Abstract

This study aimed to investigate the impact of varying proportions of dry bean powder on the rheological properties of oil-in-water emulsions. Emulsions were formulated utilizing xanthan gum or dry bean powder across a range of concentrations, including 1%, 3%, 5%, and 7%. Additionally, a control emulsion (CTR) was formulated using xanthan gum exclusively. The rheological properties of the resulting emulsions, both linear and nonlinear, were characterized. Moreover, the correlation between microstructural attributes and the interfacial rheological response within these emulsion systems was thoroughly examined. A prominent observation was the occurrence of shear thinning, characterized by a reduction in viscosity under applied shear stress. Notably, the control emulsion (CTR) displayed the lowest interfacial viscosity values, whereas emulsions incorporating increasing proportions of dry bean powder demonstrated a proportional rise in interfacial viscosity. The highest consistency coefficient and apparent viscosity was recorded in the 7%DB sample with a value of 3.23 Pa.sn and 0.56 Pa.s, respectively. This suggests that emulsions formulated with dry bean powder may yield a more resilient interfacial film, attributed to the protein content inherent in dry beans. The establishment of a viscoelastic interfacial layer facilitated by dry bean powder in appropriate concentrations significantly contributes to the long-term stability of the emulsion. Unraveling the intricate relationship between interfacial behaviors holds paramount importance in advocating for the utilization of dry bean powder as a plant-based protein source. In conclusion, the incorporation of dry bean powder enhances the formation of interfacial films in O/W emulsions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In recent times, an increasing demand among consumers for vegan options has emerged, driven by a desire for both veganism and sustainability, with the appeal of plant-based products—characterized by their cholesterol-free, antibiotic-free, and absence of potential microbial residues—contributing to this rising trend [1]. Concurrently, researchers have started to focus on the application of proteins as emulsifiers, intrigued by their interfacial activities and amphiphilic (hydrophilic and hydrophobic) properties. The surface-active nature of these proteins enhances their ability to bond with the surfaces of the droplets, leading to the formation of emulsions. This process, in turn, enhances the stability of resulting oil-in-water (o/w) emulsions [2].

Dry beans play a significant role in human nutrition, serving as a vital source of protein, dietary fiber, carbohydrates, vitamins, and minerals. They contribute substantially to dietary protein intake. Beyond their nutritional value, proteins in dry beans fulfill various roles in plant-based foods. These functions encompass hydration, surface activity, structural integrity, hydration-related properties, and certain sensory attributes. The importance of dry bean proteins extends to both human and animal nutrition, featuring water-soluble components (albumins) and dilute salt-soluble storage proteins (globulin) [3]. The utilization of dried bean powder offers versatile applications, particularly in the formulation of cookies, breads, and snacks enriched with zinc, iron, and fiber [4]. These plant protein-based products boast twice the protein content, catering to the expanding gluten-free market [5]. Additionally, they offer an extended shelf life, a valuable asset for both the food industry and retailers [6]. Furthermore, dry bean proteins hold promise in the plant protein ingredients market, given their low allergenicity in comparison to proteins from milk, eggs, peanuts, soy, and wheat [5]. Moreover, it's worth noting that dried beans are classified as non-genetically modified organisms (non-GMO) [7]. Numerous studies endorse the incorporation of dry bean protein into food products. Generally, hydrolyzed protein is recognized for its elevated concentration of phenolic compounds, resulting in heightened antioxidant activity. Additionally, hydrolyzed protein serves as a robust source of bioactive peptides, offering consumers various health benefits [8]. In a study by Los et al. [8], it was demonstrated that hydrolyzed bean protein samples exhibited comparable or superior emulsification and foaming capacity compared to soy protein samples, suggesting potential substitution possibilities. The findings from Zheng et al. [9] further support the prospective use of black bean protein hydrolysates in enhancing the shelf life of fat-rich foods, owing to their notable hydrophobicity and emulsifying properties. On the hand, in a previous study, researchers explored the impact of kidney bean protein isolates on the characteristics of gluten-free cakes made with starch. The incorporation of protein isolates led to heightened viscoelasticity in gluten-free muffin batters. This enhancement in viscoelastic properties enabled the dough to retain more gas bubbles, culminating in cakes that were not only more flexible but also exhibited a more aerated structure and increased volume [10].

As previously mentioned, existing studies on bean powder and protein lack insights into the structural aspects of O/W (oil-in-water) emulsions. Particularly, there is a dearth of information regarding the influence on linear and non-linear interfacial and bulk rheological behavior, with no prior study of interfacial rheology. Conversely, a comprehensive understanding of the interconnection between structure and function, as well as interactions among components at the O/W emulsion interface, can be gleaned by examining the nonlinear viscoelastic properties of these emulsions. Hence, this study aims to achieve the following objectives: (1) investigate the impact of O/W emulsions on the formation and microstructure of dry bean powder-based emulsions; (2) characterize the linear and nonlinear rheological properties exhibited by the resulting emulsions; and (3) explore the correlation between microstructure and interfacial rheological response within these emulsion systems. Considering the nutritional advantages identified in dry bean emulsion formulations, this research seeks to build upon existing knowledge by evaluating the influence of different ratio (1,3,5 and 7%) of dry bean powder on the quality attributes of the emulsions. Such insights are crucial, as they can significantly influence consumer acceptance of this food product.

Materials and methods

Materials and chemicals

Dry bean powder (NaturelKa/Turkey) was obtained from pre-cooked beans and its composition was 33.01% carbohydrate, 2.9% sugar, 34.40% fiber, 19.3% protein and 1.6% fat. Xanthan gum (Sigma-Aldrich/Germany) and all chemicals used in the study were of analytical purity. Sunflower oil (Yudum/Türkiye) was obtained from local producers.

Methods

Preparation of emulsions

Within the scope of the study, 0.1% xanthan gum was used in all water phase media including the control group emulsion. While the control group was prepared with only xanthan gum, the research samples were prepared with xanthan gum and four different concentrations (1, 3, 5 and 7%) of dry bean powder. Emulsions were prepared with ultra-turrax (IKA, T25, Germany) using the aqueous phase and sunflower oil in a ratio of 1/1.

Physicochemical properties

The color properties of the emulsions prepared 4 different concentrations of dry bean and control sample were determined by L*, a* and b* values with a color analyzer (Konica-Minolta, CR5, Japan). Conductivity values of the emulsion samples were determined by TDS Meter (HQ40d, Hach, Loveland, Colorado, US) at a constant temperature of 25 ℃, while pH values were measured by table type pH-meter (WTW, Inolab).

Rheological properties

Steady-state rheological properties

Rheological measurements of the prepared emulsion samples were performed with a Peltier-temperature controlled rheometer (Thermo HAAKE, Mars III, Karlsruhe, Germany). During the analysis, P35TiL (parallel plate configuration) probe head was used (1 mm gap size) and 1 ml of sample was added to the device for each analysis. All analyses were carried out at a constant temperature of 25 ℃ at a shear rate range of 0.1–100 s−1. As a result of the analysis, the apparent viscosity, shear rate and shear stress values were determined by RheoWin Data Manager (RheoWin Pro 4.0, HAAKE, Karlsruhe, Germany). In addition, consistency coefficient (K) and flow behavior index (n) values were determined in accordance with the Herschel-Bulkley model.

Dynamic shear rheological properties

The dynamic shear rheological properties of the emulsion samples were analyzed in a rheometer (Thermo HAAKE, Mars III, Karlsruhe, Germany). The viscoelastic behavior of the emulsion samples was investigated in the frequency range of 0.1–10 Hz. The analysis was performed with oscillatory stress of 0.2 Pa and the storage modulus (G') and loss modulus (G") values were evaluated by RheoWin Data Manager (RheoWin Pro 4.0, HAAKE, Karlsruhe, Germany).

Interfacial rheological properties

Rheometer (Thermo HAAKE, Mars III, Karlsruhe, Germany) and bicone probe (BC 68/5Ti) were used for interfacial rheological measurements. In the study to determine the interfacial effects of dry bean powder in emulsion media, sample preparation is carried out in 2 stages. First, the dry material included in the emulsion medium was weighed and mixed with water until homogeneous as described in the emulsion preparation stage. Then, 100 ml of this mixture was added to the apparatus used in interfacial rheology measurements in the device and the contact point was determined with the probe head. The contact point should be calculated by repeating each analysis and then sunflower oil should be added to the top. In this way, the probe remains between the water and oil phase and the changes occurring at this point can be measured. During the measurements, interfacial steady and dynamic frequency measurements were performed. The interfacial steady analysis was performed with a measurement of approximately 1 h in the range of 1–100 s−1. Interfacial frequency sweep test was performed in the linear region γ = 0.1–10 rad s−1 and ω = 0.1% [11].

Optical microscopy

Morphological images of the emulsions were obtained at 10 × magnification using an optical microscope (Leica, DM500, USA) to examine the structural forms of the emulsions.

Statistical analysis

One-way analysis of variance (ANOVA) was used to evaluate the analysis results of the emulsion samples and Tukey's HSD test was used to determine the differences between the means. Statistical analyses were performed with Minitab v19.1.1 (Minitab Ltd., Coventry, UK) software.

Results and discussion

Physicochemical properties

Physicochemical analyses are valuable in emulsion systems. Especially pH and conductivity, which are associated with emulsion stability, are important in terms of emulsion properties, while color analysis is also important because it affects sensory preferences in the final product. The physicochemical properties of dry bean emulsions prepared at different concentrations and the control emulsion were given in Table 1. In color evaluations, L* value corresponds to blackness-whiteness indicators and the product is expressed as whiter-brighter as the analysis result approaches 100. While the emulsions containing different concentrations of dry bean powder with 1% and 3% dry bean powder had the same results with the control group, it was observed that the addition of dry bean powder increased the L* value in emulsions. The a* value, where negative values are indicative of green color, was found to be negative in all emulsions, while the increase in dry bean concentration was insignificant (p > 0.05). b* value, where −b* is indicative of blue color and + b* value is indicative of yellow color. An increase in the yellowness value of the emulsions was observed with the addition of dry bean.

One of the important factors in emulsion stabilization is pH. pH changes make significant differences in emulsion structure, especially at low pH it is very difficult to ensure stability [12]. It is also known that the components used in the preparation of emulsions are effective in pH changes. Especially in protein stabilized emulsions, pH changes are known to be effective [13]. The pH values of the emulsion samples prepared with dry bean powder ranged between 7.16 and 8.57. Dry bean powder added to the model emulsion medium decreased the pH value, but the increase in dry bean powder concentration did not affect the pH value (p > 0.05).

Changes in conductivity values provide information about the properties of emulsions [14]. In the emulsion samples prepared with dry bean powder, the lowest conductivity value was 137.13 µs/cm in the control sample and the highest value was 896.67 µs/cm in the 7%DB sample. In oil–water emulsions, the aqueous phase is responsible for the conductivity because oils do not have conductivity. Especially the protein composition and amount in the aqueous phase can be important in the conductivity increase [15]. In our study, conductivity increased with the increase in the amount of dry bean powder added to the emulsion formula, which was associated with the increase in the amount of protein included in the structure due to the increase in the amount of dry bean in the emulsion. On the other hand, conductivity changes are also associated with changes in droplet size [16]. The optical microscope results show that the decrease in droplet size is parallel to the increase in conductivity.

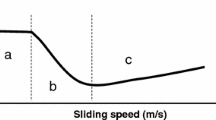

Steady shear properties

Rheological measurements are valuable in characterizing food emulsions and determining their post-formation properties [17]. The consistency coefficient (K) and flow behaviour index (n) and apparent viscosity (ƞ50) values of the emulsions containing different proportions of dry bean powder and control group were presented in Table 2. All samples were evaluated in accordance with the Herschel-Bulkley model (R2:0.99). The highest consistency coefficient value was found in the 7%DB sample with a value of 3.23 Pa.sn, while the increase in dry bean powder concentration increased the K value. On the other hand, this value of control, 1%DB and 3%DB samples was found to be statistically insignificant (p > 0.05). While the flow behaviour index values of the samples were determined in the range of 0.34–0.54, it was determined that 5%DB and 7%DB emulsions had the same n value. A unitless flow behaviour index (n) value below 1 indicates that the analyzed liquid shows pseudoplastic shear-thinning behavior [18]. This result supports the result obtained with shear rate and sheer stress graph. Apparent viscosity value was determined in parallel with the consistency coefficient value. Increasing the concentration of dry bean powder in the emulsions increased the viscosity value, while there was no difference between 1%DB and control sample (p > 0.05). The highest viscosity value was determined in 7%DB sample with 0.56 Pa.s.

Figure 1 shows the apparent viscosity and shear stress values of emulsions varying in the 0–100 s−1 shear rate range. Increasing shear stress value against increasing shear rate indicates that emulsions exhibit non-Newtonian flow type and pseudoplastic flow behavior [19]. In emulsions, increasing shear rate decreased the apparent viscosity and increased the shear stress value. Investigation of the changes in apparent viscosity at varying shear rates is important because low shear rate viscosity values are significant in sensory evaluations [20] and high shear rate values are significant in industrial production applications [21]. The decrease in apparent viscosity is explained by the fact that the macromolecules in the emulsion flow in a certain direction with increasing shear rate and undergo structural disruption [21].

Dynamic rheological properties

Oscillation tests are applied because the properties of food emulsions cannot be determined exactly by viscosity results alone and are sensitive to all changes [22, 23]. In this context, dynamic shear rheological properties of all emulsions prepared in the study were determined. Viscoelastic behaviors of emulsions were presented in Fig. 2. Of the values obtained as a result of the analysis, G′ is defined as the energy stored and is a measure of the deformation cycle that occurs during the analysis, while G″ is expressed as the energy lost in the deformation cycle [24]. The results obtained with the analyzes performed after the frequency sweep tests are shown in the graph against the In ꞷ value. All emulsion samples showed an increase in elastic modulus (G′) and viscous modulus (G″) with increasing angular frequency value, and these values also increased with the increase in the proportion of dry bean powder in the emulsion. In all emulsion samples, the evaluation based on frequency dependence reveals that the elastic modulus (G′) consistently exceeds the viscous modulus (G″) in magnitude. The results were interpreted as viscoelastic solid behavior of the emulsions. In addition, the positive trend in the graphs provides weak gel-like behavior of the samples [25]. This situation is defined as an indicator of a strong, stable emulsion in emulsion type structures [26], and it is expected that the elastic and viscous modulus values will give parallel results in the graphs obtained for the continuity of this effect [26].

Interfacial rheology

While there exist several methods for evaluating the adsorption behavior of surface-active materials, interfacial shear rheology stands out as a contemporary measurement approach. This innovative technique operates on the fundamental principle of inducing shear stress parallel to the interface by placing a probe at the interface and subsequently assessing the viscoelastic response [27]. The understanding of the viscoelastic structure at the interface plays a crucial role in deciphering the adsorption kinetics of the surfactant that constitutes the interface, as well as the robustness of the resulting film [28]. Interfacial viscoelasticity undergoes alterations influenced by diffusion, adsorption, conformation change, realignment, and intermolecular interactions among molecular chains [29]. Consequently, tracking changes in interfacial modulus and viscosity serves as a method for the behavior of the formed adsorbed layer. To investigate and compare the structural reorganization of emulsions with varying ratios of dry bean powder at the oil/water interface, shear rate-dependent interfacial viscosity tests were conducted, as illustrated in Fig. 3. As evident in this figure, the interfacial viscosity decreased with increasing shear rate. Besides, in all examined samples, there was a noticeable manifestation of shear thinning, a phenomenon characterized by a reduction in viscosity as a response to applied shear stress. The control group emulsion (CTR) exhibited the lowest interfacial viscosity values, whereas the interfacial viscosity increased proportionally with the augmentation of dry bean powder in the emulsion medium. Specifically, the emulsion with 1% dry bean powder recorded a lower interfacial viscosity compared to those containing 3–5% and 7% dry bean powder. This suggests that emulsions formulated with dry bean powder potentially generate a more robust interfacial film attributed to the protein derived from the dry beans.

Frequency-dependent changes of the films formed in the O/W interface layer of emulsions prepared with dry bean powder as a function of changing ratios were examined and the results were presented in Fig. 4A and B. The values of G' and G'' for the films formed at the O/W interface layer exhibited frequency-dependent fluctuations. The emulsion samples incorporating 7% dry bean powder displayed higher Gi' values compared to the control sample. The escalation in the proportion of dry bean powder resulted in an augmentation of both Gi' and Gi'' values. A noteworthy observation was the deviation from linearity as high frequencies increase, accompanied by a significant rise in the Gi'' value, while the Gi' value initially displayed an ascending trend followed by a decline. It's crucial to note that the surpassing of Gi'' over Gi' at a particular frequency doesn't necessarily indicate interfacial layer rupture. This phenomenon is attributed to the collective inertia effect, where significant mass dispersion occurs at higher frequencies [30]. In interfaces with a low complex modulus, escalating deformation frequencies lead to the dominance of rheological behavior by the bulk phase, especially for probe geometries with substantial contact areas with the bulk phase, such as a bicone Sánchez-Puga et al. [31]. Moreover, the interfacial shear modulus exhibited significantly reduced magnitudes in the control sample and at lower proportions of dry bean powder (1–3%). This phenomenon can be attributed to the formation of weak viscoelastic interfacial layers characterized by an insufficient number of complexes. The narrow frequency ranges of Gi' in these conditions was a result of noise effects at low frequencies and inertia effects at high frequencies. This observation aligns with the findings of Jin et al. [29] and Feng et al. [32].

In summary, the extent of the viscoelastic response in the interfacial layer aligns well with the stability levels of emulsions crafted with varying proportions of dry bean powder. The development of a viscoelastic interfacial layer, achieved through appropriate ratios of dry bean powder, significantly contributes to the prolonged stability of the emulsion. The impact of increasing the dry bean powder proportion on viscoelasticity of the interfacial layer of the emulsions demonstrated a coherent pattern. This is consistent with the findings of Imperiali et al. [33], which corroborate that interfaces possessing high viscosity or elasticity have the potential to impede flocculation, thereby enhancing the optimal stability of the interface.

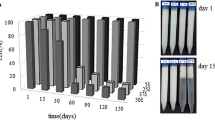

Optical properties

Optical microscope images of dry bean powder emulsions prepared within the scope of the study were given in Fig. 5. It is seen that the droplet sizes decrease with the increase in dry bean powder concentration in the emulsion medium and tighter emulsions are observed. This can be attributed to the emulsion formation thanks to the protein and fibers in the structure of dry bean powder and the oil–water binding capacity of the powder. As the concentration of dry bean powder increased, the water–oil binding and emulsion formation capacity increased and this increase also increased the emulsion viscosity and conductivity values. In terms of optical properties, this can be attributed to the smaller droplets and smaller droplet size, especially in the oil form [34]. The formation of more stable and durable emulsions can be supported by droplet size reduction. The increase in dry bean powder in the emulsion leads to emulsions with smaller droplets and this reduction in droplet size can lead to more favorable results in the storage process [35].

Conclusion

This study investigated the influence of varying dry bean powder ratios (1%, 3%, 5%, and 7%) in emulsions containing xanthan gum through comprehensive analyses including pH, conductivity, color, optical properties, and rheological assessments (steady, dynamic, and interfacial). Results revealed that, except for the 1% ratio which exhibited behavior similar to the control, an increase in dry bean powder concentration notably impacted analysis outcomes across all other ratios. Emulsions with 7% dry bean powder exhibited superior properties, indicating the effectiveness of this readily available and economical ingredient in forming stable emulsions. The method employed proved to be an effective approach for evaluating interfacial analysis results. Given the limited literature on the emulsion-forming behavior of legume powders and the determination of resulting properties, this study offers valuable insights. Furthermore, it represents a pioneering effort towards diversifying gluten-free, vegan/vegetarian product options within the food emulsion category. Future research avenues may explore additional aspects such as gelation and the effects on the digestive system associated with dry bean powder emulsions.

Data availability

The data supporting the findings of this study will be available upon a reasonable request.

References

Kopplin CS, Rausch TM (2022) Above and beyond meat: the role of consumers’ dietary behavior for the purchase of plant-based food substitutes. RMS 16(5):1335–1364

McClements DJ (2004) Protein-stabilized emulsions. Curr Opin Colloid Interface Sci 9(5):305–313

Sathe SK (2002) Dry Bean Protein Functionality. Crit Rev Biotechnol 22(2):175–223

Bento JAC et al (2021) Factors affecting the cooking quality of stored carioca beans (Phaseolus vulgaris). Ital J Food Sci 33(4):43–56

Ferreira KC et al (2022) Dry bean proteins: Extraction methods, functionality, and application in products for human consumption. Cereal Chem 99(1):67–77

Bassinello PZ et al (2020) Nutritional value of gluten-free rice and bean based cake mix. Ciência Rural 50:5

Alfaro-Diaz A et al (2021) Techno-functional properties of thermally treated black bean protein concentrate generated through ultrafiltration process. Lwt 136:110296

Los FGB et al (2020) Enzymatic hydrolysis of Carioca bean (Phaseolus vulgaris L.) protein as an alternative to commercially rejected grains. LWT 125:109191

Zheng Z et al (2019) Physicochemical and antioxidative characteristics of black bean protein hydrolysates obtained from different enzymes. Food Hydrocolloids 97:105222

Shevkani K, Singh N (2014) Influence of kidney bean, field pea and amaranth protein isolates on the characteristics of starch-based gluten-free muffins. Int J Food Sci Technol 49(10):2237–2244

Baldursdottir SG et al (2010) Adsorption of proteins at the oil/water interface—Observation of protein adsorption by interfacial shear stress measurements. Colloids Surf, B 79(1):41–46

Dille MJ, Draget KI (2021) Chewable Gelatin Emulsions for Oral Lipid Delivery: Elimination of Gastric Coalescence with κ-Carrageenan. Eur J Lipid Sci Technol 123(2):2000282

Hu J et al (2020) Influence of pH on property and lipolysis behavior of cinnamaldehyde conjugated chitosan-stabilized emulsions. Int J Biol Macromol 161:587–595

Kato A et al (1985) Determination of emulsifying properties of some proteins by conductivity measurements. J Food Sci 50(1):56–58

Al-Malah K, Azzam M, Omari R (2000) Emulsifying properties of BSA in different vegetable oil emulsions using conductivity technique. Food Hydrocolloids 14(5):485–490

Mcclements DJ (2007) Critical review of techniques and methodologies for characterization of emulsion stability. Crit Rev Food Sci Nutr 47(7):611–649

Chung C et al (2018) Impact of oil droplet concentration on the optical, rheological, and stability characteristics of O/W emulsions stabilized with plant-based surfactant: Potential application as non-dairy creamers. Food Res Int 105:913–919

Kumar L et al (2018) The effects of dairy ingredients on the pasting, textural, rheological, freeze-thaw properties and swelling behaviour of oat starch. Food Chem 245:518–524

Garcia-Diaz S et al (2016) Effects of CaCO3 treatment on the morphology, crystallinity, rheology and hydrolysis of gelatinized maize starch dispersions. Food Chem 207:139–147

Morris E, Taylor L (1983) Oral perception of fluid viscosity. Wiley, Hoboken, NJ

Dakia PA et al (2008) Composition and physicochemical properties of locust bean gum extracted from whole seeds by acid or water dehulling pre-treatment. Food Hydrocolloids 22(5):807–818

Niu F et al (2016) Ovalbumin/gum arabic-stabilized emulsion: Rheology, emulsion characteristics, and Raman spectroscopic study. Food Hydrocolloids 52:607–614

Steffe JF (1996) Rheological methods in food process engineering. Freeman press, Dallas, TX

Qiu S et al (2015) Effects of corn fiber gum (CFG) on the pasting and thermal behaviors of maize starch. Carbohyd Polym 115:246–252

Sun D, Yoo B (2015) Effect of tapioca starch addition on rheological, thermal, and gelling properties of rice starch. LWT-Food Sci Technol 64(1):205–211

Brummer R (2006) Rheology essentials of cosmetic and food emulsions. Springer, Berlin

Miller R, Liggieri L (2009) Interfacial rheology. CRC Press, Boca Raton, FL

Gul O et al (2023) Influence of pH and ionic strength on the bulk and interfacial rheology and technofunctional properties of hazelnut meal protein isolate. Food Res Int 169:112906

Jin Q et al (2017) A comparison of corn fiber gum, hydrophobically modified starch, gum arabic and soybean soluble polysaccharide: Interfacial dynamics, viscoelastic response at oil/water interfaces and emulsion stabilization mechanisms. Food Hydrocolloids 70:329–344

Jung J-M, Gunes DZ, Mezzenga R (2010) Interfacial activity and interfacial shear rheology of native β-lactoglobulin monomers and their heat-induced fibers. Langmuir 26(19):15366–15375

Sánchez-Puga P et al (2019) BiconeDrag—A data processing application for the oscillating conical bob interfacial shear rheometer. Comput Phys Commun 239:184–196

Feng T et al (2021) Plant protein-based antioxidant Pickering emulsions and high internal phase Pickering emulsions against broad pH range and high ionic strength: effects of interfacial rheology and microstructure. LWT 150:111953

Imperiali L et al (2012) Interfacial rheology and structure of tiled graphene oxide sheets. Langmuir 28(21):7990–8000

Pal R (1996) Effect of droplet size on the rheology of emulsions. AIChE J 42(11):3181–3190

Li K et al (2020) Use of high-intensity ultrasound to improve emulsifying properties of chicken myofibrillar protein and enhance the rheological properties and stability of the emulsion. Food Hydrocolloids 98:105275

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declared no potential conflicts of interest with respect to this research.

Compliance with Ethics requirements

This article does not involve any research conducted on human or animal subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Aslan Türker, D., Göksel Saraç, M. & Doğan, M. Investigating the interfacial and bulk rheological properties of emulsions containing dry bean powder. Eur Food Res Technol (2024). https://doi.org/10.1007/s00217-024-04566-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00217-024-04566-0