Abstract

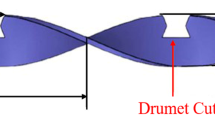

In the present study, the heat transfer, friction factor and thermal performance factor of rectangular cut twisted tape (RCT) that are inserted in inner tube side of a double pipe heat exchanger (DPHE) are numerically examined. The obtained results have been compared with the performance of heat exchangers, which are equipped/unequipped by typical twisted tape (TT). The RCTs have constant twist ratio (Y = 3.0) and are used in different cut depth ratios (DR = 0.15, 0.24 and 0.33) and cut width ratios (WR = 0.15, 0.24 and 0.33). The investigated Reynolds number range is from 6000 to 18,000 and the working fluid is considered to be water. Hot water with a variable mass flow rate is flowing through the inner pipe but cold water has counter flow through annulus side with constant mass flow rate. For the selection of the turbulence model and validation, the obtained numerical results for plain double pipe heat exchanger (P-DPHE) and heat exchanger with TT are compared with empirical correlations. Then the more accurate model was used to simulate the RCTs cases. Comparing the simulation results for RCTs and TT, it was determined that Nusselt number, friction factor and thermal performance factor will have higher value when using RCTs. This behavior is directly and inversely proportional to the DR and WR respectively. In this study, the highest thermal performance factor is about 1.46 which is obtained for RCTs in DR = 0.33 and WR = 0.15 conditions. In addition, new empirical correlations have been offered for calculating a Nusselt number and friction factor for inserted rectangular cut twisted tape in a tube.

Similar content being viewed by others

Abbreviations

- C1,C2,C1ε, C2ε, Cμ :

-

Model constant

- C p :

-

Specific heat capacity at constant pressure, J/kg K

- CD κω :

-

Cross-diffusion term, Kg/m S2

- d :

-

Rectangular cut depth, m

- D :

-

Diameter of tube, m

- D h :

-

Hydraulic diameter, m

- E :

-

Energy, J

- f :

-

Friction factor

- F1, F2 :

-

Blending function

- G κ :

-

Generation of turbulence kinetic energy due to the mean velocity gradients

- G ω :

-

Generation of specific dissipation rate

- h :

-

Heat transfer coefficient, W/(m2K)

- k :

-

Thermal conductivity, W/(mK)

- L :

-

Length of tube, m

- \( \dot{m} \) :

-

Mass flow rate, kg/s

- Nu :

-

Nusselt number

- p :

-

Pitch length based on 180 ° , m

- P :

-

Pressure, Pa

- ∆P :

-

Pressure drop, Pa

- Pr :

-

Prandtl number

- Q :

-

Heat transfer rate, W

- Re :

-

Reynolds number

- R ε :

-

Term relating to the mean strain and turbulence quantities

- S :

-

Invariant measure of the strain rate, 1/s

- t :

-

Time, s

- T :

-

Temperature, °C

- u :

-

Average velocity, m/s

- w :

-

Rectangular cut width, m

- W :

-

Width of twisted tape, m

- x :

-

Axial coordinate, m

- y :

-

Shortest distance to the near wall, m

- Y :

-

Twist ratio, (p/W)

- α ε :

-

Inverse Prandtl numbers for ε

- α κ :

-

Inverse Prandtl numbers for k

- β1, β2, β∗ :

-

Turbulent modeling constant

- γ :

-

Turbulent modeling constant

- δ ij :

-

Kronecker delta

- δ :

-

Thickness of tape, m

- ε :

-

Turbulent dissipation rate, m2/s3

- κ :

-

Turbulent kinetic energy, m2/s2

- μ :

-

Dynamic viscosity, kg/ms

- υ :

-

Kinematic eddy viscosity, m2/s

- ρ :

-

Density, kg/m3

- σ ε :

-

Turbulent Prandtl numbers for ε

- σ κ :

-

Turbulent Prandtl numbers for k

- σ ω :

-

Turbulent Prandtl numbers for ω

- τ ij :

-

Turbulent Reynolds stress tensor kg/ms2

- ω :

-

Specific dissipation rate, 1/K

- a :

-

Annulus side

- c :

-

Cold

- eff :

-

Effective

- h :

-

Hot

- i :

-

Inner tube side

- in :

-

Inlet

- out :

-

Outlet

- p :

-

Plain tube

- t :

-

Turbulent

- DPHE :

-

Double pipe heat exchanger

- DR :

-

Rectangular cut depth ratio, (d/W)

- P − DPHE :

-

Plain double pipe heat exchanger

- RANS :

-

Reynolds-averaged Navier-Stokes (equations)

- RCT :

-

Rectangular cut twisted tape

- RNG :

-

Re-Normalization Group

- SST :

-

Shear stress transport

- TPF :

-

Thermal performance factor

- TT :

-

Typical twisted tape

- WR :

-

Rectangular cut width ratio, (w/W)

References

Liu S, Sakr M (2013) A comprehensive review on passive heat transfer enhancements in pipe exchangers. Renew Sust Energ Rev 19:64–81

Azimi SS, Kalbasi M (2014) Numerical study of dynamic thermal conductivity of nanofluid in the forced convective heat transfer. Appl Math Model 38:1373–1384

Bas H, Ozceyhan V (2012) Heat transfer enhancement in a tube with twisted tape inserts placed separately from the tube wall. Exp Thermal Fluid Sci 41:51–58

Bhuiya M, Chowdhury M, Shahabuddin M, Saha M, Memon L (2013) Thermal characteristics in a heat exchanger tube fitted with triple twisted tape inserts. International Communications in Heat and Mass Transfer 48:124–132

Hasanpour A, Farhadi M, Sedighi K (2016) Experimental heat transfer and pressure drop study on typical, perforated, V-cut and U-cut twisted tapes in a helically corrugated heat exchanger. International Communications in Heat and Mass Transfer 71:126–136

Piriyarungrod N, Eiamsa-Ard S, Thianpong C, Pimsarn M, Nanan K (2015) Heat transfer enhancement by tapered twisted tape inserts. Chem Eng Process Process Intensif 96:62–71

Rahimi M, Shabanian SR, Alsairafi AA (2009) Experimental and CFD studies on heat transfer and friction factor characteristics of a tube equipped with modified twisted tape inserts. Chem Eng Process Process Intensif 48:762–770

Rehman MU, Siddique W, Haq I, Ali N, Farooqi Z (2016) CFD analysis of the influence of guide ribs/vanes on the heat transfer enhancement of a trapezoidal channel. Appl Therm Eng 102:570–585

Tamna S, Kaewkohkiat Y, Skullong S, Promvonge P (2016) Heat transfer enhancement in tubular heat exchanger with double V-ribbed twisted-tapes. Case studies in thermal engineering 7:14–24

Zhang X, Liu Z, Liu W (2012) Numerical studies on heat transfer and flow characteristics for laminar flow in a tube with multiple regularly spaced twisted tapes. Int J Therm Sci 58:157–167

Skullong S, Promvonge P, Thianpong C, Jayranaiwachira N, Pimsarn M (2018) Thermal performance of heat exchanger tube inserted with curved-winglet tapes. Appl Therm Eng 129:1197–1211

Zhang X, Liu Z, Liu W (2013) Numerical studies on heat transfer and friction factor characteristics of a tube fitted with helical screw-tape without core-rod inserts. Int J Heat Mass Transf 60:490–498

He Y, Liu L, Li P, Ma L (2018) Experimental study on heat transfer enhancement characteristics of tube with cross hollow twisted tape inserts. Appl Therm Eng 131:743–749

Nanan K, Thianpong C, Promvonge P, Eiamsa-Ard S (2014) Investigation of heat transfer enhancement by perforated helical twisted-tapes. International Communications in Heat and Mass Transfer 52:106–112

Oni TO, Paul MC (2016) Numerical investigation of heat transfer and fluid flow of water through a circular tube induced with divers' tape inserts. Appl Therm Eng 98:157–168

Mashoofi N, Pourahmad S, Pesteei S (2017) Study the effect of axially perforated twisted tapes on the thermal performance enhancement factor of a double tube heat exchanger. Case studies in thermal engineering 10:161–168

Saysroy A, Eiamsa-ard S (2017) Periodically fully-developed heat and fluid flow behaviors in a turbulent tube flow with square-cut twisted tape inserts. Appl Therm Eng 112:895–910

Suri ARS, Kumar A, Maithani R (2017) Heat transfer enhancement of heat exchanger tube with multiple square perforated twisted tape inserts: experimental investigation and correlation development. Chem Eng Process Process Intensif 116:76–96

Thianpong C, Eiamsa-Ard P, Eiamsa-Ard S (2012) Heat transfer and thermal performance characteristics of heat exchanger tube fitted with perforated twisted-tapes. Heat Mass Transf 48:881–892

Thianpong C, Eiamsa-Ard P, Promvonge P, Eiamsa-Ard S (2012) Effect of perforated twisted-tapes with parallel wings on heat tansfer enhancement in a heat exchanger tube. Energy Procedia 14:1117–1123

Man C, Lv X, Hu J, Sun P, Tang Y (2017) Experimental study on effect of heat transfer enhancement for single-phase forced convective flow with twisted tape inserts. Int J Heat Mass Transf 106:877–883

Ferroni P, Block R, Todreas N, Bergles A (2011) Experimental evaluation of pressure drop in round tubes provided with physically separated, multiple, short-length twisted tapes. Exp Thermal Fluid Sci 35:1357–1369

Eiamsa-ard S, Thianpong C, Promvonge P (2006) Experimental investigation of heat transfer and flow friction in a circular tube fitted with regularly spaced twisted tape elements. International Communications in Heat and Mass Transfer 33:1225–1233

Zheng L, Xie Y, Zhang D (2017) Numerical investigation on heat transfer performance and flow characteristics in circular tubes with dimpled twisted tapes using Al2O3-water nanofluid. Int J Heat Mass Transf 111:962–981

Eiamsa-Ard S, Thianpong C, Eiamsa-Ard P (2010) Turbulent heat transfer enhancement by counter/co-swirling flow in a tube fitted with twin twisted tapes. Exp Thermal Fluid Sci 34:53–62

Eiamsa-Ard S, Wongcharee K, Eiamsa-Ard P, Thianpong C (2010) Thermohydraulic investigation of turbulent flow through a round tube equipped with twisted tapes consisting of centre wings and alternate-axes. Exp Thermal Fluid Sci 34:1151–1161

Eiamsa-ard S, Somkleang P, Nuntadusit C, Thianpong C (2013) Heat transfer enhancement in tube by inserting uniform/non-uniform twisted-tapes with alternate axes: effect of rotated-axis length. Appl Therm Eng 54:289–309

Eiamsa-Ard S, Promvonge P (2010) Performance assessment in a heat exchanger tube with alternate clockwise and counter-clockwise twisted-tape inserts. Int J Heat Mass Transf 53:1364–1372

Eiamsa-ard S, Seemawute P, Wongcharee K (2010) Influences of peripherally-cut twisted tape insert on heat transfer and thermal performance characteristics in laminar and turbulent tube flows. Exp Thermal Fluid Sci 34:711–719

Eiamsa-Ard S, Wongcharee K, Eiamsa-Ard P, Thianpong C (2010) Heat transfer enhancement in a tube using delta-winglet twisted tape inserts. Appl Therm Eng 30:310–318

El Maakoul A, Laknizi A, Saadeddine S, Abdellah AB, Meziane M, El Metoui M (2017) Numerical design and investigation of heat transfer enhancement and performance for an annulus with continuous helical baffles in a double-pipe heat exchanger. Energy Convers Manag 133:76–86

Guo J, Xu M, Cheng L (2010) Numerical investigations of circular tube fitted with helical screw-tape inserts from the viewpoint of field synergy principle. Chem Eng Process Process Intensif 49:410–417

Murugesan P, Mayilsamy K, Suresh S, Srinivasan P (2011) Heat transfer and pressure drop characteristics in a circular tube fitted with and without V-cut twisted tape insert. International Communications in Heat and Mass Transfer 38:329–334

Seemawute P, Eiamsa-Ard S (2010) Thermohydraulics of turbulent flow through a round tube by a peripherally-cut twisted tape with an alternate axis. International Communications in Heat and Mass Transfer 37:652–659

Eiamsa-Ard S, Promvonge P (2010) Thermal characteristics in round tube fitted with serrated twisted tape. Appl Therm Eng 30:1673–1682

Murugesan P, Mayilsamy K, Suresh S (2010) Turbulent heat transfer and pressure drop in tube fitted with square-cut twisted tape. Chin J Chem Eng 18:609–617

Fluent A, "6.3, 2006, FLUENT 6.3 User’s Guide, Fluent," Inc., Lebanon, NH

El Maakoul A, Laknizi A, Saadeddine S, El Metoui M, Zaite A, Meziane M et al (2016) Numerical comparison of shell-side performance for shell and tube heat exchangers with trefoil-hole, helical and segmental baffles. Appl Therm Eng 109:175–185

Menter FR (1994) Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J 32:1598–1605

Kravchenko V (1966) Empirical equation derived of density of heavy water for temperature dependence. Atomnaya Energiya 20:168

Azmi W, Sharma K, Sarma P, Mamat R, Anuar S, Sundar LS (2014) Numerical validation of experimental heat transfer coefficient with SiO2 nanofluid flowing in a tube with twisted tape inserts. Appl Therm Eng 73:296–306

Gnielinski V (1976) New equations for heat and mass transfer in turbulent pipe and channel flow. Int Chem Eng 16:359–368

MN Ozisik, Heat transfer: a basic approach (1985)

Manglik RM, Bergles AE (1993) Heat transfer and pressure drop correlations for twisted-tape inserts in isothermal tubes: Part II—Transition and turbulent flows. J Heat Transf 115:890–896

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Barzegar, A., Jalali Vahid, D. Numerical study on heat transfer enhancement and flow characteristics of double pipe heat exchanger fitted with rectangular cut twisted tape. Heat Mass Transfer 55, 3455–3472 (2019). https://doi.org/10.1007/s00231-019-02667-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-019-02667-1