Abstract

Pork liver is a protein-rich offal, generated in large quantities in the meat industry and considered non-allergenic, although not highly appreciated by Western consumers. The recovery of its proteins through a simple and easily scalable process with the purpose of obtaining economical and environmentally friendly techno-functional ingredients might be an alternative for its valorization. Of great interest are protein fractions with good foaming properties that can act as substitutes for other highly allergenic proteins in food formulation. In this study, protein extractions from fresh pork livers were performed using buffer solutions adjusted to different pH (from 4.0 to 8.5), without a subsequent concentration/purification step. The main parameters evaluated were yield and foaming properties of the recovered extracts; their physicochemical characteristics and the SDS-PAGE protein profiles were determined as well. Acceptable extraction yields (> 50% of the total protein) were obtained using buffer solutions adjusted to pH ≥ 4.80, but their foaming properties were poor. By contrast, the extracts recovered using buffers adjusted to pH ≤ 4.75 were capable of forming very voluminous and stable foams, although rather low yields were achieved under these conditions (31.5–36.0% of the total protein). In addition to the profile of solubilized proteins, a low fat and relatively high carbohydrate content in the extracts seem to contribute to their excellent foaming properties. Therefore, protein extracts from fresh pork liver obtained using buffer solutions adjusted to pH 4.0–4.5 (extract pH: 5.3–5.6) could be a real alternative to other protein foaming agents that cause food allergies, in a simple, cost-effective and sustainable way.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Pork liver is considered a first-grade offal due to its richness in proteins, mineral elements, and vitamins [1]. However, compared to livers from other animals (lamb, calf, poultry or duck), it is unpopular with Western consumers—and therefore low-priced—due to its stringy texture, in addition to its metallic and fishy off-flavors [2]. The high number of pigs slaughtered daily makes it necessary to explore alternatives for a better purpose of the generated livers, not only to obtain a greater economic benefit but also to minimize the environmental impact associated with pig production. The protein richness of pork liver raises the possibility of recovering it for reasons beyond its nutritional value; more specifically, through obtaining protein fractions with techno-functional applications. The ability of proteins to form gels and foams is of great importance in rendering food texture. But while many different proteins from different sources with excellent gelling properties can be found and easily used as food ingredients [3,4,5,6,7,8], most of those exhibiting good foaming properties (egg white, milk proteins, gluten, soy proteins) tend to be allergenic [9]. Hence, finding alternative non-allergenic proteins able to form and stabilize foams would be beneficial for food industries. This is reinforced by the fact that there are no reports of allergy associated with consumption of pork liver [10].

For a successful valorization, the protein extraction conditions should allow obtaining the maximum yield and the best techno-functionality, as well as being cost-effective. Protein recovery can be optimized by modifying the pH during the extraction process due to its effects on protein solubility [11, 12]. Moreover, in complex matrices, the proteins recovered during this step can be modulated, thanks to the solubility differences among them [13]. One of the most common treatments based on the effect of pH on protein solubility is the pH-shifting technology, a two-stage process that combines solubilization at extreme acid/alkaline pH with subsequent isoelectric precipitation. Under these conditions, proteins are first partially unfolded at pH ≤ 3.5 or ≥ 8.0 and then refolded at the protein pI, but with conformational changes not being completely reversed [14,15,16,17,18]. It was specifically proposed as an alternative to the traditional method to produce surimi; that is, to isolate myofibrillar proteins from fish by-products and small-underused fish species because of their gelling properties, which could be negatively affected by the presence of sarcoplasmic proteins [11, 19]. In addition, lipids and other undesirable molecules can be also separated during the process, thus improving product stability. More recently, its use has been extended to meat and vegetal processing areas and even to the recovery of proteins from microalgae and seaweed [16, 20,21,22,23,24,25,26,27,28]. It has been likewise successfully applied in offal like chicken and goose livers, achieving adequate yield values and improving the emulsifying and gelling properties of their proteins [18, 29, 30]. However, for economic and environmental reasons, there is a growing interest in applying simpler methods and easy to scale industrially, to recover proteins from alternative food sources [31]. In this context, the extraction of proteins under mild conditions after grinding the raw material could be an alternative in the case of pork liver due to its relatively low fat content (3–5%) and its porous structure that could facilitate protein extraction [32]. Including a concentration/purification step using membrane technology could be considered in the case of achieving low yield or of obtaining extracts with an excessive presence of compounds other than proteins, such as lipids, which could have a negative impact on the potential of extracts as techno-functional ingredients. However, the current interest for practices with a smaller carbon footprint and lower overall environmental impact is leading to a greater preference for protein concentrates over protein isolates to avoid the impact of the purification step. Therefore, this study focuses on obtaining and characterizing pork liver extracts at different pH conditions and assessing their potential as techno-functional food ingredients based on protein extraction yield and foaming properties. The results obtained should make it possible to assess the need for a post-extraction concentration/purification step.

Materials and methods

Materials

Every sampling day, three fresh pork livers from healthy adult animals (Large White × Landrace × Pietrain × Duroc commercial crossbred; live weight of approximately 100 kg and 6 months old), regardless of sex, were supplied by a local abattoir (NORFRISA, Riudellots de la Selva, Spain), once their gallbladder was separated. At the slaughterhouse, each liver was placed separately in a sterile bag. Livers were transported and kept under refrigerated conditions for approximately half an hour, until they were processed upon arrival at the laboratory. First, each liver was visually inspected to detect any abnormalities and, after that, its pH was measured in quadruplicate with a Crison GLP 22 pH-meter (Hach Langue SLU, Ames, IA, USA) coupled to an insertion-type electrode (2-Pore F, XS Instruments, Capri, Italy) as a control measurement. Finally, the remaining blood vessels and the most evident connective tissue were completely removed from all livers.

Obtaining from fresh pork liver under different pH conditions

Initially, protein recovery from fresh pork livers was tested by following a gradient experimental design with ten pH levels (pH from 4.0 to 8.5, carrying out the protein extraction at each half-pH unit) without replicates. Livers were supplied by the slaughterhouse and processed as indicated above on as many different days as extraction buffers were tested. The order of the trials was completely randomized. Subsequently three more pH conditions (4.3, 4.75, and 4.8) were tested following the same protocol, to validate the observed behavior between yield and pH of the extraction buffer. Buffers were freshly prepared by mixing different solutions depending on the desired pH value: 0.10 mol/L citric acid and 0.20 mol/L sodium phosphate dibasic (pH ≤ 4.75); 0.07 mol/L monobasic potassium phosphate and 0.07 mol/L monobasic sodium phosphate (pH from 4.8 to 8.0, both included); and 0.10 mol/L HCl and 0.10 mol/L tris(hydroxymethyl)aminomethane (pH 8.5), all in distilled water.

Protein extraction was performed following the same method as described by Toldrà et al. [33] with slight modifications. Each sampling day, a pork liver homogenate was prepared by mixing and grinding equal amounts of the three livers (500 g final weight) at 2100 rpm for 1 min with a Cutter Sammic CKE-5 food processor emulsifier (Sammic S.L., Azkoitia, Spain). At this point, a small amount of minced liver was separated for the subsequent determination of the protein content by the Kjeldahl method as described in AOCS [34]. A specific factor of 6.25 was applied to convert total nitrogen to crude protein content [35]. Then 1 L of buffer solution adjusted to the desired pH was added and the mixture was submitted to the next extraction process at room temperature (20 ± 1 °C): two steps at 1500 rpm for 1 min followed by a step at 300 rpm for 30 min. The mixture was then centrifuged at 20,000 × g and 15 °C for 15 min (SORVALL RC 5C Plus, Dupont, Newtown, USA), and the supernatant (extract) was recovered by decanting and measured.

Physicochemical characterization of liver protein extracts

The pH of all extracts recovered after centrifugation was measured in duplicate using a Crison GLP 22 pH meter coupled to a glass electrode. Their moisture, crude protein, fat and ash contents were determined according to the methods described in AOCS [34]. Total carbohydrates were calculated by difference. Color measurements were performed in the CIELAB color space (CIE 1976 L*a*b*) using a Minolta CR-400 colorimeter (Minolta Co., Ltd, Osaka, Japan) with an optical geometry d:0°, equipped with a CIE illuminant D65 and a CIE 2° standard observer. L* coordinate corresponds to lightness, while chromaticity coordinates ± a* and ± b*, which indicate the position between red and green and between yellow and blue, respectively, were used to calculate hue \( \left[ {{\text{Hue}}\left( {\circ} \right)} = \arctan \left( {{\raise0.7ex\hbox{$b$} \!\mathord{\left/ {\vphantom {b a}}\right.\kern-0pt}\!\lower0.7ex\hbox{$a$}}} \right)\right]\) and chroma \(\left[ {C = \left( {a^2 + b^2 } \right)^{{\raise0.7ex\hbox{$1$} \!\mathord{\left/ {\vphantom {1 2}}\right.\kern-0pt}\!\lower0.7ex\hbox{$2$}}} } \right]\).

Yield of protein extraction

Yield was determined from the mass of protein in the extract and reported as a percentage of the crude protein in the sample of minced pork liver used in the extraction process.

Foaming properties

Foaming properties were determined according to the method proposed by Saguer et al. [36], but with some modifications. Briefly, 200 mL of a 2 g/L protein solution prepared from pork liver extracts were poured into a 1 L beaker placed on a turntable and mixed for 10 min at 1000 rpm with a Multimix M830 (Braun Española S.A., Esplugues de Llobregat, Spain) equipped with two BR67051155 whisks. After a waiting time of 2 min to allow the non-foamed liquid to drain, the foaming capacity was determined as the volume of foam formed. For each extract, foaming capacity was determined in duplicate. Under these test conditions, the maximum volume of foam that can be formed is 3.5 times the initial volume of the protein solution before starting the whipping process. From each foam, relative foaming stability (rFS) was measured in triplicate using a gravimetric technique by placing a known amount of foam in a stainless steel (1 mm mesh size) and measuring the foam remaining every 10 min for 1 h. rFS was expressed as the time (in min) required to lose half of the foam volume; this value was obtained by fitting the experimental data to the best mathematical model.

SDS-PAGE under reducing conditions

Diluted pork liver extracts (5.59 µg µL−1 protein concentration) were analyzed by SDS-PAGE under reducing conditions in a Mini-PROTEAN® Tetra cell (BioRad, Hercules, CA, USA) connected to a PowerPac HC Power Supplies (BioRad), after being processed. First, 50 µL of extract dilution were mixed with 50 µL of sodium dodecyl sulphate (SDS) solution (25% 1 mol/L Tris–HCl buffer pH 6.8, 4% SDS, 40% glycerol, 2% β-mercaptoethanol, and 29% bromophenol blue 0.5 g/L). The mixture was incubated at 95 °C for 5 min using a Thermoblock Digital Shaking Drybath (Thermo Fisher Scientific, Shangai, China) and then applied to the electrophoresis wells. Gels (5.5% stacking gel and 15% separating gel) were prepared in the laboratory, following the Laemmli method [37]. Acrylamide and bis-acrylamide solution (37.5:1), purchased from BioRad, were used to prepare the gels, while the BenchMark™ Unstained Protein Ladder (Invitrogen, Carlsbad, CA, USA) and the PageRuler Prestained NIR Protein Ladder (Thermo Fisher Scientific, MA, USA) were used as molecular weight standards from 10 to 220 kDa and from 11 to 250 kDa, respectively. Electrophoresis was carried out at 70 V for 30 min and then at a constant voltage of 120 V for 2 h 30 min. Gels were fixed with a solution of methanol:acetic acid:distilled water (5:1:4). The gels were then stained using a PhastGel Blue R (Sigma-Aldrich, Saint Louis, MO, USA) solution prepared in distilled water:methanol (2:3) and diluted with acid acetic and distilled water (5:1:4) before use. Destaining was performed in a solution of methanol:acetic acid:distilled water (3:1:6). The gels were then soaked in glycerol:acid acetic:distilled water (1:1:8). Images of electrophoresis gels were captured using an Epson Perfection V750 PRO scanner (SEIKO EPSON CORP., Suwa, Japan).

Statistical analysis

Pearson correlation coefficient (r) was determined to assess possible linear correlations between pH and yield, and between each of them and the other measured variables, using IBM SPSS Statistics version 28 (IBM Corporation International, Armonk, NY, USA). Linear, polynomial (squared), and segmented regression analyses [38, 39] were applied using R package [40] (R Core Team, 2022) and the mathematical functions obtained were compared to obtain the best fit between the percentage of protein recovered or yield (response variable) and the buffer pH or extract pH (exploratory variables). Segmented regression—a linear regression model that provides two or more linear lines in the model due to the existence of one or more breakpoints or discontinuities—only can be considered the best model, after showing that its fit is better than that of the single-phase models. So, an ANOVA was applied to compare linear and quadratic models, while the Akaike’s Information Criterion (AIC) value was applied to select the best of the three regression models [41], which corresponds to that with the smallest AIC value. Since the segmented models were the best fit to the experimental data, the existence of the breakpoints was assessed using the Davies test; significant breakpoints means that the difference in slopes parameter is not zero. The significance level for all tests was α = 0.05.

Statement of human and animal rights

This article does not contain any studies with human or animal subjects.

Results and discussion

The protein extraction conditions from fresh pork livers (ground liver-to-buffer ratio, and intensity and time of extraction) were established from preliminary trials. It has often been recommended to use ratios between 1:5 and 1:10 to avoid obtaining too concentrated and viscous extracts that could be difficult to separate from the insoluble fraction after centrifugation or, on the contrary, an excessive degree of dilution of the fractions of interest [11, 42]. However, greater ratios might be more appropriate to minimize the requirement for a subsequent concentration step. In the present study, protein extraction was carried out in a 1:2 (w:v) ratio because relatively high protein extraction yields (~ 60% of the total protein) had been obtained in previous assays at the liver's own pH. In fact, yields ≥ 50% and slightly over 70% have often been achieved for proteins recovery from different sources and under different extraction conditions [12, 33, 43, 44].

Physicochemical characteristics of the extracts

Table 1 shows the pH, volume, color, and composition of the extracts obtained under different pH conditions. According to the criteria established by Meghanathan [45] for the Pearson correlation coefficient, a very strong positive linear relationship was found between the pH of buffer solution and the pH of extract. However, due to the buffering capacity of some hepatic compounds (probably proteins), the pH range of extracts was narrowed, its width being 2.2 pH units (from 5.27 to 7.47). The smallest differences in pH occurred when using buffers with a pH between pH 6.0 and 7.0, with practically no change at pH 6.5, which coincided with the pH of the livers (6.34 ± 0.10, n = 39). Differences were also detected in the recovered volume, color, and chemical composition of the extracts, depending on the pH of the extraction buffer and, therefore, the pH of the extract. As can be seen in Table 1, using buffer solutions adjusted to pH ≤ 4.75, the volume of extract recovered was slightly less than the volume of buffer added, indicating that a small amount of the buffer solution was retained by components of the insoluble fraction, probably proteins. With regard to the chemical composition of these extracts, the low content of proteins but, above all, of lipids along with the relatively high carbohydrate content stands out. On the contrary, using buffer solutions adjusted to pH ≥ 4.8, the volume recovered increased by 11–12%. These extracts were relatively richer in proteins and lipids but poorer in carbohydrates, in relation to the extracts obtained under more acidic conditions. Changes in chemical composition appear to affect the color of the extracts, so that those obtained at pH ≤ 4.75 were darker and of lower intensity than those recovered at pH ≥ 4.8. Moreover, these last extracts showed a cloudy appearance.

Table 2 shows the linear correlations among all these parameters. As can be observed, the pH of the extract correlated better with all the other parameters analyzed than the pH of the buffer. Specifically, Pearson correlation coefficient showed that extract pH was very strongly and positively correlated with protein and fat contents (r ≥ + 0.8) but negatively with water (r ≥ − 0.8). Extract pH also showed a strong negative correlation with carbohydrate (r between − 0.6 and − 0.79). By contrast, ash content was not affected by extract pH and no significant correlations were found among this variable and the rest of the parameters analyzed.

Effect of pH on protein recovery from fresh pork liver

Figure 1 illustrates the effect of buffer pH on protein recovery from pork liver. As can be observed, buffer solutions adjusted to pH ≤ 4.75 had a low protein extraction capacity, with yields around 30–35%, which resulted from the relatively low volumes of extract recovered and their low protein content. In contrast, at pH > 4.75, protein recovery was always higher than 50%, but showing a rather undulating behavior, which could reflect the complexity of the protein fraction of liver [46]. The maximum yield was obtained at pH 7.5, reaching approximately 66% of the total protein. Nuckles et al. [47] and Steen et al. [48] also reported a similar behavior for pork liver proteins, although these authors reached higher yields (76% and 79%, respectively). This could be because they applied more complex extraction processes on the liver homogenates. Zou et al. [49] also achieved ~ 75% yields by applying an ultrasound-assisted alkaline extraction method. Regardless the nature of the protein source, lowest yields are often obtained under the acidic conditions [21,22,23,24, 50]. Only in a relatively small number of studies, the opposite has been reported, particularly with fish muscle [51,52,53].

A very strong and positive Pearson correlation coefficient was found between buffer pH and yield (Table 2). However, Fig. 1 suggests a discontinuity in the relationship between buffer pH and yield. Statistical analysis showed that linear, quadratic, and segmented regression models were all significant (Table 3). Furthermore, according to the results of the ANOVA, the quadratic model was significantly (p < 0.05) better than the linear one. However, from the AIC values (93.750, 87.798 and 85.402 for linear, quadratic and segmented models, respectively), it can be stated that the segmented model was the best choice. This model accounted for 83.5% of the variability in the data. In addition, according to the Davies test, a significant (p < 0.0267) discontinuity or breakpoint was obtained at pH 5.1. Below the breakpoint, protein recovery is steeply reduced by decreasing pH; conversely, at higher pH values, this parameter would have practically no effect on the extraction yield according to the terms of the model shown in Table 3.

Following the same criteria, the relationship between extract pH and yield was analyzed. Although the relationship between both parameters apparently tended to be linearized (Fig. 2), the results of the statistical analysis showed that the segmented model was also the best option (Table 4). In this sense, the quadratic model obtained was significantly (p < 0.01) better than the linear one and the AIC values were 88.193, 77.0768, and 74.837 for linear, quadratic, and segmented models, respectively.

Moreover, this model accounted for greater variability of the data compared to the segmented model presented in Table 3 (92.7% vs 83.5%), with a significant breakpoint (p < 0.005) being established at pH 6.2, showing that the sharp decrease in protein extraction yield took place when the extract pH was lower than one of the liver. At this point, it should be noted that this reduction in yield cannot be unequivocally attributed to a decrease in pH, as there was also a change in the composition of the buffer solutions. Buffer solutions adjusted to pH ≤ 4.75 contained acid citric while phosphate buffers were prepared to extract liver proteins in the range of pH from 4.8 to 8.0. Many studies have highlighted the importance of the buffer system for protein recovery. Poor extraction properties have been reported for citrate buffers at low pH [54], while it has been shown that phosphate buffers enhance protein extractability compared to other buffers or distilled water [47, 48].

Foaming properties

Figure 3 shows the foaming capacity (FC) of the liver extracts and the relative stability of the obtained foams (rFS) as a function of the buffer pH. As can be observed, both parameters seemed to be closely related. In fact, Pearson correlation coefficient shows a very strong and positive correlation between them (Table 2). However, non-significant linear correlations were found between the buffer or extract pH and the foaming properties.

Foam capacity (FC) and relative foam stability (rFS) of pork liver extracts obtained under different pH conditions, this last expressed as the time for the initial foam volume to decay by half. Black circles: pH of extraction buffers initially considered; white squares: pH of extraction buffers included in a second step

As a whole, the extracts recovered can be clearly separated into three groups, depending on whether these properties were excellent (pH 4.0–4.5), medium-poor (pH 6.5–8.5) or very poor (pH 4.75–6.0). The extracts included in this last group seemed to behave more like anti-foaming agents [55], which could also have applications in the food industry. The high whippability of the extracts recovered at pH ≤ 4.5 resulted in foam volumes that were around three times that of the unfoamed protein solution. Also, these foams were very stable, with rFS values between 40 and 50 min for any of them (Fig. 3). In addition, to the naked eye, the structure of the foams appeared very uniform, compact, and firm, and with very small bubbles, which could explain the good stability of the foam since drainage and disproportionation could be slowed down [13, 56]. Similar foam volumes and relative stabilities were reported for porcine blood plasma proteins under comparable assay conditions in relation to both the air incorporation system and the geometry and size of the bowl containing the solution to be foamed [57]. However, the protein concentration in the test solution was 2 g/L for pork liver extracts and 5 g/L for pork plasma. So, liver extracts form and stabilize foams much more efficiently than plasma. Foam formation is influenced by protein concentration as it affects the adsorption rate [13, 58, 59]. Most proteins have the maximum expansion at concentrations of 2–8 g/L [26, 60], although lower concentrations have also been applied for proteins with excellent foaming properties such as egg albumen [61]. Foam volume increases with protein concentration up to a threshold value beyond which it decreases, probably caused by high protein concentrations which may favor the formation of insoluble aggregates [62]. Liver extracts obtained at pH ≤ 4.5 had pH values in the range from 5.27 to 5.58; that is, relatively close to the apparent pI of liver proteins (pH 5), according to da Costa et al. [24]. At pH values close to the pI, the adsorption of proteins on the surface is favored and foam stability improved [63,64,65,66,67,68,69]. However, the proximity of the extract pH to the pI of liver proteins cannot explain in this case the good foaming properties since most of the proteins whose pI was found around 5.0 should have precipitated during the centrifugation step. These extracts were transparent but, as mentioned before, those ones obtained at higher pH presented a cloudy appearance that could be due to the presence of protein complexes and/or other superstructures like lipoproteins [9, 13, 70,71,72]. Both can strongly affect foaming properties. High-molecular-weight proteins and protein aggregates are slowly adsorbed on the surface, thus limiting foam formation. In addition, they are not very efficient in reducing surface tension [73]. By contrast, proteins of relatively low molecular weight, soluble and flexible, tend to form voluminous foams because they can diffuse rapidly at the air–water surface. Martin et al. [58] observed that the minimum protein concentration required for foam formation could differ by a factor of 100 among proteins with different molecular weight. The ratio of low/high-molecular-weight proteins (including protein aggregates) can likely play an important role in modulating these properties. When a proper ratio is found in the solution, foam expansion can be improved, especially thanks to low-molecular-weight proteins. At the same time, high-molecular-weight proteins can improve the stability of the foam by increasing the viscoelasticity of the film and/or by forming a gel-like network [70, 72, 74,75,76,77].

The cloudy appearance of some extracts could also be due to the presence of lipids such as VLDL, which would also explain their poor foaming properties. Hepatocytes accumulate lipids packaged into VLDL that then secrets into the circulatory system [78]. VLDL are globular and high-molecular-weight particles soluble in aqueous solutions consisting of approximately 90% lipids and 10% proteins (apolipoproteins). Triacylglycerols, phospholipids—mainly, phosphatidylcholine—cholesterol and cholesteryl esters are found in the VLDL’s lipid fraction [79,80,81]. Apolipoproteins act as detergents, stabilizing the structure of the lipoprotein particle [82] resembling a spheroidal microemulsion. VLDL are relatively high in size but they are low in density (0.930–1.006 g mL−1) due to their high lipid content [83]. If the extraction conditions do not alter their stability, VLDL should be found in the extract or partially separated during the centrifugation step. However, VLDL stability decreases with lowering pH, which could lead to the disintegration of VLDL even at room temperature [79]. This disintegration could give rise to smaller but denser particles, which would favor their precipitation during centrifugation. This probably explains the differences not only in appearance and composition but also in techno-functional behavior among the extracts obtained at different pH. The presence of these particles could have a detrimental effect on foaming properties similar to that observed for yolk-contaminated egg white, which has been specifically attributed to yolk plasma fraction [84, 85]. This fraction is mainly composed of low-density lipoproteins (LDL) and livetins, a globular protein fraction [86]. A very low percentage of egg yolk is enough to drastically reduce the foaming properties of egg white [87]. The foaming properties of milk are also highly dependent not only on the fat content but also on the size of fat globules [88].

Interestingly, sugars can also strongly interact with proteins, thus affecting their techno-functionality in general, and their foaming properties in particular. In fact, it has been observed that adding sucrose or glucose (1%) to protein solutions (10% total dry extract) has beneficial effects on the foaming properties [89]. Glucose could actually be present in liver extracts as a consequence of gluconeogenesis during the fasting state [90]. As can be observed in Table 2, the carbohydrate content is relatively high in liver extracts obtained using buffer solutions adjusted to pH ≤ 4.5, which also showed very low fat contents. Both aspects could stimulate the foaming properties of these extracts. However, differences in the content of carbohydrates and fats between the extracts obtained using buffer solutions adjusted to pH 4.75 and pH 4.8 contrast with the similarity in terms of their foaming properties.

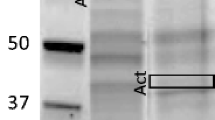

SDS-PAGE under reducing conditions

Qualitative effects of the buffer pH on the protein extraction were determined by SDS-PAGE under reducing conditions (Fig. 4a, b). All the analyzed protein profiles exhibited multiple bands of different intensity throughout the range of molecular weights analyzed (~ 10 kDa to 220 kDa) and even, in some of them, bands of higher molecular weight were evident. The profiles obtained revealed that there was a predominance of bands with a molecular weight ≤ 70 kDa. This would agree with Li et al. [91], who maintain that ~ 76% of liver proteins have a molecular weight ≤ 60 kDa. However, changes can be observed along the profile depending on the pH of the extraction buffer in relation to the presence/absence of specific bands and/or their intensity. Figure 4a shows clear differences between the electrophoretic profiles corresponding to the extracts obtained with buffers adjusted to pH ≤ 4.5 and those recovered with buffers adjusted to pH ≥ 5.0, which could be particularly relevant in the upper range of molecular weights. At pH 4.0 and 4.5, high-molecular-weight (> 220 kDa) polypeptide chains were poorly solubilized. In this sense, both the absence of the band in the upper part of the gel, corresponding to protein molecules incapable of penetrating the stacking gel, and the lower intensity of the band that did not penetrate the running gel, are remarkable. These bands probably correspond to certain apolipoproteins. Apolipoproteins with a molecular weight > 220 kDa can actually be found in very-low-density lipoproteins (VLDL) synthesized in the liver. In pork liver, the main protein component is apolipoprotein B-100 (Apo B-100), whose molecular weight is 515–550 kDa [81, 83, 92,93,94], being one of the largest monomeric proteins known [82]. Apolipoprotein(a) or Apo(a), with a molecular weight varying from 300 to 800 kDa, is also synthesized in the liver [83]. This apolipoprotein is covalently linked to Apo B-100 through a disulfide bond in a particular type of low-density lipoprotein known as lipoprotein(a), although liver processes and releases both proteins independently to form particles extracellularly, either in circulation or at the hepatocyte surface [95,96,97]. Interestingly, the profiles corresponding to the extracts recovered at pH 4.75 and 4.8 (Fig. 4b) also show the band that cannot penetrate the stacking gel.

SDS-PAGE under reducing conditions of pork liver protein extracts depending of the pH of extraction solution. a Lines 1–6, extracts recovered at pH 4.0, 4.5, 5.0, 6.0, 7.0, and 8.0, respectively; Std: molecular weight standards; b lines 1 and 2, extracts recovered at pH 4.75 and 4.80; Std: molecular weight standards

These changes in the electrophoretic profiles seem to be in accordance with the foaming properties of the different extracts because they were excellent when the extraction conditions did not favor the recovery of the highest molecular weight polypeptide chains. On the contrary, when they were recovered, extracts showed poor (buffer pH from 4.75 to 6.0) or medium-poor (buffer pH ≥ 6.5) foaming properties. In this last case, greater electrostatic repulsion acquired as the pH moves away from the pI could reduce the negative impact that high-molecular-weight proteins have on the foaming properties.

Conclusion

Protein extracts of pork liver obtained using buffer solutions adjusted to pH ≤ 4.5 exhibited excellent foaming properties. They were capable of forming large volumes of highly stable foam at very low protein concentration. Under these pH conditions, very large polypeptide chains—which seemed to be detrimental on the foaming properties—were not solubilized. Moreover, these extracts were very low in fat and relatively high in carbohydrates, both characteristics positively affecting the foaming properties. Therefore, despite the limited protein recovery (~ 30%), under these extraction conditions, it should not be necessary to include a concentration/purification step of the extract, unless subsequent spray-drying of the extract is planned to be incorporated to facilitate its conservation and storage.

Data availability

Data are available from the corresponding author upon reasonable request.

References

Shimizu M, Tanabe S, Morimatsu F, Nagao K, Yanagita T, Kato N, Nishimura T (2006) Consumption of pork-liver protein hydrolysate reduces body fat in otsuka long-evans tokushima fatty rats by suppressing hepatic lipogenesis. Biosci Biotechnol Biochem 70(1):112–118. https://doi.org/10.1271/bbb.70.112

Im S, Kurata T (2003) Characterization of off-flavors in porcine liver collected by SDE. Food Sci Technol Res 9(4):338–341. https://doi.org/10.3136/fstr.9.338

Hettiarachchy N, Kannan A, Schafer C, Wagner G (2013) Ch. 8. Gelling of plant based proteins. In: Bröckel U, Meier W, Wagner G (eds) Product design and engineering: formulation of gels and pastes. Wiley-VCH Verlag GmbH & Co, Weinheim, pp 221–245

Koyama S, Oka D, Tsujii Y, Takano K, Handa H (2020) Effects of lanthionine and lysinoalanine on heat induced gelation of egg white. Food Sci Technol Res 26(6):789–795. https://doi.org/10.3136/fstr.26.789

Lonchamp J, Akintoye M, Clegg PS, Euston SR (2020) Functional fungal extracts from the Quorn fermentation co-product as novel partial egg white replacers. Eur Food Res Technol 246:69–80. https://doi.org/10.1007/s00217-019-03390-1

Lucey JA (2002) Formation and physical properties of milk protein gels. J Dairy Sci 85(2):281–294. https://doi.org/10.3168/jds.S0022-0302(02)74078-2

Paraskevopoulou A, Kiosseoglou V (1997) Texture profile analysis of heat-formed gels and cakes prepared with low cholesterol egg yolk concentrates. J Food Sci 62(1):208–211. https://doi.org/10.1111/j.1365-2621.1997.tb04401.x

Saguer E, Fort N, Alvarez PA, Sedman J, Ashraf I (2008) Structure–functionality relationships of porcine plasma proteins probed by FTIR spectroscopy and texture analysis. Food Hydrocoll 22(3):459–467. https://doi.org/10.1016/j.foodhyd.2007.01.004

Zayas JF (1997) Foaming properties of proteins. In: Functionality of proteins in food. Springer, Berlin

EFSA CEP Panel (EFSA Panel on Food Contact Materials, Enzymes and Processing Aids, Lambré C, Barat Baviera JM, Bolognesi C, Cocconcelli PS, Crebelli R, Gott DM, Grob K, Lampi E, Mengelers M, Mortensen A, Rivière G, Steffensen I-L, Tlustos C, Van Loveren H, Vernis L, Zorn H, Herman L, Andryszkiewicz M, Maya J, Liu Y, Rainieri S Chesson A (2022) Scientific opinion on the safety evaluation of the food enzyme catalase from porcine liver. EFSA J 20(1):7009 https://doi.org/10.2903/j.efsa.2022.7009

Chomnawang C, Yongsawatdigul J (2013) Protein recovery of tilapia frame by-products by pH-shift method. J Aquat Food Prod Technol 22(2):112–120. https://doi.org/10.1080/10498850.2011.629077

Selmane D, Christophe V, Gholamreza D (2008) Extraction of proteins from slaughterhouse by-products: influence of operating conditions on functional properties. Meat Sci 79(4):640–647. https://doi.org/10.1016/j.meatsci.2007.10.029

Yang J, de Wit A, Diedericks CF, Venema P, van der Linden E, Sagis LMC (2022) Foaming and emulsifying properties of extensively and mildly extracted Bambara groundnut proteins: a comparison of legumin, vicilin and albumin protein. Food Hydrocoll 123(4):107190. https://doi.org/10.1016/j.foodhyd.2021.107190

Hrynets Y, Omana DA, Xu Y, Betti M (2011) Comparative study on the effect of acid- and alkaline-aided extractions on mechanically separated turkey meat (MSTM): chemical characteristics of recovered proteins. Process Biochem 46(1):335–343. https://doi.org/10.1016/j.procbio.2010.09.006

Jiang J, Chen J, Xiong YL (2009) Structural and emulsifying properties of soy protein isolate subjected to acid and alkaline pH-shifting processes. J Agric Food Chem 57(16):7579–7583. https://doi.org/10.1021/jf901585n

Jiang J, Xiong YL, Chen J (2010) pH shifting alters solubility characteristics and thermal stability of soy protein isolate and its globulin fractions in different pH, salt concentration, and temperature conditions. J Agric Food Chem 58(13):8035–8042. https://doi.org/10.1021/jf101045b

Muranyi IS, Otto C, Pickardt C, Osen R, Koehler P, Schweiggert-Weisz U (2016) Influence of the isolation method on the technofunctional properties of protein isolates from Lupinus angustifolius L. J Food Sci 81(11):C2656–C2663. https://doi.org/10.1111/1750-3841.13515

Pu S, Yin C, Zhang X, Zhang Y, Lu N, Xiong G (2022) The emulsion properties of chicken liver protein recovered through isoelectric solubilization/precipitation processes. Foods 11:1644. https://doi.org/10.3390/foods11111644

Dewitt CAM, Gomez G, James JM (2002) Protein extraction from beef heart using acid solubilization. J Food Sci 67(9):3335–3341. https://doi.org/10.1111/j.1365-2621.2002.tb09588.x

Abdollahi M, Undeland I (2019) Physicochemical and gel-forming properties of protein isolated from salmon, cod and herring by-products using the pH-shift method. LWT- Food Sci Technol 101:678–684. https://doi.org/10.1016/j.lwt.2018.11.087

Albe-Slabi S, Mesieres O, Mathé C, Ndiaye M, Galet O, Kapel R (2022) Combined effect of extraction and purification conditions on yield, composition and functional and structural properties of lupin proteins. Foods 11:1646. https://doi.org/10.3390/foods11111646

Cavonius LR, Albers E, Undeland I (2015) pH-shift processing of Nannochloropsis oculata microalgal biomass to obtain a protein-enriched food or feed ingredient. Algal Res 11:95–102. https://doi.org/10.1016/j.algal.2015.05.022

Chanted J, Panpipat W, Cheong LZ, Chaijan M (2022) Recovery of functional proteins from pig brain using pH-shift processes. Foods 11(5):695. https://doi.org/10.3390/foods11050695

da Costa CGC, Paula MMO, Massingue AA, Filho RAT, Ramos EM, Carneiro JDS (2019) Protein concentrates obtained from pig by-products using pH-shifting technique: a preliminary study. Ciência Rural 49(6):e20181048. https://doi.org/10.1590/0103-8478cr20181048

Güzel M, Çelik M, Yildirim M (2019) Effect of pH on protein extraction from mahaleb kernels and functional properties of resulting protein concentrate. Int J Food Eng 15(7):20180388. https://doi.org/10.1515/ijfe-2018-0388

Nissen SH, Schmidt JM, Gregersen S, Hammershøj M, Møller AH, Danielsen M, Stødkilde L, Nebel C, Dalsgaard TK (2021) Increased solubility and functional properties of precipitated Alfalfa protein concentrate subjected to pH shift processes. Food Hydrocoll 119:106874. https://doi.org/10.1016/j.foodhyd.2021.106874

Tsermoula P, Virgili C, Ortega RG, Mullen AM, Álvarez C, O’Brien NM, O’Flaherty EAA, O’Neill EE (2019) Functional protein rich extracts from bovine and porcine hearts using acid or alkali solubilisation and isoelectric precipitation. Int J Food Sci Technol 54(4):1292–1295. https://doi.org/10.1111/ijfs.14065

Vilg JV, Undeland I (2017) pH-driven solubilization and isoelectric precipitation of proteins from the brown seaweed Saccharina latissima—effects of osmotic shock, water volume and temperature. J Appl Phycol 29(1):585–593. https://doi.org/10.1007/s10811-016-0957-6

Shen K, Mu W, Xia S, Chen Y, Ren H, Xie X, Fang Y, Huang G (2021) Preparation of protein powder from the liver of Yellowfin tuna (Thunnus albacores): a comparison of acid- and alkali-aided pH-shifting. Food Sci Technol (Campinas). https://doi.org/10.1590/fst.40120

Xue S, Yu X, Li X, Zhao X, Han M, Xu X, Zhou G (2019) Structural changes and emulsion properties of goose liver proteins obtained by isoelectric solubilisation/precipitation processes. LWT-Food Sci Technol 102(4):190–196. https://doi.org/10.1016/j.lwt.2018.12.019

Sridharan S, Meinders MBJ, Bitter JH, Nikiforidis CV (2020) Pea flour as stabilizer of oil-in-water emulsions: protein purification unnecessary. Food Hydrocoll 101(2):105533. https://doi.org/10.1016/j.foodhyd.2019.105533

Feliu-Alsina N, Saguer E (2023) Microbiological quality and physicochemical characteristics of pork livers supplied by an industrial slaughterhouse. Polish J Food Nutr Sci 73(2):130–138. https://doi.org/10.31883/pjfns/162874

Toldrà M, Parés D, Saguer E, Carretero C (2019) Recovery and extraction of technofunctional proteins from porcine spleen using response surface methodology. Food Bioprocess Technol 12(7):298–312. https://doi.org/10.1007/s11947-018-2208-0

American Oil Chemist’ Society (2009) Official methods and recommended practices of the AOCS. 6th edition. Urbana

Benedict RC (1987) Determination of nitrogen and protein content of meat and meat products. J Assoc Off Anal Chem 70(1):69–74

Saguer E, Fort N, Regenstein JM (2006) Fish (Rainbow trout) blood and its fractions as food ingredients. J Aquat Food Prod Technol 15(1):19–54. https://doi.org/10.1300/J030v15n01_03

Laemmli UK (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 227(5259):680–685. https://doi.org/10.1038/227680a0

Muggeo VMR (2003) Estimating regression models with unknown break-points. Stat Med 22(19):3055–3071. https://doi.org/10.1002/sim.1545

Muggeo VMR (2008) Segmented: an R package to fit regression models with broken-line relationships. R News 8(1):20–25. Available on: https://cran.r-project.org/doc/Rnews

R Core Team (2022) R: a language and environment for statistical computing. The R Foundation for Statistical Computing, Vienna, Austria. Available on: https://www.R-project.org/

Akaike H (1974) A new look at the statistical model identification. IEEE Trans Autom Control 19(6):716–723. https://doi.org/10.1109/TAC.1974.1100705

Dyshlyuk LS, Izgaryshev AV, Garmashov SY, Sukhikh SA, Kashirskih EV (2017) Studying the features of the protein extraction from oat grains. J Pharm Sci Res 9(8):1344–1349

Gao Z, Shen P, Lan Y, Cui L, Ohm J-B, Chen B, Rao J (2020) Effect of alkaline extraction pH on structure properties, solubility, and beany flavor of yellow pea protein isolate. Food Res Int 131:109045. https://doi.org/10.1016/j.foodres.2020.109045

Parés D, Toldrà M, Camps E, Geli J, Saguer E, Carretero C (2020) RSM optimization for the recovery of technofunctional protein extracts from porcine hearts. Foods 9(12):1733. https://doi.org/10.3390/foods9121733

Meghanathan N (2016) Assortativity analysis of real-world network graphs based on centrality metrics. Comput Inf Sci 9(3):7–25. https://doi.org/10.5539/cis.v9n3p7

Trefts E, Gannon M, Wasserman DH (2017) The liver. Curr Biol CB 27(21):R1147–R1151. https://doi.org/10.1016/j.cub.2017.09.019

Nuckles RO, Smith DM, Merkel RA (1990) Meat by-product protein composition and functional properties in model systems. J Food Sci 55(3):640–643. https://doi.org/10.1111/j.1365-2621.1990.tb05196.x

Steen L, Glorieux S, Goemaere O, Brijs K, Paelinck H, Foubert I, Fraeye I (2016) Functional properties of pork liver protein fractions. Food Bioprocess Technol 9(6):970–980. https://doi.org/10.1007/s11947-016-1685-2

Zou Y, Bian H, Li P, Sun Z, Sun C, Zhang M, Geng Z, Xu W, Wang D (2018) Optimization and physicochemical properties of nutritional protein isolate from pork liver with ultrasound-assisted alkaline extraction. Anim Sci J 89(2):456–466. https://doi.org/10.1111/asj.12930

Avila Ruiz G, Xiao W, van Boekel M, Minor M, Stieger M (2016) Effect of extraction pH on heat-induced aggregation, gelation and microstructure of protein isolate from quinoa (Chenopodium quinoa Willd). Food Chem 209:203–210. https://doi.org/10.1016/j.foodchem.2016.04.052

Chen YC, Jaczynski J (2007) Protein recovery from rainbow trout (Oncorhynchus mykiss) processing byproducts via isoelectric solubilization/precipitation and its gelation properties as affected by functional additives. J Agric Food Chem 55(22):9079–9088. https://doi.org/10.1021/jf071992w

Kristinsson HG, Liang Y (2006) Effect of pH-shift processing and surimi processing on Atlantic croaker (Micropogonias undulates) muscle proteins. J Food Sci 71(5):C304–C312. https://doi.org/10.1111/j.1750-3841.2006.00046.x

Nolsoe N, Undeland I (2009) The acid and alkaline solubilization process for the isolation of muscle proteins: state of art. Food Bioprocess Technol 2(1):1–27. https://doi.org/10.1007/s11947-008-0088-4

Nugraha R, Ruethers T, Johnston EB, Rolland JM, O’Hehir RE, Kamath SD, Lopata AL (2021) Effects of extraction buffer on the solubility and immunoreactivity of the Pacific oyster allergens. Foods 10(2):409. https://doi.org/10.3390/foods10020409

Höfer R, Jost F, Schwuger MJ, Scharf R, Geke J, Kresse J, Lingmann H, Veitenhansl R, Erwied W (2000) Foams and foam control. In: Bailey JE et al (eds) Ullmann’s encyclopedia of industrial chemistry 6th edition. Wiley-VCH, Verlag GmbH & Co, Weinheim

Zhang T, Gong P, Wang Y, Jiang H, Zhang M, Yang M, Liu J, Liu X (2022) Lipid oxidation induced egg white protein foaming properties enhancement: the mechanism study revealed by high resolution mass spectrometry. Food Res Int 152:110713. https://doi.org/10.1016/j.foodres.2021.110713

Dàvila E, Saguer E, Toldrà M, Carretero C, Parés D (2007) Surface functional properties of blood plasma protein fractions. Eur Food Res Technol 226(1):207–214. https://doi.org/10.1007/s00217-006-0527-2

Martin AH, Grolle K, Bos MA, Cohen Stuart MA, van Vliet T (2002) Network forming properties of various proteins adsorbed at the air/water interface in relation to foam stability. J Colloid Interface Sci 254(1):175–183. https://doi.org/10.1006/jcis.2002.8592

van Koningsveld GA, Walstra P, Gruppen H, Wijngaards G, van Boekel MAJS, Voragen AGJ (2002) Formation and stability of foam made with various potato protein preparations. J Agric Food Chem 50(26):7651–7659. https://doi.org/10.1021/jf025587a

Damodaran S (2017) Amino acids, peptides and proteins. In: Damodaran S, Parkin KL (eds) Fennema’s food chemistry, 5th edn. CRC Press, London

Hammershøj M, Prins A, Qvist KB (1999) Influence of pH on surface properties of aqueous egg albumen solutions in relation to foaming behaviour. J Sci Food Agric 79(6):859–868. https://doi.org/10.1002/(SICI)1097-0010(19990501)79:6%3c859::AID-JSFA301%3e3.0.CO;2-C

Britten M, Lavoie L (1992) Foaming properties of proteins as affected by concentration. J Food Sci 57(5):1219–1241. https://doi.org/10.1111/j.1365-2621.1992.tb11303.x

Dachmann E, Nobis V, Kulozik U, Dombrowski J (2020) Surface and foaming properties of potato proteins: impact of protein concentration, pH value and ionic strength. Food Hydrocoll 107(1–2):105981. https://doi.org/10.1016/j.foodhyd.2020.105981

Engelhardt K, Lexis M, Gochev G, Konnerth C, Miller R, Willenbacher N, Peukert W, Braunschweig B (2013) pH effects on the molecular structure of β-lactoglobulin modified air−water interfaces and its impact on foam rheology. Langmuir 29(37):11646–11655. https://doi.org/10.1021/la402729g

Fameau A-L, Salonen A (2014) Effect of particles and aggregated structures on the foam stability and aging. Comptes Rendus Phys 15(8–9):748–760. https://doi.org/10.1016/j.crhy.2014.09.009

Narsimhan G, Xiang N (2018) Role of proteins on formation, drainage, and stability of liquid food foams. Annu Rev Food Sci Technol 9(1):45–63. https://doi.org/10.1146/annurev-food-030216-030009

Phillips LG, Schulman W, Kinsella JE (1990) pH and heat treatment effects on foaming of whey protein isolate. J Food Sci 55(4):1116–1119. https://doi.org/10.1111/j.1365-2621.1990.tb01612.x

Richert ME, García Rey N, Braunschweig B (2018) Charge-controlled surface properties of native and fluorophore-labeled bovine serum albumin at the air–water interface. J Phys Chem B 122(45):10377–10383. https://doi.org/10.1021/acs.jpcb.8b06481

Zhang Z, Dalgleish DG, Goff HD (2004) Effect of pH and ionic strength on competitive protein adsorption to air/water interfaces in aqueous foams made with mixed milk proteins. Colloids Surf B 34(2):113–121. https://doi.org/10.1016/j.colsurfb.2003.11.009

Nicorescu I, Loisel C, Riaublanc A, Vial C, Djelveh G, Cuvelier G, Legrand J (2009) Effect of dynamic heat treatment on the physical properties of whey protein foams. Food Hydrocoll 23(4):1209–1219. https://doi.org/10.1016/j.foodhyd.2008.09.005

Poirier A, Stocco A, Kapel R, In M, Ramos L, Banc A (2021) Sunflower proteins at air–water and oil–water interfaces. Langmuir 37(8):2714–2727. https://doi.org/10.1021/acs.langmuir.0c03441

Zhu H, Damodaran S (1994) Heat-induced conformational changes in whey protein isolate and its relation to foaming properties. J Agric Food Chem 42(4):846–855. https://doi.org/10.1021/jf00040a002

Pugnaloni LA, Dickinson E, Ettelaie R, Mackie AR, Wilde PJ (2004) Competitive adsorption of proteins and low molecular-weight surfactants: computer simulation and microscopic imaging. Adv Coll Interface Sci 107(1):27–49. https://doi.org/10.1016/j.cis.2003.08.003

Oboroceanu D, Wang L, Magner E, Auty MAE (2014) Fibrillization of whey proteins improves foaming capacity and foam stability at low protein concentrations. J Food Eng 121:102–111. https://doi.org/10.1016/j.jfoodeng.2013.08.023

Rullier B, Axelos MAV, Langevin D, Novales B (2009) β-Lactoglobulin aggregates in foam films: correlation between foam films and foaming properties. J Colloid Interface Sci 336(2):750–755. https://doi.org/10.1016/j.jcis.2009.04.034

Schmidt I, Novales B, Boué F, Axelos MAV (2010) Foaming properties of protein/pectin electrostatic complexes and foam structure at nanoscale. J Colloid Interface Sci 345(2):316–324. https://doi.org/10.1016/j.jcis.2010.01.016

Wierenga PA, Gruppen H (2010) New views on foams from protein solutions. Curr Opin Colloid Interface Sci 15(5):365–373. https://doi.org/10.1016/j.cocis.2010.05.017

Sheng L, Jiang B, Rui L (2013) Intracellular lipid content is a key intrinsic determinant for hepatocyte viability and metabolic and inflammatory states in mice. Am J Physiol Endocrinol Metab 305(9):E1115–E1123. https://doi.org/10.1152/ajpendo.00401

Guha M, Gursky O (2011) Human plasma very low-density lipoproteins are stabilized by electrostatic interactions and destabilized by acidic pH. J Lipids. https://doi.org/10.1155/2011/493720

Juarez Casso FM, Farzam K (2023) Biochemistry, very low density lipoprotein. In: StatPearls [Internet]. StatPearls Publishing. Treasure Island, FL, USA. Available from: https://www.ncbi.nlm.nih.gov/books/NBK587400/

Rutledge AC, Su Q, Adeli K (2010) Apolipoprotein B100 biogenesis: a complex array of intracellular mechanisms regulating folding, stability, and lipoprotein assembly. Biochem Cell Biol 88(2):251–267. https://doi.org/10.1139/o09-168

Segrest JP, Jones MK, De Loof H, Dasht N (2001) Structure of apolipoprotein B-100 in low density lipoproteins. J Lipid Res 42(9):1346–1367. https://doi.org/10.1016/S0022-2275(20)30267-4

Feingold KR (2021) Introduction to lipids and lipoproteins. In: Feingold KR et al (eds.), Endotext [Internet]. MDText.com, Inc. South Dartmouth (MA). Avalaible on: https://www.ncbi.nlm.nih.gov/books/NBK305896/

Lomakina K, Mı́ková K (2006) A study of the factors affecting the foaming properties of egg white—a review. Czech J Food Sci 24(3):110–118. https://doi.org/10.17221/3305-CJFS

Wang G, Wang T (2009) Effects of yolk contamination, shearing, and heating on foaming properties of fresh egg white. J Food Sci 74(2):C147–C156. https://doi.org/10.1111/j.1750-3841.2009.01054.x

Li X, Wang YM, Sun CF, Lv JH, Yang YJ (2021) Comparative study on foaming properties of egg white with yolk fractions and their hydrolysates. Foods 10(9):2238. https://doi.org/10.3390/foods10092238

Li X, Li J, Chang C, Wang C, Zhang M, Su Y, Yang Y (2019) Foaming characterization of fresh egg white proteins as a function of different proportions of egg yolk fractions. Food Hydrocoll 90:118–125. https://doi.org/10.1016/j.foodhyd.2018.12.014

Ho TM, Dhungana P, Bhandari B, Bansal N (2021) Effect of the native fat globule size on foaming properties and foam structure of milk. J Food Eng 291:110227. https://doi.org/10.1016/j.jfoodeng.2020.110227

Farrag AF (2008) Emulsifying and foaming properties of whey protein concentrates in the presence of some carbohydrates. Int J Dairy Sci 3(1):20–28. https://doi.org/10.3923/ijds.2008.20.28

Rui L (2014) Energy metabolism in the liver. Compr Physiol 4(1):177–197. https://doi.org/10.1002/cphy.c130024

Li B, Yang J, Gong Y, Xiao Y, Zeng Q, Xu K, Duan Y, He J, He J, Ma H (2021) Integrated analysis of liver transcriptome, miRNA, and proteome of Chinese indigenous breed Ningxiang pig in three developmental stages uncovers significant miRNA–mRNA–protein networks in lipid metabolism. Front Genetics 12:709521. https://doi.org/10.3389/fgene.2021.709521

Birchbauer A, Wolf G, Knipping G (1992) Metabolism of very low density lipoproteins in the pig. An in vivo study. Int J Biochem 24(10):1591–1597. https://doi.org/10.1016/0020-711x(92)90175-z

Greeve J, Altkemper I, Dieterich JH, Greten H, Windler E (1993) Apolipoprotein B mRNA editing in 12 different mammalian species: hepatic expression is reflected in low concentrations of apoB-containing plasma lipoproteins. J Lipid Res 4(8):1367–1383. https://doi.org/10.1016/S0022-2275(20)36966-2

Lusis AJ, West R, Mehrabian M, Reuben MA, LeBoeuf RC, Kaptein JS, David F, Schumaker VN, Yuhasz MP, Schotz MC, Elovson J (1985) Cloning and expression of apolipoprotein B, the major protein of low and very low density lipoproteins. Proc Natl Acad Sci USA 82(14):4597–4601. https://doi.org/10.1073/pnas.82.14.4597

Dieplinger H, Utermann G (1999) The seventh myth of lipoprotein(a): where and how is it assembled? Curr Opin Lipidol 10(3):275–283. https://doi.org/10.1097/00041433-199906000-00010

Uccello M, Malaguarnera G, Pelligra EM, Biondi A, Basile F, Motta M (2011) Lipoprotein(a) as a potential marker of residual liver function in hepatocellular carcinoma. Indian J Med Paediatr Oncol 32(2):71–75. https://doi.org/10.4103/0971-5851.89775

Utermann G (1989) The mysteries of lipoprotein(a). Science 246(4932):904–910. https://doi.org/10.1126/science.2530631

Acknowledgements

We acknowledge NORFRISA (Girona, Spain) for kindly donation of pork livers. We also want to thank Professor Emili García-Berthou for his support in the statistical analysis of the data.

Funding

Open Access funding provided thanks to the CRUE-CSIC agreement with Springer Nature. This work was financially supported by the Government of Spain (project ref. RTA2017-00024-C04-02).

Author information

Authors and Affiliations

Contributions

ES contributed to the study conception and design. Material preparation, data collection, and analysis were performed by NF-A and ES. The first draft of the manuscript was written by ES. NF-A and ES commented on previous versions of the manuscript. NF-A and ES read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Compliance with ethics requirements

The authors declare this study was conducted in accordance with ethical guideline and principles.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Feliu-Alsina, N., Saguer, E. Pork liver as a source of protein with excellent foaming properties. Eur Food Res Technol 250, 677–689 (2024). https://doi.org/10.1007/s00217-023-04427-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-023-04427-2