Abstract

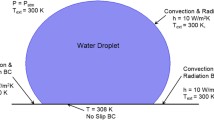

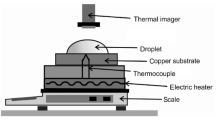

Heat transfer from replicated hydrophobic and transparent PDMS surface to a water droplet is considered. The laser texturing of alumina surface is carried out to obtain hydrophobic surface and later the textured surface is replicated by polydimethylsiloxane (PDMS) via a solvent casting method. An experiment is carried out to assess the water droplet pinning on the replicated inclined PDMS surface while keeping the replicated surface at uniform temperature (308 K). The flow and temperature fields inside the inclined water droplet are simulated in line with the experimental conditions. The flow velocities inside the droplet are validated through the data obtained from the particle imaging velocimetry (PIV). It is found that the velocity predictions agree well with the PIV data. The droplet heating results in a circulation cell inside the droplet due to the Marangoni and the buoyancy currents. Increasing inclination angle of the PDMS replicated surface enhances the maximum velocity inside the droplet, which is more pronounced for the large size droplets. The Nusselt and the Bond numbers increase with the inclination angle of the PDMS surface.

Similar content being viewed by others

Abbreviations

- a c :

-

Characteristic diameter, m

- Ayse:

-

Ayse number

- Bo :

-

Bond number, dimensionless

- C p :

-

Specific heat capacity, J.kg−1.K−1

- d :

-

Diameter of the droplet, m

- g :

-

Acceleration due to gravity, m.s−2

- Gr :

-

Grashoff number, dimensionless

- h :

-

Convection Heat transfer coefficient, Wm−2 K−1

- Ja :

-

Jakob number

- k :

-

Thermal conductivity, W.m−1 K−1

- L :

-

Total PDMS layer thickness, m

- Ma :

-

Marangoni number, dimensionless

- Nu :

-

Nusselt number, dimensionless

- p :

-

Pressure, Pa

- PIV :

-

Particle image velocimetry

- R :

-

Overall thermal resistance, m.KW−1

- R w :

-

Wetting radius, m

- T :

-

Temperature, K

- t :

-

Time, s

- V :

-

Velocity, m.s−1

- ∀:

-

Volume, m3

- α:

-

Thermal diffusivity, m2 s−1

- α c :

-

Contact angle of the water droplet cap at the rim, degree

- β :

-

Thermal expansion coefficient, K−1

- γ :

-

Surface tension, N.m−1

- γT :

-

Temperature derivative of surface tension, N.m−1 K−1

- ∇:

-

Laplace operator

- θ :

-

Contact angle, degree

- μ :

-

Dynamic viscosity, Pa.s

- ν :

-

Kinematic viscosity, m2.s−1

- ρ :

-

Density, kg.m−3

- a :

-

Air

- eff :

-

Effictive

- s :

-

Solid PDMS

References

Al-Sharafi A, Yilbas BS, Sahin AZ, Ali H, Al-Qahtani H (2016) Heat transfer characteristics and internal fluidity of a sessile droplet on hydrophilic and hydrophobic surfaces. Appl Therm Eng 108:628–640

Yilbas BS, Yousaf MR, Ali H, Al-Aqeeli N (2016) Replication of laser-textured alumina surfaces by polydimethylsiloxane: Improvement of surface hydrophobicity. J Appl Polym Sci 133

Gezer PG, Brodsky S, Hsiao A, Liu GL, Kokini JL (2015) Modification of the hydrophilic/hydrophobic characteristic of zein film surfaces by contact with oxygen plasma treated pdms and oleic acid content. Colloids Surf B: Biointerfaces 135:433–440

Liu H, Huang J, Chen Z, Chen G, Zhang K-Q, Al-Deyab SS, Lai Y (2017) Robust translucent superhydrophobic PDMS/PMMA film by facile one-step spray for self-cleaning and efficient emulsion separation. Chem Eng J 330:26–35

Liu B, Wang W, Jiang G, Mei X, Wang Z, Wang K, Cui J (2016) Study on hierarchical structured PDMS for surface super-hydrophobicity using imprinting with ultrafast laser structured models. Appl Surf Sci 364:528–538

Martin S, Bhushan B (2017) Transparent, wear-resistant, superhydrophobic and superoleophobic poly (dimethylsiloxane) (PDMS) surfaces. J Colloid Interface Sci 488:118–126

Zhang Y, Karasu F, Rocco C, van der Ven L, van Benthem R, Allonas X, Croutxé-Barghorn C, Esteves A (2016) PDMS-based self-replenishing coatings. Polymer 107:249–262

Cheng Y, Wang F, Xu J, Liu D, Sui Y (2018) Numerical investigation of droplet spreading and heat transfer on hot substrates. Int J Heat Mass Transf 121:402–411

Al-Sharafi A, Ali H, Yilbas BS, Sahin AZ, Al-Aqeeli N, Al-Sulaiman F, Khaled M (2017) Internal flow and heat transfer in a droplet located on a superhydrophobic surface. Int J Therm Sci 121:213–227

Misyura S (2017) Contact angle and droplet heat transfer during evaporation on structured and smooth surfaces of heated wall. Appl Surf Sci 414:188–196

Al-Sharafi A, Yilbas BS, Ali H (2018) Water droplet mobility on a hydrophobic surface under a thermal radiative heating. Appl Therm Eng 128:92–106

Ljung A-L, Lundström TS (2017) Heat and mass transfer boundary conditions at the surface of a heated sessile droplet. Heat Mass Transf 53:3581–3591

Adhikari S, Nabil M, Rattner AS (2017) Condensation heat transfer in a sessile droplet at varying biot number and contact angle. Int J Heat Mass Transf 115:926–931

Lee D-Y, Chung B-J (2017) Visualization of natural convection heat transfer on a sphere. Heat Mass Transf 53:3613–3620

Volkov R, Strizhak P (2018) Motion of water droplets in the counter flow of high-temperature combustion products. Heat Mass Transf 54:193–207

Volkov RS, Strizhak PA (2017) Planar laser-induced fluorescence diagnostics of water droplets heating and evaporation at high-temperature. Appl Therm Eng 127:141–156

Wen R, Lan Z, Peng B, Xu W, Ma X (2015) Droplet dynamics and heat transfer for dropwise condensation at lower and ultra-lower pressure. Appl Therm Eng 88:265–273

Chai An-Ti, Arpaci VS (1994) A realistic model of evaporation for a liquid droplet. Second Microgravity, NASA Technical Report. 95N14543:19950008129, https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19950008129.pdf

Lu G, Duan Y-Y, Wang X-D, Lee D-J (2011) Internal flow in evaporating droplet on heated solid surface. Int J Heat Mass Transf 54:4437–4447

Mackenzie J, Mekwi W (2011) An unconditionally stable second-order accurate ALE–FEM scheme for two-dimensional convection–diffusion problems. IMA J Numer Anal 32:888–905

Incropera F, DeWitt D, Bergman T, Lavine A (2006) Fundamentals of Heat and Mass Transfer, 6th edn. John Wiley & Sons, Hoboken

Zografos AI, Martin WA, Sunderland JE (1987) Equations of properties as a function of temperature for seven fluids. Comput Methods Appl Mech Eng 61:177–187

Heib F, Hempelmann R, Munief W, Ingebrandt S, Fug F, Possart W, Groß K, Schmitt M (2015) High-precision drop shape analysis (HPDSA) of quasistatic contact angles on silanized silicon wafers with different surface topographies during inclining-plate measurements: influence of the surface roughness on the contact line dynamics. Appl Surf Sci 342:11–25

Schmitt M, Groß K, Grub J, Heib F (2015) Detailed statistical contact angle analyses;“slow moving” drops on inclining silicon-oxide surfaces. J Colloid Interface Sci 447:229–239

Al-Sharafi A, Sahin AZ, Yilbas BS, Shuja S (2016) Marangoni convection flow and heat transfer characteristics of water–CNT nanofluid droplets. Numerical Heat Transfer, Part A: Applications 69:763–780

Li J, Shi L, Chen Y, Zhang Y, Guo Z, B-l S, Liu W (2012) Stable superhydrophobic coatings from thiol-ligand nanocrystals and their application in oil/water separation. J Mater Chem 22:9774–9781

Jung YC, Bhushan B (2007) Wetting transition of water droplets on superhydrophobic patterned surfaces. Scr Mater 57:1057–1060

Antonini C, Carmona F, Pierce E, Marengo M, Amirfazli A (2009) General methodology for evaluating the adhesion force of drops and bubbles on solid surfaces. Langmuir 25:6143–6154

ElSherbini A, Jacobi A (2006) Retention forces and contact angles for critical liquid drops on non-horizontal surfaces. J Colloid Interface Sci 299:841–849

Pilat D, Papadopoulos P, Schaffel D, Vollmer D, Berger R, Butt H-J (2012) Dynamic measurement of the force required to move a liquid drop on a solid surface. Langmuir 28:16812–16820

Ayyad AH (2010) Thermodynamic derivation of the young–Dupré form equations for the case of two immiscible liquid drops resting on a solid substrate. J Colloid Interface Sci 346:483–485

Tam D, von ARNIM V, McKinley G, Hosoi A (2009) Marangoni convection in droplets on superhydrophobic surfaces. J Fluid Mech 624:101–123

Acknowledgements

The authors acknowledge the financial support of King Fahd University of Petroleum and Minerals (KFUPM) through Project# IN171001 to accomplish this work and King Abdullah City for Atomic and Renewable Energy (K.A.CARE).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors do not have any conflict of interest with third parties.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix 1: Evaporation of water from liquid droplet

Appendix 1: Evaporation of water from liquid droplet

Evaporation of liquid from the droplet was presented previously [18] and the formulation of rate of evaporation is introduced briefly herein. Evaporation of water from a water droplet depends on water temperature, air temperature, air humidity and air velocity above the water surface.

The amount of evaporated water (kg/s) can be expressed as:

where ϕis the evaporation coefficient ((ϕ = 25 − 19v), v velocity of air above the water surface (m/s)), A is droplet free surface area (m2), xs is the maximum humidity ratio of saturated air at the same temperature as the water surface (kg H2O in kg Dry Air), and x is the humidity ratio air (kg/kg) (kg H2O in kg Dry Air).

1.1 Appendix 2: Formulation of thermal contact resistance

Consider the interface condition as shown in Fig. 16 The thermal contact resistance between the textured surface and the droplet meniscus at the interface can be formulated while assuming the air gaps in the textured surface act like porous structures. In addition, temperature equilibrium is assumed between the air inside the air gap and the texture of the solid surface. The overall effective thermal resistance (R) in accordance Fig. 16 can be written as:

where R is the overall thermal contact resistance, L is the total PDMS layer thickness including the air-gap due to surface texture, ε is the void fraction, which corresponds to the fraction of air gap volume in the overall texture volume including solid pillars and the air gap volume. In 2-dimensional analogy, the void fraction can be simplified as the ratio of area occupied by air pockets in the pillars gap over the total projected area including the air gap and the solid pillars. Eq. 21 can be simplified as:

However, the overall effective contact resistance is:

Hence, the combination of equations Eqs. 22 and 23 yieds:

The overall effective thermal conductivity yields:

Rights and permissions

About this article

Cite this article

Al-Sharafi, A., Yilbas, B.S. & Ali, H. Heating of a water droplet on inclined transparent polydimethylsiloxane (PDMS) surface. Heat Mass Transfer 56, 1503–1522 (2020). https://doi.org/10.1007/s00231-019-02790-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-019-02790-z