Abstract

The product of thermochemical processing of lignocellulosic biomass is biochar. It has a range of properties that make it suitable for a variety of economic applications. However, during pyrolysis and torrefaction, volatile organic compounds (VOCs) are released and may redeposit on the surface of the biochar. Some of these compounds may be harmful to the environment and humans. Bibliometric study shows that, to date, studies on the release of VOCs from biochar have been of an inventory nature and concerned with specific case studies of the specific types of biomass. To date, there has been no comprehensive and systematic analysis of the influence of lignocellulosic biomass properties and pyrolysis/torrefaction process parameters on VOC formation and redeposition on biochar. In this paper, the analysis is presented of the potential harmfulness of VOCs released during the thermochemical processing of lignocellulosic biomass components, based on cellulose, hemicellulose, and lignin pyrolysis/torrefaction chemistry data. 10 volatile organic compounds from cellulose, hemicellulose, and lignin pyrolysis were identified as potentially harmful due to the following properties: carcinogenicity, toxicity, flammability, skin corrosion/irritation, eye irritation, and mutagenicity, with different degrees of harmfulness. Additionally, the VOCs identified on biochar samples show a potential hazard. Among 140 identified compounds, 33 of them had harmful properties. Therefore, the redeposition on biochar of ketones, aldehydes, cyclic and aromatic hydrocarbons including polyaromatic hydrocarbons, and their derivatives, esters, and furans may lead to environmental contamination due to their release from biochar. A new niche for systematic research on the development of new knowledge regarding the biochars produced from biomass as a source of pollutant emission has been identified.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introductions

Thermal biomass conversion is the direct combustion or conversion of biomass into solid, gaseous, or liquid products. The gaseous and liquid products can be collected and sold, processed into higher-value materials, or combusted to obtain electrical power and/or heat. The solid product of torrefaction and pyrolysis is biochar, which in addition to its use in the energy sector, is also used in agriculture, construction, and environmental protection (Lewandowski et al. 2020).

Biochar is a product of the thermochemical treatment of biomass and biowaste (torrefaction, pyrolysis, gasification, and hydrothermal treatment). As such, biochar is a key element in many industries and biorefinery configurations (Sun et al. 2020). Depending on the biorefinery’s design, it can serve as a primary or co-product, either as an output of the main manufacturing process or as a processed product from other biorefinery wastes or outputs. Biochar is a versatile product that is projected to have large markets for soil amendment, carbon storage, adsorption, and biomaterials, among other uses, including environmental engineering (Mood et al. 2022). Extensive research indicates that biochar may be used for energy purposes, remediation of contaminated soil, improvement of soil properties, and for carbon sequestration (Białowiec et al. 2017; Kamarudin et al. 2023; Shaaban et al. 2018; Yadav et al. 2023).

Besides the beneficial application of biochar, some negative aspects “The dark side of the biochar” have been reported (Bernardo et al. 2010; Białowiec et al. 2018; Buss and Masek 2014; Gell et al. 2011; Kloss et al. 2014; Quilliam et al. 2012; Rogovska et al. 2012; Smith et al. 2013). Biochar, as a product of the thermochemical conversion of biomass, may contain potentially harmful substances PAHs, VOCs, and dioxins (Sobol et al. 2023). The content of these pollutants and their release into the environment may depend on the thermochemical process parameters and properties of the feedstock. One of the identified risks related to the development of thermochemical conversion of biomass is the potential health and environmental impact of emissions of VOCs from the surface of biochar. Spokas et al. (2011) report 140 different compounds on biochar; 74 were identified in all studied biochar samples, produced from 77 different biomasses, produced under temperatures from 200 °C to 800 °C. The previous study does not detect a clear picture of the influence of the feedstock on emitted VOCs’ composition. It suggests a strong dependence on the conditions of the biochar production process, including the handling and processing of biochar. Pyrolysis conditions, temperature, and residence time (Li 2024; Tomczyk et al. 2020) should be considered as the most important factors influencing contaminant enrichment during biochar production. Feedstock type may also play a role, although studies do not report a robust relationship between feedstock type and VOC production/deposition (Spokas et al., 2011).

To date, the main measures of biochar quality in documents from trade organizations such as the International Biochar Initiative (IBI), Delinat Institute, or British Biochar Foundation are organic carbon content, H/C or O/C ratios, bulk density, conductivity, pH, heavy metals, and other parameters without including VOCs.

While the promise and potential for biochar are great, hazards associated with its production and use of biochar must be understood and managed. This literature review examines scientific evidence that harmful compounds can be produced and deposited on biochar under some manufacturing conditions. Contaminants within biochar may pose an environmental risk.

This article focuses on a review of scientific research on VOC emissions from biochar. Particular attention is paid to the impact of the properties of the biomass feedstock on the characteristics of the products, with a focus on the structural components of biomass (cellulose (C), hemicellulose (H), and lignin (L)). The end goal of this review is to clarify the current understanding of the mechanisms of VOC formation, including the catalytic effects of the alkali elements, and their potential impact on the environment due to emissions from biochar, and identification of the existing gaps in this field. A detailed comparison of identified VOCs with the list of hazardous substances and their properties is also presented to provide a summary of the scope and potential severity of VOCs on biochar.

Bibliometric analysis of VOC formation and the presence in biochar

The combination of the keywords “volatile organic compounds-biochar” yielded 266 records in Web of Science (listed in Appendix 1 in Supplementary Information). Most of the papers, 200, cover aspects related to environmental sciences. Other papers belong to energy, chemical sciences, biotechnology and microbiology, and agriculture scientific domains. The first paper was published in 2011, with a dramatic growth in the number of papers and citations starting in ∼ 2015 and leveling off somewhat since 2020 (Fig. 1). Thus, research interest in this field is increasing but not as rapidly as in recent years.

Detailed “co-occurrence” or “clustering” analyses of the 266 records, with the constraint that only keywords appearing a minimum of 5 times will be considered, revealed that the papers can be grouped into 5 clusters (Fig. 2). The red cluster grouped papers are mostly dedicated to the application of biochar as a soil amendment, with some implications regarding the improvement of plant germination and PAHs and heavy metals phytotoxicity mitigation. The green cluster represents papers concerning biochar production aspects, pyrolysis, temperature, feedstock, kinetics, and optimization, including some aspects related to anaerobic digestion. The blue cluster includes papers related to the application of biochar for the removal of VOCs, the influence of the porous structure of biochar, and its adsorption capacity. The yellow cluster is the development of the blue cluster containing papers dedicated to the application of biochar for the adsorption of VOCs from water, air, and soil. The last cluster, purple, contains mostly papers dedicated to the conversion of wet waste like sewage sludge to hydrochar due to hydrothermal carbonization.

The co-occurrence analysis revealed that among all of the identified 266 papers, there is no clear cluster of papers dealing only with negative aspects of biochar application posed by the presence of VOCs or other harmful compounds. Therefore, a manual parsing of the 266 papers was carried out to select those that deal with the problem of the negative influence of biochar on the environment, without focusing only on VOC presence and emission. 49 papers were selected (listed in Appendix 2). Most of them, 39, were related to the environmental sciences. The occurrence analysis showed that the first paper related to the impact of biochar on the environment was published in 2011 (Spokas et al. 2011) and the trend of papers and citations follows a similar pattern to that shown in Fig. 1. In the next years, the increasing tendency of the number of papers published and citations is visible, however, the highest number of papers (7) published was noted in the year 2021.

Due to the lower number of papers (49) for the clustering analysis, the co-occurrence of at least 3 keywords was chosen. 5 clusters of papers were identified (Fig. 3).

The red cluster grouped papers mostly dedicated to the thermal degradation of biomass and waste due to torrefaction and pyrolysis, with some implications regarding the formation of VOC. The green cluster contains papers concerning the biochar production aspects, pyrolysis, temperature, feedstock, stability, and content of the cellulose. The blue cluster includes papers related to the presence of harmful substances VOC, PAH, persistent free radicals, and heavy metals, and the influence of the pyrolysis process on their formation with some implications for ecotoxicity. The yellow cluster shows papers dedicated to the negative impact of biochar on the environment including the impact on soil, plants, plant germination, and phytotoxicity. The last cluster, purple, contains mostly papers related to toxicity analyses, and the bioavailability of harmful substances, with some implication to the specific group of waste – sewage sludge (Fig. 3).

The keyword cluster analysis reveals that, while VOCs and harmful compounds on biochar are not a dominant focus of research to date, researchers do see the problem of the negative impact of biochar on the environment. Studies of the subject are mostly based on the inventory approach, reporting different cases of negative impact related to different pollutants, different thermochemical treatment conditions, and types of feedstocks, without systematic research on the influence of the composition and structure of the biomass and the conditions of the biochar generation.

Because of the potential problem of hazardous organic compounds, research is needed to rigorously study the mechanisms by which the problem occurs, as well as the means to either prevent or treat it. The key research question that needs to be addressed in future research is: How does the composition of lignocellulosic biomass and varied process conditions impact the speciation of emitted and redeposited organic compounds on biochar? The premise of such research would be that the presence of organic contaminants including VOC on biochar can be controlled through the careful application of specific types of lignocellulosic biomass and controlling of the process conditions.

Lignocellulosic biomass composition

Plant-derived biomass consists of plant fibers, which are mainly made up of carbohydrates. Lignocellulosic biomass consists mainly of the biopolymers lignin, cellulose, and hemicellulose, which account for about 85 to 90% of total mass with the remainder being extracts and minerals. Typically, in lignocellulosic biomass, the relative proportions are 40–60% C, 20–40% H, and 10–24% L (Putro et al. 2016; Yogalakshmi et al. 2022). The content of individual structural components is influenced by morphological structure resulting from the origin and environmental conditions. The large differences in the content of structural components are mainly due to the origin, composition, age, and growth stage of the plant or contamination of the raw material. Biomass is a heterogeneous material that complicates the detailed understanding of biomass conversion pathways and VOC formation on biochar, which may depend on the content of the main groups of compounds in lignocellulosic lignin, cellulose, and hemicellulose.

Lignin

Lignin is an amorphous polymer of aromatic compounds consisting of monomers of organic compounds derived from phenolic alcohols (p-coumaric, coniferyl, and sinapyl alcohol). Lignin consists of numerous functional groups like carbonyl and hydroxyl groups giving high polarity to this polymer. C-C and C-O-C bonds are present in abundance in lignin, which reduces the ability to hydrolyze this compound. The surface of lignin absorbs cellulolytic enzymes, blocking hydrolytic enzymes’ access to polysaccharides. The hydrolysis efficiency of other compounds present in the biomass such as cellulose is also affected by the presence of lignin. This compound is resistant to chemical and biological degradation. This biopolymer coats the cellulose fibers which are arranged in a cylindrical fashion. The main function of L in the plant cell structure is to build structural stability, impermeability, and resistance to microbial attacks. The amorphous biopolymer is not soluble in water. Lignin is usually found in greater amounts in higher plants. The type of lignin found in biomass will depend on the plant species and will vary depending on the type of plant tissue (Fernández-Rodríguez et al. 2017).

Cellulose

Cellulose (C6H10O5)n occurs in the plant in two forms, organized, i.e. crystalline, and poorly organized, i.e. amorphous. The structure of cellulose in the crystalline form is linearly consisting of up to several hundred thousand B-D-anhydroglucopyranose units which are joined by B-1-4-glycosidic bonds. The cellulose chains are arranged in parallel and packed into cellulose microfibrils, stabilized by intramolecular hydrogen bonds with the forces of van der Waals. This structure contributes to high resistance to hydrolytic enzyme attacks. The amorphous part of cellulose, on the other hand, shows greater susceptibility to enzymatic degradation. Cellulose microfibrils in the amorphous structure are stabilized by covalent and hydrogen bonds. Cellulose, compared to other biomass components, is characterized by a straight chain in which there is no wrapping or branching. Cellulose chains can stack on top of each other to form larger microfibrils, which contributes to high, water insolubility. There may also be cellulose microfibrils that combine with water and matrix of the following polysaccharides (1/3, 1/4)-b-D-glucans, arabinoxylan heteroxylans, and glucomannans. The solubility of cellulose depends on many factors in particular its structure, origin, or molecular weight. In addition to poor solubility, cellulose is characterized by relative thermal stability, high sorption capacity, and resistance to hydrolysis (Harmsen et al. 2010).

Hemicellulose

Hemicellulose is a biopolymer composed of polymers of hexose (mannose, glucose, and galactose), pentose (xylose, arabinose), and uronic acids (glucuronic, methylgalacturon, and galacturonic acids). Hemicellulose has a lower polymerization degree and lower molecular weight compared to cellulose. The short side chains that comprise hemicellulose consist of hydrolyzable sugars. This polymer binds lignin to cellulose fibers and gives the entire structure greater rigidity. The solubility of hemicellulose compounds ordered in descending order are mannose, xylose, glucose, arabinose, and galactose. The higher the temperature, the more the solubility increases. Compared to the other components of lignin and cellulose, hemicellulose is the most chemically and thermally sensitive. Hemicellulose occurs only in amorphous form. Xylans are most abundant in the structure of hemicellulose making up about 20–30% of the biomass of deciduous trees, while in grasses or cereals, xylans can account for as much as 50%. In contrast, mannose-type hemicelluloses such as galactoglucomannans occur in deciduous wood in small amounts. Individual hemicellulose components such as glucuronoxylans, glucomannans, xyloglucans, xyloglucans, arabinoglucuronoxylans, arabinogalactan, arabinoxylan occur in different proportions depending on the biomass species (Lu et al. 2021).

Biochar production due to the thermochemical treatment of biomass

The solid, bulk product of thermochemical conversion of biomass due to pyrolysis or torrefaction is biochar (Glaser et al. 2001). Pyrolysis is the thermochemical degradation of organic molecules occurring with limited access to oxygen, generation of pyrolytic gas, pyrolytic oil, and solid biochar. Pyrolytic gas may be characterized by the content of condensable and non-condensable components, and during cooling the condensable compounds convert into the liquid form of the pyrolytic oil. The temperatures in the range from 350 to 600 °C characterize the low-temperature pyrolysis (Ansah et al. 2016; Buah et al. 2007). Pyrolysis can be classified into three main types: flash, rapid, and slow. During slow one, the temperature ramp-up is about 5–7 °C/min. Such a slow heating rate favors the generation of biochar. Rapid pyrolysis uses the temperature ramp up to 300 °C/min. Due to that, the generation of liquid products is preferred. Flash pyrolysis employs a higher temperature ramp-up than rapid, and requires particle size of biomass in the range of 105 and 250 μm. It leads to the generation of mostly gasses and oils (Stępień et al. 2019).

Torrefaction is also thermochemical processing of biomass occurring under a temperature range between 200 °C and 350 °C. In that case, mostly hemicellulose depolymerizes (Dhungana 2011). Similarly, to pyrolysis, it requires a non-oxidizing environment, low heating ramp up below 50 °C/min, and long biomass residence time in the reactor (typically 1 h) (Wannapeera et al. 2011). During torrefaction, the organic matter partly vaporizes and degrades releasing condensable and non-condensable gasses. The main product is a carbon-rich solid, which is named biocarbon, biochar, or torrefied biomass (Lehmann et al. 2011).

Pyrolysis and torrefaction are commonly used for lignocellulose biomass treatment (Ratte et al. 2011). However, the occurrence of harmful substances in biochar is a derivative of the initial composition of biomass, process conditions (temperature, duration), and the chemistry of thermal conversion of biomass components. Therefore, the main chemical mechanisms of biomass transformation during torrefaction/pyrolysis have been discussed. Chemical transformations during biochar production from lignocellulosic biomass have been evaluated.

Numerous reactions occur during lignocellulosic torrefaction/pyrolysis, and the overall process can be challenging to rigorously describe, from a chemical perspective, due to the complexity and diversity of compounds involved, and the many complex reactions that take place. Generally speaking, the process can be thought to consist of three main steps: (a) water evaporation (b) primary degradation of biomass, during which thermal activation causes biomass molecules to break down into smaller components, and (c) secondary reactions, during which the products of primary degradation react with one another, with the unreacted biomass residue, and with contaminants in the biomass, to form fairly stable final products (inclusive of repolymerisation and oil cracking). The maximum rate of biomass decomposition occurs under temperatures from 200 to 400 °C, although hemicellulose decomposition occurs primarily between 200 and 280 °C whereas cellulose degradation happens primarily between 250 and 400 °C, and lignin degrades at the highest temperature range of 300–550 °C (Yogalakshmi et al. 2022). During the production of biochar, chemical processes that occur include decomposition, polymerization, aromatization, cracking, condensation, volatilization, and rearrangement. The non-condensable components of pyrolytic gas are CO2, CO, H2, CH4, and very short-chain hydrocarbons (C1-C4) (Kan et al. 2016). The CO2 formation occurs due to the decomposition of the carboxyl and carbonyl functional groups. CO is generated due to the detachment of C = O and C–O–C bonds. H2 is formed mostly due to the breaking of C–H and the aromatics group. Lignin depolymerization leads to the formation of CH4 (Zhan et al. 2019).

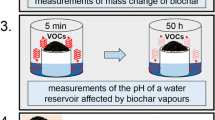

The biochars, with adsorbed VOCs consisting of short-chain aldehydes, ketones, and furans, are produced under temperatures below 350 °C. The biochars generated under temperatures higher than 350 °C contain mostly adsorbed longer-chain hydrocarbons and even aromatic compounds. It has been observed that with the increase in the process temperature, the VOCs content on the biochar surface decreases. Wang et al. (2017b) found a similar observation, in which, the lowest concentration of polyaromated hydrocarbons (PAH) was found on biochar originating from the slow pyrolysis with long retention time. It can therefore be expected that biochars produced by biomass torrefaction will contain qualitatively and quantitatively more VOC than those from pyrolysis. The most frequently found compounds in biochar were acetic acid, acetone, ethanol, benzene, toluene, methyl acetate, methyl ethyl ketone, phenol, and cresols. Buss et al. (2015) found high levels of different aliphatic acids and also naphthalene. Allaire et al. (2015) found 26 VOCs in biochar. The problem of VOCs presence in biochar produced from compost has also been reported by Taherymoosavi et al. (2017). The presence of VOCs from the BTEX (benzene, toluene, ethylbenzene, and xylene), group in biochar should also be monitored. The presence of VOCs in biochar depends on feedstock type and properties as well as the thermochemical process conditions (Wang et al. 2017b). The emission of the VOCs may pose the risk of some harmful effect on humans and the environment, and the risk of self-ignition. Therefore, the formation during the biomass thermochemical treatment, and emission of VOCs should be investigated, and methods and technologies for the mitigation of the emission VOCs from biochar should be developed.

It has been confirmed in numerous studies that the organic pyrolytic products from holocellulose (cellulose and hemicellulose) pyrolysis contain mostly furan derivatives, anhydrosugars, and light-oxygenated compounds. Gases released during the process of torrefaction and pyrolysis are commonly passed through a condenser, where the condensation of volatile organic compounds occurs forming the pyrolytic oil or bio-oil (Mettler et al. 2012a, b; Lu et al. 2011; Wang et al. 2017b; Shen et al. 2015). Yogalakshmi et al. (2022) classify pyrolytic oil under three categories small carbonyl molecules (acids, aldehydes, ketones), sugar-based molecules (hydrosugars and furans), and lignin-based derivatives (aromatic oligomers and phenols).

The contamination of biochar by organic compounds is believed to occur by the condensation and redeposition of VOC that were generated during the pyrolysis. Therefore, the generation and occurrence of volatile organic compounds will be discussed with a particular focus on biomass component conversion. The volatile organic compounds produced when pyrolyzing the individual structural polymers of biomass (i.e. cellulose, hemicellulose, lignin) are first examined, followed by a review of studies of biomass samples. While the decomposition temperature ranges of hemicellulose, cellulose, and lignin are different from one another, it is conceivable that the production of VOCs from biomass cannot be treated as three independent processes, since the decomposition temperature ranges do overlap to a certain degree, most practical pyrolysis devices will expose biomass to conditions where all three primary components are degrading simultaneously, and unreacted biomass solids can play a part as a reactant or catalyst in the overall array of reactions occurring during the production of biochar.

Products of cellulose thermal transformations

Zheng et al. (2016) noted that when the temperature of pyrolysis is lower than 300 °C, due to the cellulose decomposition and polymerization, the low molecular compounds like H2O, CO2, formic acid, hydroxyl acetaldehyde, glycolaldehyde, and furan are produced. Stefanidis et al. (2014) indicated that when the cellulose pyrolysis temperature is higher than 800 °C mostly anhydrosugars, including levoglucosan are the product generated due to the dehydration reactions and the cleavage of glycosidic bonds. They found that at temperatures higher than 300 °C, levoglucosan conversion occurs due to relocation and hydration reactions producing the levoglucosenone. Finally, it converts due to the cyclization into stable oxygenated compounds like pyran, furfural, and 5-hydroxyl methyl. Additionally, due to the polymerization of levoglucosan, this compound is a source of the following active functional groups: –OH, –C = O, –COOH, –COO–, and C–O–C. Wei et al. (2012) estimated that during the cellulose pyrolysis under the temperature of 400 °C, the yield of levoglucosan may reach 51.3% of all of the organic compounds produced. Additionally, the levoglucosan yield decreases when the temperature increases to 530 °C. Lu et al. (2016) noted that hydroxyacetaldehyde may be generated during cellulose pyrolysis as an effect of the secondary degradation of levoglucosan. This compound is generated under high temperatures between 550 °C and 600 °C (Dong et al. 2012). During the cellulose pyrolysis monophenols (and acetol (1-hydroxy-2-propanone) can be produced (Chang et al., 2016, Usino et al. 2020), especially when the temperature ranges between 400 and 600 °C.

Products of hemicellulose thermal transformations

Thermal degradation of hemicellulose occurs under temperatures 220–315 °C due to decomposition and polymerization reactions leading to a similar set of low molecular compounds to those found from cellulose: H2O, and CO2 elements, formic acid, furan, glycolaldehyde, hydroxyl acetaldehyde, etc. (Zheng et al. 2016). Additionally, it causes the breaking of the glycosidic bonds resulting in the formation of oligosaccharides and their next transformation to xylose. Further increase in temperature causes the cracking and rearrangement of depolymerized xylose generating light molecules of oxygenated compounds, including acetic acid, furfural, formic acid, and furan (Yogalakshmi et al. 2022). Another compound that may be produced during the pyrolysis of hemicellulose is 5-Hydroxymethylfurfural (HMF) (Yang et al. 2020). The torrefaction process studies confirmed that the condensable volatiles from hemicellulose mainly consist of acetic acid, and a smaller fraction of formic acid, lactic acid, methanol, hydroxyl acetone, furfural, and phenol (Prins et al. 2006).

Products of lignin thermal transformations

Pyrolysis of lignin leads to the generation of phenol, anisole, guaiacol, cresol, syringol, etc. (Yogalakshmi et al. 2022; Zhao et al. 2009). During the pyrolysis of lignin generally, the following phenolic monomers phenol, 4-ethyl phenol, p-cresol, guaiacol, syringol, and 2-methoxy-4-vinylphenol are produced. However, further thermal degradation and secondary reactions lead to the generation of products including dimethoxybenzene, phenol, 2-ethyl phenol hydroxy benzaldehyde. In the case of transformation of syringol Methyl 3,4,5-trimethoxybenzoate, 3-methoxy guaiacol, 3- methoxy-1, 2-benzenediol, and 2-methoxy-3-methyl phenol may be produced. In other studies, the 2-methoxy-4-(1- propenyl) phenol, guaiacol, 2-methoxy-4-vinyl phenol, and 4-methyl-2-methoxyphenol) were identified in bio-oil from pyrolysis of wheat straw (Chang et al. 2016).

Other studies reveal a long list of VOCs produced during lignin pyrolysis, mainly (Bai et al. 2014; He et al. 2016; Jiang et al. 2010; Patwardhan et al. 2011a, c; Trinh et al. 2013; Zhang et al. 2019):

-

anhydrosugars (1,6-anhydro-β-D-mannopyranose, 1,6-anhydro-β-D-glucopyranose, 1,4:3,6-dianhydro-α-D-glucopyranose, 1,6-anhydro-3,4-dideoxy-β-D-glycero-hex-3-enopyranos-2-ulose, 1,5-anhydro-4-deoxy-D-glycero-hex-1-en-3-ulose, 1,4:3,6-dianhydro-α-D-mannopyranose, 1,6-anhydro-β-D-mannofuranose, 1-hydroxy-3,6- dioxabicyclo[3.2.1]octan-2-one, 1,4-anhydro-β-D-xylopyranose, and 1,6-anhydro-β-D-glucofuranose);

-

Furan derivatives (furfural and 5-hydroxymethylfurfural);

-

Lightweight oxygenated compounds (acetic acid, formic acid, hydroxy acetaldehyde, and hydroxyacetone;

-

phenolic derivatives (phenol, cresol, guaiacol, 4-vinyl phenol, 4-vinyl guaiacol, isoeugenol, 4-methyl guaiacol, and 4-vinylphenol).

All the listed compounds that can be produced during the thermochemical treatment of lignocellulosic biomass components are elements of the condensable fraction of the pyrolytic gas. Some of them may be harmful to humans and the environment. For this reason, their harmfulness should be considered.

The influence of the other factors on VOC formation during biochar production

Biomass itself can be a source of VOCs. The biochemical pathways of the VOCs formation in trees have been classified into three categories the lipoxygenase (fatty acid derivatives or green leaf volatiles), the terpenoids (also known as isoprenoids), and the shikimic acid pathways (phenyl propanoids/ benzenoids) (Dudareva et al. 2006). The first one leads to the production of fatty acids (C18 unsaturated fatty acids, including linoleic or linolenic acids) and their breakdown products such as trans-2-hexenal, cis-3-hexenol, methyl jasmonate, and other compounds (Dudareva et al. 2006). The terpenoids, representing the largest class of plant secondary metabolites, include molecules such as hemiterpenes (C5), monoterpenes (C10), sesquiterpenes (C15), homoterpenes (C11 and C16), and some diterpenes (C20) (Taiti et al. 2017). However, the aromatic compounds, such as methyl salicylate, indole, and other phenolic compounds are formed via the shikimic acid pathway (D’Alessandro et al. 2006). Short-chain VOC, including formic and acetic acids, acetone, formaldehyde, acetaldehyde, methanol, and ethanol has been identified (Roffael et al. 2015). All these VOCs, originating from the biomass, which could be present on the biochar surface, could be named as primary source VOCs. Their availability depends on the volatility expressed as a boiling point, the thermal degradability, and their affinity to the biochar surface by physical or chemical sorption. Some of them could overlap with the secondary source VOCs –which are produced due to lignocellulosic biomass thermal degradation. The presence of the secondary source VOCs depends on the thermochemical process conditions (temperature, residence time), the feedstock type (the content of cellulose, hemicellulose, and lignin), the properties of VOC as in the case of primary source VOCs, and some other chemical interactions catalyzed by inorganic components.

The lignocellulosic biomass is mainly composed of carbon, oxygen, and hydrogen, however other minor or trace elements, including sulfur, nitrogen, and ash including alkali and alkaline earth metals (AAEMs) are also commonly detected. Especially, the presence of the AAEMs can significantly influence both the pyrolysis process and the composition of the products, due to catalytic effects on the pyrolysis of biomass (Wang et al. 2022a). The AAEMs depend mainly on the type of biomass. It has been confirmed that solved cations can penetrate biopolymers to foster depolymerization and dehydration reactions, thereby enhancing biomass conversion (Wang et al. 2022b). The main mechanisms and pathways underlying the AAEM-catalyzed pyrolysis of biomass (e.g., depolymerization, dehydration, cracking, etc.) have been summarized by Wang et al. (2022c) and Rangel et al. (2023). AAEMs may influence the water content of bio-oil by dehydration, and decrease the yield of levoglucosan while facilitating the formation of char and oligomers (Hwang et al. 2015). Additionally, the synergistic effect of K and Ca during pyrolysis was studied (Tian et al. 2021). The addition of K2CO3 promoted the decomposition and condensation of lignin, however, the addition of Ca(OH)2 and K2CO3 promoted the uniform distribution of each other. Some AAEMs may promote the oxidation of organic compounds influencing the decrease of emitted VOC (Guo et al. 2022; Lou et al. 2022; Zhang et al. 2016).

The presence of the VOCs in biochar may depend also on the boiling point value of the specific volatile compound. According to USEPA, depending on the boiling point the VOCs may be classified into the 3 categories: VVOC—very volatile organic compounds (0–100 °C), VOC—volatile organic compounds (100–240 °C), SVOC—semi-volatile organic compounds (240–400 °C). Białowiec et al. (2019) showed that most of the identified VOCs had boiling points between 100 and 240 °C. However, the biochar itself may serve as a trap for VOCs. It is well-recognized that biochar with highly-developed surface area may be used as an adsorbent for VOCs removal (Shen 2022; Barquilha and Braga 2021; Zhang et al. 2017).

The feedstock type of biochar determines its physiochemical properties that would further influence its adsorption performance (Zhang et al. 2017). Numerous factors influence the adsorption performance including the specific surface area, pore size (micro-, mezzo-, and macropores), surface chemical functional groups, hydrophobicity, the molar ratios of H/C and O/C indicating the aromaticity and polarity of biochar, and bulk density. The influence of these factors on the adsorption of different VOCs on the biochar designed and used for VOCs removal has been widely studied. However, up to date, there is no comprehensive study, or literature review, showing the influence of all discussed factors, and possible interactions between them, on the formation, and the presence of VOCs on biochar. Moreover, other potential phenomena, related to the presence of the eutectic salts (phase-changing materials) (Wang et al. 2023; Wu et al. 2024) in the biomass on the formation of VOCs on the surface of biochar. That aspect is still unknown. It has been revealed that the formation and presence of VOCs in the biochar are influenced by numerous factors including:

-

Internal (biomass) factors: the content of cellulose, hemicellulose, lignin (producing the secondary source VOCs due to degradation), the content of primary source VOCs (producing the secondary source VOCs due to degradation), the content of AAEMs (catalysis of the degradation), the content of eutectic salts (influence on the interphases phenomenons);

-

External (process) factors: ramp-up, process, and rump-down temperature of torrefaction, or pyrolysis, residence time (degradation of the organic matter, volatilization. of primary and secondary source VOCs, re-deposition of the primary and secondary source VOCs;

-

Internal (VOCs) factors: the properties of the individual VOC including the boiling point, affinity to the biochar surface;

-

Internal (biochar) factors: adsorption of primary and secondary source VOCs influenced by the type of VOC, the biochar-specific surface area, pore size (micro-, mezzo-, and macropores), surface chemical functional groups, hydrophobicity, the molar ratios of H/C and O/C indicating the aromaticity and polarity of biochar, and bulk density (Fig. 4).

That complex model, containing the direct influence of specific factors on VOCs in biochar considering the cross-relationships between all of the factors, should be deeply studied and developed to explain the real nature of the formation and presence of VOC in biochar, especially, as part of those VOCs may be considered harmful to humans and the environment.

The hazard potential of organic compounds produced due to pyrolysis of lignocellulosic biomass

The list of identified organic compounds produced during the separate pyrolysis of cellulose, hemicellulose, and lignin has been evaluated, and compared to the EU classification standards (Regulation (EC) No 1272/2008 of the European Parliament and of the Council of 16 December 2008 / on classification, labeling and packaging of substances and mixtures, amending and repealing Directives 67/548/EEC and 1999/45/EC, and amending Regulation (EC) No 1907/2006) (Table 1). 10 volatile organic compounds are identified as potentially harmful due to the following properties: carcinogenicity, toxicity, flammability, skin corrosion/irritation, eye irritation, mutagenicity, with different degree of harmfulness (Table 1).

A similar approach was used for the evaluation of the hazard potential of VOCs found on 77 biochar samples produced from different lignocellulosic materials (Spokas et al. 2011). Among 140 identified compounds, 33 of them have harmful properties (Table 2). A comparison of data obtained on the pyrolysis of pure components of lignocellulosic biomass (Table 1) with data for biomass samples shows that only in the case of 3 compounds (methanol, furan, and furfural), results overlapped. While this comparison is not exhaustive, it does suggest that the production of hazardous VOCs is highly dependent on interactions between the cellulose, hemicellulose, and lignin, and not just the thermal breakdown of individual components. Suppose it is possible to better isolate the degradation of cellulose, hemicellulose, and lignin in biomass during the biochar production process. In that case, lower VOC production (or perhaps a lesser variety of compounds) may result. However, in reality, from a technical point of view, it would be difficult and economically not effective, to do such a separation for the VOCs formation mitigation. Therefore, other methods or mechanisms of the mitigation of VOC generation, are also related to the presence of other organic and inorganic components of biomass. Co-pretreatment of dry torrefaction and de-ashing followed by thermochemical conversion is a promising technology, that can improve raw material quality, inhibit the release of organic pollutants, and transform biomass into eco-friendly energy carriers (Sun et al. 2023).

The most frequently occurring compounds in the biochar samples (more than 80% of cases) were short-chain hydrocarbons (alkanes, alkenes, and alkynes), and short-chain alcohols. These compounds’ harmful properties are mostly related to their flammability and gas high pressure when compressed in cylinders. However, in the case of methanol, acute toxicity and specific target organ toxicity are also a concern (Table 2).

VOCs occurring in 25–80% of the analyzed biochars can be classified as moderately dangerous. This group contains more complex compounds including ketones, aldehydes, cyclic and aromatic hydrocarbons, and their derivatives, esters, and furans. These compounds have a wider variety of harmful properties related to different degrees of acute toxicity, carcinogenicity, flammability, mutagenicity, eye and skin irritation, reproductive toxicity, specific target organ toxicity, harm to the aquatic environment, and aspiration hazard. This group of compounds can be considered to be severe to human health and the environment, as they can bring serious harm not only due to flammability but especially due to direct and indirect effects on living organisms. Therefore, deeper studies should be done on the identification of the mechanisms of the formation of these compounds during pyrolysis of lignocellulosic biomass.

The less prevalent hazardous compounds found on biochar samples (< 25% of samples tested) include polyaromatic hydrocarbons, cyclic and aromatic hydrocarbons, and their derivatives, and different chlorinated organic compounds (Table 2). Their properties are similar to those compounds classified in the moderately prevalent group. However, they have a higher degree of hazard. Therefore, these compounds should not be neglected, even if they occur not frequently and in low concentration. Polycyclic Aromatic Hydrocarbons (PAHs) have been a compound of special interest for human health, and their presence in biochar is a subject of relevant study.

The potential impact of biochar on the environment

The production of biochar from a wide variety of biomass feedstocks and its addition to soils and bioproducts could result in negative environmental, health, and safety impacts such as unsustainable biomass provisioning if the biomass feedstock is not sustainably sourced. However, health aspects of biochar production such as gas emissions and pollutants on biochar should be carefully considered. This is an area that needs further research. The problem of environmental pollution, as a result of using biochar-containing pollutants that have been produced during pyrolysis (e.g. VOCs, PAHs, persistent organic pollutants (POPs)) has been discussed here. Chemical composition and contaminant content depend on many factors that need to be considered during the biochar risk assessment procedure.

With an increase in process temperature, fewer volatile compounds are found in the biochar. In general, lower-temperature biochar can cause a higher risk of pollutant release to the environment, while pollutant “trapping” is more effective with the increase of biochar aromaticity and sorption properties that result from high-temperature processes. Changes in biochar properties and release of the contaminants into the environment can be driven by different processes. More risks should be considered during emission, leaching, weathering, or biochar aging. For example, inadequate biochar storage may cause the emission of contaminants from stockpiles through leaching and volatilization processes and pollution of air, water, and soils (Sorrenti et al. 2016).

Organic contaminants in biochar are complex and still not enough characterized, as these are produced in elaborate reactions during the thermochemical processes in torrefaction/pyrolysis units; including VOCs, PAHs, and dioxins. A limited number of studies (Spokas et al. 2011, Buss et al. 2015; Taherymoosavi et al. 2017; Wang et al. 2017b), indicated that a wide range of VOCs may be found in biochar with substantial potential for negative or positive impact on soil and plants as a result of their high availability and mobility. Furthermore, during the production, post-treatment, storage of biochar, workers may be exposed to potentially toxic VOCs and PAHs and either directly through the inhalation of biochar particles or VOCs emitted from biochar, or indirectly through the ingestion of eatable plants grown in biochar-contaminated soil (Białowiec et al. 2019). Such a situation may create a significant risk to human health due to the mutagenic, carcinogenic, or/and toxic effects of VOCs including PAHs.

Oleszczuk et al. (2013) stated that contaminants associated with biochar may pose toxicity to different organisms during the application of biochar in the environment. Re-condensation of VOCs on the biochar surface may result in their bioavailability to organisms and phytotoxicity (Pranagal et al. 2013). Bucheli et al. (2015) and Paz-Ferreiro et al. (2014) indicated that this hazard potential of biochar may be limited, due to the high adsorption potential of biochar being an effect of the porous structure. Due to that biochar may strongly bind the hazardous substances in biochar strongly limiting their bioavailability. Additionally, the aforementioned hazardous substances have a hydrophobic character, which decreases the bioavailability, and limits the metabolization, as their structure contains the aromatic benzene rings skeleton (Beesley et al. 2010; Chen et al. 2012). It has been found, that, some of the VOCs present in biochar may potentially either stimulate or reduce both microbial processes (Khodadad et al. 2011) and plant growth (Deenik et al. 2010), due to biochar’s adsorbed organic chemical composition.

Discussion and recommendations

Since there are only a limited number of reported studies on the presence of VOCs and PAHs in biochars (Olsson et al. 2003, 2004; Mun and Ku 2010; Song and Peng 2010) there is a need to further investigate the potential of the “Dark side of the biochar”. That aspect is important, while biochar (potentially contaminated by VOCs) may be applied in the environment for different purposes including biochar application to soil (Jeffery et al. 2011) and those contaminants released from the biochar may cause some of the positive and negative effects that cannot be explained by factors like pH, nutrients contents, soil maintenance, or soil structure improvements (Elad et al. 2011; Nelson et al. 2012; Spokas et al., 2011). Unfortunately, there is limited knowledge about the impact of feedstock initial properties (content of cellulose, hemicellulose, lignin, and other compounds), and the biomass thermochemical treatment conditions on the chemical characteristics of biochars generated.

Neglecting this problem is likely to lead to higher levels of contamination in manufactured biochar, leading to greater contamination of land where biochar is used, and in turn contamination of food, soil, and water, and human exposure to harmful VOCs. Furthermore, not addressing this problem can lead to over-concern about this issue in situations where it is not a problem, leading to shrinkage of the biochar market owing to perceived liability problems, which in turn will limit the economic viability of biochar producers. Biochar manufacturers and end users would benefit from clear, scientifically rigorous information on this topic to allow them to make informed decisions concerning biochar process conditions and utilization.

The issues and problems presented here, regarding the potential negative impact of biochar on human health and the environment, may be considered novel, not deeply explored, and open a new niche for investigations, research, and experiments. Especially, from the fundamental science perspective, the mechanism of VOC production and re-deposition on biochar during torrefaction or pyrolysis, and the influence of the feedstock properties (the content of cellulose, hemicellulose, lignin, and other compounds) and the influence of the thermochemical lignocellulosic biomass treatment conditions on the presence of VOCs in biochar are intriguing and should be investigated. Therefore, the execution of the research on the phenomenon of VOC generation, redeposition on biochar, and emissions from biochar is important to environmental engineering and other related disciplines. There is a need for further fundamental research, e.g., an explanation of VOC formation, condensation, and emission mechanisms, and the potential exposure of workers to VOCs during biochar post-treatment, maintenance, and storage. Systematic research on the development of new knowledge about the phenomena of pollutant emission from biochars produced from lignocellulosic biomass components (individually, and mixed) under different temperatures and retention times should be executed. These experiments should be focused on the identification, and a better mechanistic understanding of VOC formation and release from biochar, and the influence of internal and external factors on their emission and redeposition. The compliance of biochar with existing VOC threshold values has not been tested significantly before yet, which could be highly relevant for human and environmental health and safety.

Additionally, while higher severity treatment conditions (higher temperatures) can reduce the presence of VOCs in biochar, economic pressures will tend to encourage lower severity process conditions because they result in higher yield (and hence more product and more income). Manufacturers need to understand the point at which contaminant production can become an issue, and be able to effectively manage that problem either through adjustment of operating conditions or removal of contaminants from their products.

Conclusion

As VOCs produced during the pyrolysis of lignocellulosic biomass are the main components of the condensable fraction of pyrolytic gas, the phenomenon of condensation and redeposition of VOCs on the surface of biochar may occur. Moreover, the qualitative and quantitative characteristics of VOCs on the surface of biochar may be different from the VOCs generated and emitted during the biochar production process. Some of the VOCs released during lignocellulosic biomass thermochemical treatment and redeposited on the biochar may be harmful to humans and the environment, causing the biochar may be a source of contamination and negative impact on living organisms. The chemistry of lignocellulosic biomass pyrolysis has been well studied and described in the literature. However, the chemistry, thermodynamics, and other factors influencing the redeposition, and condensation of VOC on the biochar during/after lignocellulosic biomass have not been studied in depth. This is a new research opportunity for researchers, that may have great importance due to the increasing interest in the development of high-quality and “healthy” biochar as a component of the bioeconomy.

Data availability

No datasets were generated or analysed during the current study.

References

Allaire SE, Lange SF, Auclair IK, Quinche M, Greffard L (2015) Analyses of biochar properties. CRMR-2015-SA-5. Presented at the Char Team. Report, Centre de Recherche sur les Mat.riaux

Ansah E, Wang L, Shahbazi A (2016) Thermogravimetric and calorimetric characteristics during co-pyrolysis of municipal solid waste components. Waste Manage. https://doi.org/10.1016/j.wasman.2016.06.015

Bai X, Kim KH, Brown RC, Dalluge E, Hutchinson C, Lee YJ, Dalluge D (2014) Formation of phenolic oligomers during fast pyrolysis of lignin. Fuel 128:170–179

Barquilha CER, Braga MCB (2021) Adsorption of organic and inorganic pollutants onto biochars: challenges, operating conditions, and mechanisms. Bioresource Technol Rep 15:100728. https://doi.org/10.1016/j.biteb.2021.100728

Beesley L, Moreno-Jim.nez E, Gomez-Eyles JL (2010) Effects of biochar and greenwaste compost amendments on mobility, bioavailability and toxicity of inorganic and organic contaminants in a multielement polluted soil. Environ Pollut 2282–2287. https://doi.org/10.1016/j.envpol.2010.02.003

Bernardo M, Lapa N, Gon.alves M, Barbosa R, Mendes B, Pinto F, Gulyurtlu I (2010) Toxicity of char residues produced in the co-pyrolysis of different wastes. Waste Manage 30:628e635. https://doi.org/10.1016/j.wasman.2009.10.015

Białowiec A, Pulka J, Stępień P, Manczarski P, Gołaszewski J (2017) The RDF/SRF torrefaction: an effect of temperature on characterization of the product - carbonized refuse derived fuel. Waste Manage 70:91–100. https://doi.org/10.1016/j.wasman.2017.09.020

Białowiec A, Micuda M, Szumny A, Łyczko J, Koziel JA (2018) Quantification of VOCs emissions from carbonized refuse-derived fuel using solid-phase microextraction and gas chromatography – mass spectrometry. Molecules 23(3208). https://doi.org/10.3390/molecules23123208

Białowiec A, Micuda M, Szumny A, Łyczko J, Koziel JA (2019) The Proof-of-the-Concept of Application of Pelletization for Mitigation of Volatile Organic Compounds Emissions from Carbonized Refuse-Derived Fuel. Materials 12, 1692

Buah WK, Cunliffe AM, Williams PT (2007) Characterization of products from the pyrolysis of municipal solid waste. Process saf Environ Prot. https://doi.org/10.1205/psep07024

Bucheli TD, Hilber I, Schmidt H-P (2015) Polycyclic Aromatic Hydrocarbons and Polychlorinated Aromatic compounds in Biochar. In Biochar for Environmental Management: Science and Technology; Lehmann

Buss W, Masek O (2014) Mobile organic compounds in biochar - a potential source of contamination phytotoxic effects on cress seed (Lepidium sativum) germination. J Environ Manage 137:111e119. https://doi.org/10.1016/j.jenvman.2014.01.045

Buss W, Masek O, Graham M, Wüst D (2015) Inherent organic compounds in biochar-their content, composition and potential toxic effects. J Environ Manage 156:150–157. https://doi.org/10.1016/j.jenvman.2015.03.035

Chang G, Huang Y, Xie J, Yang H, Liu H, Yin X, Wu C (2016) The lignin pyrolysis composition and pyrolysis products of palm kernel shell, wheat straw, and pine sawdust. Energy Conv Manag 124:587–597. https://doi.org/10.1016/j.enconman.2016.07.038

Chen Z, Naidu R, Bolan NS, Megharaj M, Choppala GK (2012) The influence of Biochar and Black Carbon on reduction and bioavailability of Chromate in Soils. J Environ Qual 41:1175–1184

D’Alessandro M, Held M, Triponez Y, Turlings TC (2006) The role of indole and other shikimic acid derived maize volatiles in the attraction of two parasitic wasps. J Chem Ecol 32(12):2733–2748. https://doi.org/10.1007/s10886-006-9196-7

Deenik JL, McClellan T, Uehara G, Antal MJ, Campbell S (2010) Charcoal volatile matter content influences plant growth and soil nitrogen transformations. Soil Sci Soc Am J 74:1259–1270

Dhungana A (2011) Torrefaction of biomass. M.Sc thesis. Dalhousie University, Halifax, Nova Scotia

Dong C, Zhang Z, Lu Q, Yang Y (2012) Characteristics and mechanism study of analytical fast pyrolysis of poplar wood. Energy Conv Manag 57:49–59. https://doi.org/10.1016/j.enconman.2011.12.012

Dudareva N, Negre F, Nagegowda DA, Orlova I (2006) Plant volatiles: recent advances and future perspectives. Crit Rev Plant Sci 25(5):417–440. https://doi.org/10.1080/07352680600899973

Elad Y, Cytryn E, Harel YM, Lew B, Graber ER (2011) The Biochar effect: plant resistance to biotic stresses. Phytopathol Mediterr 50:335e349

Fernández-Rodríguez J, Erdocia X, Sánchez C, Alriols MG, Labidi J (2017) Lignin depolymerization for phenolic monomers production by sustainable processes. J Energy Chem 26(4):622–631. https://doi.org/10.1016/j.jechem.2017.02.007

Gell K, van Groenigen J, Cayuela ML (2011) Residues of bioenergy production chains as soil amendments: immediate and temporal phytotoxicity. J Hazard Mater 186:2017e2025. https://doi.org/10.1016/j.jhazmat.2010.12.105

Glaser B, Haumaier L, Guggenberger G, Zech W (2001) The Terra Preta phenomenon: a model for sustainable agriculture in the humid tropics. Naturwissenschaften 88:37–41

Guo Y, Wen M, Song S, Liu Q, Li G, An T (2022) Enhanced catalytic elimination of typical VOCs over ZnCoOx catalyst derived from in situ pyrolysis of ZnCo bimetallic zeolitic imidazolate frameworks. Appl Catal B: Environ Volume 308:121212. https://doi.org/10.1016/j.apcatb.2022.121212

Harmsen P, Huijgen W, Bermudez L, Bakker R (September 2010) Literature review of physical and chemical pretreatment processes for lignocellulosic biomass. Biosynergy. (Access on 29.12.2023)https://edepot.wur.nl/150289

He T, Zhang Y, Zhu Y, Wen W, Pan Y, Wu J, Wu J (2016) Pyrolysis mechanism study of lignin model compounds by synchrotron vacuum ultraviolet photoionization mass spectrometry. Energy Fuels 30(3):2204–2208

Hwang H, Oh S, Choi I-G, Choi JW (2015) Catalytic effects of magnesium on the characteristics of fast pyrolysis products—Bio-oil, bio-char, and non-condensed pyrolytic gas fractions. J Anal Appl Pyrol 113:27–34

Jeffery S, Verheijen FGA, van der Velde M, Bastos AC (2011) A quantitative review of the effects of biochar application to soils on crop productivity using meta-analysis. Agric Ecosyst Environ 144:175e187. https://doi.org/10.1016/j.agee.2011.08.015

Jiang G, Nowakowski DJ, Bridgwater AV (2010) Effect of the temperature on the composition of lignin pyrolysis products. Energy Fuels 24(8):4470–4475

Kamarudin NS, Dahalan FA, Hasan M, An OS, Parmin NA, Ibrahim N, Hamdzah M, Zain NAM, Muda L, Wikurendra EA (2022) Biochar: a review of its history, characteristics, factors that influence its yield, methods of production, application in Wastewater Treatment and recent development. Biointerface Research in Applied Chemistry 12(6):7914?7926. https://doi.org/10.33263/BRIAC126.79147926

Kan T, Strezov V, Evans TJ (2016) Lignocellulosic biomass pyrolysis: a review of product properties and effects of pyrolysis parameters. Renew Sustain Energy Rev 57:1126–1140. https://doi.org/10.1016/j.rser.2015.12.185

Khodadad CLM, Zimmerman AR, Green SJ, Uthandi S, Foster JS (2011) Taxa- specific changes in soil microbial community composition induced by pyrogenic carbon amendments. Soil Biol Biochem 43:385–392

Kloss S, Zehetner F, Wimmer B, Buecker J, Rempt F, Soja G (2014) Biochar application to temperate soils: effects on soil fertility and crop growth under greenhouse conditions. J Plant Nutr Soil Sci 177:3e15. https://doi.org/10.1002/jpln.201200282

Lehmann J, Rillig MC, Thies J, Masiello CA, Hockaday WC, Crowley D (2011) Biochar effects on soil biota – A review. Soil Biol Biochem 43(9):1812–1836

Lewandowski WM, Ryms M, Kosakowski W (2020) Thermal Biomass Conversion: a review. Processes 8:516. https://doi.org/10.3390/pr8050516

Li L, S (2024) Reviewing Air pollutants generated during the pyrolysis of SolidWaste for Biofuel and Biochar production: toward Cleaner Production practices. Sustainability 16:1169. https://doi.org/10.3390/su16031169

Lou B, Shakoor N, Adeel M, Zhang P, Huang L, Zhao Y, Zhao W, Jiang Y, Rui Y (2022) Catalytic oxidation of volatile organic compounds by non-noble metal catalyst: current advancement and future prospectives. J Clean Prod Volume 363:132523. https://doi.org/10.1016/j.jclepro.2022.132523

Lu Q, Yang X, Dong C, Zhang Z, Zhang X, Zhu X (2011) Influence of pyrolysis temperature and time on the cellulose fast pyrolysis products: Analytical Py-GC/MS study. J Anal Appl Pyrol 92(2):430–438

Lu Q, Tian H, Hu B, Jiang X, Dong C, Yang Y (2016) Pyrolysis mechanism of holocellulose-based monosaccharides: the formation of hydroxyacetaldehyde. J Anal Appl Pyrol 120:15–26. https://doi.org/10.1016/j.jaap.2016.04.003

Lu Y, He Q, Fan G, Cheng Q, Song G (2021) Extraction and modification of hemicellulose from lignocellulosic biomass: a review. Green Process Synthesis 10(1):779–804. https://doi.org/10.1515/gps-2021-0065

Mettler MS, Mushrif SH, Paulsen AD, Javadekar AD, Vlachos DG, Dauenhauer PJ (2012a) Revealing pyrolysis chemistry for biofuels production: Conversion of cellulose to furans and small oxygenates. Energy Environ Sci 5(1):5414–5424

Mettler MS, Paulsen AD, Vlachos DG, Dauenhauer PJ (2012b) The chain length effect in pyrolysis: bridging the gap between glucose and cellulose. Green Chem 14(5):1284–1288

Mood SH, Pelaez-Samaniego MR, Garcia-Perez M (2022) Perspectives of Engineered Biochar for Environmental Applications: a review. Energy Fuels 36:15, 7940–7986. https://doi.org/10.1021/acs.energyfuels.2c01201

Mun S, Ku C (2010) Pyrolysis GC–MS analysis of tars formed during the aging of wood and bamboo crude vinegars. J Wood Sci 56:47–52

Nelson DC, Flematti GR, Ghisalberti EL, Dixon KW, Smith SM (2012) Regu- lation of seed germination and seedling growth by chemical signals from burning vegetation. Annu Rev Plant Biol 63:107e130. https://doi.org/10.1146/annurev-arplant-042811-105545

Oleszczuk P, Jośko I, Kuśmierz, M (2013) Biochar properties regarding to contaminants content and ecotoxicological assessment. J Hazard Mater 260:375e382. https://doi.org/10.1016/j.jhazmat.2013.05.044

Olsson M, Kjällstrand J, Petersson G (2003) Oxidative pyrolysis of integral softwood pellets. J Anal Appl Pyrol 67:135–141

Olsson M, Ramnäs O, Petersson G (2004) Specific volatile hydrocarbons in smoke from oxidative pyrolysis of softwood pellets. J Anal Appl Pyrol 71:847–854

Patwardhan PR, Brown RC, Shanks BH (2011a) Product distribution from the fast. Pyrol Hemicellulose ChemSusChem 4:636–643. https://doi.org/10.1002/cssc.201000425

Patwardhan PR, Dalluge DL, Shanks BH, Brown RC (2011b) Distinguishing primary and secondary reactions of cellulose pyrolysis. Bioresour Technol 102(8):5265–5269

Patwardhan PR, Brown RC, Shanks BH (2011c) Understanding the fast pyrolysis of lignin. Chemsuschem 4(11):1629–1636

Paz-Ferreiro J, Lu H, Fu S, M.ndez A, Gasc G (2014) Use of Phytoremediation and Biochar to Remediate Heavy Metal Polluted soils: a review. Solid Earth 5:65–75

Peng Y, Wu S (2010) The structural and thermal characteristics of wheat straw hemicellulose. J Anal Appl Pyrol 88(2):134–139. https://doi.org/10.1016/j.jaap.2010.03.006

Pranagal J, Kuśmierz M, Oleszczuk P, Ligęza S, Jośko I, Futa B, Wielgosz E (2013) Microbiological, biochemical and Ecotoxicological Evaluation of Soils in the area of Biochar production in relation to Polycyclic Aromatic Hydrocarbon Content. Geoderma 213:502–511

Prins MJ, Ptasinski KJ, Janssen F (2006) J.J.G. Torrefaction of wood part 2. Analysis of products. J Anal Appl Pyrol 77:35–40

Putro JN, Soetaredjo FE, Lin SY, Ju YH, Ismadji S (2016) Pretreatment and conversion of lignocellulose biomass into valuable chemicals. RSC Adv 6(52):46834–46852

Quilliam RS, Marsden KA, Gertler C, Rousk J, DeLuca TH, Jones DL (2012) Nutrient dynamics, microbial growth and weed emergence in biochar amended soil are influenced by time since application and reapplication rate. Agric Ecosyst Environ 158:192e199. https://doi.org/10.1016/j.agee.2012.06.011

Rangel MDC, Mayer FM, Carvalho MDS, Saboia G, de Andrade AM (2023) Selecting catalysts for pyrolysis of lignocellulosic biomass. Biomass 3, 31–63. https://doi.org/10.3390/biomass3010003

Ratte J, Fardet E, Mateos D, Hery JS (2011) Mathematical modelling of a continuous biomass torrefaction reactor: TORSPYD column. Biomass Bioenerg 35:3481–3495. https://doi.org/10.1016/j.biombioe.2011.04.045

REGULATION (EC) 1272/2008 OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 16 December 2008 on classification, labelling and packaging of substances and mixtures, amending and repealing directives 67/548/EEC and 1999/45/EC, and amending Regulation (EC) 1907/2006

Roffael E, Schneider T, Dix B (2015) Effect of oxidising and reducing agents on the release of volatile organic compounds (VOCs) from strands made of scots pine (Pinus sylvestris L). Wood Sci Technol 49:957–967. https://doi.org/10.1007/s00226-015-0744-6

Rogovska N, Laird D, Cruse RM, Trabue S, Heaton E (2012) Germination tests for assessing biochar quality. J Environ Qual 41:1014e1022. https://doi.org/10.2134/jeq2011.0103

Shaaban M, Van Zwieten L, Bashir S, Younas A, Núñez-Delgado A, Chhajro MA, Kubar KA, Ali U, Rana MS, Mehmood MA, Hu R (2018) A concise review of biochar application to agricultural soils to improve soil conditions and fight pollution. J Environ Manage 228:429–440. https://doi.org/10.1016/j.jenvman.2018.09.006

Shen Y (2022) Biomass-derived porous carbons for sorption of volatile organic compounds (VOCs). Fuel 336:126801. https://doi.org/10.1016/j.fuel.2022.126801

Shen DK, Gu S, Bridgwater AV (2010) Study on the pyrolytic behaviour of Xylan-based hemicellulose using TG–FTIR and Py–GC–FTIR. J Anal Appl Pyrol 87(2):199–206. https://doi.org/10.1016/j.jaap.2009.12.001

Shen D, Jin W, Hu J, Xiao R, Luo K (2015) An overview on fast pyrolysis of the main constituents in lignocellulosic biomass to valuedadded chemicals: structures, pathways and interactions. Renew Sustainable Energy Rev 51:761–774

Smith CR, Buzan EM, Lee JW (2013) Potential impact of biochar water- extractable substances on environmental sustainability. ACS Sustain Chem Eng 1:118e126. https://doi.org/10.1021/sc300063f

Sobol Ł, Dyjakon A, Soukup K (2023) Dioxins and furans in biochars, hydrochars and torreficates produced by thermochemical conversion of biomass: a review. Environ Chem Lett 21:2225–2249. https://doi.org/10.1007/s10311-023-01600-7

Song JZ, Peng PA (2010) Characterisation of black carbon materials by pyrolysis-gas chromatography–mass spectrometry. J Anal Appl Pyrol 87:129–137

Sorrenti G, Masiello CA, Dugan B, Toselli M (2016) Science of the total Environment Biochar physico-chemical properties as affected by environmental exposure. Sci Total Environ the 563–564:237–246. https://doi.org/10.1016/j.scitotenv.2016.03.245

Spokas KA, Novak JM, Stewart CE, Cantrell KB, Uchimiya M, Dusaire MG, Ro KS (2011) Qualitative analysis of volatile organic compounds on biochar. Chemosphere 85(5):869–882. https://doi.org/10.1016/j.chemosphere.2011.06.108

Stefanidis SD, Kalogiannis KG, Iliopoulou EF, Michailof CM, Pilavachi PA, Lappas AA (2014) A study of lignocellulosic biomass pyrolysis via the pyrolysis of cellulose, hemicellulose and lignin. J Anal Appl Pyrol 105:143–150. https://doi.org/10.1016/j.jaap.2013.10.013

Stępień P, Pulka J, Serowik M, Białowiec A (2019) Thermogravimetric and calorimetric characteristics of alternative fuel in terms of its use in low-temperature pyrolysis. Waste Biomass Valor 10:1669–1677. https://doi.org/10.1007/s12649-017-0169-6

Sun X, Atiyeh HK, Li M, Chen Y (2020) Biochar facilitated bioprocessing and biorefinery for productions of biofuel and chemicals: a review. Bioresour Technol 295:122252. https://doi.org/10.1016/j.biortech.2019.122252

Sun S, Wang Q, Wang X, Wu C, Zhang X, Bai J, Sun B (2023) Dry torrefaction and continuous thermochemical conversion for upgrading agroforestry waste into eco-friendly energy carriers: current progress and future prospect. Sci Total Environ Volume 905:167061. https://doi.org/10.1016/j.scitotenv.2023.167061

Taherymoosavi S, Verheyen V, Munroe P, Joseph S, Reynolds A (2017) Characterization of organic compounds in biochars derived from municipal solid waste. Waste Manage 67:131–142. https://doi.org/10.1016/j.wasman.2017.05.052

Taiti C, Costa C, Nissim G (2017) Assessing VOC emission by different wood cores using the PTR-ToF-MS technology. Wood Sci Technol 51:273–295. https://doi.org/10.1007/s00226-016-0866-5

Tian X, Wang Y, Zeng Z, Dai L, Peng Y, Jiang L, Yang X, Yue L, Liu Y, Ruan R (2021) Study on the mechanism of co-catalyzed pyrolysis of biomass by potassium and calcium. Bioresource Technology, Volume 320, Part B, 124415, https://doi.org/10.1016/j.biortech.2020.124415

Tomczyk A, Sokołowska Z, Boguta P (2020) Biochar physicochemical properties: pyrolysis temperature and feedstock kind effects. Rev Environ Sci Biotechnol 19:191–215. https://doi.org/10.1007/s11157-020-09523-3

Trinh TN, Jensen PA, Sárossy Z, Dam-Johansen K, Knudsen NO, Sørensen HR, Egsgaard H (2013) Fast pyrolysis of lignin using a pyrolysis centrifuge reactor. Energy Fuels 27(7):3802–3810

United States Environmental Protection Agency (2024) Technical Overview of Volatile Organic Compounds. https://www.epa.gov/indoor-air-quality-iaq/technical-overview-volatile-organic-compounds#definition (accessed on 2nd of

Usino DO, Supriyanto YP, Pettersson A, Richards T (2020) Influence of temperature and time on initial pyrolysis of cellulose and xylan. J Anal Appl Pyrol 147:104782. https://doi.org/10.1016/j.jaap.2020.104782

Wang C, Wang Y, Herath HMSK (2017) Polycyclic aromatic hydrocarbons (PAHs) in biochar – their formation, occurrence and analysis: a review. Org Geochem 114:1–11. doi.org/10.1

Wang S, Dai G, Yang H, Luo Z (2017b) Lignocellulosic biomass pyrolysis mechanism: a state-of-the-art review. Prog Energy Combust Sci 62:33–86

Wang W, Lemaire R, Bensakhria A, Luart D (2022a) Review on the catalytic effects of alkali and alkaline earth metals (AAEMs) including sodium, potassium, calcium and magnesium on the pyrolysis of lignocellulosic biomass and on the co-pyrolysis of coal with biomass. J Anal Appl Pyrol 163:105479. https://doi.org/10.1016/j.jaap.2022.105479

Wang W, Lemaire R, Bensakhria A, Luart D (2022b) Analysis of the Catalytic effects Induced by Alkali and Alkaline Earth metals (AAEMs) on the pyrolysis of Beech Wood and Corncob. Catalysts 12:1505. https://doi.org/10.3390/catal12121505

Wang W, Lemaire R, Bensakhria A, Luart D (2022c) Review on the catalytic effects of alkali and alkaline earth metals (AAEMs) including sodium, potassium, calcium and magnesium on the pyrolysis of lignocellulosic biomass and on the co-pyrolysis of coal with biomass. J Anal Appl Pyrol 163:105479

Wang Q, Wu C, Wang X, Sun S, Cui D, Pan S, Sheng H (2023) A review of eutectic salts as phase change energy storage materials in the context of concentrated solar power. Int J Heat Mass Transf Volume 205:123904. https://doi.org/10.1016/j.ijheatmasstransfer.2023.123904

Wannapeera J, Fungtammasan B, Worasuwannarak N (2011) Effects of temperature and holding time during torrefaction on the pyrolysis behaviors of woody biomass. J Anal Appl Pyrol 92:99–105. https://doi.org/10.1016/j.jaap.2011.04.010.016/j.orggeochem.2017.09.001

Wei X, Lu Q, Sui X, Wang Z, Zhang Y (2012) Characterization of the water-insoluble pyrolytic cellulose from cellulose pyrolysis oil. J Anal Appl Pyrol 97:49–54. https://doi.org/10.1016/j.jaap.2012.07.002

Wu C, Wang Q, Wang X, Sun S, Bai J, Cui D, Pan S, Sheng H (2024) Effect of Al2O3 nanoparticle dispersion on the thermal properties of a eutectic salt for solar power applications: experimental and molecular simulation studies, vol 288. Energy, p 129785. https://doi.org/10.1016/j.energy.2023.129785

Yadav SPS, Bhandari S, Bhatta D, Poudel A, Bhattarai S, Yadav P, Ghimire N, Paudel P, Paudel P, Shrestha J, Oli B (2023) Biochar application: a sustainable approach to improve soil health. J Agric Food Res 11:100498. https://doi.org/10.1016/j.jafr.2023.100498

Yang H, Li S, Liu B, Chen Y, Xiao J, Dong Z, Gong M, Chen H (2020) Hemicellulose pyrolysis mechanism based on functional group evolutions by two-dimensional perturbation correlation infrared spectroscopy. Fuel 267:117302. https://doi.org/10.1016/j.fuel.2020.117302

Yogalakshmi KN, Poornima Devi T, Sivashanmugam P, Kavitha S, Yukesh Kannah R, Varjani S, Adish Kumar S, Gopalakrishnan K, Banu R (2022) Lignocellulosic biomass-based pyrolysis: a comprehensive review. Chemosphere 286(2):131824. https://doi.org/10.1016/j.chemosphere.2021.131824

Zhan H, Zhuang X, Song Y, Liu J, Li S, Chang G, Yin X, Wu C, Wang X (2019) A review on evolution of nitrogen-containing species during selective pyrolysis of waste wood-based panels. Fuel 253:1214–1228. https://doi.org/10.1016/j.fuel.2019.05.122

Zhang Z, Jiang Z, Shangguan W (2016) Low-temperature catalysis for VOCs removal in technology and application: a state-of-the-art review. Catal Today 264:270–278. https://doi.org/10.1016/j.cattod.2015.10.040

Zhang X, Gao B, Creamer AE, Cao C, Li Y (2017) Adsorption of VOCs onto engineered carbon materials: a review. J Hazard Mater Volume 338:102–123. https://doi.org/10.1016/j.jhazmat.2017.05.013

Zhang Z, Li K, Ma S, Cui M, Lu Q, Yang Y (2019) Fast pyrolysis of biomass catalyzed by magnetic solid base catalyst in abhydrogen atmosphere for selective production of phenol. Ind Crops Prod 137:495–500

Zhao C, Kou Y, Lemonidou A, Li X, Lercher J (2009) Highly selective Catalytic Conversion of Phenolic Bio-oil to Alkanes. Angew Chem Int Ed 48:3987–3990. https://doi.org/10.1002/anie.200900404

Zheng M, Wang Z, Li X, Qiao X, Song W, Guo L (2016) Initial reaction mechanisms of cellulose pyrolysis revealed by ReaxFF molecular dynamics. Fuel 177:130–141. https://doi.org/10.1016/j.fuel.2016.03.008

Acknowledgements

The article is part of a PhD dissertation titled “Research on the impact of pyrolysis technological parameters and substrate properties on the release of volatile organic compounds from biochar”, prepared during Doctoral School at the Wrocław University of Environmental and Life Sciences. The APC is financed by Wrocław University of Environmental and Life Sciences. This work was conducted at the Waste and Biomass Valorization Group (WBVG), and the Department of Applied Bioeconomy, Wrocław University of Environmental and Life Sciences, Poland.

Funding

This research was funded in whole by National Science Centre, Poland, Grant Number UMO-2019/35/O/ST8/03353. For the purpose of Open Access, the author has applied a CC-BY public copyright licence to any Author Accepted Manuscript (AAM) version arising from this submission.

Author information

Authors and Affiliations

Contributions

ES - Writing - First Draft, Writing - Review and Editing, Visualisation, Conceptualization; DC-Conceptualization, Writing - Review and Editing; AB- Conceptualization, Writing - Review and Editing, and Funding acquisition.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Syguła, E., Ciolkosz, D. & Białowiec, A. The significance of structural components of lignocellulosic biomass on volatile organic compounds presence on biochar - a review. Wood Sci Technol 58, 859–886 (2024). https://doi.org/10.1007/s00226-024-01557-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-024-01557-y