Abstract

The industrial drying of tomatoes using hot air is a widespread practice. However, air drying has several issues in terms of time, energy consumption and qualitative characteristics of the final product. The study aims to improve drying through the monitoring of the tomato’s physical characteristics. The study was divided into two parts. In the first part, the kinetics of moisture, color, volume, and rehydration ratio during the drying of tomatoes were modeled according to the temperature used (50, 60, 70, and 80 °C). Moisture loss kinetics has an initial zero-order, followed by first-order kinetics once the critical moisture is exceeded. For color, a first constant trend is observed followed by a steadily increasing or decreasing variation according to the color considered (i.e., red, or brown). The use of low temperatures guarantees the least changes of physical characteristics but significantly increases the time (+ 189%). Conversely, high temperatures guarantee faster drying but cause greater tomato browning (+ 200%). During the drying, the volume decreased linearly according to the considered temperature. In the second part of the work, a tentative drying optimization was performed, based on color kinetics. A two-stage process using two temperatures was developed to reduce drying times without affecting the product quality. Also, two control tests were conducted at 50 °C and 70 °C constant temperatures. No significant quality differences were observed between tomatoes dried at 50 °C and those using the two-stage process (p < 0.05). This type of approach did not produce a qualitative deterioration of the final product and at the same time allowed a significant reduction (− 27.6%) in time.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The cultivation of tomatoes (Solanum lycopersicum) plays a key role in the agricultural production of many countries. Once harvested, the tomatoes can be used for various purposes, ranging from being sold in markets for fresh consumption to large-scale distribution to produce tomato sauce or dried tomatoes. The drying process represents one of the main and oldest methods of food preservation. The technique is based on the reduction of the moisture content in the product to prevent the development of pathogenic microorganisms or those that can deteriorate the product. In addition to increasing the shelf life of the product, drying guarantees advantages in terms of ease of transport, thanks to the smaller volume and weight. It also offers economic advantages, due to lower packaging costs, and avoids the expensive conservation of the product at low temperatures [1, 2].

Tomatoes can be dried using various techniques. However, the most common methods applied on an industrial scale are sun drying and convective hot air drying [3, 4]. Sun drying is the most traditional system, still widely used worldwide in rural areas, based on the natural dehydration of tomatoes exposed to sunlight. This technique has several disadvantages compared to the use of convective hot air. In the food industry, there is a tendency to favor the use of dryers guaranteeing better hygiene conditions, and better nutritional value of the dried product as well as a significant reduction in drying time [5]. The use of higher temperatures determines a lower presence of bacteria and fungi in the hot-air-dried tomatoes compared to sun-dried ones, allowing better preservation of the product [3]. The sun drying process is difficult to monitor due to the impossibility of controlling the temperature and weather conditions and also requires large surfaces and high labor costs [6]. On the contrary, hot air convective dryers usually operate at high stationary temperatures, ranging from 50 to 70 °C [6].

Several factors affect the final tomato characteristics. The pre-treatments performed, the cultivars used, and the drying method, as well as drying time and temperature, affect the properties of dried tomatoes [7, 8]. During the use of hot-air convective dryers, prolonged exposure of tomatoes to high temperatures and oxygen causes irreversible chemical reactions reducing the quality of the final product in terms of composition, nutritional properties, structure, and flavor [8,9,10]. Among the qualitative parameters affected by the drying process are color, shape, taste, and antioxidant content [4, 8, 11].

Color represents one of the most important aspects for consumers. Among the physical parameters, color is recognized to be the most susceptible to the drying process. The color change in dried tomatoes is due to the combined effect of non-enzymatic browning reactions [8, 9] and carotenoid degradation [10]. Browning is the factor determining the main loss of quality in dried tomatoes. As the drying process progresses, a loss of moisture occurs, increasing the incidence of this phenomenon as a function of the temperature used [1, 9]. Heat treatment at high temperatures also causes the loss of the antioxidants naturally contained within tomatoes. Among the chemical compounds degraded by the drying process is ascorbic acid, an important antioxidant [3, 5, 7, 9, 10]. Tomatoes are a major source of carotenoids, including lycopene, whose antioxidant properties have positive effects on human health. The degradation of lycopene during the drying process has repercussions, both in terms of color loss and also on the nutritional properties of dried tomatoes [10]. The combined action of heat and oxygen causes the destruction of tomato tissue, consequently degrading the lycopene [8, 10, 12,13,14]. Another factor determining degradation is the isomerization process where the lycopene converts from the trans form to the less biologically active cis form [10].

A valid alternative to traditional stationary drying processes is intermittent or multistage drying, guaranteeing both economic and qualitative advantages. In these processes, temperature, pressure, moisture, and air velocity are changed during the drying [15, 16]. Among the factors affecting the drying process, temperature plays the most important role [17, 18]. A combination of high and low temperatures can lead to a reduction in drying times without compromising the quality of the final product which can be even better than that which is dried continuously thanks to greater retention of nutrients and fewer chemical degradation reactions [7, 9, 15]. Multistage processes also allow energy saving compared to continuous drying [16]. Moreover, the use of low temperatures for a prolonged time is associated with higher energy consumption compared to the use of high temperatures for a shorter drying time [19, 20]. The multistage process could guarantee optimization of the drying process, reducing time, energy consumption and obtaining higher-quality products.

Numerous works in the literature studied the moisture content loss kinetics in dried tomatoes [8, 14, 18, 21, 22]. However, only a small number of these also modeled the kinetics of qualitative parameters during the drying process [9, 23] and, to the best of the author’s knowledge, there are no papers that model the change in the physical parameters of tomatoes and use the developed models to optimize the drying process. Moreover, the study of the physical parameters’ kinetics during the drying process, not focused exclusively on the kinetics of loss of moisture content, could be used for the development of multistage drying processes that would allow further advantages both in terms of product quality and a drastic reduction in drying times. To make this approach suitable at the industrial scale, the monitoring of color, volume and rehydration capacity was performed. These physical parameters were selected since they are quick, cheap, and easy to be determined.

The main goals of this work are: (i) to model the kinetics of physical parameters (moisture, color, volume, and rehydration capacity) of tomatoes during the drying process, and (ii) based on the physical parameter kinetics to develop a two-stage process to optimize tomato drying in terms of time and the quality of the final product.

The work was divided into two trials. In the first trial, physical parameter kinetics as a function of the drying time and temperature were analyzed. The tests were conducted at 50, 60, 70 and 80 °C. In the second trial, based on the results of the first one, a two-stage drying process at variable temperatures was developed and compared with two stationary drying processes at 50 °C and 70 °C.

Materials and methods

Sample preparation and drying tests

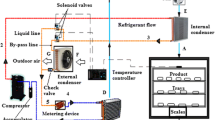

The tomatoes used in the drying tests belong to the H 1015 variety (Heinz Seeds). The tomatoes had an ellipsoidal shape, an average width of 30.6 ± 1.3 mm, an average length of 54.5 ± 0.9 mm, and an average weight of 44.1 ± 1.3 g. Tomatoes were analyzed on the same day as the harvest and selected for color and physical damage absence. The tomatoes analyzed are included within the red color classification according to the USDA Color Scheme Categorization since more than 90% of the surface is red. The tomatoes were cut into two parts through a longitudinal cut and placed, with the cut surface facing up, on different solid aluminum trays. For each drying temperature, three replicates of 1 kg of tomatoes were prepared. For the first trial, tomatoes were dried in a laboratory-scale convection hot-air cabinet dryer with an airflow rate of 0.1 m/s at four different temperatures (50, 60, 70 and 80 °C) until the target moisture of 25% (w.b.) was reached. Environmental air was at 28 °C and 50% RH, resulting after the air heating, in 14.0%, 7.9%, 4.4%, and 2.2% of RH at 50 °C, 60 °C, 70 °C, and 80 °C, respectively. The temperatures were selected among those commonly used in the industrial field for drying the tomatoes. Furthermore, these temperatures have been selected as they have already been used in literature to have a better comparison with our results [1, 9]. The target value was decided according to the internal standards of a local dry tomato producer (Coelsanus Industria Conserve S.p.A., Sossano, Vicenza, Italy). For calculation convenience, the target moisture was changed to a dry basis (X). At predetermined intervals, the trays were weighed using a digital scale balance RadWag ®PS. 6000/C/2, with a sensitivity of 0.01 g, to monitor weight loss until the target moisture of 0.33 d.b. (dry basis) was reached.

Kinetic-based process optimization

Based on the results of the first trial a two-stage drying was developed using two different temperatures. Initially a temperature of 70 °C was applied for the first 20 h. The use of temperatures higher than 70 °C in the initial phase could guarantee a further reduction of drying times but also a greater loss of lycopene and beta-carotene in the dried tomatoes [23]. After the initial stage, the temperature was reduced to 50 °C, until the target moisture was reached. In parallel, two dehydration processes were conducted at a constant temperature of 50 °C and 70 °C and used as controls and for quality comparison of the dried tomatoes. The drying tests were performed using the same hot-air cabinet dryer used in the first trial. Environmental air was available at 26.5 °C and RH 65%, resulting in heated air with 16.6% RH at 50 °C and 5.2% RH at 70 °C. For each test, three replicates of 1 kg of halved tomatoes were placed in solid aluminum trays. Also, in this case, the trays were weighed using the same balance previously used to monitor the weight loss until the target humidity was reached (0.33 d.b.).

Moisture contents

The moisture content of tomatoes before drying and the achievement of the target moisture at the end of the process were determined using an oven drier (model Binder® FD115). Around 100 g of tomatoes were dried at 105 °C for 24 h. The moisture content was calculated using the following formula:

where: M (%) is the moisture content of the sample, W0 is the initial weight of the sample (g) and WF is the final weight of the sample after oven drying (g). Knowing the moisture content of the sample, the dry matter value DM (%) was determined using:

Following, moisture was expressed in dry basis:

Color

A Nikon® Coolpix W300 camera (resolution = 16 M-pixels) was used for color monitoring. The tomatoes were placed on a black background inside a controlled light chamber to avoid external interference. The camera was positioned on top of the chamber at 40 cm of the focal distance. Calibration was performed using a Color Checker, showing a set of 24 colored squares with known RGB values. Before color analysis, the GNU Image Manipulation Program (GIMP)® software was used to remove the background. The method used for color analysis was described by [24]. Briefly, 3-dimensional RGB coordinates were obtained for each pixel. Following this, the whole RGB color space was divided into eight equal zones, and pixels were attributed to one of the zones according to their RGB values. Finally, pixels in each RGB zone were counted and divided for the total number of pixels to obtain frequencies. Color analyses were performed using RStudio® software.

Volume

Tomato volume measurements were performed using a Microsoft Kinect™ RGB-depth camera. This type of low-cost sensor has already been successfully applied to determine the volume of agricultural products [25]. The volume is determined through a triangulation process where the beam emitted by the infrared projector installed on the camera is compared with that detected by the infrared depth sensor, allowing the three-dimensional reconstruction of the surface hit by the beam [26]. The camera was placed on a worktable with support for keeping it at a constant height. At each pre-established time interval, the tomatoes were placed under the camera, alternating the cut surface upwards and downwards. To be able to compare the volume change of the same tomatoes, the ten largest tomatoes were selected for each measurement. Scanning Probe Image Processor™ software was used to determine the volume of the tomatoes. To allow the estimation of quantitative parameters, the Kinect sensor was calibrated through a so-called substitution procedure, as discussed in [27]. The substitution approach takes advantage of a calibration carried out on reference standard surfaces resembling the shapes of interest for experimental work. For this specific experimental activity, polystyrene hemispheres with dimensions in a range between 50 and 120 mm of diameter were used (i.e., between 32.7 cm3 and 452.2 cm3). Such artifacts resemble the typical dimensions and curvatures of half tomatoes, the object of the study. Volume was expressed in cm3. The volumetric shrinkage ratio of tomatoes (SR) was expressed as the ratio between the volume during the drying process (V) and the initial volume (V0):

Rehydration ratio

The rehydration tests were conducted following what is described by [28] and [29]. Briefly, 15 g of tomatoes were immersed in a beaker with 750 ml of water at 25 °C and 100 °C. For the tests at 100 °C, a heating plate with a magnetic stirrer (model Velp® ARE) and a digital thermometer (Xs Instruments® Temp 7 PT100 Basic) for measuring water temperature were used. The temperature was maintained at a temperature of about 98 ± 1 °C. After immersion, the samples were dried with tissue paper, to remove the excess water present on the tomato surface and weighed at regular intervals. For rehydration tests at 25 °C, samples were weighed at 0, 15, 30, 60, 90, 150 min and subsequently at regular intervals of 60 min until weight constancy was reached. In the same way for the tests carried out at 100 °C, the samples were weighed at 0, 1, 2, 4, 6, 8, and 10 min and then at 4-min intervals. The Rehydration Ratio (RR) was calculated using the following equation [30]:

where Wt is the weight of the sample at time t, W0 represents the initial weight of the sample. Three replicates were performed for each trial.

Statistical analysis

For all the treatments examined, three replicates were done. At the end of the drying process, the collected data were subjected to a one-way analysis of variance (ANOVA) with a 95% confidence interval. Before performing the ANOVA test, the normality of the distribution was verified using the Shapiro–Wilk Test. Homoscedasticity was also tested using Levene’s Test. Using Tukey's Honestly Significant Difference (HSD) test, it was verified which sample means had statistically significant differences. Statgraphics Centurion 19® software was used for the analyses.

During drying, the data contained in the present work was modeled according to the presence, or the absence of a mechanistic model in the literature. Moreover, the changes in tomato moisture were modeled as zero-order kinetics until the attainment of the critical moisture, and as first-order kinetics [31]. For the changes in color and volume, no established model was available from the literature. Hence, phenomenological models based on data fitting were built. Linear, quadratic, reciprocal, power law, and exponential models were tested. In the absence of significative improvements in data variability explanation, the simplest model was preferred [32]. The significance of each term of the built model was tested with an ANOVA. As above, before performing the analysis the requirements of homoscedasticity and residual normality were checked.

Results and discussion

Trial 1: effect of different constant temperatures on physical parameters

The used experimental plan allows the evaluation of the main physical parameters of the final product (i.e., tomatoes at the end of the drying process) and during the drying. The former results are required to evaluate the final product, while the latter was used to model the process and optimize the drying. Final tomato characteristics are summarized in Table 1, while the results obtained during the drying are shown in Figs. 1, 2, and 3 and mathematically modeled in Tables 2, 3 and 4.

Drying kinetics

The measured drying curves are reported in Fig. 1. The target moisture was reached at different times according to the drying temperature (Fig. 1 and Table 1). At the end of drying the water activity of tomatoes was 0.49 ± 0.05 without significant statistical difference among the temperatures. Drying the tomatoes at 50 °C required 81 ± 1 h, while the increase of the temperature to 60 °C allowed the saving of 42% of drying time. Further increases to 70 °C and 80 °C decreased the drying time by 60% and 65%, respectively.

The observed tomato drying kinetic can be divided into two stages. A zero-order kinetic occurs in the first section of the drying process where the moisture content decreases steadily. In this stage, the surface of the tomato is saturated by a thin layer of water and the drying speed remains constant (rate constant—RC) until the critical moisture value (Xc) is reached [33]. Xc represents the transition point where a trend change occurs. From the RC, the moisture loss speed exponentially decreases, following a first-order kinetic.

The critical moisture value was determined by iteratively shifting the Xc until the distance between the linear model and the exponential model was minimized. Above Xc, tomato moisture content consistently decreased linearly (i.e., the straight line), while below Xc moisture content decreased exponentially. The Xc value determined during our trial was 3.49 ± 0.56 kgH2O/kgdw. No significant difference was found for the different drying temperatures.

Table 2 reports the kinetic coefficients in zero-order (i.e., linear) and first-order (i.e., exponential) stages, and the last column reports the time required to reach Xc at the trial temperatures. The R2 of the model in the zero-order stage was 0.98 with a residual standard error (RSE) of 0.48 kgH2O/kgdw, while the first-order stage had R2 = 0.91 and RSE = 0.23 kgH2O/kgdw.

The intercept of the linear coefficient represents the moisture of the tomatoes at the beginning of drying. Obviously, no significant difference was found for the intercept since the tomatoes had the same initial moisture. The X0 term of the first-order equation must be determined to build the exponential model. It represents the initial moisture of tomatoes considering the whole drying as first-order, but it is important to remember that the first-order model is only valid for moisture lower than Xc (3.49 kgH2O/kgdw). RC and k are related parameters. Moreover, before the drying deceleration, at the beginning of the first-order stage (Xc) the speed of the drying process is RC, and k is the only term in the exponential equation accounting for drying speed.

Color

At the end of all the drying processes (50, 60, 70 and 80 °C), temperature significantly affected the final color of the tomatoes. Particularly, significant differences in the frequencies of pixels belonging to the first and second sector of the RGB color space were found. The average RGB of pixels in the first sector was R = 207, G = 80, B = 51 (Chilean Fire Red), while the average for the second sector was R = 98, G = 35, B = 23 (Baker’s Chocolate). For the sake of simplicity, below we will refer to them as red and brown pixels. Table 1 reports the final frequencies of red and brown pixels. Brown pixel frequency was found to be higher in tomatoes dried at 80 °C and decreased with temperature. No significant difference was found between 50 °C and 60 °C. Conversely, red pixel frequency was higher at lower temperatures (i.e., 50 and 60 °C) and decreased with temperature increase.

The frequencies of brown (upper graph) and red (lower graph) pixels during the drying process are shown in Fig. 2. The frequency of brown pixels remained constant for a time period. The length of the period with constant frequency changed according to the drying temperature. Following, brown pixel frequency linearly increased. Red pixel frequency had an initial constant phase, with variable length according to drying temperature, as already observed for brown pixel frequency. Following drying, red pixel frequency linearly decreased. Hence, the modeling of these kinetics involves the identification of the first constant trend duration and the description of the slopes in the increasing and decreasing stretch.

The parameters of the color models are summarized in Table 3. The brown frequency model has an R2 of 0.91 and an RSE = 0.026, while the red frequency model has an R2 of 0.93 and an RSE = 0.032. The increase in drying temperature increases the ratio of the appearance of brown pixels and of the disappearance of red pixels (i.e., the change in the slope). The length of the constant color frequency phase changed consistently. The higher the temperature, the lower the period of red and brown frequency constancy.

As the temperature increases, the brown pixel frequency increases while the red pixel frequency decreases. Drying at 80 °C is the fastest process. However, drying at 80 °C determines a greater browning of the tomato tissue. On the contrary, the process at 50 °C is the most time-consuming but determines a lower loss of red pigments. The results of this work agree with what was observed at the end of drying by [1, 9, 11]. The increase in brown frequency could be explained by the non-enzymatic browning reactions favored using high temperatures, obtaining darker and less appreciated tomatoes for consumers [1]. The decrease in red frequency could instead be related to the combined action of non-enzymatic browning and the reactions of lycopene. Carotenoids, and in particular lycopene, determine the red color in tomatoes [17]. Moreover, lycopene degradation as well as lycopene isomerization from the trans form to the less colored cis form results in a decrease in the red tomato surface [8,9,10, 12]. The drying process, due to the combined action of oxygen and heat, determines the degradation of lycopene and decreases the red color of tomatoes [9, 10].

Volume kinetics and rehydration ratio

The drying process involves the onset of physical phenomena determining a volume reduction of the tomatoes affecting their rehydration capacity and the quality of the final product [34]. Temperature and moisture gradients induce microstructural stresses in tomatoes, determining their deformation due to the loss of water contained in the tissues [33, 34]. Figure 3 shows shrinkage trends during drying at different temperatures.

Volume loss follows a linear trend at all the temperatures considered. In our trial, the built linear model shows an R2 of 0.93 and an RSE of 24.3 cm3. Table 4 summarizes the model coefficient.

Volume loss during the drying process is linked to various factors such as temperature, moisture, and air velocity [35]. Consistently, drying temperature significantly affects the speed of volume decrease. The hourly loss of volume (model slope) was higher at 80 °C and lower at 50 °C. As the drying process continued, there was a loss of moisture content in the tomatoes determining their volumetric reduction [35, 36]. This is due to the progressive reduction in the size of the pores and capillaries determining the material shrinkage [33].

The evaluation of the shrinkage ratio as a function of the moisture ratio (Fig. 3-left) often results in useful information. Moreover, linear trends are reported for lower drying temperatures, while non-linear trends are reported at higher temperatures [37]. For example, in a blueberry drying experiment, the shrinkage ratio assumed a linear trend for temperatures below 60 °C. In our trials, in the early stages of drying, where the moisture ratio of tomatoes is high, shrinkage is less pronounced. As drying progresses, the shrinkage ratio loss becomes faster as the moisture ratio decreases. No difference due to drying temperature was found. Moreover, for all the temperatures considered, deviation from the linear trend was observed. This type of trend was also observed by [35] in terms of the thickness reduction rate on tomato slices. As stated by [38], deviations from the shrinkage-moisture relationship from linearity could be due to changes in the porosity and density of the material during drying.

However, an increase in the drying temperature was not related to a variation in the final volumes and shrinkage ratios (Table 1). There were no significant differences (p > 0.05) between the average final volumes of dried tomatoes and shrinkage ratios at different temperatures. This agrees with [35], who stated that air velocity is the factor that most influences tomato shrinkage at the end of drying, while the temperature had no significant influence.

The rehydration capacity of dried tomatoes is an important quality parameter. By increasing water temperature, faster rehydration rates are obtained [39]. Rehydration tests at 100 °C take a total time of 46 min, while tests at 25 °C require 630 min. At both temperatures, rehydration rates rise dramatically in the early minutes, then follow a steady trend (data not shown). The observed trends were consistent with those found in the literature [22, 27, 28]. The high rate of rehydration at the beginning of the process could be due to the rapid water filling of the capillaries and cavities in the tomato surface [40]. The RR values of the samples rehydrated at 100 °C are lower than those observed at 25 °C [27, 28]. Lower RR values are related to structural damage occurring in the tomato during the rehydration process [38], from exposure to high temperatures during the rehydration process, or a combination of both. The drying temperature does not have a direct impact on the rehydration capacity of tomatoes. In both tests, there were no significant differences between the final RR values among the different temperatures considered (p > 0.05) (Table 1).

Mold occurrence

In low-temperature tomato drying processes, mold growth is usually prevented by adding NaCl or potassium metabisulfite [6, 36]. In the experiment setting, the authors considered that (i) the required NaCl would have an impact on the final product taste, and (ii) potassium metabisulfite is a compound harmful to human health. Thus, aware of the spoilage risks, the authors decided not to use any additive. In the drying carried out at 50 °C and 60 °C, some molds were visible on the tomato surface, while temperatures of 70 °C and 80 °C successfully prevented mold growth in our experimental conditions. In the 50 °C drying, molds were visible after 20.5 h in replicate 1, and after 25 h in replicates 2 and 3 when the dry weight moisture ranged between 8.9 and 7.9. At 60 °C, molds were visible after 21.5 h in replicates 1 and 3, while no mold was found in replicate 2. Moisture at 21.5 h was roughly 4.5. Moldy tomatoes were excluded from the color analysis.

Modelling the effect of temperature through Arrhenius equation

The effect of temperature on process rate is frequently modeled using the Arrhenius equation [41, 42]. Arrhenius equation has the general form of:

relating the temperature (T, [K]) to the speed of the process (k [h−1]). The equation could be linearized in:

where the constant k0 [h−1] is the intercept (i.e., the speed at T = ∞), and the slope is represented by the ratio between the activation energy ∆E [J mol−1]and the universal gas constant (8.314 J mol−1 K−1).

The results are reported in Table 5. Except for the brown pixel frequency increase, Arrhenius models successfully described the time–temperature dependency for the observed physical kinetics. Moreover, a good prediction of the change in the drying speed (i.e., RC) according to the temperature increase is provided (R2 = 0.89). The slopes of red color depletion and volume decrease were also successfully modeled, resulting in R2 of 0.93 and 0.95, respectively. Arrhenius models described the speed of red color change and tomato shrinkage as a function of temperature. In the same way, the length of the time without color change could be modeled for brown frequency (R2 = 0.98) and red frequency (R2 = 0.97). In these cases, being lengths instead of speeds, the higher the temperature the lower the time of color constancy. In Arrhenius models, this resulted in a change of sign in the activation energy terms.

Drying process optimization

Drying kinetics

Optimization trials were aimed at simultaneously decreasing the drying time and minimizing the color change. As previously shown, drying processes at high temperatures cause tomato quality deterioration in terms of color degradation. Furthermore, industrial drying is also an energy-intensive process and often not adequately efficient, representing 7–15% of industrial energy consumption in many countries, causing high costs and energy waste [43].

For the development of the two-stage drying process, shrinkage and rehydration ratio were not considered since no differences were found in the temperature range tested. Hence, color was considered the best qualitative reference parameter to optimize the process. Moreover, color represents one of the most important organoleptic criteria for consumers, being immediately perceptible [9]. As reported in paragraph 3.1.2, in the first 20 h of the stationary drying processes, no significant increase in the browning nor the red decrease was found in the tomatoes at the 50–70 °C temperature range. Therefore, higher temperatures could be applied at the beginning of the process to reduce drying times and then the temperature should be decreased, to reduce thermal damage to the product [8, 9, 11]. Moreover, at the end of the process, the water loss rate decreases and the tomatoes surface become dry. The application of high temperatures in this phase could cause surface degradation of the product [16].

The drying curves of the second trial are reported in Fig. 4. The two-stage process allows a significant drying time reduction compared to the test at 50 °C (− 27.6%) and at the same time does not compromise final product quality (Table 6). At the target humidity, the water activity of tomatoes was 0.52 ± 0.01, without significant difference due to the treatment.

As in the first trial, the moisture loss kinetic can be divided into two kinetics of distinct order. The initial phase is a zero-order kinetic, and the last phase is a first-order kinetic. The Xc value determined during the second trials was 4.63 ± 0.26 kgH2O/kgdw.

Table 7 shows the kinetic coefficients in zero-order (i.e., linear) and first-order (i.e., exponential) stages of the second trial. The R2 of the model in the zero-order stage was 0.99 with a residual standard error (RSE) of 0.49 kgH2O/kgdw, while the first-order stage had R2 = 0.94 and RSE = 0.29 kgH2O/kgdw.

Color

No statistically significant differences were observed between the final brown and red content in tomatoes dried at 50 °C and in the two-stage process (p > 0.05). Conversely, tomatoes dried at 70 °C showed greater browning and a reduction in red pigments. Lower temperatures and two-stage drying resulted in less thermal degradation of the color [11].

Volume kinetics and rehydration ratio

As noted previously, no significant differences (p > 0.05) in final mean volumes and shrinkage ratios were observed between tomatoes dried with the two-stage process and at 50 and 70 °C. Despite the tomatoes dried using the two-stage process having lower rehydration values, there were no statistically significant differences (p > 0.05) in terms of rehydration capacity, either at 25 and 100 °C.

Mold occurrence

As in the first trial, molds were able to grow in the 50 °C drying. In replicate 1, molds were found after 22.5 h, while in replicates 2 and 3 after 25.5 h of drying. The moisture ranged between 7.7 w/d.w and 6.7 w/d.w in replicate 1 and 3, respectively. The two-stage process and drying at 70 °C did not allow the growth of molds. The use of high drying temperatures during the first drying phase reduces the risk of mold occurrence in dried tomatoes.

Overall, the two-stage process allows a significant reduction of drying time and the gradual transfer of moisture from the internal tissues of the tomatoes to the surface, reducing thermal damage (color loss) and improving product quality (less mold occurrence) [8, 16].

Conclusions

In this work, the physical parameter kinetics of tomatoes (moisture, color, volume, and rehydration capacity) during the drying process at 50, 60, 70, and 80 °C were modeled. In all the drying temperatures the kinetics of moisture loss was composed of an initial zero-order trend followed by a first-order kinetic one once the critical moisture was reached. The volume loss kinetics showed a steady linear decreasing trend in all the temperatures considered. By increasing the drying temperature, a strong decrease in drying times is obtained (− 189%), but also a significant deterioration in the quality of the tomato due to an increase in the incidence of browning phenomena (+ 200%). However, color kinetics are characterized by an initial steady trend (no significant variations were observed) followed by a linear growth (brown pixels) or decrease (red pixels). Therefore, it is possible to apply higher temperatures in the initial stages of drying without affecting the quality of the product.

Based on this, a two-stage drying process was developed using 70 °C during the first 20 h and then lowering the temperature to 50 °C to avoid color changes. By comparing the results obtained with two control tests conducted in parallel at 50 °C and 70 °C, the two-stage process allows both a reduction in drying times, lower tomato quality degradation, and avoiding mold occurrence without using additives.

In this work, the benefits provided by the change of process settings based on color monitoring during the drying are assessed. However, the coefficients estimated in the developed models could change according to tomato’s natural variability. Hence, to make the process more adaptable to the raw material used, the implementation of an online color measurement system (e.g., computer vision) will further increase productivity and quality.

Data Availability

The datasets generated during the current study are available on request from the corresponding author.

References

Abano EE, Ma H, Qu W (2011) Influence of air temperature on the drying kinetics and quality of tomato slices. J Food Process Technol. https://doi.org/10.4172/2157-7110.1000123

Kumar S, Jadhav SV, Thorat BN (2022) Life cycle assessment of tomato drying in heat pump and microwave vacuum dryers. Mater Today Proc 57:1700–1705. https://doi.org/10.1016/j.matpr.2021.12.333

Dauda A, Abiodun O, Salami T, Akintayo O (2019) Chemical and microbiological evaluation of dried tomato slices for Nigerian system. GJNFS. https://doi.org/10.33552/gjnfs.2019.01.000521

Gümüşay ÖA, Borazan AA, Ercal N, Demirkol O (2015) Drying effects on the antioxidant properties of tomatoes and ginger. Food Chem 173:156–162. https://doi.org/10.1016/j.foodchem.2014.09.162

Alfeo V, Planeta D, Velotto S, Palmeri R, Todaro A (2021) Cherry tomato drying: sun versus convective oven. Horticulturae 7(3):1–12. https://doi.org/10.3390/horticulturae7030040

Bakir S, Hall RD, de Vos RCH, Mumm R, Kadakal C, Capanoglu E (2023) Effect of drying treatments on the global metabolome and health-related compounds in tomatoes. Food Chem 403:2. https://doi.org/10.1016/j.foodchem.2022.134123

Zalewska M, Marcinkowska-Lesiak M, Onopiuk A (2022) Application of different drying methods and their influence on the physicochemical properties of tomatoes. Eur Food Res and Technol 248(11):2727–2735. https://doi.org/10.1007/s00217-022-04081-0

Zanoni B, Peri C, Nani R, Lavelli V (1999) Oxidative heat damage of tomato halves as affected by drying. Food Res Int 31(5):395–401. https://doi.org/10.1016/S0963-9969(98)00102-1

Cernîşev S (2010) Effects of conventional and multistage drying processing on non-enzymatic browning in tomato. J Food Eng 96(1):114–118. https://doi.org/10.1016/j.jfoodeng.2009.07.002

Shi J, le Maguer M, Kakuda Y, Liptay A, Niekamp F (1999) Lycopene degradation and isomerization in tomato dehydration. Food Res Int 32:15–21. https://doi.org/10.1016/S0963-9969(99)00059-9

Ashebir D, Jezik K, Weingartemann H, Gretzmacher R (2009) Change in color and other fruit quality characteristics of tomato cultivars after hot-air drying at low final-moisture content. Int J Food Sci Nutr 60:308–315. https://doi.org/10.1080/09637480903114128

Coelho K, Costa BR, de Almeida Pinto LA (2013) Evaluation of lycopene loss and colour values in convective drying of tomato by surface response methodology. Int J Food Eng 9(2):233–238. https://doi.org/10.1515/ijfe-2012-0202

Goula AM, Adamopoulos KG (2010) Retention of ascorbic acid during drying of tomato halves and tomato pulp. Drying Technol 24(1):57–64. https://doi.org/10.1080/07373930500538709

Muratore G, Rizzo V, Licciardello F, Maccarone E (2008) Partial dehydration of cherry tomato at different temperature, and nutritional quality of the products. Food Chem 111(4):887–891. https://doi.org/10.1016/j.foodchem.2008.05.001

Kowalski SJ, Pawłowski A (2011) Energy consumption and quality aspect by intermittent drying. Chem Eng Process 50(4):384–390. https://doi.org/10.1016/j.cep.2011.02.012

Kumar C, Karim MA, Joardder MUH (2014) Intermittent drying of food products: a critical review. J Food Eng 121(1):48–57. https://doi.org/10.1016/j.jfoodeng.2013.08.014

Abano EE, Ma H, Qu W (2014) Optimization of drying conditions for quality dried tomato slices using response surface methodology. J Food Process Preserv 388(3):996–1009. https://doi.org/10.1111/jfpp.12056

Krokida MK, Karathanos VT, Maroulis ZB, Marinos-Kouris D (2003) Drying kinetics of some vegetables. J Food Eng 59(4):391–403. https://doi.org/10.1016/S0260-8774(02)00498-3

El-Mesery HS (2022) Improving the thermal efficiency and energy consumption of convective dryer using various energy sources for tomato drying. Alex Eng J 61(12):10245–10261. https://doi.org/10.1016/j.aej.2022.03.076

Motevali A, Minaei S, Khoshtagaza MH (2011) Evaluation of energy consumption in different drying methods. Energy Convers Manag 52(2):1192–1199. https://doi.org/10.1016/j.enconman.2010.09.014

Doymaz I (2014) Mathematical modeling of drying of tomato slices using infrared radiation. J Food Process Preserv 388(1):389–396. https://doi.org/10.1111/j.1745-4549.2012.00786.x

Doymaz I, Özdemir Ö (2014) Effect of air temperature, slice thickness and pretreatment on drying and rehydration of tomato. Int J Food Sci Technol 49(2):558–564. https://doi.org/10.1111/ijfs.12337

Demiray E, Tulek Y, Yilmaz Y (2013) Degradation kinetics of lycopene, β-carotene and ascorbic acid in tomatoes during hot air drying. LWT - Food Sci Technol 50(1):172–176. https://doi.org/10.1016/j.lwt.2012.06.001

Pulcini D, Capoccioni F, Franceschini S, Martinoli M, Faccenda F, Secci G, Perugini A, Tibaldi E, Parisi G (2021) Muscle pigmentation in rainbow trout (Oncorhynchus mykiss) fed diets rich in natural carotenoids from microalgae and crustaceans. Aquaculture 543:2. https://doi.org/10.1016/j.aquaculture.2021.736989

Marinello F, Pezzuolo A, Meggio F, Martínez-Casasnovas JA, Yezekyan T, Sartoli L (2017) Application of the Kinect sensor for three dimensional characterization of vine canopy. Adv Anim Biosci 8:525–529. https://doi.org/10.1017/s2040470017001042

Marinello F, Pezzuolo A, Gasparini F, Arvidsson J, Sartori L (2015) Application of the kinect sensor for dynamic soil surface characterization. Precis Agric 16(6):601–612. https://doi.org/10.1007/s11119-015-9398-5

Marinello F, Proto AR, Zimbalatti G, Pezzulo A, Cavalli R, Grigolato S (2017) Determination of forest road surface roughness by kinect depth imaging. Ann For Res 6082:217–226. https://doi.org/10.15287/afr.2017.893

Gaware TJ, Sutar N, Thorat BN (2010) Drying of tomato using different methods: comparison of dehydration and rehydration kinetics. Dry Technol 28(5):651–658. https://doi.org/10.1080/07373931003788759

Lin TM, Durance TD, Scaman CH (1998) Characterization of vacuum microwave, air and freeze dried carrot slices. Food Res Int 318(2):111–117. https://doi.org/10.1016/S0963-9969(98)00070-2

Santos-Sánchez NF, Valadez-Blanco R, Gómez-Gómez MS, Pérez-Herrera A, Salas-Coronado R (2012) Effect of rotating tray drying on antioxidant components, color and rehydration ratio of tomato saladette slices. LWT Food Sci Technol 468(1):298–304. https://doi.org/10.1016/j.lwt.2011.09.015

Friso D (2018) Engineering of the agri-food industry (Ingegneria dell’industria agroalimentare). Italy

Pinheiro J, Bates D (2006) Mixed-effects models in S and S-PLUS

Aguilera JM, Stanley DW (1999) Microstructural principles of food processing and engineering, 2nd edn. Aspen Publishers, Gaithersburg

Mahiuddin M, Khan MIH, Kumar C, Rahman MM, Karim MA (2018) Shrinkage of food materials during drying: current status and challenges. Compr Rev Food Sci Food Saf 17(5):1113–1126. https://doi.org/10.1111/1541-4337.12375

Dianda B, Ousmane M, Kam S, Ky T (2015) Experimental study of the kinetics and shrinkage of tomato slices in convective drying. Afr J Food Sci 9(5):262–271. https://doi.org/10.5897/ajfs2015.1298

An K, Li H, Zhao D, Ding S, Tao H, Wang Z (2013) Effect of osmotic dehydration with pulsed vacuum on hot-air drying kinetics and quality attributes of cherry tomatoes. Dry Technol 31(6):698–706. https://doi.org/10.1080/07373937.2012.755192

Chen Y, Martynenko A (2013) Computer vision for real-time measurements of shrinkage and color changes in blueberry convective drying. Dry Technol 31(10):1114–1123. https://doi.org/10.1080/07373937.2013.775587

Martynenko AI (2011) Porosity Evaluation of Ginseng Roots from Real-Time Imaging and Mass Measurements. Food Bioproc Tech 4(3):417–428. https://doi.org/10.1007/s11947-008-0158-7

Krokida MK, Marinos-Kouris D (2003) Rehydration kinetics of dehydrated products. J Food Eng 57:1–7. https://doi.org/10.1016/S0260-8774(02)00214-5

Markowski M, Bondaruk J, Błaszczak W (2009) Rehydration behavior of vacuum-microwave-dried potato cubes. Dry Technol 27(2):296–305. https://doi.org/10.1080/07373930802606600

Djebli A, Hanini S, Badaoui O, Boumahdi M (2019) A new approach to the thermodynamics study of drying tomatoes in mixed solar dryer. Sol Energy 193:164–174. https://doi.org/10.1016/j.solener.2019.09.057

Trapani S, Guerrini L, Masella P, Parenti A, Canuti V, Picchi M, Caruso G, Gucci R, Zanoni B (2017) A kinetic approach to predict the potential effect of malaxation time-temperature conditions on extra virgin olive oil extraction yield. J Food Eng 195:182–190. https://doi.org/10.1016/j.jfoodeng.2016.09.032

Xiao HW, Mujumdar AS (2020) Importance of drying in support of human welfare. Dry Technol 38(12):1542–1543

Acknowledgements

The authors would like to thank Coelsanus Industria Conserve S.p.A., Sossano, Vicenza, Italy and their technicians for their support during the trials. We also thank the Laboratorio ABC of the TESAF department and Dr. Rosa Greco for providing the laboratory instruments used during the tests.

Funding

Open access funding provided by Università degli Studi di Padova within the CRUI-CARE Agreement. This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

AM: methodology, validation, formal analysis, investigation, writing—original draft, writing—review & editing, visualization. FM: methodology, software, resources. AM: investigation, resources, visualization. LG: conceptualization, methodology, software, formal analysis, data curation, writing—original draft, writing—review & editing, supervision, project administration.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Ethical approval

This article does not contain any studies with human participants performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mencarelli, A., Marinello, F., Marini, A. et al. Two-stage drying of tomato based on physical parameter kinetics: operative and qualitative optimization. Eur Food Res Technol 249, 2253–2264 (2023). https://doi.org/10.1007/s00217-023-04288-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-023-04288-9