Abstract

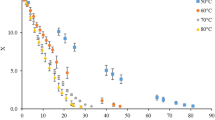

In recent years, there is an increased demand on the international market of dried fruits and vegetables with significant added value. Due to its important production, consumption and nutrient intake, drying of tomato has become a subject of extended and varied research works. The present work is focused on the drying behavior of thin-layer tomato and its mathematical modeling in order to optimize the drying processes. The moisture desorption isotherms of raw tomato were determined at four temperature levels namely 45, 50, 60 and 65 °C using the static gravimetric method. The experimental data obtained were modeled by five equations and the (GAB) model was found to be the best-describing these isotherms. The drying kinetics were experimentally investigated at 45, 55 and 65 °C and performed at air velocities of 0.5 and 2 m/s. In order to investigate the effect of the exchange surface on drying time, samples were dried into two different shapes: tomato halves and tomato quarters. The impact of various drying parameters was also studied (temperature, air velocity and air humidity). The drying curves showed only the preheating period and the falling drying rate period. In this study, attention was paid to the modeling of experimental thin-layer drying kinetics. The experimental results were fitted with four different models.

Similar content being viewed by others

Abbreviations

- T:

-

Air temperature (dry bulb temperature) (°C)

- U:

-

Air velocity (m/s)

- RH:

-

Air relative humidity (%)

- t:

-

Time (min)

- s:

-

Second

- X:

-

Moisture content (kg/kgdb)

- MR:

-

Moisture ratio (–)

- DR:

-

Drying rate ratio (–)

- \(- \left( {\frac{\text{dX}}{\text{dt}}} \right)\) :

-

Drying rate [(kg/kgdb)/s]

- \(\overline{{\text{MR}}}\) :

-

Average moisture ratio (–)

- aw :

-

Water activity (–)

- χ2 :

-

Reduced Chi square

- R2 :

-

Coefficient of determination

- N:

-

Number of experimental data points

- n:

-

Number of parameters in model

- Xm, C, K, k:

-

Constants proper to each sorption isotherm’s model

- k, a, b, n:

-

Constants proper to each drying model

- eq:

-

Equilibrium

- 0:

-

Initial

- db:

-

Dry basis

- exp:

-

Experimental

- pre:

-

Predicted

References

Akanbi CT, Adeyemi RS, Ojo A (2006) Drying characteristics and sorption isotherm of tomato slices. J Food Eng 73:157–163

Al Harahsheh M, Al-Muhtaseb Ala’a H H, Magee TRA (2009) Microwave drying kinetics of tomato pomace: effect of osmotic dehydration. Chem Eng Process 48:524–531

Al Hodali R (1997) Numerical simulation of an agricultural foodstuffs drying unit using solar energy and adsorption process. Ph.D Thesis, Université Libre de Bruxelles, Belgium

Al Muhtaseb AH, Al-Harahsheh M, Hararah M, Magee TRA (2010) Drying characteristics and quality change of unutilized-protein rich-tomato pomace with and without osmotic pre-treatment. Ind Crops Prod 31:171–177

Amiri Chayjan R (2012) Modeling some drying characteristics of high moisture potato slices in fixed, semi fluidized and fluidized bed conditions. J Agric Sci Technol 14:1229–1241

AOAC (1980) Official methods of analysis. Association of Official Analytical Chemists Inc, Washinghton

Boughali S, Benmoussa H, Bouchekima B, Mennouche D, Bouguettaia H, Bechki D (2009) Crop drying by indirect active hybrid solar—Electrical dryer in the eastern Algerian Septentrional Sahara. Sol Energy 83:2223–2232

Brunauer S, Emmett PH, Teller E (1938) Adsorption of Gases in multimolecular layers. J Am Chem Soc 60(2):309–319

Brunauer S, Deming LS, Deming WE, Teller E (1940) On a theory of the Van der Waals adsorption of gases. J Am Chem Soc 62:1723–1732

Celma AR, Cuadros F, López-Rodríguez F (2009) Characterization of industrial tomato by-products from infrared drying process. Food Bioprod Process 87:282–291

Celma AR, Rojas S, Lopez F, Montero I, Miranda T (2007) Thin-layer drying behavior of sludge of olive oil extraction. J Food Eng 80:1261–1271

Chemkhi S, Jomaa W, Zagrouba F (2009) Application of a coupled thermo-hydro mechanical model to simulate the drying of nonsaturated porous media. Drying Technol 27:842–850

Doymaz and Pala (2002) the effects of dipping pretreatments on air-drying rates of the seedless grapes. J Food Eng 52:413–417

Doymaz I (2005) Drying behavior of green beans. J Food Eng 69:161–165

Doymaz I (2007) Air-drying characteristics of tomatoes. J Food Eng 78:1291–1297

Ertekin FK, Sultanoglu M (2001) Moisture sorption isotherm characteristics of peppers. J Food Eng 47:225–231

Greenspan L (1977) Humidity fixed points of binary saturated aqueous solutions. J Res Natl Bur Stand A Phys Chem 81:89–96

Giovanelli G, Zanoni B, Lavelli V, Nani R (2002) Water sorption, drying and antioxidant properties of dried tomato products. J Food Eng 52:135–141

Halsey G (1948) Physical adsorption on non-uniform surfaces. J Chem Phys 16:931–937

Hasatani M, Itaya Y (1996) Drying-induced strain and stress: a review. Drying Technol 14:1011–1040

Hawlader MNA, Uddin MS, Ho JC, Teng ABW (1991) Drying characteristics of tomatoes. J Food Eng 14:259–268

Henderson SM (1952) A basic concept of equilibrium moisture. Agric Eng 33:29–32

Hossain MD, Bala BK, Hossain MA, Mondol MRA (2001) Sorption isotherms and heat of sorption of pineapple. J Food Eng 48:103–107

Karathanos VT, Belessiotis VG (1997) Sun and artificial air drying kinetics of some agricultural products. J Food Eng 31(1):35–46

Karel Kross R, Moreira Cavalcanti Mata MER, Martins Duarte ME, Junior VS (2004) Drying kinetics of tomatoes (Lycopersicon esculentum L.) submitted to a previous osmotic treatment. In: Proceedings of the 14th international drying symposium (IDS 2004). vol. C, pp 2133–2140

Kiranoudis CT, Maroulis ZB, Tsami E, Marinos-Kouris D (1993) Equilibrium moisture content and heat of desorption of some vegetables. J Food Eng 20:55–74

Krokida MK, Karathanos VT, Maroulis ZB, Marinos-Kouris D (2003) Drying kinetics of some vegetables. J Food Eng 59:391–403

Lahsasni S, Kouhila M, Mahrouz M, Idlimam A, Jamali A (2004) Thin layer convective solar drying and mathematical modeling of prickly pear peel (Opuntia ficus indica). Energy. 29:211–224

Maskan A, Kaya S, Maskan M (2002) Hot air and sun drying of grape leather (pestil). J Food Eng 54(1):81–88

Midilli A, Kucuk H, Yapar Z (2002) A new model for single-layer drying. Drying Technol 20(7):1503–1513

Movagharnejad K, Nikzad M (2007) Modeling of tomato drying using artificial neural network. Comput Electron Agric 59:78–85

Mulet A, Berna A, Rossello C (1989) Drying of carrots. I. Drying models. Drying Technol 7(3):537–557

Oswin CR (1946) The kinetics of package life III. The isotherm. J Chem Ind 65:419–421

Page C (1949) Factors influencing the maximum rates of air drying shelled corn in thin layers. MSc thesis, Purdue University, Indiana, USA

Palipane KB, Driscoll RH (1993) Moisture sorption characteristics of in-shell macadamia nuts. J Food Eng 18(1):63–76

Perea-Flores MJ, Garibay-Febles V, Chanona-Pérez JJ, Calderón-Domínguez G, Méndez-Méndez JV, Palacios-González E, Gutiérrez-López GF (2012) Mathematical modeling of castor oil seeds (Ricinus communis) drying kinetics in fluidized bed at high temperatures. Ind Crops Prod 38:64–71

Prabhanjan DG, Ramaswamy HS, Raghavan GSV (1995) Microwave-assisted convective air drying of thin layer of carrots. J Food Eng 25:283–293

Sacilik et al (2006) Mathematical modeling of solar tunnel drying of thin layer organic tomato. J Food Eng 73:231–238

Shyam SS, Shafiur Rahman M (2003) Effect of syrup concentration, temperature and sample geometry on equilibrium distribution coefficients during osmotic dehydration of mango. Food Res Int 36:65–71

Sopade PA (2001) Criteria for an appropriate sorption model based on statistical analysis. Int J Food Prop 4(3):227–240

Takahashi T, Hayakawa F, Kumagai M, Akiyama Y, Kohyama K (2009) Relations among mechanical properties, human bite parameters, and ease of chewing of solid foods with various textures. J Food Eng 95:400–409

Van den Berg C (1984) Description of water activity of foods for engineering purposes by means of the GAB model of sorption. In: McKenna BM (ed) Engineering and food. Elsevier Applied Science, London, pp 311–321

Wang CY, Singh RP (1978) A single layer drying equation for rough rice. ASAE, paper no. 3001, ASAE, St.Joseph

Whitaker S (1977) Simultaneous heat mass and momentum transfer in porous media: a theory of drying. Adv Heat Mass Transf 13:110–203

Yaldiz O, Ertekin C (2001) Thin layer solar drying of some vegetables. Drying Tech 19(3, 4):583–597

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Belghith, A., Azzouz, S. & ElCafsi, A. Desorption isotherms and mathematical modeling of thin layer drying kinetics of tomato. Heat Mass Transfer 52, 407–419 (2016). https://doi.org/10.1007/s00231-015-1560-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-015-1560-0