Abstract

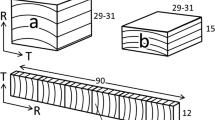

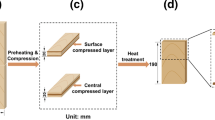

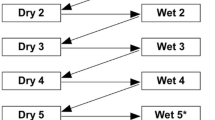

In this paper, the compressive deformation of hybrid poplar wood (Populus deltoides × Populus trichocarpa) at high temperature (150, 160, and 170°C) and under various conditions of steam pressure was studied. Temperature and conditions of steam environment affected the relative density change and creep deformation during compression, as well as properties of the resulting densified material. While the temperature significantly affected the compression deformation of specimens compressed under transient and superheated steam conditions, temperature within the range studied had little effect on the compressive deformation in saturated steam. In all tested conditions, compression deformation was achieved without cell wall fractures. Higher temperature of compression, regardless of steam condition, resulted in lower equilibrium moisture content. In specimens compressed under saturated steam, the modulus of rupture (MOR) and modulus of elasticity (MOE) were increased proportionally to the increase in density, while the compression under superheated steam produced lower increase in the MOE and MOR than expected based on the increase in density. Compression in transient steam conditions at 170°C produced densified wood with higher MOE and MOR than expected based on the increase in density.

Similar content being viewed by others

References

Blomberg J, Persson B (2004) Plastic deformation in small clear pieces of Scots pine (Pinus sylvestris) during densification with the CaLignum process. J Wood Sci 50:307–314

Dai C, Steiner PR (1993) Compression behavior of randomly formed wood flake mats. Wood Fiber Sci 25(4):349–358

Dornyak OR (2003) Modeling of the rheological behavior of wood in compression processes. J Eng Phys Thermophys 76(3):648–654

Grossman PUA (1976) Requirements for a model that exhibits mechano-sorptive behavior. Wood Sci Technol 10:163–168

Hillis WE, Rozsa AN (1978) The softening temperatures of wood. Holzforschung 32(2):68–73

Holzer SM, Loferski JR, Dillard DA (1989) A review of creep in wood: concepts relevant to develop long-term behavior predictions for wood structures. Wood Fiber Sci 21(4):376–392

Hunt DG (1999) A unified approach to creep of wood. Proc R Soc Lon A Math Phys Eng Sci 455:4077–4095

Kunesh RH (1961) The inelastic behavior of wood: a new concept for improved panel forming processes. Forest Prod J 11:395–406

Kutnar A, Kamke FA, Sernek M (2008) The mechanical properties of densified VTC wood relevant for structural composites. Holz Roh- Werkst 66(6):439–446

Kutnar A, Kamke FA, Sernek M (2009) Density profile and morphology of viscoelastic thermal compressed wood. Wood Sci Technol 43(1):57–68

Lenth CA, Kamke FA (2001) Equilibrium moisture content of wood in high temperature pressurized environments. Wood Fiber Sci 33(1):104–118

Morsing N (2000) Densification of wood—the influence of hygrothermal treatment on compression of beech perpendicular to the grain. Department of structural engineering and materials technical university of Denmark, Series R, 79, 138 pp

Östberg G, Salmen L, Terlecki J (1990) Softening temperature of moist wood measured by differential calorimetry. Holzforschung 44:223–225

Placet V, Passard J, Perré P (2007) Viscoelastic properties of green wood across the grain measured by harmonic tests in the range 0–95°C: hardwood vs. softwood and normal wood vs. reaction wood. Holzforschung 61:548–557

Sadoh T (1981) Viscoelastic properties of wood in swelling systems. Wood Sci Technol 15:57–66

Wolcott MP (1989) Modelling viscoelastic cellular materials for the pressing of wood composites. PhD Dissertation. Virginia Tech, Blacksburg, Virginia, 182 pp

Wolcott MP, Kamke FA, Dillard DA (1990) Fundamentals of flakeboard manufacture: viscoelastic behavior of the wood component. Wood Fiber Sci 22(4):345–361

Wolcott MP, Kamke FA, Dillard DA (1994) Fundamental aspects of wood deformation pertaining to manufacture of wood-base composites. Wood Fiber Sci 26(4):496–511

Acknowledgments

The project was supported by the National Research Initiative of the USDA Cooperative State Research, Education and Extension Service, grant number 2006-35504-17444 and USDA Wood Utilization Research Center Special Grant number 2008-34158-19302.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kutnar, A., Kamke, F.A. Compression of wood under saturated steam, superheated steam, and transient conditions at 150°C, 160°C, and 170°C. Wood Sci Technol 46, 73–88 (2012). https://doi.org/10.1007/s00226-010-0380-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-010-0380-0