Abstract

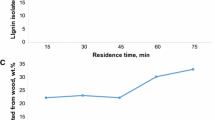

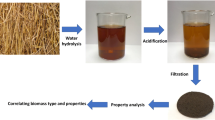

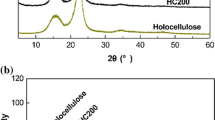

Autohydrolysis is a widely used technology for extracting hemicelluloses from wood chips. In addition to hemicelluloses, hydrolysates produced in this process contain lignin. Hemicelluloses and lignin could be isolated from hydrolysates and used for generating value-added products. In this study, hydrolysates were produced via autohydrolysis of spruce wood chips. Then, acidification and ethanol precipitation were employed to isolate lignocelluloses from hydrolysates. Generally, acidification and ethanol treatment led to the precipitation of lignin–carbohydrate complexes, but their removals depended on the hydrolysis conditions. The heat capacity (Cp) of the dried hydrolysates was in the range of 0.41–0.45 J/g °C, while the precipitates of acidification and ethanol treatment had the Cp of 1.18 J/g °C and 1.38 J/g °C, respectively. This increment could be related to their higher lignin content and thus their molecular mobility as these segments had a higher amount of methoxyl groups and more Hα and Hβ inter-linkages. The results of this study suggested that the lignocellulosic materials obtained after acid or ethanol treatment of hydrolysates could be considered as additives for heat-resistant biopolymers or hemicellulose-based films, respectively.

Similar content being viewed by others

References

Aro T, Fatehi P (2017) Production and application of lignosulfonates and sulfonated lignin. ChemSusChem 10:1861–1877

Azadi P, Inderwildi OR, Farnood R, King DA (2013) Liquid fuels, hydrogen and chemicals from lignin: a critical review. Renew Sustain Energy Rev 21:506–523

Bahcegul E, Toraman HE, Erdemir D, Akinalan B, Ozkan N, Bakir U (2014) An unconventional approach for improving the integrity and mechanical properties of xylan type hemicellulose-based films. RSC Adv 4:34117–34126

Carrier M, Loppinet-Serani A, Denux D, Lasnier J-M, Ham-Pichavant F, Cansell F, Aymonier C (2011) Thermogravimetric analysis as a new method to determine the lignocellulosic composition of biomass. Biomass Bioenergy 35:298–307

Carvalheiro F, Duarte L, Girio F (2008) Hemicelluloses biorefineries: a review on biomass pretretments. J Sci Ind Res 67:849–864

Carvalheiro F, Silva-Fernandes T, Duarte LC, Gurio FM (2009) Wheat straw autohydrolysis: process optimization and products characterization. Appl Biochem Biotechnol 153:84–93

Cateto CA, Barreiro MF, Rodrigues AE, Brochier-Salon MC, Thielemans W, Belgacem MN (2008) Lignins as macromonomers for polyurethane synthesis: a comparative study on hydroxyl group determination. J Appl Polym Sci 109:3008–3017

Chen X, Li H, Sun S, Cao X, Sun R (2016) Effect of hydrothermal pretreatment on the structural changes of alkaline ethanol lignin from wheat straw. Sci Rep 6:1–9

Chua MGS, Wayman M (1979) Characterization of autohydrolysis aspen (P. Tremuloides) lignins. Part 1. Composition and molecular weight distribution of extracted autohydrolysis lignin. Can J Chem 57:1141–1149

Dammstrom S, Salmen L, Gatenholm P (2009) On the interactions between cellulose and xylan, a biomimetic simulation of the hardwood cell wall. Bioresources 4(1):3–14

Du X, Gellerstedt G, Li J (2013) Universal fractionation of lignin–carbohydrate complexes (LCCs) from lignocellulosic biomass: an example using spruce wood. Plant J 74(2):328–338

Du X, Perez-Boada M, Fernandez C et al (2014) Analysis of lignin–carbohydrate and lignin–lignin linkages after hydrolase treatment of xylan–lignin, glucomannan–lignin and glucan–lignin complexes from spruce wood. Planta 239:1079–1090

Fatehi P, Gao W, Sun Y, Dashtban M (2016) Acidification of prehydrolysis liquor and spent liquor of neatural sulfite semichemical pulping process. Bioresour Technol 218:518–525

Foston M, Samuel R, He J, Ragauskas AJ (2015) A review of whole cell was NMR by the direct-dissolution of biomass. Green Chem 18:608–621

Gao H, Rao J, Guan Y, Li W, Zhang M, Shu T, Lv Z-W (2018) Investigation of the thermo-mechanical properties of blend films based on hemicelluloses and cellulose. Int J Polym Sci 2018:1–10

Garcia J, Zamudio M, Perez A, Feria M, Gomide J, Coledette J, Lopez F (2001) Soda-AQ pulping of paulownia wood after hydrolyis treatment. Bioresources 6(2):971–986

Gasparovic L, Labovský J, Markos J, Jelemensky L (2012) Calculation of kinetic parameters of the thermal decomposition of wood by distributed activation energy model (DAEM). Chem Biochem Eng Q J 26(1):45–53

Gordobil O, Delucis R, Egüés I, Labidi J (2015) Kraft lignin as filler in PLA to improve ductility and thermal properties. Ind Crop Prod 72:46–53

Granada E, Lopez Gonzalez LM, Miguez JL, Moran J (2002) Fuel lignocellulosic briquettes, die design and products study. Renew Energy 27:561–573

Gröndahl M, Bindgard L, Gateholm P, Hjertberg T (2013) Polymeric film or coating comprising hemicellulose. U.S. Patent 8,557,033 B2

Guigo N, Mija A, Vincent L, Sbirrazzuoli N (2009) Molecular mobility and relaxation process of isolated lignin studied by multifrequency calorimetric experiments. Phys Chem Chem Phys 11:1227–1236

Hatakeyama H, Hatakeyama T (2010) Thermal properties of isolated and in situ lignin. In: Heitner C, Dimmel DR, Schmidt JA (eds) Lignin and lignas advances in chemistry. CRC Press, Boca Raton, pp 301–319

Irvine GM (1985) The significance of the glass transition of lignin in thermomechanical pulping. Wood Sci Technol 19:139–149

Khazraie T, Zhang Y, Tarasov D, Gao W, Price J, Demartini N, Hupa L, Fatehi P (2017) A process for producing lignin and volatile compounds from hydrolysis liquor. Biotechnol Biofuels 10(1):47

Kong L, Zhao Z, He Z, Yi S (2017) Effects of steaming treatment on crystallinity and glass transitiontemperature of Eucalyptuses grandis × E. urophylla. Results Phys 7:914–919

Kosikova B, Joniak D, Kosakova L (1979) On the properties of benzyl ether bonds in the lignin–saccharidic complex isolated from spruce. Holzforschung 33:11–14

Lawoko M, Berggren R, Berthold F, Henriksson G, Gellerstedt G (2004) Changes in the lignin–carbohydrate complex in softwood kraft pulp during kraft and oxygen delignification. Holzforschung 58:603–610

Lawoko M, Henriksson G, Gellerstedt G (2005) Structural differences between the lignin–carbohydrate complexes present in wood and in chemical pulps. Biomacromolelules 6:3467–3473

Leppanen K, Spetz P, Pranovich A, Hartonen K, Kitunen V, Ilvesniemi H (2011) Pressurized hot water extraction of Norway spruce hemicelluloses using a flow-through system. Wood Sci Technol 45:223–236

Leschinsky M, Zuckerstätter G, Weber HK, Patt R, Sixta H (2008) Effect of autohydrolysis of Eucalyptus globulus wood on lignin structure. Part 1: comparison of different lignin fractions formed during water prehydrolysis. Holzforschung 62(6):645–652

Li S, Lundquist K (1994) A new method for the analysis pf phenolic groups in lignins by 1H NMR spectrometry. Nord Pulp Pap Res J 9(3):191–195

Li H, McDonald AG (2014) Fractionation and characterization of industrial lignins. Ind Crops Prod 62:67–76

Li J, Henriksson G, Gellerstedt G (2007) Lignin depolymerization/repolymerization and its critical role for delignification of aspen wood by steam explosion. Bioresour Technol 98(16):3061–3068

Li M, Pu Y, Ragauskas AJ (2016) Current understanding of the correlation of lignin structure with biomass recalcitrance. Front Chem 4(45):1–8

Liu S (2008) A kinetic model on autocatalytic reactions on woody biomass hydrolysis. J Biobased Mater Bio 2(2):135–147

Liu Z, Fatehi P, Jahan MS, Ni Y (2011a) Separation of lignocellulosic materials by combined processes of pre-hydrolysis and ethanol extraction. Bioresour Technol 102:1264–1269

Liu Z, Ni Y, Fatehi P, Saeed A (2011b) Isolation and cationization of hemicelluloses from pre-hydrolysis liquor of kraft-based dissolving pulp production process. Biomass Bioenergy 35(5):1789–1796

Long J, Xu Y, Wang T, Shu R, Zhang Q, Zhang X, Fu J, Ma L (2014) Hydrothermal depolymerization of lignin: understanding the structural evolution. Bioresources 9(4):7162–7175

Lora JH, Glasser WG (2002) Recent industrial applications of lignin: a sustainable alternative to nonrenewable materials. J Polym Environ 10(112):39–48

Lumadue MR, Cannon FS, Brown NR (2012) Lignin as both fuel and fusing binder in briquetted anthracite fines for foundry coke substitute. Fuel 97:869–875

Mainka H, Tager O, Korner E, Hilfert L, Busse S, Edelmann FT, Herrmann AS (2015) Lignin—an alternative precursor for sustainable and cost-effective automotive carbon fiber. J Mater Res Technol 4(3):283–296

Menezes F, Rocha GJ, Filho RM (2016) Obtainment and characterization of lignin from enzymatic hydrolysis of sugarcane bagasse of 2G ethanol process in pilot scale. Chem Eng Trans 50:397–402

Monot C, Chirat C, Evangelista B, Brochier-Salon MC (2017) Characterization of lignin and lignin–carbohydrate complexes (LCCs) in prehydrolysed wood chips. Holzforschung 71(3):199–205

Nagy M, Kosa M, Theliander H, Ragauskas AJ (2010) Characterization of CO2 precipitated Kraft lignin to promote its utilization. Green Chem 12:31–34

Nonaka H, Kobayashi A, Funaoka M (2013) Separation of lignocresol from eucalyptus lignocresol–cellulase complex using organic solvents. Bioresour Technol 143:657–659

Olivares M, Guzman JA, Natho A, Saavedra A (1988) Kraft lignin utilization in adhesives. Wood Sci Technol 22:157–165

Olsson AM, Salmen L (1997) The effect of lignin composition on the viscoelastic properties of wood. Nord Pulp Pap Res J 12:140–144

Overend RP, Chornet E (1987) Fractionation of lignocellulosics by steam-aqueous pretreatments. Philos Trans R Soc Lond A 321:523–536

Pedersen M, Meyer AS (2010) Lignocellulose pretreatment severity—relating pH to biomatrix opening. New Biotechnol 27(6):739–750

Persson J, Dahlmon O, Albertsson AC (2012) Birch xylan grafted with PLA branches of predictable length. Bioresources 7(3):3640–3655

Pothiraj C, Kanmani P, Balaji P (2006) Bioconversion of lignocellulose materials. Mycobiology 34(4):159–165

Pu Y, Treasure T, Gonzalez R, Venditti R, Jameel H (2013) Autohydrolysis pretreatment of mixed softwood to produce value prior to combustion. Bioenergy Res 6:1094–1103

Saggi SK, Gupta G, Dey P (2016) Biological pretreatment of lignocellulosic biomaterials. In: Singh LK, Chaudhary G (eds) Advances in biofeedstocks and biofuels: biofeedstocks and their processing, vol 1. Wiley, Hoboken, pp 97–120

Sammons RJ, Harper DP, Labbe N, Bozell JJ, Elder T, Rials TG (2013) Characterization of organosolv lignins using thermal and FT-IR spectroscopic analysis. Bioresources 8(2):2752–2767

Santos RB, Hart PW, Jameel H, Chang HM (2013) Wood based lignin reaction important to the biorefinery and pulp and paper industries. Bioresourses 8(1):1456–1477

Shi H, Fatehi P, Xiao H, Ni Y (2011) A combined acidification/PEO flocculation process to improve the lignin removal from the pre-hydrolysis liquor of kraft-based dissolving pulp production process. Bioresour Technol 102(8):5177–5182

Singh R, Singh S, Trimukhe KD, Pandare KV, Bastawade KB, Gokhale DV, Varma A (2005) Lignin–carbohydrate complexes from sugarcane bagasse: preparation, purification, and characterization. Carbohydr Polym 62(1):57–66

Sipponen MH, Pihlajaniemi V, Sipponen S, Pastinen O, Laakso S (2014) Autohydrolysis and aqueous ammonia extraction of wheat straw: effect of treatment severity on yield and structure of hemicellulose and lignin. RSC Adv 4:23177–23184

Sixta H, Iakovlev M, Testova L, Roselli A, Hummel M, Borrega M, van Heiningen A, Froschauer C, Schottenberger H (2013) Novel concepts of dissolving pulp production. Cellulose 20(4):1547–1561

Song T, Pranovich A, Sumersky I, Holmbom B (2008) Extraction of galactoglucomannan from spruce wood with pressurised hot water. Holzforschung 62:659–666

Spiridon I, Leluk K, Resmerita AM, Darie RN (2015) Evaluation of PLA–Lignin bioplastics properties before and after accelerated weathering. Compos Part B Eng 69:342–349

Stelte W, Clemons C, Holm JK, Ahrenfeldt J, Henriksen UB, Sanadi AR (2012) Fuel pellets from wheat straw: the effect of lignin glass transition and surface waxes on pelletizing properties. Bioenergy Res 5(2):450–458

Stewart D (2008) Lignin as a base material for materials applications: chemistry, application and economics. Ind Crops Prod 27:202–207

Sun YC, Xu JK, Feng X, Sun RC (2013) Efficient separation and physico-chemical characterization of lignin from eucalyptus using ionic liquid–organic solvent and alkaline ethanol solvent. Ind Crops Prod 47:277–285

Sun YC, Lin Z, Peng WX, Yuan TQ, Xu F, Wu YQ, Yang J, Wang YS, Sun RC (2014) Chemical changes of raw materials and manufactured binderless boards during hot pressing: lignin isolation and characterization. Bioresources 9(1):1055–1071

Tamminen T, Vuorinen T, Tenkanen M, Hausalo T, Hortling B (1995) Analysis of lignin and lignin–carbohydrate complexes isolated from black liquor. In: 8th ISWPC, Helsinki, 6–9 June, vol II. Gummerus Kirjapaino Oy, Jyvaskyla, pp 297–302

Tanger P, Field JL, Jahn CE, DeFoort MW, Leach JE (2013) Biomass for thermochemical conversion: targets and challenges. Front Plant Sci 4:1–20

Tarasov D, Leitch M, Fatehi P (2015) Production of lignosulfonate in NSSC-based biorefinery. Biotechnol Prog 31(6):1508–1514

Tarasov D, Leitch M, Fatehi P (2017) Thermal properties of lignocellulosic precipitates from neutral sulfite semichemical pulping process. Fuel Process Technol 158:146–153

Tarasov D, Leitch M, Fatehi P (2018) Flow through autohydrolysis of spruce wood chips and lignin carbohydrate complex formation. Cellulose 25(2):1377–1393

Tong R, Wu C, Zhao C, Yu D (2017) Separation and structural characteristics of lignin in the prehydrolysis liquor of whangee dissolving pulp. Bioresources 12(4):8217–8229

Tunc M (2014) Effect of liquid to solid ratio on autohydrolysis of Eucalyptus globulus wood meal. Bioresources 9(2):3014–3024

Tunc MS, Lawoko M, van Heininggen A (2010) Understanding the limitation of removal of hemicelluloses during autohydrolysis of a mixture of southern hardwoods. Bioresources 5(1):356–371

Uraki Y, Usukura Y, Kishimoto T, Ubukata M (2006) Amphiphilicity of a lignin–carbohydrate complex. Holzforschung 60(6):659–664

Vishtal A, Kraslawski A (2011) Challenges in industrial applications of technical lignins. Bioresources 6(3):3547–3568

Wang G, Chen H (2013) Fractionation and characterization of lignin from steam-exploded corn stalk by sequential dissolution in ethanol–water solvent. Sep Purif Technol 120:402–409

Yao L, Chen C, Zheng X, Peng Z, Yang H, Xie Y (2016) Determination of lignin–carbohydrate complexes structure of wheat straw using carbon-13 isotope as a tracer. Bioresources 11(3):6692–6707

You T-T, Zhang L-M, Zhou S-K, Xu F (2015) Structural elucidation of lignin–carbohydrate complex (LCC) preparations and lignin from Arundo donax Linn. Ind Crops Prod 71:65–74

Youssefian S, Rahbar N (2015) Molecular origin of strength and stiffness in bamboo fibrils. Sci Rep 5:1–13

Zhang B, Fu GQ, Niu YS, Peng F, Yao CL, Sun RC (2016) Variations of lignin–lignin and lignin–carbohydrate linkages from young Neosinocalamus affinis bamboo culms. RSC Adv 6:15478–15484

Zhou S, Wang Z, Liaw S, Li C, Garcia-Perez M (2013) Effect of sulfuric acid on the pyrolysis of Douglas fir and hybrid poplar wood: Py-GC/MS and TG studies. J Anal Appl Pyrolysis 104:117–130

Zoia L, Orlandi M, Argyropoulos D (2008) Microwave-assisted lignin isolation using the enzymatic mild acidolysis (EMAL) protocol. J Agric Food Chem 56:10115–10122

Acknowledgements

The authors would like to thank Early Researcher Award program of the government of Ontario, NSERC, Canada foundation for Innovation and Canada Research Chairs programs for supporting this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Tarasov, D., Leitch, M. & Fatehi, P. Chemical and thermal properties of precipitates made from hydrolysate of spruce wood chips. Wood Sci Technol 53, 889–909 (2019). https://doi.org/10.1007/s00226-019-01101-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-019-01101-3