Abstract

A theory has been developed for calculating the twist that develops in boards during drying without restraint, as well as the deformation in cross-section that accompanies the development of twist. Calculations require a knowledge of only a limited number of parameters: width, thickness and length of the board, annual ring orientation, distance from the pith, radial, tangential and longitudinal shrinkage coefficients, and the variation of spiral grain angle (SGA) with distance from the pith. The theory is derived from geometrical and physical principles and shows that a complicated interaction between all the above parameters gives rise to twist. A novel coordinate system is used that is better adapted to the fact that spiral grain lies at an angle to the log axis rather than the usual Cartesian or cylindrical polar coordinates. Unlike the finite element models that have recently been developed this theory does not allow for the effect of stresses that develop in a board, although the theory in its present form can easily be extended to incorporate this effect. The advantage of this theory over the more exact finite element models lies in its educational value in that it clearly identifies the mechanisms that are responsible for twist. An associated MS Excel spreadsheet allows rapid analysis of different scenarios such as the effect on twist of changing the shrinkage coefficients, annual ring orientations and moisture content. The theory predicts that for radiata pine 100×50 mm boards maximum twist occurs near the pith, and that the direction of twist reverses when the distance from the pith is greater than about 120 mm. These predictions are shown to agree with experiment. The theory also predicts that if a radiata pine log is live-sawn (through-and-through sawn) there will be two regions in the mature wood where the quartersawn boards will have large negative twist values, but that this can be avoided by cant- or grade-sawing. In contrast, the theory also predicts that if the SGA is constant at 4° from pith to bark, board twist will decrease smoothly from pith to bark for all annual ring orientations without ever becoming negative.

Similar content being viewed by others

References

Balodis V (1972) Influence of grain angle on twist in seasoned boards. Wood Sci Technol 5(1):44–50

Barber NF, Meylan BA (1964) The anisotropic shrinkage of wood. A theoretical model. Holzforschung 18(5):146–156

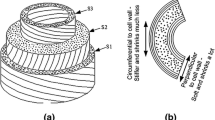

Booker RE (1993) The importance of the S3 cell wall layer in collapse and wood hardness, vol 3/17. In: Proceedings of the 24th forest products research conference, CSIRO division of forest products, Clayton,15–18 November 1993, pp 1–13

Booker RE (2003) Shrinkage and theories of differential shrinkage. In: Proceedings of “Wood research, knowledge and concepts for future demands” conference, EMPA wood laboratory research and work report 115/50, pp 29–46

Cown DJ, Young GD, Kimberley MO (1991) Spiral grain patterns in plantation-grown Pinus radiata. NZ J Forestry Sci 21(2/3):206–216

Gu H, Zinc-Sharp A, Sell J (2001) Hypothesis on the role of cell wall structure in differential transverse shrinkage of wood. Holz Roh- Werkstoff 59(6):436–442

Harris JM (1989) Spiral grain and wave phenomena in wood formation. Springer, Berlin Heidelberg New York

Haslett AN (1998) Drying Radiata pine in New Zealand, research and commercial aspects. Forest Research FRI Bulletin No. 206, Forest Research Institute Ltd, New Zealand

Mishiro A, Booker RE (1988) Warping in new crop radiata pine 100×50 mm boards. Bull Tokyo Univ Forests 80:37–68

Mishiro A, Booker RE (1989) Warping of new crop radiata pine 100×50 mm (2×4) boards. In: Proceedings of second pacific regional wood anatomy conference. Forest Products Research and Development Institute, Los Banos (College), Laguna, Philippines

Ormarsson S (1995) A finite element study of the shape stability of sawn timber subjected to moisture variations. Licentiate Thesis, Report TVSM-3017, Division of Structural Mechanics, Lund University, Sweden

Persson, K (2000) Micromechanical modelling of wood and fibre properties. Doctoral Thesis, Department of Mechanics and Materials, Structural Mechanics, Lund University, Sweden, p 213

Säll H (2002) Spiral grain in Norway Spruce. Doctoral Thesis, Växjö University Press, Intellecta Docusys. ISBN 91-7636-356-2

Stevens WC, Johnston DD (1960) Distortion caused by spiral grain. Timber Technol 68:217–218

Woxblom L (1999) Warp of sawn timber of Norway spruce in relation to end-user requirements. Department of Forest Management and Products, Swedish University of Agricultural Sciences, Uppsala. ISBN 91-576-5860-9

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1

Shrinkage factors to use after the isotropic shrinkage step

Assume a length H lying along the grain direction. In this analysis the first step is an isotropic shrinkage of the board by a fraction r. This reduces this length to H×(1−r). The real shrinkage fraction along the grain direction is L, so that the final dimension should be H×(1−L).

To achieve this, after the isotropic shrinkage step all lengths along the grain direction must be swelled by a factor of 1+(r−L)/(1−r), so that the expansion factor is (r−L)/(1−r). Similarly, after the isotropic shrinkage step all dimensions in the tangential direction must be reduced by a tangential shrinkage fraction of (t−r)/(1−r).

Appendix 2

Relative horizontal rotation of a point along the cylinder

A point F on the circumference of a board at height H rotates along a cylinder of diameter RF (Fig. 2). The movement ∇ along the horizontal plane is equal to QU′−QN (Figs. 4 and 5). Then from Eq. 18 and Figs. 4 and 5:

Then substituting from Eqs. 4 and 5 for QS′ and S′F′ leads to:

Substituting for QS and SF from Eqs. 11 and 15 into Eq. 23 leads to

After further trigonometric and algebraic manipulation this leads to:

The term \(\left( {{1 \mathord{\left/ {\vphantom {1 {(1 - r)}}} \right. \kern-\nulldelimiterspace} {(1 - r)}}} \right) \times R_{\text{F}} \times \theta _{\text{F}} \times (r - t)\) represents a small movement that is responsible for normal cupping (i.e. without a contribution from spiral grain). The term \( \left( {{{(t - L)} \mathord{\left/ {\vphantom {{(t - L)} {(1 - r)}}} \right. \kern-\nulldelimiterspace} {(1 - r)}}} \right) \times R_{\text{F}} \times \theta _{\text{F}} \times {\text{sin}}^2 \phi \) is responsible for an additional cross-sectional distortion that is normally small. Both the first and the second term are very small compared to the third term. Moreover, these displacements are the same at the top and the bottom of the board, so that the relative distance of rotation # is:

In the range from 0° to 21° the relationship between sin(2φ) and φ is given by a linear equation with r2=0.998, where sin(2φ)=1.8358×φ, so that for SGAs up to 21°

Hence the distance of rotation at a point on a board is proportional to the SGA in radians, the length of the board, and the difference between the tangential and longitudinal shrinkage fractions.

Rights and permissions

About this article

Cite this article

Booker, R.E. Geometric model to predict twist in unrestrained boards. Wood Sci Technol 39, 269–289 (2005). https://doi.org/10.1007/s00226-004-0260-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-004-0260-6