativus L.). J Food Process Pres. 39:142–149

Midilli A, Kucuk H, Yapar Z (2002) A new model for single-layer drying. Dry Technol 20(7):1503–1513

Beigi M (2016) Hot air drying of apple slices: dehydration characteristics and quality assessment. Heat Mass Transf 52:1435–1442

Mechlouch RF, Elfalleh W, Ziadi M, Hannachi H, Chwikhi M, Aoun AB, Elakesh I, Cheour F (2012) Effect of different drying methods on the physico-chemical properties of tomato variety 'Rio Grande'. Int J Food Eng 8:1–13

Caliskan G, Dirim SN (2017) Drying characteristics of pumpkin (Cucurbita moschata) slices in convective and freeze dryer. Heat Mass Transf 53:2129–2141

Motevali A, Minaei S, Khoshtagaza MH (2011) Evaluation of energy consumption in different drying methods. Energy Convers Manag 52:1192–1199

Motevali A, Minaei S, Banakar A, Ghobadian B, Darvishi H (2016) Energy analyses and drying kinetics of chamomile leaves in microwave-convective dryer. J Saudi Soc Agric Sci 15:179–187

Jiang H, Zhang M, Mujumdar AS, Lim RX (2013) Analysis of temperature distribution and SEM images of microwave freeze drying banana chips. Food Bioprocess Tech. 6:1144–1152

Tian Y, Wu S, Zhao Y, Zhang Q, Huang J, Zheng B (2015) Drying characteristics and processing parameters for microwave-vacuum drying of kiwifruit (Actinidia deliciosa) slices. J Food Process Pres 39:2620–2629

Doymaz İ, İsmail O (2011) Drying characteristics of sweet cherry. Food Bioprod Process 89:31–38

Salehi F, Kashaninejad M, Jafarianlari A (2017) Drying kinetics and characteristics of combined infrared-vacuum drying of button mushroom slices. Heat Mass Transf 53:1751–1759

Thakur AK, Saharan VK, Gupta RK (2010) Drying of ‘Perlette’ grape under different physical treatment for raisin making. J Food Sci Technol 47:626–631

Martínez-García JJ, Gallegos-Infante JA, Rocha-Guzmán NE, Ramírez-Baca P, Candelas-Cadillo MG, González-Laredo RF (2013) Drying parameters of half-cut and ground figs (Ficus carica L.) var. mission and the effect on their functional properties. J Eng.1–8

Bhattacharya M, Srivastav PP, Mishra HN (2015) Thin-layer modeling of convective and microwave-convective drying of oyster mushroom (Pleurotus ostreatus). J Food Sci Technol 52:2013–2022

Horszwald A, Julien H, Andlauer W (2013) Characterisation of aronia powders obtained by different drying processes. Food Chem 141:2858–2863

Tolić MT, Jurčević IL, Krbavčić IP, Marković K, Vahčić N (2015) Phenolic content, antioxidant capacity and quality of chokeberry (Aronia melanocarpa) products. Food Technol Biotech 53:171–179

Scher CF, de Oliveira RA, Noreña CPZ (2009) Hot air drying of yacon (Smallanthus sonchifolius) and its effect on sugar concentrations. Int J Food Sci Technol 44:2169–2175

Rudy S (2009) Energy consumption in the freeze-and convection-drying of garlic. Kom Mot I Energ Roln 9:259–266

Lewicki PP (2006) Design of hot air drying for better foods. Trends Food Sci Technol 17:153–163

Serna-Cock L, Vargas-Muñoz DP, Aponte AA (2015) Structural, physical, functional and nutraceutical changes of freeze-dried fruit. Afr J Biotechnol 14:442–450

Motevali A, Minaei S, Banakar A, Ghobadian B, Khoshtaghaza MH (2014) Comparison of energy parameters in various dryers. Energ Convers Manage 87:711–725

Celen S (2019) Effect of microwave drying on the drying characteristics, color, microstructure, and thermal properties of Trabzon persimmon. Foods. 8:1–19

Huang LL, Zhang M, Wang LP, Mujumdar AS, Sun DF (2012) Influence of combination drying methods on composition, texture, aroma and microstructure of apple slices. LWT-Food Sci Technol. 47:183–188

Ong SP, Law CL (2011) Microstructure and optical properties of salak fruit under different drying and pretreatment conditions. Dry Technol 29:1954–1962

Acknowledgments

The author thanks the support of Bursa Uludag University and Atatürk Central Horticultural Research Institute.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Taskin, O. Evaluation of Freeze Drying for Whole, Half Cut and Puree Black Chokeberry (Aronia melanocarpa L.). Heat Mass Transfer 56, 2503–2513 (2020). https://doi.org/10.1007/s00231-020-02867-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-020-02867-0