Abstract

This work aims to determine the effect on the aromatic profile and phenolic content of red wine vinegars produced by surface culture at two different temperatures (30 °C and 37 °C) and using different inocula of acetic acid bacteria (Acetobacter malorum, Gluconobacter oxydans and a mixture of bacteria isolated from a Sherry vinegar). Fifty-seven volatile compounds and 23 polyphenolic and furfural compounds were identified. Vinegars obtained at 37 °C had poorer volatile profiles, with no significant influence of the strain of acetic bacteria. For polyphenolic content, temperature was also the most significant variable, so that the vinegars produced at higher temperatures had lower total anthocyanin contents, while no clear trend was observed regarding the influence of temperature on the low-molecular-weight phenolic constituents. The total tannin content in the vinegars obtained experienced slight increases after acetification, although this was not affected by temperature, and it was observed that when using the mixture of acetic acid bacteria from the Sherry vinegar, the total tannin content was significantly higher than when individual bacteria cultures of Acetobacter malorum or Gluconobacter oxydans were used. Temperature appears as a key parameter for the volatile and phenolic composition of red wine vinegar versus the use of different acetic acid bacteria.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Red wine vinegar is a popular condiment used in cooking as a dressing. In addition to its culinary use, its interest lies in its complex chemical composition and its potential as a source of bioactive compounds such as volatiles, anthocyanins and polyphenols [1], which are responsible for its organoleptic properties, including the characteristic color, aroma and flavor of this type of vinegar.

At present, the submerged culture production process is the most prevalent in the industry, mainly because it shortens production times. However, the final product is a vinegar which is less rich in organoleptic properties than those obtained by the traditional surface process which, although it requires longer production times, the resulting vinegars exhibit a more pronounced organoleptic profile [2].

One of the variables to be taken into account is the temperature at which the acetification process takes place. This factor determines both the final composition of the vinegars and their bacterial activity, and it has been well established that, as a general rule, the temperature should be adjusted above 30 °C in order to favor such activity. For this reason, numerous studies have focused on the influence of temperature on the production of vinegars using different matrices [3,4,5,6]. In relation to the temperature factor, and with the aim of reducing the costs associated to the cooling of the exothermic acetification process, thermotolerant acetic acid bacteria have already proven their suitability, since they allow the fermentation of vinegar to take place at temperatures around 37 °C [7].

The most commonly used bacteria for the production of wine vinegar are those of the genus Acetobacter, especially Acetobacter aceti, although others such as Acetobacter pasteurianus or A. polysogenes are also used. Each strain of bacteria has different characteristics and capabilities that exert certain influences on the processing and on the chemical composition of the resulting vinegars. For example, A. aceti strains produce acetic acid more efficiently than those of A. pasteurianus, which results in more acidic wine vinegars with a subsequently more intense flavor. Therefore, the selection of the acetic bacteria strain can have a significant impact on the quality and flavor of the final wine vinegar. Other bacteria of the genus Gluconobacter are also used for acetification processes. These differ from the above in their preference for glucose, rather than alcohol, as the initial substrate for the reaction. In addition, they have a high tolerance to alcohol and acidity [8].

The acetification conditions will therefore determine the composition of the vinegars obtained. In this regard, polyphenols and volatile constituents are of paramount significance, as they are the main contributors to the organoleptic characteristics of vinegar.

Among polyphenols, anthocyanins and tannins are probably the most important compounds in red wine vinegar. Anthocyanins are natural pigments that are found in grapes and other red fruits, and these contribute to the color of vinegar. Tannins, on the other hand, are phenolic compounds derived from the seeds and skins of grapes and they provide flavor and structure to the vinegar. These compounds are associated with the antioxidant capacity of vinegars and, therefore, with their beneficial effect on human health [9,10,11]. Along with these, we also find non-flavonoid polyphenols, which are also related to the susceptibility to oxidation of oenological products.

With regard to the aroma of vinegar, volatile compounds are the ones which play a fundamental role. This makes the analysis of the volatile content of vinegars of great interest because of the impact that it has on the sensory properties and quality of the final product. There are numerous studies that address this influence according to factors such as the nature of the matrix, the type of culture, or the bacteria used for acetification, among others. Chanivet et al. [12] studied the influence of the type of wood on the aging of Sherry vinegar and observed that the different samples presented a variable volatile profile depending on the botanical origin of the wood of the cask in which the vinegar had been aged. Wang et al. [13] studied the effect of using a bioreactor to produce vinegar of Chinese origin on their volatile content. The studies conducted by Chen et al. [14] on the other hand, focused on the effect that using mixed cultures of Saccharomyces cerevisiae and Lactobacillus plantarum, for the alcoholic fermentation of citrus vinegar, had on its physicochemical and sensory properties. The authors found that these cultures were more efficient than pure cultures with regard to the fermentation process.

In summary, we propose that the choice of the bacterial strain and the conditions under which the acetification process is to be carried out are key factors that must be taken into account if a high quality red wine vinegar with the appropriate organoleptic and sensory characteristics is to be obtained. All these factors will be crucial in its polyphenolic and volatile composition.

Taking into account all of the above, this study has been aimed to determine the effect of two fermentation temperatures (30 °C and 37 °C) and the use of different bacterial inocula which had initially showed to be thermotolerant according to the test describe by Sharafi et al. [15] on the volatile and phenolic content of final red wine vinegars.

Among the thermotolerant bacteria, one strain of Gluconobacter oxydans (AG70), and 3 Acetobacter malorum strains (CR23, CR1, and AM17) have been considered. For comparative purposes, a mixture of bacteria from a Sherry vinegar was also employed. Surface culture was used in all acetification processes.

Materials and methods

Acetic fermentation

Red wine and acetic acid bacteria

For the acetification process, a Tempranillo red wine corresponding to the 2020 vintage from the Jerez de la Frontera production area was used [alcohol, 11.5% (v/v); pH 3.4; total acidity, 6 g/L tartaric acid; 25 mg/L free sulfur dioxide].

In order to carry out the acetic fermentation process, 10 individual colonies of Acetic Acid Bacteria (AAB) resistant to ethanol and high temperatures [15, 16], obtained from Moroccan prickly pear were previously isolated. After the identification analysis, 8 of them were classified as A. malorum (A1-8) (3 CR23 strains, 4 CR1 strains, and 1 AM17 strain) and 2 as G. oxydans (G1-2) (1 AG70 strain) [16, 17]. On the other hand, in order to study the differences between the acetification profiles depending on the bacterial inoculants, a mixture of strains obtained from unfiltered Sherry vinegar (Jerez, Spain) was used (M).

The selected AAB were cultured in a culture medium prior to their use. For this purpose, they were incubated at 30 °C for 24 h with continuous agitation to promote their proliferation. Once the optical density (OD at 600 nm) of the suspension exceeded a value of 1.2, the acetic fermentation process was initiated by inoculating the bacterial culture into a red Sherry wine at a concentration of 10% (v/v).

Acetification by surface process

The acetification process was carried out using a surface process. For this purpose, 500 mL erlenmeyer flasks previously sterilized and lined with absorbent cotton were used. Each flask was filled with 250 mL of red wine and inoculated with 10% (v/v) of the different inocula of the AAB previously described together with that obtained from a mixture of strains from unfiltered Sherry vinegar.

The trials were conducted in duplicate at two temperatures: 30 °C and 37 °C, in order to determine if temperature increments would affect the acetification process performance or the final characteristics of the vinegar. During the whole process, the flasks were kept without agitation to allow a slow diffusion of atmospheric oxygen into the fermentation medium. The total acidity of the different vinegars was evaluated throughout the acetification process. For this purpose, titration was carried out with NaOH using phenolphthalein as an indicator and the total acidity content was expressed as grams of acetic acid/100 mL vinegar. When the level of acidity ceased to increase for three consecutive evaluations (two-week intervals), the fermentation process was considered as completed. The samples that have been studied correspond to the final stage of the acetification process.

Determining the volatile and polyphenolic contents in the vinegars

Reactants

In order to determine the volatile content of the samples, 4-methyl-2-pentanol supplied by Sigma-Aldrich (St Louis, Missouri, USA) of the commercial brand Scharlab (Barcelona, Spain) was used as internal standard. The rest of the volatile commercial standards were acquired from Merck KGaA (Darmstadt, Germany), Sigma Aldrich (USA) and Fluka (Buchs, Switzerland), all of them presenting purities higher than 99%. NaCl was purchased from Scharlab (Spain).

For the individualized analysis of the polyphenols, Milli-Q quality water, acetonitrile, (HPLC purity grade; Panreac, Barcelona, Spain) and acetic acid (HPLC purity grade; Merck, Germany), were used to prepare the eluents for the mobile phase. The standards used to prepare the calibration lines were purchased from Fluka (Switzerland) and Sigma (USA).

The sodium acetate, potassium chloride, and sulfuric acid were purchased from Sigma Aldrich (USA).

Determination of total anthocyanins and tannins

The total anthocyanin content of each sample was determined according to the Giusti and Wrolstad method [18]. First, the samples were filtered and diluted 1:5. Then 600 μL of each sample were added to 2.4 mL of sodium acetate (pH 4.5) or 2.4 mL of potassium chloride buffer (pH 1). After 15 min, the absorbances at 520 and 700 nm of both solutions (pH 1.0 and 4.5) were measured.

The results were calculated as follows: A = (A520 − A700)pH1.0 − (A520 − A700)pH4.5; C (mg/L) = (A × molecular weight × dilution factor × 1000)/εl; The molecular weight of cyanidin 3-glucoside is 449.7.0 g/mol and ɛ is 26,900/mol. 1 = path length (1 cm).

As for total tannins, they were quantified using the vanillin method [19]. In this case, the results were expressed as mg/L epicatechin equivalents. The measurements, in both cases, were performed in triplicate and using a UV–vis. spectrophotometer (Spectronic Helios, Thermo Electron Corporation, Waltham, USA).

Determination of the low molecular weight phenolic content

The low molecular weight polyphenols were determined by Ultra High Performance Liquid Chromatography (UPLC) following the procedure used by Chanivet et al. [12]. The measurements were carried out in a Waters Acquity UPLC equipment (Waters Corp., Milford, USA) with an Acquity UPLC BEH C18 column (2.1 × 100 mm internal diameter and 1.7 μm particle size) of the same brand, coupled to a UV–Vis photodiode array detector (PDA). The temperature was maintained at 47 °C during the measurement process. The injection volume was 2.5 μL, with a 0.7 mL/min flow rate and an analysis time (run time) of 6.5 min.

The binary phase system employed consisted of an aqueous phase, or phase A, (95% Milli-Q water, 3% acetonitrile and 2% acetic acid) and an organic phase, or phase B, (85% acetonitrile, 13% Milli-Q water and 2% acetic acid). The gradient used during the 6.5 min of the analyses was from 100 to 90% of A in 3 min and from 90 to 25% of A in 2.5 min. Finally, the column was washed with 100% of B for 3 min and stabilized with 100% of A for 3 more minutes.

The samples were fed into the equipment after being filtered through a 0.22 µm nylon filter (Filter-Lab, Barcelona, Spain).

The results were processed with the software Empower Pro (Waters Corp., USA) to identify the compounds by comparison of their retention times and UV–Vis spectra with those obtained from the injection of commercial standards (Sigma Aldrich, Spain). The absorbances at 280 nm (for benzoic derivatives) and at 320 nm (for cinnamic derivatives) were used for quantification purposes. Finally, their concentration values were calculated using calibration lines that had been previously constructed from commercial standards, using at least 7 concentration points and covering the range of concentrations expected to be found in the samples.

Determination of the volatile content by SBSE-GC–MS

The study of the volatile content of the samples was carried out by Stir Bar Sorptive Extraction (SBSE) following the procedure described by Es-sbata et al. [17]. The analyses were performed in duplicate. For extraction, 25 mL of sample along with 5.85 g of NaCl and 84 μL of internal standard, 4-methyl-2-pentanol (2.2894 g/L in Milli-Q water containing 80 g/L acetic acid) were transferred into 100 mL erlenmeyer flasks at room temperature. The stir bars (polydimethylsiloxane stirs bars, 10 mm length × 0.5 mm film thickness) were then added and the contents of the flask were sealed with parafilm. The optimum extraction conditions were: 25 °C, 1250 rpm and 120 min. The agitation was carried out in a 15-position panel of the commercial brand Gerstel (Gerstel, Müllheim a/d Ruhr, Germany).

Once the extraction process was completed, the Twister was placed in the TDS-2 thermal desorption unit (Gerstel, Germany), equipped with an MPS 2L autosampler (Gerstel, Germany) with capacity for 98 stirring bars and connected to a CIS-4 injector with Programmed Temperature Vaporization (PTV) (Gerstel, Germany). The desorption temperature was programmed from 40 to 300 °C at a rate of 60 °C/min under a 75 mL/min helium flow rate. The desorbed compounds were cryoconcentrated in the PTV system using liquid nitrogen at a temperature of − 140 °C. Subsequently, a temperature ramp from − 140 to 300 °C (10 °C/s) was used and maintained for 5 min.

Finally, a gas chromatograph with a Agilent 6890 GC-5973N MS mass spectrometer type detector (Agilent Technologies, Palo Alto, CA, USA) was used for the GC–MS analyses. The capillary column used was a DB-Wax model (J&W Scientific, Folsom, CA, USA) of 60 m × 0.25 mm internal diameter with a 0.25 μm coating. A 1 mL/min helium flow rate was used as carrier gas.

The different volatile compounds were identified by means of mass spectra analogy based on Wiley library (Wiley Registry of Mass Spectral Data, 7th Edition, 2000). In order to confirm the identified compounds, the linear retention index of each compound was determined using a DB-Wax column and the results were compared against the data found in the bibliography [12, 20].

For the quantification, the measurement of the relative area of the base peak of each compound in relation to that of the internal standard, 4-methyl-2-pentanol, was used.

Statistical study

The statistical study was conducted by means of Statgraphics Centurion XVI software (Statpoint, Virginia, USA). Analysis of Variance (ANOVA) and Tukey's test, Cluster Analysis (CA), and Principal Component Analysis (PCA) were applied to treat the data from the different measurements and experiences.

Results and discussion

General parameters: total acidity, total anthocyanins and total tannins

The red wine vinegar samples that had fermented at 30 °C presented significantly higher acidity values (p < 0.05) than those corresponding to the vinegars subjected to the fermentation process at 37 °C (Table 1). This behavior was observed for each of the three genera of bacteria studied, even when two genera had displayed thermotolerant characteristics in a previous study [16].

These results are in agreement with previous findings, such as those reported by Ndoye et al. [21] who observed that at temperatures above 30 °C, Acetobacter strains ceased their acetic acid production. Similarly, Es-sbata et al. [17] had observed, for these same genera of acetic bacteria, a higher production of acetic acid in prickly pear vinegar samples that were acetified at 30 °C compared to those fermented at higher temperatures. Zheng et al. [22] in turn, observed that both acetic acid content and temperature were variables that greatly affected bacteria populations.

High temperatures can destroy acetic acid bacteria and increase the evaporation of volatile compounds, such as ethanol or acetic acid, and therefore, reduce bacterial activity and thus the acidity of the samples [23]. However, Saeki et al. [24] observed that at temperatures above 37 °C, certain strains of acetic acid bacteria (Acetobacter rancens subspecies pasteurianus,, Acetobacter lovaniensis subspecies lovaniensis, Acetobacter aceti subspecies liquefaciens, and Acetobacter xylinum subspecies xylinum) produced significant amounts of acetic acid.

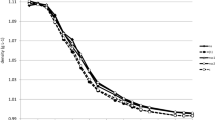

In terms of total anthocyanin and condensed tannin contents, as can be seen from Fig. 1A, the anthocyanin fraction showed clear losses with respect to the starting wine, ranging from 7 to 14% with respect to the initial red wine. Thus, the vinegars produced at 37 °C showed higher losses, with temperature being a significant factor regarding the total anthocyanin content of the resulting vinegars (ANOVA, p < 0.05), while the genus bacteria variable proved not to be significant with regard to total anthocyanin content, since all the vinegars registered statistically similar losses, regardless of the bacteria used.

On the other hand, the total tannin content experienced small increases during the acetification process (Fig. 1B), close to 8% in those vinegars that had been obtained by using the mixture of bacteria from Sherry vinegar, and no significantly different increments could be associated to their fermentation temperature (ANOVA, p < 0.05). Those vinegars fermented by the mixture of bacteria from a Sherry wine vinegar exhibited significant different increments respect to those fermented by A. malorum and G. oxydans.

Other authors found significant losses of anthocyanins during the acetic fermentation process of strawberry vinegars, which they attributed to the oxidative processes that took place in a medium with a large amount of oxygen, as in their study they used submerged fermentation to produce the vinegars [25]. Similar results were found by [26,27,28] when using different alcoholic matrices. In our case, the lower losses with respect to those observed in the above mentioned studies could be due to the lower availability of oxygen during the acetification process, as the surface process was employed.

On the other hand, the small increases in the condensed tannin content registered for all vinegars with respect to the starting wine were also observed by [29]. According to these authors, the increments in tannin contents when producing persimmon vinegar could be due to the breaking of cell walls induced by the acetic bacteria and the release of this type of compounds to the liquid medium during the fermentation process.

Low molecular weight phenolic compounds and furans

The characterization of the polyphenolic content in the red wine vinegar samples allowed to identify a total of 23 compounds. A Multivariate Analysis of Variance (MANOVA, p < 0.05) was carried out in order to detect any significant differences between the polyphenolic profiles of the samples studied. The concentration of each compound was taken as the dependent variable, with the type of bacteria, the temperature and the interaction between the two (type of bacteria-temperature) being the independent variable in each case. Table 2 shows the data resulting from this analysis.

Most of the low molecular weight phenolic compounds found were acids, such as benzoic acid, syringic acid, caffeic acid or gallic acid. Some flavonoid-type compounds such as catechin or epicatechin were also identified. The analysis of variance revealed that temperature was the variable with the greatest influence on the low molecular weight polyphenolic composition, with more than half of the compounds presenting values of p < 0.05 in contrast with the effect attributable to bacterial genus or to the temperature-bacteria interaction, which were variables of little significance regarding the evolution of the polyphenolic content in the red wine vinegar samples studied.

Table 3 shows the mean concentrations of each of the polyphenolic compounds, as well as their standard deviation, for the vinegars produced at 30 °C and 37 °C and for those obtained by fermentation through the different genera of acetic acid bacteria used.

As can be seen from Table 3, there was no marked trend regarding the influence of temperature on the phenolic contents of the samples, with some of them showing a greater presence of these compounds when the fermentation temperature had been 30 °C, as in the case of p-coumaric acid and caffeic acid. In contrast, when a higher temperature had been used, some of the samples exhibited a greater concentration of specific polyphenols, such as procatechualdehyde or caftaric acid (Table 3). On the other hand, certain compounds such as HMF (5-hydroxymethylfurfural) or furoic acid, which had been derived from sugar dehydration, showed higher concentrations at higher temperatures, as higher levels of dehydration had been reached. Syringic acid was the most abundant compound in the vinegar samples studied, followed by tyrosol and gallic acid, the latter matching the results obtained by [1] for Sherry vinegar samples and by [30] in their comparative studies on the polyphenolic content of traditionally and industrially produced wine vinegars.

The data from the individualized low molecular weight polyphenol and furan analyses were subjected to multivariate statistical analysis (Principal Component Analysis, PCA), where a total of 5 principal components (PCs) were identified that explained 79.1% of the total variability between the samples (eigenvalues > 1). Figure 2 displays the graphical representation of the red wine vinegar samples distributed in the orthogonal plane defined by the first two principal components 1 and 2.

PCA on polyphenolic compounds. Distribution of all the vinegar samples on the plane defined by the first two PCs. A 30/A 37: Acetobacter malorum at 30 °C and 37 °C, respectively; G 30/G 37: Gluconobacter oxydans at 30 °C and 37 °C, respectively; M 30/M 37: Mixture of bacteria at 30 °C and 37 °C, respectively

PC2 separated the samples according to their fermentation temperatures, with positive values assigned to those fermented at 37 °C and negative values to the samples obtained through a 30 °C fermentation process. With regard to this principal component (PC2), the most significant compounds were 5-hydroxymethylfurfural, protocatechualdehyde, tyrosol and furoic acid, all of them with positive values, as well as syringialdehyde, with a negative value.

Finally, these results were subjected to Cluster Analysis (CA) (Fig. 3). Three groups can be clearly distinguished as follows: two groups on the left, with a marked greater presence of the vinegars obtained at 37 °C, and one group on the right, where the majority of the vinegars had been produced at 30 °C. As already noted according to the ANOVA, it was again the temperature the factor to exert the greatest influence on the low molecular weight phenolic and furanic fractions of the vinegars, even if such influence did not has a clear sign.

Cluster analysis taking into consideration the polyphenolic and furanic composition of the vinegar samples. A 30/A 37: Acetobacter malorum at 30 °C and 37 °C, respectively; G 30/G 37: Gluconobacter oxydans at 30 °C and 37 °C, respectively; M 30/M 37: Mixture of bacteria at 30 °C and 37 °C, respectively

Volatile compounds

During the analysis of the red wine vinegar samples by SBSE-GS-MS, a total of 57 volatile compounds of different nature were detected, including esters, acetates, aldehydes, alcohols, ketones and terpenes, among others, which contribute with different notes to the aroma of the red wine vinegar.

In order to determine the possible significant differences between the amounts of these volatile compounds in the vinegar samples studied, a Multivariate Statistical Analysis of Variance (MANOVA, p < 0.05) was carried out, where the relative area of each compound, calculated as the area of the base peak of each compound with respect to the area of the base peak of the internal standard, would be the dependent variable, and the temperature, type of bacteria and the interaction between these two (type of bacteria-temperature) would be taken as the independent variable in each case. Table 4 shows the results from this analysis.

As can be seen, in the same way as for the low molecular weight phenolic compounds, most of the volatile compounds that were identified presented values of p < 0.05 and were therefore significantly affected by temperature. These were expected results, given that as compounds of a volatile nature and with a high vapor pressure, temperature would be a factor that a priori should be regarded as rather relevant. In fact, similar results had also been observed in previous studies with vinegars made from other matrices, as in the case of prickly pear vinegar [17].

Regarding the relationship between the type of bacteria and the content of volatile compounds, there was practically no significant variation in the content of volatiles in the vinegar samples studied. Other researchers have reported slight variations in the aromatic profile of rice vinegar that could be attributable to the type of bacteria used in the fermentation process [31], where bacteria of the genus Acetobacter proved to be somewhat more determinant or even predominant, as in the case of Zhejiang pink vinegar [32], where this genus was the main protagonist in its fermentation.

Finally, the interaction between temperature and acetic bacterial genus showed no correlation with regard to the production of virtually all volatile compounds. That is, all of the bacteria tested were equally affected by temperature changes in terms of their ability to produce volatile compounds.

Table 5 shows the mean relative areas of each of the volatile compounds, as well as their standard deviation, for all the vinegars produced at 30 °C and 37 °C and for those produced by fermentation using different bacteria.

It has been observed that, as a general rule, volatile compounds increased their average relative area in those cases in which fermentation had been conducted at lower temperatures, with a higher presence in those cases. It is worth noting the particular case of acid-type compounds, which, unlike the rest of the volatiles, were found to increase their content in the final vinegar when fermented at 37 °C and therefore, presented greater relative areas at higher acetification temperatures. Other authors such as [33] also observed this effect and assumed that it could possibly due to the metabolism of acetic acid bacteria, which produces a large amount of acetic acid and other organic acids during fermentation processes at elevated temperatures. Other compounds, such as γ-Butyrolactone or δ-Decalactone, which are derived from the organic acids produced during the vinegar production process, were found to also increase their presence at a fermentation temperature of 37 °C [34]. Other authors have detected increments of this type of compounds during the acetification process that seem to be linked to high temperatures, give that high temperatures favor changes in the content of organic acids [35].

Ethyl acetate, diethyl succinate and phenyl acetate, in the case of esters and acetates, and phenethyl alcohol, in the case of alcohols, were the volatile compounds with the greatest presence in the red wine vinegar produced at 30 °C. Other authors such as [36] observed that as the temperature of the process was increased, the concentration and the presence of this type of volatile compounds decreased notably.

The presence of esters and acetates in wine vinegars, which has been extensively demonstrated by numerous studies, contributes with floral and fruity aroma notes [37], providing a positive effect on the sensory characteristics, not only of this type of vinegars, but also of vinegars of different nature, such as cherry vinegars [38]. In the case of alcohols, they arise from the conversion of fermentable sugars by the bacteria during the fermentation process [39]. A high concentration of these compounds softens the flavor of the vinegars, by neutralizing the pungent effect of certain acids, such as acetic acid, which is the main one found in vinegars [40].

Finally, the data from the volatile analysis were subjected to multivariate statistical analysis (principal component analysis, PCA), where a total of 12 principal components (PC) were identified that explained 95.5% of the total variability between the samples (eigenvalues > 1). Figure 4 shows the distribution of all the vinegar samples on the plane defined by the principal components 1 and 2.

PCA on volatile compounds. Distribution of all the vinegar samples on the plane defined by the first two PCs. A 30/A 37: Acetobacter malorum at 30 °C and 37 °C, respectively; G 30/G 37: Gluconobacter oxydans at 30 °C and 37 °C, respectively; M 30/M 37: Mixture of bacteria at 30 °C and 37 °C, respectively

As can be seen, PC1 separated the vinegars produced at a temperature of 30 °C, with positive values for this component, from the vinegars produced at 37 °C, which were in the negative region of this principal component. PC1 was mainly related to esters and acetates, all of which presented positive values, with ethyl acetate, isobutyl acetate, ethyl butyrate and isoamyl acetate standing out among the latter. This confirms the greater presence of this type of compounds in the vinegars fermented at 30 °C, a fact that had already been confirmed through the MANOVA that had been conducted. On the other hand, PC2 was related to a great extent with certain acids such as octanoic acid, nonanoic acid or decanoic acid and with alcohols, including benzyl alcohol, p-ethylguaiacol and 4-ethylphenol.

In addition, and following the approach adopted for the study of the phenolic profiles, these data were also subjected to Cluster Analysis (CA) (Fig. 5). The analysis was based on Ward's method and the squared Euclidean distance was used as the metric for comparison. As expected, the vinegars were grouped according to their fermentation temperature, resulting in two groups that separated the vinegars fermented at 30 °C from those whose fermentation temperature was set at 37 °C. On the other hand, small subclusters of samples were registered that attended to the type of G/A/M bacteria, although this was not a variable that significantly affected the volatile compounds present in the samples, as previously mentioned.

Conclusion

We can therefore conclude that although the different strains of acetic acid bacteria had shown initially their resistance to high temperatures during the acetic fermentation process, the results obtained from our study have evidenced that when the surface culture acetification process was conducted at higher temperatures, the resulting vinegars presented poorer volatile profiles. With regard to their phenolic compounds content, anthocyanins, in particular, were confirmed to present significant temperature-dependent losses in all the cases. Tannins, on the other hand, increased independently from the fermentation temperature. With respect to the vinegar's content of low molecular weight polyphenols and furfurals, although the factor temperature was significant for a high number of compounds, no clear trend was observed. The strain of bacteria used did not prove to be a significant factor for practically none of the analytical parameters considered, although the mixture of bacteria from Sherry vinegar gave rise to vinegars with a higher total tannin content.

References

Alonso ÁM, Castro R, Rodriguez MC et al (2004) Study of the antioxidant power of brandies and vinegars derived from Sherry wines and correlation with their content in polyphenols. Food Res Int 37:715–721. https://doi.org/10.1016/j.foodres.2004.03.007

Tesfaye W, Morales ML, Garcia-Parrilla MC, Troncoso AM (2002) Wine vinegar: technology, authenticity and quality evaluation. Trends Food Sci Technol 13:12–21. https://doi.org/10.1016/S0924-2244(02)00023-7

Fregapane G, Rubio-Fernández H, Salvador M (2001) Influence of fermentation temperature on semi-continuous acetification for wine vinegar production. Eur Food Res Technol 213:62–66. https://doi.org/10.1007/s002170100348

Matsumoto N, Osumi N, Matsutani M et al (2021) Thermal adaptation of acetic acid bacteria for practical high-temperature vinegar fermentation. Biosci Biotechnol Biochem 85:1243–1251. https://doi.org/10.1093/bbb/zbab009

Mu J, Uehara T, Furuno T (2004) Effect of bamboo vinegar on regulation of germination and radicle growth of seed plants II: composition of moso bamboo vinegar at different collection temperature and its effects. J Wood Sci 50:470–476. https://doi.org/10.1007/s10086-003-0586-y

Tang H, Liang H, Song J et al (2019) Comparison of microbial community and metabolites in spontaneous fermentation of two types Daqu starter for traditional Chinese vinegar production. J Biosci Bioeng 128:307–315. https://doi.org/10.1016/j.jbiosc.2019.03.011

Perumpuli PABN, Watanabe T, Toyama H (2014) Identification and characterization of thermotolerant acetic acid bacteria strains isolated from coconut water vinegar in Sri Lanka. Biosci Biotechnol Biochem 78:533–541. https://doi.org/10.1080/09168451.2014.882758

Gullo M, Giudici P (2008) Acetic acid bacteria in traditional balsamic vinegar: phenotypic traits relevant for starter cultures selection. Int J Food Microbiol 125:46–53. https://doi.org/10.1016/j.ijfoodmicro.2007.11.076

Andreou V, Giannoglou M, Xanthou MZ et al (2023) Aging acceleration of balsamic vinegar applying micro-oxygenation technique. Food Chem 419:136077. https://doi.org/10.1016/j.foodchem.2023.136077

Lee J, Koo N, Min DB (2004) Reactive oxygen species, aging, and antioxidative nutraceuticals. Compr Rev Food Sci Food Saf 3:21–33. https://doi.org/10.1111/j.1541-4337.2004.tb00058.x

Sakanaka S, Tachibana Y, Okada Y (2005) Preparation and antioxidant properties of extracts of Japanese persimmon leaf tea (kakinoha-cha). Food Chem 89:569–575. https://doi.org/10.1016/j.foodchem.2004.03.013

Chanivet M, Durán-Guerrero E, Barroso CG, Castro R (2020) Suitability of alternative wood types other than American oak wood for the ageing of Sherry vinegar. Food Chem 316:126386. https://doi.org/10.1016/j.foodchem.2020.126386

Wang W, Ma Q, Zhang F et al (2023) Changes in bioactive and volatile aroma compounds in vinegar fermented in a rotary drum bioreactor. J Food Compos Anal 121:105345. https://doi.org/10.1016/j.jfca.2023.105345

Chen Y, Huang Y, Bai Y et al (2017) Effects of mixed cultures of Saccharomyces cerevisiae and Lactobacillus plantarum in alcoholic fermentation on the physicochemical and sensory properties of citrus vinegar. LWT 84:753–763. https://doi.org/10.1016/j.lwt.2017.06.032

Sharafi SM, Rasooli I, Beheshti-Maal K (2010) Isolation, characterization and optimization of indigenous acetic acid bacteria and evaluation of their preservation methods. Iran J Microbiol 2:41–48

Es-sbata I, Lakhlifi T, Yatim M et al (2021) Screening and molecular characterization of new thermo- and ethanol-tolerant Acetobacter malorum strains isolated from two biomes Moroccan cactus fruits. Biotechnol Appl Biochem 68:476–485. https://doi.org/10.1002/bab.1941

Es-sbata I, Castro R, Durán-Guerrero E et al (2022) Production of prickly pear (Opuntia ficus-indica) vinegar in submerged culture using Acetobacter malorum and Gluconobacter oxydans: study of volatile and polyphenolic composition. J Food Compos Anal 112:104699. https://doi.org/10.1016/j.jfca.2022.104699

Giusti MM, Wrolstad RE (2001) Anthocyanins. Characterization and measurement with UV–visible spectroscopy. In: Wrolstad RE, Acree TE, Decker EA et al (eds) Handbook of food analytical chemistry. Wiley, New York, pp 19–24

Zou B, Dong X, Ge Z et al (2014) Development of suitable standards for quantitative determination of persimmon phenol contents in Folin-Ciocalteu and vanillin assays. Eur Food Res Technol 239:385–391

Bruna-Maynou FJ, Castro R, Rodríguez-Dodero MC et al (2020) Flavored Sherry vinegar with citric notes: characterization and effect of ultrasound in the maceration of orange peels. Food Res Int 133:109165. https://doi.org/10.1016/j.foodres.2020.109165

Ndoye B, Lebecque S, Dubois-Dauphin R et al (2006) Thermoresistant properties of acetic acids bacteria isolated from tropical products of Sub-Saharan Africa and destined to industrial vinegar. Enzyme Microb Technol 39:916–923. https://doi.org/10.1016/j.enzmictec.2006.01.020

Zheng Y, Zhao C, Li X et al (2022) Kinetics of predominant microorganisms in the multi-microorganism solid-state fermentation of cereal vinegar. LWT 159:113209. https://doi.org/10.1016/j.lwt.2022.113209

Luzón-Quintana LM, Castro R, Durán-Guerrero E (2021) Biotechnological processes in fruit vinegar production. Foods 10:945. https://doi.org/10.3390/foods10050945

Saeki A, Theeragool G, Matsushita K et al (1997) Development of thermotolerant acetic acid bacteria useful for vinegar fermentation at higher temperatures t. Biosci Biotechnol Biochem 61:138–145

Hornedo-Ortega R, Álvarez-Fernández MA, Cerezo AB et al (2017) Influence of fermentation process on the anthocyanin composition of wine and vinegar elaborated from strawberry. J Food Sci 82:364–372. https://doi.org/10.1111/1750-3841.13624

Klopotek Y, Otto K, Böhm V (2005) Processing strawberries to different products alters contents of vitamin C, total phenolics, total anthocyanins, and antioxidant capacity. J Agric Food Chem 53:5640–5646. https://doi.org/10.1021/jf047947v

Cerezo AB, Cuevas E, Winterhalter P et al (2010) Anthocyanin composition in Cabernet Sauvignon red wine vinegar obtained by submerged acetification. Food Res Int 42:1577–1584

Ubeda C, Callejón RM, Hidalgo C et al (2013) Employment of different processes for the production of strawberry vinegars: effects on antioxidant activity, total phenols and monomeric anthocyanins. LWT Food Sci Technol 52:139–145. https://doi.org/10.1016/j.lwt.2012.04.021

Zou B, Wu J, Yu Y et al (2017) Evolution of the antioxidant capacity and phenolic contents of persimmon during fermentation. Food Sci Biotechnol 26:563–571. https://doi.org/10.1007/s10068-017-0099-x

Budak HN, Guzel-Seydim ZB (2010) Antioxidant activity and phenolic content of wine vinegars produced by two different techniques. J Sci Food Agric 90:2021–2026. https://doi.org/10.1002/jsfa.4047

Sun D, Li W, Luo L (2023) Deciphering the brewing process of Cantonese-style rice vinegar: main flavors, key physicochemical factors, and important microorganisms. Food Res Int 171:113068. https://doi.org/10.1016/j.foodres.2023.113068

Zhang L, Qin Z, Zhang L et al (2023) Dynamic changes of quality and flavor characterization of Zhejiang rosy vinegar during fermentation and aging based on untargeted metabolomics. Food Chem 404:134702. https://doi.org/10.1016/j.foodchem.2022.134702

Chen C, Wu S, Li Y et al (2022) Effects of different acetic acid bacteria strains on the bioactive compounds, volatile compounds and antioxidant activity of black tea vinegar. LWT Food Sci Technol 171:114131. https://doi.org/10.1016/j.lwt.2022.114131

Călugăr AM, Emilia Coldea T, Pop CR et al (2020) Evaluation of volatile compounds during ageing with oak chips and oak barrel of Muscat Ottonel wine. Processes 8:1000. https://doi.org/10.3390/pr8081000

Ferreira V, López R (2019) The actual and potential aroma of winemaking grapes. Biomolecules 9:818

Liu M, Yang K, Qi Y et al (2018) Fermentation temperature and the phenolic and aroma profile of persimmon wine. J Inst Brew 124:269–275. https://doi.org/10.1002/jib.497

Boffo EF, Tavares LA, Ferreira MMC, Ferreira AG (2009) Classification of Brazilian vinegars according to their 1H NMR spectra by pattern recognition analysis. LWT Food Sci Technol 42:1455–1460. https://doi.org/10.1016/j.lwt.2009.05.008

Niu Y, Zhang X, Xiao Z et al (2011) Characterization of odor-active compounds of various cherry wines by gas chromatography–mass spectrometry, gas chromatography–olfactometry and their correlation with sensory attributes. J Chromatogr B 879:2287–2293. https://doi.org/10.1016/j.jchromb.2011.06.015

Zhao S, Niu C, Yang X et al (2022) Roles of sunlight exposure on chemosensory characteristic of broad bean paste by untargeted profiling of volatile flavors and multivariate statistical analysis. Food Chem 381:132115. https://doi.org/10.1016/j.foodchem.2022.132115

Xu S, Ma Z, Chen Y et al (2022) Characterization of the flavor and nutritional value of coconut water vinegar based on metabolomics. Food Chem 369:130872. https://doi.org/10.1016/j.foodchem.2021.130872

Funding

Funding for open access publishing: Universidad de Cádiz/CBUA.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Compliance with ethics requirements

The authors declare this study was conducted in accordance with ethical guidelines and principles.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Chanivet, M., Es-sbata, I., Astola, A. et al. Thermotolerant acetic acid bacteria in the production of a red wine vinegar by surface culture at different temperatures: volatile and polyphenolic composition. Eur Food Res Technol (2024). https://doi.org/10.1007/s00217-024-04580-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00217-024-04580-2