Abstract

As a consequence of refining on bleached kraft pulps of Eucalyptus grandis W. Hill ex Maiden, at 25°SR, 30°SR and 35°SR, substantial modifications of the fibre are observed. Such changes affect the quality of pulp and are related to specific cellulose microfibrils distribution pattern, nanofissures, micropores, cell wall fibrillation, the presence of dislocations and to the partial or less frequent entire erosion of the S1 layer of secondary wall fibre. The Schopper–Riegler degree (°SR) is a useful index to measure the value of the mechanical treatment (refining) to which the pulp has been subjected to. When refining at 25°SR, the S2 layer presents a loose cellulose microfibril pattern, whereas after refining at 30°SR, the S2 layer displays concentric and successive lamellae and visible nanofissures. After refining at 35°SR, bleached kraft pulps are heterogeneous, and the S2 layer of the twisted fibre exhibits an outer zone with radially oriented fractures between cellulose aggregates and an electron-dense inner zone with cellulose microfibrils parallel to the axis. Fibre changes in length, diameter and wall thickness were analyzed with a nonparametric ANOVA by ranges (Kruskal–Wallis H test) which varied significantly.

Similar content being viewed by others

References

Adusumalli RB, Kombaiah W, Mook R, Passas R, Raghavan R, Michler J (2011) Nano- and micro- mechanics of single wood pulp fibres. COST Action E54 Book, pp 147–162

Ander P, Daniel G (2003) Morphology of spruce fiber dislocation as study by ballon swelling and acid cleveage-light and electron microscope observation. In: Schmitt U, Ander P, Barnett JR, Emons AMC, Jeronimidis G, Sarampää P, Tschegg S (eds) Cost action E20 wood fiber cell wall structure, ISBN: 91-576-6803-5, Swedish University of Agricultural Science, Upsala, p 319

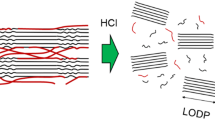

Ander P, Hildén L, Daniel G (2008) Cleavage of softwood kraft pulp fibres by HCL and cellulases. BioResources 3(2):477–490

Ander P, Henniges U, Potthast A (2011) Sec studies on HCL treated softwood and birch kraft pulps. In: Ander P, Bauer W, Heinemann S, Kallio P, Passas R, Treimanis A (eds) COST action E54 fine structure of papermaking fibres, ISBN: 978-91-576-9007-4, Swedish University of Agricultural Sciences, Uppsala, Sweden, p 283

Celulosa Argentina (2012). http://www.celulosaargentina.com.ar/_CelulosaArgentina/

Cerutti J (2016) Análisis tecnológicos y prospectivos sectoriales. Papel y Celulosa. (Technological analysis and sectorial forecast. Paper and cellulose) (In Spanish). Secretaría de Planeamiento y Políticas. Ministerio de Ciencia, Tecnología e Innovación Productiva. Argentina. February 2016

Chevalier-Billosta V, Joseleau J, Cochaux A, Ruel K (2007) Tying together the ultrastructural modifications of wood fiber induced by pulping processes with the mechanical properties of paper. Cellulose 14:141–152

Dharm D, Tyagi C (2011) Comparison of various eucalyptus species for their morphological, chemical, pulp and paper making characteristics. Indian J Chem Technol 18:145–151

Donaldson L (2007) Cellulose microfibril aggregates and their size variation with cell type. Wood Sci Technol 41:443–460

Eckhart R, Hirn U, Bauer W (2011) A method capable to determine damage of the outer fiber wall layers fine structure of papermaking fibres. In: Ander P, Bauer W, Heinemann S, Kallio P, Passas R, Treimanis A (eds) COST action E54 fine structure of papermaking fibres, ISBN: 978-91-576-9007-4, Swedish University of Agricultural Sciences, Uppsala, Sweden, p 283

Eriksen O, Syverud K, Gregersen O (2008) The use of microfibrillated cellulose produced from kraft pulp as strength enhancer in TMP paper. Nord Pulp Pap Res J 23(3):299–304

Fahlén J, Salmén L (2003) Cross sectional structure of the secondary wall of wood fibres as affected by processing. J Mater Sci 38:119–126

Fardim P, Durán N (2001) Surfaces chemical composition and mechanical properties of Eucalyptus grandis kraft pulp investigated by XPS and PCA. In: Proceedings of the 11th ISWPC international symposium on wood and pulping chemistry, pp 1–305

Fardim P, Durán N (2003) Modification of fibre surfaces during pulping and refining as analysed by SEM, XPS and ToF-SIMS. Colloids Surf A Physicochem Eng Asp 223:263–276

Fernando D, Daniel G (2010) Characterization of spruce thermomechanical pulps at the fiber cell wall level: a method for quantitatively assessing pulp fiber development using Simons’ stain. Tappi J 9(10):47–55

Fernando D, Muhic D, Engstrand P, Daniel G (2011) Fundamental understanding of pulp property development under different thermomechanical pulp refining conditions as observed by a new Simons’ staining method and SEM observation of the ultrastructure of fibre surfaces. Holzforschung 65(6):777–786

Gharehkhani S, Sadeghinezhad E, Newaz Kazi S, Yarmand H, Badarudin A, Reza Safaei M, Nashrul Mohd Zubi M (2015) Basic effects of pulp refining on fiber properties-A review. Carbohydr Polym 115:785–803

Henriksson M, Henriksson G, Berglund L, Lindstrom T (2007) An environmentally friendly method for enzyme-assisted preparation of microfibrillated cellulose (MFC) nanofibres. Eur Polym J 43:3434–3441

Hietanen S, Ebeling K (1990) Fundamental aspects of the refining process. Pap Puu 72(10):952–960

Hirn H, Schennach R (2015) Comprehensive analysis of individual pulp fiber bonds quantifies the mechanisms of fiber bonding in paper. Sci Rep Nat 5:10503

InfoStat versión (2009) Grupo infoStat. Universidad Nacional de Córdoba, Argentina. http://www.infostat.com.ar

Iwamoto S, Abe K, Yano H (2008) The effect of hemicelluloses on wood pulp nanofibrillation and nanofiber network characteristics. Biomacromol 9:1022–1026

Kappel L, Hirn U, Bauer W, Schennach R (2011) Comparison of two different methods for fiber-fiber bonded area measurement. In: Ander P, Bauer W, Heinemann S, Kallio P, Passas R, Treimanis A (eds) COST action E54 fine structure of papermaking fibres, ISBN: 978-91-576-9007-4, Swedish University of Agricultural Sciences, Uppsala, Sweden, p 283

Kärenlampi P (1996) Strength and toughness of paper: the effect of pulp fiber properties. Report A4, Laboratory of paper technology, Helsinki University of Technology

Kruskal WH, Wallis WA (1952) Use of ranks in one-criterion variance analysis. J Am Stat Assoc 47:583–621 (and errata, ibid. 48, 907–911)

Larsen M, Winandy J, Green F (1995) A proposed model of the tracheid cell wall of southern yellow pine having an inherent radial structure in the S2 layer. Material und Organismen 29(3):197–210

Mörseburg K, Chinga-Carrasco G (2009) Assessing the combined benefits of clay and nanofibrillated cellulose in layered TMP-based sheets. Cellulose 16(5):795–806

Paavilainen L (1991) Influence of morphological properties of softwood fibres on sulphate pulp fibres and paper properties. In: Paper presented at the international paper physics conference Book 2, Tappi

Paavilainen L (1993) Conformability, flexibility and collapsibility of sulphate pulp fibres. Pap Puu 75:689–702

Pattara P (2012) Low consistency refining of chemical pulp, investigating the effect of intensity on fibre cutting. Master thesis. Asian Institute of Technology, Pulp and paper technology, Pathumthani, Thailand

Reynolds ES (1963) The use of lead citrate at high pH as an electron-opaque stain in electron microscopy. J Cell Biol 17:208–212

Scallan AM (1974) The structure of the cell wall of wood—A consequence of anisotropic inter-microfibrillar bonding? Wood Sci 6(3):266–271

Secretary of Agroindustria—Argentina. Industrial Forest Development (2017).https://www.argentina.gob.ar/buscar/desarrollo%20foresto%20industrial

Spurr AR (1969) Low-viscosity epoxy resin embedding medium for electron microscopy. J Ultrastruct Res 26:31–43

Tappi (2007) Technical Association of the Pulp and Paper Industry. Official test methods. Tappi testing procedures vol 1 and 2

Topgaard D, Söderman O (2002) Changes of cellulose fiber wall structure during drying investigated using NMR selfdiffusion and relaxation experiments. Cellulose 9:138–147

Wan J, Wang Y, Xiao Q (2010) Effects of hemicellulose removal on cellulose fiber structure and recycling characteristics of Eucalyptus pulp. Bioresour Technol 101:4577–4583

Zimmermann T, Richter K, Bordeanu N, Sell J (2007) Arrangement of cell-wall constituents in chemically treated Norway spruce tracheids. Wood Fiber Sci 39(2):221–231

Acknowledgements

The authors acknowledge the valuable financial support from Celulosa Argentina S.A., Capitán Bermúdez, Santa Fé Province, Argentina. Special thanks to C. del Río who kindly improved the language.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sparnochia, L., Castro, M.A. Cell wall changes caused by refining in fibre of Eucalyptus grandis W. Hill ex Maiden bleached kraft pulp: a ultra- and nano-structural approach. Wood Sci Technol 53, 911–925 (2019). https://doi.org/10.1007/s00226-019-01103-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-019-01103-1