Abstract

Edible insects are a promising and sustainable food source for humans due to their low environmental footprint, high feed conversion ratio, and high protein content. Furthermore, the nutritional profile of the edible insects can be modified depending on the provided diet. The aim of this study was to evaluate the growth performance, proximate composition, and ellagic acid accumulation in Tenebrio molitor larvae fed on corn flour media enriched with pomegranate peel. Corn flour and pomegranate peel were mixed in a 1:1 ratio (w/w) (PCM) and 50 T. molitor larvae were added to each jar. After 12 days of rearing, the weight of T. molitor larvae fed on PCM and the control increased by 88.35% and 58.6%, respectively, compared to their initial values. An increase in carbohydrate, protein and ash contents, along with a decrease in lipid content, was observed in the control diet after 12 days of feeding compared to the initial larvae. Conversely, the PCM diet exhibited an increase in ash and carbohydrate contents and a decrease in lipid and protein contents after 12 days of feeding compared to the initial larvae. Total phenolic content (TPC) of T. molitor larvae did not significantly vary when fed with the control group, while it increased on the fourth and twelfth days for larvae fed with the PCM diet. The CUPRAC antioxidant activity of larvae also increased on the fourth day of feeding on the PCM diet. Ellagic acid was not detected in larvae fed with control and initially, it accumulated in T. molitor larvae fed with PCM after 8 and 12 days of rearing, with concentrations of 92.54 and 115.6 µg/g larvae, respectively. This study highlights the importance of diet in changing the phenolic profile of T. molitor larvae, which can be used as a functional food ingredient to obtain value-added products from agricultural wastes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Consumption of insects by human, known as entomophagy, is practiced in many regions such as Asia, Africa, and Latin America. Recently, the use of edible insects as human food has received increasing attention, particularly from the Food and Agricultural Organization of the United Nations (FAO), which has recommended the use of some insects as a sustainable alternative to traditional livestock. Insects are rich in high-quality proteins, polyunsaturated fatty acids, fibers and some micronutrients [1, 2]. Additionally, insects have a high feed conversion ratio, a low ecological footprint, and are less land-dependent than livestock production. More than 1500 edible insect species are consumed all over the world, either as whole insects or as insect flour for incorporation into food products, primarily for their protein content [3]. However, the exploration of other ways to utilize insects has been scarcely considered. The minor compounds in insects may include bioactive compounds, which could be valuable in determining the potential use of insects to produce functional insect-based food products [4, 5].

Tenebrio molitor, also known as mealworm, is a favorable candidate for insect rearing due to its high protein content, well-balanced amino acid profile, efficient feed conversion ratio, lower greenhouse gas emissions, lower water consumption, less land use, and ability to consume organic by-products [6]. T. molitor larvae can be grown exclusively on wheat bran; however, their survival rate, development time, larval weight and nutritional profile can be influenced by provided diets. Various organic wastes, such as banana peels, watermelon rinds, broiler’s eggshells, seed meals (e.g., flax seed, chia seed, hemp seed and rapeseed), olive pomace, carrot pomace, potato peels, spent grains, beet molasses, beer yeast, bread and cookie remains have been studied to modify the nutritional composition of the larvae, to increase the larval weight and survival rate, decrease the development time, and lower production costs to make them more feasible [1, 7,8,9,10]. Additionally, antioxidant capacity of T. molitor larvae was investigated by Liu et al. [6] who fed the larvae with orange, red cabbage and carrot as a source of antioxidants. Navarro del Hierro et al. [3] investigated the antioxidant activity of T. molitor larvae extracts obtained from different extraction methods. Baek et al. [11] examined the effects of processing methods on the antioxidant activity of T. molitor. In another study, carob pods were used as feeding substrate to evaluate the effects on the growth, nutritional value and antioxidant activity of T. molitor larvae [12]. However, the investigation of the phenolic composition and the accumulation of phenolics in T. molitor larvae depending on the provided diet is limited.

Pomegranate is a popular fruit consumed worldwide due to its bioactive and nutritional properties. Pomegranate peel accounts for approximately 50% of its total weight, considered a by-product after juice processing in the food industry [13]. Pomegranate peels contain a high amount of polyphenolic compounds, primarily rich in ellagitannins such as punicalagin, punicalin, tannic acid, and ellagic acid [14]. Valorization of pomegranate peel provides a low-cost substrate for obtaining bioactive substances and also helps in addressing pollution problems. Efficient recovery of nutrients and phenolic compounds from substrate can be used to create high-value products from agro-industrial waste. In this study, we hypothesize that the T. molitor larvae can accumulate phenolic compounds found in pomegranate peel, primarily ellagic acid, and the majority of the nutrients found in corn flour will be recovered by larvae. Furthermore, the study investigates the growth performance, proximate composition and phenolic profile of T. molitor larvae before and after rearing.

Materials and methods

Materials

T. molitor larvae (3rd instar) were purchased from Mira Canlı Hayvan ve Böcek Turizm Inşaat Tarım Sanayi Co. (Antalya, Turkiye). Pomegranate peel, collected after concentrated juice processing, was kindly provided by Serdar Orel, Targid Food and Agricultural Products Industry and Trade Co. (Mersin, Türkiye). Corn flour was purchased from a local grocery market in Istanbul, Türkiye. All chemicals used for proximate analysis were of analytical grade and purchased from Sigma–Aldrich (Steinheim, Germany). Chemicals for HPLC and UPLC–ESI-QqQMS/MS analysis were of high purity and also provided by Sigma–Aldrich (Steinheim, Germany).

Feeding media preparation

Pomegranate peel was dried using a freeze dryer (Teknosem, Istanbul, Türkiye) for 24 h at 0.001 mBar (− 55 °C). The dried pomegranate peel was finely ground to a particle size of < 200 μm using a stainless-steel mill (IKA, Wilmington, North Carolina, USA) and then stored at − 20 ºC for further analysis. A total of 25 g of corn flour and pomegranate peel were mixed in different ratios (1:1, 1:2 and 1:4, w/w), and then weighed into glass jars with perforated lids to enable the transfer of moisture and gas during larval rearing. The moisture content was adjusted to 40% (w/w) with distilled water and a cup of water was added to the incubator to prevent surface drying. Corn flour was used as the control.

Larval rearing

In each glass jar, 50 T. molitor larvae were added and incubated in darkness at 30 ºC for 12 days. Twelve jars were prepared for each diet under the same conditions. After interval times (0, 4, 8, and 12 days), the jars were removed from the incubator, and the larvae were separated from the residual feed using forceps. To remove the residual substrate, the larvae were rinsed with distilled water and dried with paper towels. First, wet weights and the number of larvae were determined, and then the larvae and spent feed were stored at – 20 ºC for further analysis.

Growth performance of T. molitor larvae

The survival rate was calculated as the number of live larvae at the end of each interval (0, 4, 8 and 12 days) divided by the initial larvae number (exactly 50 larvae), multiplied by 100. Weight gain was determined by subtracting the final larval weight at each interval from the initial larval weight. The length, width, and thickness of 10 fresh larvae were measured using a digital caliper, and their volume was calculated by multiplying the length, width, and thickness of the larvae.

Physicochemical analysis of T. molitor larvae

The chemical composition of T. molitor larvae was determined during rearing. Larval moisture content was measured using gravimetric analysis based on AOAC Method #930.15 [15] with some modifications. To prevent any deterioration of phenolic compounds, the larvae were dehydrated using a freeze dryer (Teknosem, Istanbul, Türkiye) for 18 h at 0.001 mBar (− 55 ºC). The freeze-dried larvae were then finely ground using a porcelain mortar, and the ground larvae were used for ash, protein and lipid analysis. The ash content was determined using a gravimetric method outlined in AOAC Method #942.05 [15]. Larvae samples were weighted into crucibles and carbonized using a hot plate. The crucibles were then placed in a muffle furnace at 550 ºC overnight to ensure that all impurities on the surface of crucible were burnt off. Lipid content was assessed using the Soxhlet method, following the procedure described by Mancini et al. [16], with petroleum ether as the solvent. Crude protein content was quantified using the Kjeldahl method [15]. The protein content of T. molitor larvae was calculated by multiplying the nitrogen amount determined after Kjeldahl analysis by a conversion factor of 4.76, accounting for the presence of non-protein nitrogen content in the larvae [6, 17]. To determine the carbohydrate content of the larvae, the weights of lipids, proteins, and ash were subtracted from the total weight of dried larvae [18].

Extraction of phenolic compounds

Phenolic compounds found in both larvae and spent feed were extracted using the method of Andreadis et al. [19] with some modifications. Specifically, 1.5 mL and 5 mL of a methanol/water/formic acid solution (80/20/0.1; v/v) was added to 0.1 g of grounded freeze-dried larva and 1 g of freeze-dried spent feed in 15 mL falcon tubes. These tubes were then placed in an ultrasonic bath (Azakli, Turkey) for 30 min at room temperature. Subsequently, the sample mixture was centrifuged at 2500×g for 10 min at 4 ºC, and the resulting supernatant was collected. The supernatants were further filtered using Whatman No.1 filter paper (Springfield Mill, Maidstone Kent, UK) and stored at – 20 ºC for subsequent analyses.

Total phenolic content

The total phenolic content (TPC) of methanolic extracts was determined using the Folin–Ciocalteau method [20]. To perform this analysis, 1.5 mL of Folin–Ciocalteau reagent were added to 200 µL of extracts or standards and thoroughly mixed. After a 6-min incubation, 1.2 mL of sodium carbonate (Na2CO3, 7.5%, w/v) was added, and the mixture was left to incubate in the dark at room temperature for 90 min. The absorbance of the solution was measured using a spectrophotometer (VWR, UV-3100PC, Radnor, USA) at 765 nm. The TPC results were expressed in mg Gallic Acid Equivalents (GAE) per g of dry matter (dm), based on the prepared standard curve (linear range: 10–400 mg/kg, R2 = 0.9938).

Antioxidant activity

The DPPH (2,2-diphenyl-1-picrylhydrazyl) free radical scavenging activity was determined using the procedure described by Rai et al. [21]. To assess the antioxidant activity, 2 mL, 0.1 mM solution of DPPH in methanol was added to 100 μL of the sample or standard. The mixture was then mixed for 10 s, and left in the dark for 30 min at room temperature. The absorbance was measured at 517 nm using a spectrophotometer. Results were expressed in terms of mg of Trolox Equivalents (TE) per g of dm based on the Trolox standard curve (linear range: 10–200 mg/kg, R2 = 0.9915). The CUPRAC (copper reducing antioxidant capacity) method was performed as described by Apak et al. [22]. A 100 μL of extract was mixed with 1 mL of CuCl2 solution (0.01 mM), 1 mL of Neocuproine solution (7.5 mM), 1 mL of ammonium acetate buffer (pH 7.0, 1.0 M) and 1 mL of distilled water. The mixture was incubated for 30 min in the dark at room temperature, and then the absorbance was measured at 450 nm using a spectrophotometer. The results were expressed in terms of mg of TE per g dm based on the prepared Trolox standard curve (linear range:10–600 mg/kg, R2 = 0.9989).

Quantification and identification of phenolic compounds

The amount of phenolic compounds in both larvae and spent feed was determined using high-performance liquid chromatography (HPLC, Waters 2695, W600 Waters, Milford, MA, USA), following the method described by Bino et al. [23]. The separation of phenolic compounds was carried out on a supelcosil LC-18 column (25 cm × 4.60 mm, 5-µm) (Sigma–Aldrich; Steinheim, Germany) with a mobile phase consisting of solvent A (Milli-Q water with 0.1% (v/v) trifluoroacetic acid (TFA)) and solvent B (acetonitrile with 0.1% (v/v) TFA) at a flow rate of 1 mL/min. The samples were injected in a volume of 10 µL, and detection was performed at 280 nm for gallic acid, ellagic acid and its derivatives, 312 nm for m-coumaric acid, and 360 nm for ellagitannin derivatives. Gallic acid (linear range: 0.1–200 mg/kg, R2 = 0.9938), ellagic acid (linear range: 0.5–200 mg/kg, R2 = 0.9901), and m-coumaric acid (linear range: 0.1–200 mg/kg, R2 = 0.9926) were quantified using available standards. However, the concentration of ellagic acid derivatives and ellagitannin derivatives, which were identified based on UV-spectra and m/z values from literature, were calculated as ellagic acid equivalents. The concentrations were expressed as μg per g dm for all identified phenolic compounds.

The phenolic profile of both the larvae and spent feed was identified based on the method described by Catalkaya et al. [24] using an ultra-performance liquid chromatography coupled with triple quadrupole mass spectrometry equipped with an electrospray ionization source (UPLC-ESI-QqQMS/MS, Waters Co., Milford, MA, USA). In accordance with the method, extracts from larvae and spent feed were filtered through a 0.22 μm membrane filter, and then 5 μL of the extracts were injected onto an Acquity HSS T3 C18 column (2.1 mm × 100 mm, 1.8 μm). The column temperature and autosampler temperature were set at 45 °C and 10 °C, respectively. The mobile phase consisted of eluent A (Ultrapure water:formic acid, 100:0.1, v/v) and eluent B (acetonitrile:formic acid, 100:0.1, v/v). The linear gradient program was as follows: 0 min, 95% A; 0–6.48 min, 65%A; 6.48–6.77 min, 25%A; 6.77–7.06 min, 65% A; 7.06–7.20 min, 95% A; 7.20–8.50 min, 95% A. Both positive and negative ionization modes were used with the following parameters: 600 °C for desolvation temperature; 150 °C for ion source temperature; 3.5 kV for capillary voltage; 1000 L/h for desolvation gas flow rate; and 50 L/h for cone gas flow rate. The cone and collision voltages were optimized by adding authentic standards of the phenolic compounds to the system. Data acquisition and analysis were conducted using Waters MassLynx 4.1 software (Waters Co.). Phenolic compounds in the larvae and spent feed were identified by comparing obtained ions with available standards or mass data from literature.

Statistical analysis

The analytical experiments and feeding trials were performed thrice, and the impact of different treatments on the measured parameters was analyzed using one-way analysis of variance (ANOVA) in MINITAB software (MINITAB 18, Minitab Inc., Coventry, UK). Mean values among different treatments were compared using Tukey's test at a significance level of 0.05. The correlation between measured variables was assessed using the Pearson correlation coefficient, calculated in Microsoft Excel for MAC Version 15.32 (MS Office, Albuquerque, NM, USA).

Results and discussion

Growth performance of T. molitor larvae

Three different ratios of corn flour and pomegranate peel (1:1, 1:2 and 1:4, w/w) were investigated to determine the optimal growth conditions for T. molitor larvae. When we examined the weight gains and volumes of the larvae, a statistically significant decrease was observed in the media with 1:2 and 1:4 concentrations (data not shown). This can be attributed to the fact that an increased addition of pomegranate peel in the diet may hinder larval growth. Additionally, it’s important to emphasize that excessive inclusion of pomegranate peel in the diet can have adverse effects on both feed intake and growth, primarily due to the elevated tannin levels [12]. Therefore, the 1:1 ratio of corn flour and pomegranate peel was selected for further experiments. This 1:1 ratio will be referred to as PCM throughout the text.

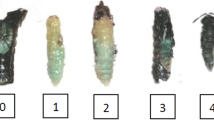

Larval weight, volume, and survival rate of T. molitor larvae fed with PCM were determined over a 12-day period (Table 1). The initial weight of larvae was found to be 5.58 ± 0.28 mg on a dry weight basis per larva. The weight of larvae increased to 10.51 ± 2.46 mg when fed with PCM; however, there were no significant differences between the PCM-fed group and the control (8.85 ± 1.45 mg) on the 12th day of rearing. The volume of larvae increased by 47.5% and 61.6% when fed with the control and PCM, respectively. At the end of the feeding period, 96.7–98.7% of the initial larvae survived, with no significant differences observed across diets. The presence of different components in the substrate can affect weight gain, survival rate and development time [25]. Additionally, it has been shown that the developmental performance of larvae can be improved by feeding them with food wastes that contains high dietary fibers [7]. Ruschioni et al. [8] also reported that the growth performance, survival rates and weight gains of T. molitor larvae increased when fed on olive pomace-enriched media. Oonincx et al. [10] demonstrated that the development time and mortality of T. molitor larvae decreased when carrot was added to the feeding media. In this study, the supplementation of pomegranate peel to the larvae did not result in significant differences in terms of weight gain and survival rate compared to the control; however, the volume of larvae increased significantly when the media was enriched with pomegranate peel.

Composition of T. molitor larvae

The proximate composition of larvae grown on both control and PCM was determined (Fig. 1). Initially, T. molitor larvae contained 47.17% lipid, 30.59% protein, 1.09% ash, and 21.15% carbohydrates. After a 12-day feeding period, the lipid, protein, ash and carbohydrate contents changed to 34.54%, 34.78%, 1.81% and 28.87% for the control group, and 41.41%, 27.64%, 1.93% and 29.02% for the PCM group, respectively. The protein content was significantly higher in larvae fed with the control diet compared to those fed PCM (p < 0.05). When examining the substrate, there were significantly differences in proximate composition, particularly in protein content. Pomegranate peel contained 3.7% protein, while corn flour contained 9.8% protein [9, 26]. T. molitor larvae require nitrogen to synthesize proteins, which explains the differences in protein content between larvae fed PCM and the control diet [2]. Rovai et al. [9] also observed a decrease in the protein content of T. molitor larvae when fed wheat bran enriched with carrot pomace. However, Antonopoulou et al. [12] noted an increase in protein content of T. molitor larvae when fed carob meal. Moreover, Kröncke and Benning [27] also reported higher protein yield and lower fat content in T. molitor larvae when fed with pea and rice protein supplementation, whereas lower protein and higher fat content were observed when larvae fed cassava flour, potato flakes and sweet lupine flour. The variations in larval body composition reported in the literature can be attributed to differences in the protein content of the experimental substrates.

The lipid content of the larvae decreased from 47.17% ± 0.93 to 34.54% ± 1.00 and 41.41% ± 1.26 when fed with control and PCM diets, respectively, on day 12. Some studies in the literature have suggested that the lipid content of T. molitor larvae can be influenced by the provided diet [9]. However, there are no significant models that can predict lipid content based on the feed sources. Liu et al. [6] found that the lipid content of T. molitor larvae raised on wheat bran enriched with carrot, orange, or red cabbage did not significantly differ among the different diets over a four-week period. The ash content of T. molitor larvae increased from 1.09% ± 0.03 to 1.81% ± 0.09 and 1.93 ± 0.02 for the control and PCM diets, respectively, after 12 days of feeding. According to the observed data, the ash content of T. molitor larvae was not significantly different in the PCM group compared to control group (p > 0.05). A study conducted by Tan et al. [7] showed that the lipid and ash contents of T. molitor larvae were higher when larvae were fed with fruit wastes such as banana peels and watermelon rinds. However, Antonopoulou et al. [12] reported that T. molitor larvae fed with carob meal did not affect the dry matter and ash contents of larvae. Initially, the carbohydrate content of T. molitor larvae was 21.15% ± 0.82, and, after a 12-day feeding period, the carbohydrate content increased to 28.87% ± 1.32 and 29.02% ± 1.19 when fed with the control and PCM diets, respectively. When we compared different diets for all days, the highest carbohydrate content was found in T. molitor larvae fed with PCM on the 4th day. In plants, fiber typically consists of cellulose, lignin, hemicelluloses, and the proportions of these compounds vary among different vegetable species. The efficiency of larval growth is not solely influenced by the overall carbohydrate or crude fiber content, but also by the specific composition and type of plant fiber present. Tenebrionidae exhibit greater resistance to digesting potato starch compared to starch derived from wheat and maize [27]. However, to make precise predictions, a more detailed examination of the carbohydrate and fiber composition for each substrate and diet is necessary. This aspect can be explored further in subsequent studies.

Antioxidant activity of T. molitor larvae and spent feed

Insects possess their own antioxidant enzyme systems to maintain a balance between prooxidants and antioxidants. However, the consumption of dietary antioxidants can further support this process [6]. T. molitor larvae exhibit the ability to break down lignocellulosic waste through the action of extracellular enzymes within their digestive tract [28]. Consequently, larval fermentation can influence the phenolic content of the substrate by either releasing or converting these compounds. The antioxidant activities of both T. molitor larvae and spent feed after larval rearing were assessed at the end of each 4-day interval using the CUPRAC and DPPH methods. The results obtained from the CUPRAC and DPPH antioxidant activity analyses are presented in Fig. 2 for both larvae and spent feed. The initial CUPRAC antioxidant activity of the larvae was 20.50 ± 1.67 mg TE/g larvae, and there were no significant differences in the CUPRAC antioxidant activities of T. molitor larvae fed with the control diet over the observation period. However, the CUPRAC antioxidant activity of T. molitor larvae fed with PCM showed a significant increase on the 4th day (28.86 ± 0.59 mg TE/g larvae). A notable positive correlation was observed between TPC and CUPRAC antioxidant activity of larvae fed with PCM (Pearson’s r = 0.70). On the other hand, no clear trend was observed between the DPPH and CUPRAC antioxidant activities of larvae fed with both the control and PCM diets during the rearing period. In comparison to the initial DPPH antioxidant activity of larvae (4.98 ± 0.34 mg TE/g larvae) those fed with PCM displayed a decrease on the 4th day (4.06 ± 0.71 mg TE/g larvae), followed by an increase after 12 days (5.32 ± 0.24 mg TE/g larvae). In contrast, DPPH antioxidant activity of larvae fed with the control diet exhibited a significant decrease on the 4th day (3.15 ± 1.00 mg TE/g larvae), after which no significant differences were observed between days 4, 8 and 12.

TPC and antioxidant activity of larvae and spent feed during rearing. For each graph, bars marked with different lowercase letters (a, b, c) are significantly different between days for control, and bars marked with different capital letters (A, B, C) indicate significant differences between days for PCM (p < 0.05). Asterisk (*) indicates significantly higher values between diets on each day (p < 0.05)

According to Navaroo del Hierro et al. [3] the antioxidant activity of T. molitor larvae can be attributed to phenolic compounds. Similarly, Antonopoulou et al. [12] investigated the antioxidant activity of T. molitor larvae when fed with various levels of milled carob pods, known for their antioxidant effects due to polyphenolic compounds such as flavonoids and condensed tannins. They reported that when over 75% of the carob pod content was included in the larvae’s diet, it led to a decrease in the antioxidant activity of the larvae. The authors explained this decrease by the formation of chemical complexes and the prooxidant behavior of certain antioxidant compounds due to the presence of metal ions [12]. In another study, Liu et al. [6] observed that T. molitor larvae fed on different diets supplemented with carrot, orange and red cabbage showed minimal variation in ferric reducing power, ferrous chelating activity, and ABTS activity. Furthermore, they reported that the antioxidant bioaccumulation of the larvae did not exhibit a clear trend under the examined conditions.

After the larval rearing on both control and PCM diets, the antioxidant activities of the spent feed were also assessed (Fig. 2). The results indicated that the CUPRAC antioxidant activity of the spent feed increased significantly after 12 days of rearing in the control group. However, there were no significant differences observed between the 4th, 8th and 12th days within this group. Similarly, the DPPH antioxidant activity of the spent feed showed a significant increase after 4 days of rearing in the control group, with no significant differences noted between the 4th, 8th and 12th days. There was a slight increase in both CUPRAC and DPPH antioxidant activities of spent feed on the 4th day following larval rearing on both control and PCM diets. However, no significant differences were observed among the various observation days within these groups.

Total phenolic content of T. molitor larvae and spent feed

T. molitor larvae are known to contain bioactive compounds such as phenolics, peptides and fatty acids [1, 2]. According to our results, the initial TPC of the larvae was measured as 11.29 ± 0.37 mg GAE/g larvae (Fig. 2). Larvae fed with PCM showed a significant increase in TPC on the 12th day of rearing (13.11 ± 0.55 mg GAE/g larvae); however, there were no significant differences observed among the different observation days for larvae fed with the control diet. The TPC results obtained in this study were higher than those reported by Kim et al. [29] (5.6 mg GAE/g) and lower than the findings of Navarro del Hierro et al. [3] (38 mg GAE/g). The variations between these studies may be attributed to differences in the extraction methods and solvents used. Furthermore, it’s worth noting that while the previous studies only measured the total phenolic compounds, our study also determined the phenolic profile of both the larvae and the spent feed.

TPC values of the control spent feed after larval rearing did not exhibit any significant differences among the observation days. In the case of the PCM spent feed, the lowest TPC value was recorded on the 8th day, while the highest value was observed on the 4th day. However, these values were not significantly different when compared to the initial measurement and the TPC values at the end of the 12-day rearing period. A direct relationship was observed between TPC and the antioxidant activities of the spent feed. The correlation coefficients for TPC and CUPRAC were relatively lower for the PCM spent feed (0.867) compared to the control spent feed (0.968). For TPC and DPPH, the correlation coefficients were found to be 0.988 and 0.808 for the PCM and control spent feed, respectively.

Identification and quantification of phenolic compounds in T. molitor larvae and spent feed

The phenolic profile of T. molitor larvae fed with both the control and PCM diets, as well as the spent feed after larval rearing, was quantified using HPLC–PDA and identified through UPLC-ESI-QqQ-MS/MS (Table 2). The main phenolic compounds identified in the larvae samples included gallic acid, ellagic acid and m-coumaric acid. Identification was achieved by comparing the absorption spectra with those of established standards, and confirming their identities by matching the m/z values obtained from UPLC-ESI-QqQ-MS/MS. The MS/MS transitions used included 169.05 > 125 for gallic acid, 163 > 119, 92.9, 90.9 for m-coumaric acid, both monitored in negative ion mode, and 303.1 > 229 for ellagic acid in positive ion mode. In the PCM spent feed, ellagic acid, two ellagic acid derivatives, and two ellagitannins were identified as the main phenolic compounds. These compounds were tentatively identified using UV–VIS spectra and m/z values reported in the literature due to the unavailability of standards. The spectrum of ellagic acid derivative 1, which exhibited an absorption peak at ~ 252 nm and a shoulder at 360 nm, closely resembled that ellagic acid. The most abundant ion fraction obtained from ellagic acid derivative 1 had a parent mass of 465.1 m/z with a fragment ion at m/z of 303.1. This compound is most likely ellagic acid hexoside, as previously reported in pomegranate [30, 31]. Ellagic acid derivative 2 displayed a parent ion at m/z of 449.1 with a fragment ion at m/z of 303.2 and exhibited maximum absorbance at 252 nm, with a shoulder at 360 nm and a retention time of 4.68 min. Ellagic acid derivative 2 was identified as ellagic acid-rhamnoside, a compound also reported by Abid et al. [32] and Sentandreu et al. [30] in pomegranate, with a parent ion at m/z of 447 and releasing fragments at m/z of 301 and 300.

After conducting MS analysis, it was determined that the two phenolic compounds discovered in the spent feed of PCM were likely derivatives of ellagitannins commonly found in pomegranate. While the compounds’ molecular weights were identified as 783, their precise chemical identities could not be conclusively determined. Previous studies by Mena et al. [31] and Calani et al. [33] identified phenolic compounds in pomegranate with molecular ions at m/z of 783 as pedunculagin I isomers. Notably, the distinct gallagyl-fragment with a mass-to-charge ratio of 601 was not detected in this study. Therefore, the phenolic compounds were identified as ellagitannin derivatives. Ellagitannin derivatives 1 and 2 exhibited nearly identical UV–VIS spectra but had different retention times at 4.04 and 4.14 min, respectively. The spectrum of ellagitannin derivative 1 displayed an absorption peak at 258 nm with shoulders at ~ 375 nm. This compound generated a parent ion at m/z of 783, accompanied by fragment ions at m/z of 448, 303, 242 and 149. Similarly, ellagitannin derivative 2, with an absorption peak at 258 nm and shoulders at 368 nm, produced a parent ion at m/z 783, along with a fragment ion at m/z 525, 420, 303 and 149. The presence of m/z 303 (+) and m/z 301 (−) ions in the MS analysis indicated the existence of an ellagic acid precursor, consistent with previous observations in the studies involving pomegranate [14, 31, 33,34,35].

Table 3 displays the changes in the phenolic profile of larvae fed with both the control and PCM diets. Initially, the primary phenolic compounds identified in T. molitor larvae were gallic acid and m-coumaric acid. Over the course of the feeding period, the concentration of gallic acid decreased in larvae fed with the control diet, while larvae fed with PCM exhibited an increase in gallic acid content. The concentration of m-coumaric acid in the larvae decreased when compared to its initial concentration, regardless of whether they were fed with control or PCM diets. This reduction in m-coumaric acid concentrations in the larvae can be attributed to the degradation of phenolics during the rearing process. Interestingly, larvae fed with the control diet did not contain any ellagic acid initially. However, ellagic acid was observed in the larvae fed with PCM after 8 days of rearing, with a concentration of 92.54 ± 12.65 µg/g dm, which further increased to 115.58 ± 33.44 µg/g dm by the 12th day. This finding suggests that the larvae accumulated a significant amount of ellagic acid in their bodies when they were raised on a pomegranate peel-enriched diet. In summary, our results demonstrate that T. molitor larvae fed with PCM have the capacity to accumulate ellagic acid in their bodies.

The digestion of PCM by T. molitor larvae led to changes in the concentration of phenolic compounds in the spent feed (Table 4). Ellagic acid concentration increased approximately 2.2-fold in PCM spent feed after 12 days of larval rearing. Ellagic acid was identified as the major phenolic compound in both the soluble-free and insoluble-bound forms of pomegranate peel [36]. The increase in ellagic acid concentration in PCM after larval rearing can be attributed to the release of ellagic acid from the cell-wall structure of pomegranate peel, facilitated by the action of larval enzymes such as cellulases [37]. Ellagic acid derivatives 1 and 2 exhibited the highest concentrations on the 4th day of rearing. Among them, ellagitannin derivative 1 was the most abundant phenolic compound in PCM spent feed, with its concentration remaining relatively unchanged over time. The concentration of ellagitannin derivative 2 increased significantly after four days of rearing, and thereafter, it remained relatively stable until the 12th day. The changes in phenolic concentration in PCM spent feed after larval rearing can be explained by the release of phenolic compounds from their insoluble-bound forms and/or the conversion of ellagitannins to ellagic acid or its derivatives through phase I and phase II reactions, influenced by the actions of bacteria and enzymes in the larval intestinal system [38, 39].

Conclusion

In conclusion, the 12-day dietary supplementation with pomegranate peel significantly enhanced the phenolic profile of T. molitor larvae, leading to notable changes in their chemical composition. In particular, T. molitor larvae fed on the PCM exhibited higher lipid and lower protein content compared to those fed on the control after the 12-day rearing period. The observed accumulation of ellagic acid in T. molitor larvae has garnered significant interest due to its potential applications across various fields. These findings indicate the significance of T. molitor larvae as a valuable and unique source of bioactive substances, which could be beneficial for the development of valuable feed and food ingredients.

Data availability

The data that support the findings of this study are available on request from the corresponding author, ZG-K.

References

Lawal KG, Kavle RR, Akanbi TO et al (2021) Enrichment in specific fatty acids profile of Tenebrio molitor and Hermetia illucens larvae through feeding. Future Foods 3:100016. https://doi.org/10.1016/j.fufo.2021.100016

Li L, Zhao Z, Liu H (2013) Feasibility of feeding yellow mealworm (Tenebrio molitor L.) in bioregenerative life support systems as a source of animal protein for humans. Acta Astronaut 92:103–109. https://doi.org/10.1016/j.actaastro.2012.03.012

Navarro del Hierro J, Gutiérrez-Docio A, Otero P et al (2020) Characterization, antioxidant activity, and inhibitory effect on pancreatic lipase of extracts from the edible insects Acheta domesticus and Tenebrio molitor. Food Chem 309:125742. https://doi.org/10.1016/J.FOODCHEM.2019.125742

Hwang BB, Chang MH, Lee JH et al (2019) The edible insect Gryllus bimaculatus protects against gut-derived inflammatory responses and liver damage in mice after acute alcohol exposure. Nutrients 11:857. https://doi.org/10.3390/NU11040857

Seo M, Goo TW, Chung MY et al (2017) Tenebrio molitor larvae inhibit adipogenesis through AMPK and MAPKs signaling in 3T3-L1 adipocytes and obesity in high-fat diet-induced obese mice. Int J Mol Sci 18:518. https://doi.org/10.3390/IJMS18030518

Liu C, Masri J, Perez V et al (2020) Growth performance and nutrient composition of mealworms (Tenebrio Molitor) fed on fresh plant materials-supplemented diets. Foods 9:1–10. https://doi.org/10.3390/foods9020151

Tan SW, Lai KS, Loh JY (2018) Effects of food wastes on yellow mealworm Tenebrio molitor larval nutritional profiles and growth performances. Examines Mar Biol Oceanogr 2:173–178. https://doi.org/10.31031/eimbo.2018.02.000530

Ruschioni S, Loreto N, Foligni R et al (2020) Addition of olive pomace to feeding substrate affects growth performance and nutritional value of mealworm (Tenebrio molitor L.) larvae. Foods 9(3):317. https://doi.org/10.3390/foods9030317

Rovai D, Ortgies M, Amin S et al (2021) Utilization of carrot pomace to grow mealworm larvae (Tenebrio molitor). Sustainability 13:9341. https://doi.org/10.3390/su13169341

Oonincx DGAB, van Broekhoven S, van Huis A, van Loon JJA (2015) Feed conversion, survival and development, and composition of four insect species on diets composed of food by-products. PLoS ONE 10:e0144601. https://doi.org/10.1371/JOURNAL.PONE.0144601

Baek M, Kim MA, Kwon YS et al (2019) Effects of processing methods on nutritional composition and antioxidant activity of mealworm (Tenebrio molitor) larvae. Entomol Res 49:284–293. https://doi.org/10.1111/1748-5967.12363

Antonopoulou E, Panteli N, Feidantsis K et al (2022) Carob (Ceratonia siliqua) as functional feed is beneficial in yellow mealworm (Tenebrio molitor) rearing: evidence from growth, antioxidant status and cellular responses. Antioxidants 11(9):1840. https://doi.org/10.3390/antiox11091840

Man G, Xu L, Wang Y et al (2022) Profiling phenolic composition in pomegranate peel from nine selected cultivars using UHPLC-QTOF-MS and UPLC-QQQ-MS. Front Nutr 8:1–12. https://doi.org/10.3389/fnut.2021.807447

Liu Y, Kong KW, Wu DT et al (2022) Pomegranate peel-derived punicalagin: ultrasonic-assisted extraction, purification, and its α-glucosidase inhibitory mechanism. Food Chem 374:131635. https://doi.org/10.1016/j.foodchem.2021.131635

AOAC (2005) Official Methods of Analysis, 18 Ed. AOAC International: Rockville, MD, USA

Mancini S, Fratini F, Turchi B et al (2019) Former foodstuff products in Tenebrio molitor rearing: effects on growth, chemical composition, microbiological load, and antioxidant status. Animals 9:1–13. https://doi.org/10.3390/ani9080484

Janssen RH, Vincken JP, van den Broek LAM et al (2017) Nitrogen-to-protein conversion factors for three edible insects: Tenebrio molitor, Alphitobius diaperinus, and Hermetia illucens. J Agric Food Chem 65:2275–2278. https://doi.org/10.1021/acs.jafc.7b00471

Gulsunoglu Z, Aravind S, Bai Y et al (2019) Deoxynivalenol (DON) accumulation and nutrient recovery in black soldier fly larvae (Hermetia illucens) fed wheat infected with Fusarium spp. Fermentation 5(3):83. https://doi.org/10.3390/fermentation5030083

Andreadis SS, Panteli N, Mastoraki M et al (2022) Towards functional insect feeds: agri-food by-products enriched with post-distillation residues of medicinal aromatic plants in Tenebrio molitor (Coleoptera: Tenebrionidae) breeding. Antioxidants 11(1):68. https://doi.org/10.3390/antiox11010068

Singleton VL, Orthofer R, Lamuela-Raventós RM (1999) Analysis of total phenols and other oxidation substrates and antioxidants by means of folin-ciocalteu reagent. Methods Enzymol. https://doi.org/10.1016/S0076-6879(99)99017-1

Rai S, Wahile A, Mukherjee K et al (2006) Antioxidant activity of Nelumbo nucifera (sacred lotus) seeds. J Ethnopharmacol 104:322–327

Apak R, Guçlu K, Mustafa O, Karademir SE (2004) Novel total antioxidant capacity index for dietary polyphenols and vitamins C and E, using their cupric ion reducing capability in the presence of neocuproine. ACS Publications 52:7970–7981. https://doi.org/10.1021/jf048741x

Bino RJ, de Vos CHR, Lieberman M et al (2005) The light-hyperresponsive high pigment-2dg mutation of tomato: alterations in the fruit metabolome. New Phytol 166:427–438. https://doi.org/10.1111/J.1469-8137.2005.01362.X

Catalkaya G, Guldiken B, Capanoglu E (2022) Encapsulation of anthocyanin-rich extract from black chokeberry (Aronia melanocarpa) pomace by spray drying using different coating materials. Food Funct 13(22):11579–11591

Nijhout HF (2003) The control of body size in insects. Dev Biol 261:1–9. https://doi.org/10.1016/s0012-1606(03)00276-8

Milosevic N, Peric L, Lukic M, Filipovic S (2007) Nutritive value of corn meal in nutrition of fattening chickens. Biotechnol Anim Husb 23:535–542. https://doi.org/10.2298/bah0701535m

Kröncke N, Benning R (2023) Influence of dietary protein content on the nutritional composition of mealworm larvae (Tenebrio molitor L.). Insects 14:1–19. https://doi.org/10.3390/insects14030261

Przemieniecki SW, Kosewska A, Ciesielski S, Kosewska O (2020) Changes in the gut microbiome and enzymatic profile of Tenebrio molitor larvae biodegrading cellulose, polyethylene and polystyrene waste. Environ Pollut 256:113265. https://doi.org/10.1016/J.ENVPOL.2019.113265

Kim JJ, Kim KS, Yu BJ (2018) Optimization of antioxidant and skin-whitening compounds extraction condition from Tenebrio molitor larvae (mealworm). Molecules 23:2340. https://doi.org/10.3390/MOLECULES23092340

Sentandreu E, Cerdán-Calero M, Sendra JM (2013) Phenolic profile characterization of pomegranate (Punica granatum) juice by high-performance liquid chromatography with diode array detection coupled to an electrospray ion trap mass analyzer. J Food Compos Anal 30:32–40. https://doi.org/10.1016/j.jfca.2013.01.003

Mena P, Calani L, Dall’Asta C et al (2012) Rapid and comprehensive evaluation of (poly)phenolic compounds in pomegranate (Punica granatum L.) Juice by UHPLC-MSn. Molecules 17:14821–14840. https://doi.org/10.3390/molecules171214821

Abid M, Yaich H, Cheikhrouhou S et al (2017) Antioxidant properties and phenolic profile characterization by LC–MS/MS of selected Tunisian pomegranate peels. J Food Sci Technol 54:2890–2901. https://doi.org/10.1007/s13197-017-2727-0

Calani L, Beghe D, Mena P et al (2013) Ultra-HPLC–MS Ultra-HPLC–MS n (poly) phenolic profiling and chemometric analysis of juices from ancient Punica granatum L. cultivars: a nontargeted approach. J Agric Food Chem 61(23):5600–5609

Nuncio-Jáuregui N, Nowicka P, Munera-Picazo S et al (2015) Identification and quantification of major derivatives of ellagic acid and antioxidant properties of thinning and ripe Spanish pomegranates. J Funct Foods 12:354–364. https://doi.org/10.1016/j.jff.2014.11.007

Fracassetti D, Costa C, Moulay L, Tomás-Barberán FA (2013) Ellagic acid derivatives, ellagitannins, proanthocyanidins and other phenolics, vitamin C and antioxidant capacity of two powder products from camu-camu fruit (Myrciaria dubia). Food Chem 139:578–588. https://doi.org/10.1016/j.foodchem.2013.01.121

Gulsunoglu Z, Karbancioglu-Guler F, Raes K, Kilic-Akyilmaz M (2019) Soluble and insoluble-bound phenolics and antioxidant activity of various industrial plant wastes. Int J Food Prop 22:1501–1510. https://doi.org/10.1080/10942912.2019.1656233

Willis JD, Oppert C, Jurat-Fuentes JL (2010) Methods for discovery and characterization of cellulolytic enzymes from insects. Insect Sci 17:184–198. https://doi.org/10.1111/j.1744-7917.2010.01322.x

Akgedik AN, Oder G, Erdem C et al (2023) Utilization of insect gut as a biosource for the development of future biotransformation processes. Johnson Matthey Technol Rev. https://doi.org/10.1595/205651323X16732719244908

Gulsunoglu-Konuskan Z, Kilic-Akyilmaz M (2022) Microbial bioconversion of phenolic compounds in agro-industrial wastes: a review of mechanisms and effective factors. J Agric Food Chem 70:6901–6910. https://doi.org/10.1021/ACS.JAFC.1C06888/ASSET/IMAGES/MEDIUM/JF1C06888_0003.GIF

Acknowledgements

The authors are grateful to Dr. Gizem Catalkaya and Dr. Duygu Ceylan Adrar, Food Engineering Department, Istanbul Technical University, for their help to operate UPLC-ESI-QqQ-MS/MS and HPLC-PDA.

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK).

Author information

Authors and Affiliations

Contributions

ZG-K: conceptualization, investigation, methodology, data curation, writing—original draft, writing—review and editing. SD: investigation, methodology, data curation.

Corresponding author

Ethics declarations

Conflict interests

The authors declare that they have no conflicts of interest.

Compliance with ethics requirements

This study does not contain any studies with human or animal subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gulsunoglu-Konuskan, Z., Dag, S. Physicochemical properties and ellagic acid accumulation in Tenebrio molitor larvae fed with pomegranate peel-enriched media. Eur Food Res Technol 250, 1473–1483 (2024). https://doi.org/10.1007/s00217-024-04480-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-024-04480-5