Abstract

Meat grinders are composed of a combination of individual functional elements (e.g., screw conveyor, perforated plates, knives). This setup, and in particular the chosen cutting set, influences the characteristics of ground meat and hamburgers produced. In this study, we took a closer look at the effect of cutting set variations and process parameters on structural, functional, and physicochemical properties of beef hamburgers produced. It was found that the specific mechanical energy input during grinding increased when cutting levels, i.e., a set of one hole plate and one knife, were increased, causing more cell disintegration (r = 0.387, p = 0.02). Surprisingly though, an influence on the functional and quality parameters of the hamburgers could not be found for most parameters tested. The findings indicate that variations in the cutting set affect the process parameters and the stress applied to the meat, but residence times in this zone are too small to cause noticeable effects on the analytical and qualitative properties of hamburgers. As such, there are options for energy and cost optimization of industrial grinding processes without sacrificing quality.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Sausages, ground meat, and other ground meat products are very important product classes in the German meat industry [1], using grinding as a key processing technique for size reduction. As the meat industry has shifted from small-scale, handcrafted to high-capacity, industrial-scale production [2], maintaining high product quality requires optimal process design based on in-depth knowledge of processes and mechanisms. The choice of a suitable cutting set, i.e., the specific combination of a series of hole plates and knives, is crucial for the size reduction in the grinder [3, 4], affecting the morphological structure and thus the physicochemical, sensory, and functional properties of ground products such as hamburgers [5,6,7,8,9,10,11,12,13].

Meat is an anisotropic, plasto-elastic material with a fibrous structure, able to store and release forces to a certain degree [4, 13,14,15,16,17]. When meat is conveyed through grinders, it is subjected to shear forces and wall friction between the rotating grinding screw, the meat, and the housing. In the cutting set zone, the material is comminuted by the superimposition of irreversible deformations [4, 12, 17, 18]. During conveying, the grinding screw compresses the meat and creates a pressure gradient with the highest pressure in front of the cutting set [12, 17,18,19]. The comminution of meat already begins during the conveying and that associated compression, due to the applied pressure and shear forces [12, 15, 20, 21]. The applied forces disintegrate the inner structures of the meat due to mechanical overloading, while the rotating knives of the cutting set then cut the extruded meat strands by applying shear forces. This results in reduced particle sizes of the raw material [3, 12, 17, 22, 23].

A cutting set contains several static hole plates and rotating knives with different geometries, layouts, and amounts of combined plates and knives depending on the raw material, the process, and the desired product properties. The number of combined plates and knives determines the number of cutting levels [3]. The meat-cutting processes on the hole plates are mainly influenced by the knife sets, the number of blades, and the speed of rotation [2, 3]. The knife geometry affects the continuous flow of the raw material, following the principle of drag flow [3, 12, 18]. Increasing the number of blades per knife can result in a more uniform and smaller particle size of the ground meat, and significantly increases throughput [3, 17]. On the other hand, excessive knife speed can negatively affect the cutting process due to increased abrasion of the cutting tools and material [23]. The sharpness of the knife sets is crucial for the quality of the produced ground product. Sharp knives protect the material by cutting it rather than squeezing it, thus reducing frictional forces and juice leakage [2, 24]. A non-optimal adjusted arrangement and speed of the knives can negatively affect the process, e.g., by causing a blockage of the cutting set, increasing energy consumption, and abrasion [17, 23], and leakage of liquid, ultimately reducing product quality [25].

Intense processes might also cause stronger oxygen incorporation into the meat mass during manufacturing which accelerates the oxidation processed [26]. Besides the oxidation of myoglobin to metmyoglobin, fats and other components are oxidized due to higher oxygen exposure. As it is reported that the oxidation of lipids and myoglobin follow the same mechanisms based on oxy-free radical generation, myoglobin and metmyoglobin might be used as quality degradation indicators [27, 28].

The hole plates are essential for the size reduction performance and quality of the grinding process. Hole plates narrow the outlet area of the grinder and facilitate pressure buildup [12, 18], allowing for fixation of the raw material during rotational cutting and, ensuring the comminution of the raw material by partial ruptures through sharp-edged holes [29]. The size of the drill holes determines the particle sizes [29]. It was reported that applied forces are reduced the larger the drill holes of the plate [17]. A higher number of drilled holes increases the throughput of a grinder, but higher pressures on the bridges between the holes can increase abrasion [30]. Zhao and Sebranek [31] reported that an improved adjustment of the hole sizes of the plates improves the sensory quality of the products. Mechanical over-processing can cause cell structure disintegration and meat juice leakage [2, 29]. As a consequence, stepwise comminution in the cutting set results in the best comminution performance and involves combining knives and hole plates with varying diameters [2, 15]. This method pre-cuts meat at larger diameter hole plates and disintegrates the collagenous structures before the final size reduction. Knowledge about the influence of the cutting sets on structural and quality parameters of ground meat is primarily based on practical experience gained over several decades [19, 23, 32,33,34]. Based on this knowledge it was hypothesized, that cutting sets with inclined drill holes and with fewer cutting levels cause less cell disintegration, thus causing fewer changes in the structural, physicochemical, and functional properties of the hamburgers. The aim of the present study is therefore to investigate correlations between cutting set composition and the morphological, physicochemical, and functional properties of beef hamburgers.

Materials and methods

Materials and sample preparation

The hamburgers were produced according to the production flowchart in Fig. 1.

Beef from the flanks of heifers (M. obliquus externus abdominis, M. transversus abdominis, M. obliquus internus abdominis; Prändl, Fischer [35]) was purchased from MEGA (MEGA—Das Fachzentrum für die Metzgerei und Gastronomie eG, Stuttgart, Germany), manually standardized to 20% fat, roughly freed from tendons and cut into cubes of ca. 5 × 5 × 5 cm size. The standardized meat material was homogeneously mixed at 32 rpm for 30 s in left-hand rotation and for 30 s in right-hand rotation in a horizontal paddle mixer (Paddle mixer type RC-40, Equipamientos Cárnicos, S.L., Mainca, Barcelona, Spain). Until further manufacturing, 75% of the meat was stored at T = 1 °C, and 25% was frozen to a core temperature of T = − 12 °C overnight. The temperatures were chosen to ensure that frictional heat generated during grinding is sufficiently counteracted to prevent protein denaturation. The cooled and frozen meat cubes were mixed in the horizontal paddle mixer for 30 s at 32 rpm in left-hand rotation to ensure homogeneous distribution and first ground to a particle size of 13 mm using a meat grinder (Forschungsautomatenwolf Typ AE 130, Maschinenfabrik Seydelmann KG, Stuttgart, Germany) equipped with a three-part cutting set (pre-cutter, 4-blade knife, 13 mm inclined end hole plate). Throughout the entire experiment, the rotational speed of the meat grinder was set to 20 rpm at the feeding screw and 187 rpm at the grinding screw. The pre-ground 13 mm meat was ground to a final particle size of 3 mm in the second grinding step. Batches of ca. 10 kg were separately ground using different cutting set compositions (Fig. 1). Details of all cutting set parts are listed in Table 1, and the cutting set variations are displayed in Fig. 1. One cutting level (CL) is thereby defined as the combination of one hole plate and one knife. In straight hole plates, the drill holes are drilled perpendicular to the surface of the perforated disc, whereas the drill holes in the inclined hole plates are arranged in a spiraling pattern with a certain angle inclined to the surface [33, 34]. The ratio between the total drill hole area and total plate area is 0.42 for the straight 3 mm end hole plate and 0.44 for the inclined 3 mm end hole plate.

The ground meat was formed using a modified hamburger press (MH-100 (modified), Equipamientos Cárnicos, S.L. (Mainca), Barcelona, Spain) by applying p = 5 bar forming pressure. The hamburgers weighed m = 90 g, had a height of h = 0.9 cm, and a diameter of d = 10 cm. The experiment was performed in duplicate.

Methods

Chemical composition of hamburgers

Before the water, fat, and protein determination, one hamburger per batch was homogenized for 30 s in a blender (Blixer® 2, Robot-Coupe, Montceau-en-Bourgogne, France). The water content was determined from the meat mass by the sea-sand method (§64 LFGB L 06.00–3 [36]), the fat content by Soxhlet extraction (Büchi 810, Büchi Laboratoriums-Technik AG, Flawil, Switzerland) from the residues of the water determination (§64 LFGB L 06.00–6 [36] and the protein content by the Dumas’ combustion method (Dumatherm N Pro, C. Gerhardt GmbH & Co. KG, Königswinter, Germany) (§64 LFGB method L 06.00–20 [36] using a nitrogen-to-protein conversion factor of 6.25 [37]. The Dumas method as a rapid method was chosen due to the large sample sizes analyzed. The pH was determined using a puncture electrode (Microprocessor pH Meter 537 equipped with electrode WTW SenTix Sp, Xylem Analytics Germany Sales GmbH & Co. KG, Weilheim, Germany).

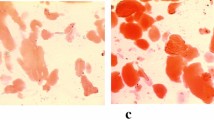

Histochemical analyses

The amount of non-intact cells (ANIC) in the hamburgers was histochemically assessed using a previously described method by Berger, Gibis [6] and Berger, Witte [7] following the official guidelines of § 64 LFGB (L 06.00-13) [36]. The ANIC was calculated based on the results of the point-count method, where the amount of non-intact cells in thin cryo-cut cross sections of the hamburgers was counted. Per sample at least n = 6 cross sections were investigated, and two cross sections each were averaged. The mean and the standard deviation of the three repetitions was calculated.

Determination of drip loss

The centrifugation method was used to determine the drip loss of the hamburgers. According to Berger, Gibis [6] and Berger, Witte [7], a 10 g sample was centrifuged for 20 min at 5 °C and 24,040g (Centrifuge Z32HK, Hermle Labortechnik GmbH, Wehingen, Germany). The drip loss was obtained by differential weighing.

Determination of firmness by forward extrusion

The forward extrusion method described by Berger, Gibis [6] was used to determine the firmness of the ground meat. For this, a texture measurement device (Instron, Model 3365, Instron Engineering Corporation Ltd, Massachusetts, USA) recorded the required force to press ground meat through a cylinder (d = 50 mm) with a 7.5 mm hole opening at a crosshead speed of 0.33 mm/s.

Grilling procedure of hamburgers

Frozen hamburgers were grilled on an electric contact grill (Nevada, Neumärker, Hemer, Germany) for 150 s at 200 ± 5 °C until a core temperature of 72 °C had been reached. Hamburgers were covered by a sheet of aluminum foil on both sides, to prevent sticking and disintegration on the surface of the grill. The hamburgers were allowed to cool to ambient temperature for at least 30 min and stored airtight in plastic bags until further analyses.

Determination of hardness by Warner–Bratzler shear cell

Hamburgers were grilled as described in “Grilling procedure of hamburgers” and allowed to cool to ambient temperature for at least 30 min. Then strips (width: 1.5 cm) were manually cut from the center to ensure sample homogeneity. The hardness of the grilled hamburger was analyzed by a texture analyzer (Model 3365, Instron Engineering Corporation Ltd., Massachusetts, USA) equipped with a V-shaped Warner–Bratzler guillotine (63° opening angle and 60 mm opening height). A crosshead speed of 250 mm/min was applied to cut through the sample completely. The maximal shear force (N) was recorded (n = 24 per sample).

Preparation of the extracted meat solution

Extracted meat solutions from all samples were produced to be used in further analyses. Following the instructions of Berger, Witte [7], hamburgers were diluted 1:10 with 10 mM potassium phosphate buffer (pH 7, T = 2 °C), filtered, and stored cooled in brown glass bottles until further analysis.

Determination of soluble protein content (SPC)

The amount of soluble protein in the extracted meat solution was quantified in triplicate through rapid nitrogen analysis according to the Dumas combustion method (Dumatherm N Pro, C. Gerhardt GmbH & Co. KG, Königswinter, Germany) [36]. The rapid Dumas method was used due to large sample sizes. A nitrogen-to-protein conversion factor of 6.25 according to Mariotti, Tomé [37] was used.

Determination of myoglobin (Mb) and metmyoglobin (MetMb) content

Oxidative changes of meat pigments were assessed by photometric determination of the myoglobin (Mb) and metmyoglobin (MetMb) content of the respective extracted meat solution, as already described by Berger, Gibis [6] (MetMb determination) and Berger, Witte [7] (Mb determination). For this, 100 μL of each meat extract was transferred into a 96-well transparent plate (NunclonTM Delta Surface, Thermo Fisher Scientific, Roskilde, Denmark) and absorption spectra were recorded at 25 °C using a microplate reader (Biotek Synergy HT, Biotek Instruments, Inc., Winooski, USA). The MetMb and Mb contents were then calculated according to Trout [38].

Sensory and optical evaluation

Sensory and optical properties of grilled hamburgers (see “Grilling procedure of hamburgers”) were evaluated using a 10-point rating scale. A sensory score of 5 points represents the compared reference standard. The reference was defined as standard in pretests by sensory experts. For the sensory evaluation, grilled and cooled (T = 7 °C) hamburgers were cut into quarters using a standardized cutting template. For reheating before the sensory testing, one hamburger was placed on a melamine plate (white melamine plate 190 × 145 mm, WACA-Kunststoffwarenfabrik, Halver, Germany), covered with another plate of the same type and reheated in a microwave (model HF15M541, Siemens Aktiengesellschaft, Munich, Germany) under standardized conditions (P = 800 W; t = 45 s) to a core temperature of T = 70 ± 2 °C. The parameters hardness, juiciness, texture, and overall acceptability of the hamburgers were assessed. For optical evaluation, cooled hamburgers were cut cross-sectionally with a slicer (Bizerba VS8A, Wilhelm Kraut GmbH & Co. KG, Balingen, Germany), and the inner structure was evaluated in terms of the coarseness of the particles, amount of batter-like substance and overall acceptability. The sensory evaluation was performed using a 10-point scale (0 = harder/dryer/compacter/worse/finer/more batter-like substance and 10 = softer/juicer/looser/better/coarser/less batter-like substance). Each sample was evaluated by at least n = 18 panelists. The panel consisted of persons of different genders, ages, and backgrounds making the sensory test diverse and enabling to reduction of errors. Informed consent was obtained from each panelist prior to their participation in the study.

Process control parameters

The grinding screw torque was recorded during the second grinding by the operating software of the meat grinder (S7-To-Excel Tool—Expert—for Windows, Träger Industry Components, Weiden, Germany) for all batches produced with different cutting set compositions. The idle torque of the grinding screw was previously determined to be M = 6.9 ± 1.1 Nm (data not shown). The mass flow was determined by weighing the output of ground meat over the course of 15 s.

Determination of specific mechanic energy input (SME)

The mass-specific mechanical energy input SME (J/kg) as the degree of shear strain during grinding was calculated according to the following Eq. 1 and 2 [18, 39,40,41].

with P the average power during grinding process (W), M the average grinding screw torque during grinding (Nm), \({M}_{\mathrm{empty}}\) the idling torque of grinding screw (Nm), \(\dot{m}=\frac{m}{t}\) being the mass flow (kg/s), \({n }_{\mathrm{rad}}=\frac{2\pi \times {n}_{\mathrm{grinding screw}}}{60}\) being the radial rotational speed of the grinding screw (s−1), and \({n}_{\mathrm{grinding screw}}\) the rotational speed of the grinding screw (s−1). The average torque during grinding is determined as the torque during the plateau phase of grinding.

Statistical analyses

Two independent experiments (biological replicates) with at least three analytical replicates (technical replicates) were performed per cutting set variations. All results are presented as mean ± standard deviation or mean ± standard error (torque profiles), both calculated by MS Excel (Microsoft, Redmond, WA, USA), plotted with OriginPro 2020 (OriginLab Corporation, North Hampton, MA, USA), and statistically analyzed using SPSS (IBM SPSS Statistics 26, IBM Deutschland GmbH, Ehningen, Germany).

Shapiro–Wilk and Levene tests were used to check the normal distribution and variance homogeneity of the data. An analysis of variance (ANOVA) was performed by applying the Tukey post hoc test for data sets tested for variance homogeneity (confidence interval of 95%, p = 0.05). Additionally, a two-factorial analysis of variance (two-way ANOVA) was performed for the sensory and optical attributes using the Tukey post hoc test (confidence interval of 95%, p = 0.05). For data sets without homogeneous variances, a robust Welch-ANOVA with a Games–Howell post hoc test was performed (confidence interval of 95%, p = 0.05). To assess the linear correlation between two normally distributed variables, a Pearson correlation analysis was carried out. A statistically significant difference between means was considered if p < 0.05 and is indicated by small letters attached to the mean value of the measurement.

Results and discussion

Chemical composition

The hamburgers in this study were produced according to German guidelines for meat and meat products and contained beef only, i.e., no salt or spices were added [42]. They were composed of 60.9 ± 0.8% water, 19.8 ± 0.7% fat, and 18.75 ± 0.07% protein, and had a pH of 5.75 ± 0.03.

Structural changes

As a parameter for structural changes in hamburgers upon manufacturing with different cutting set compositions, the amount of non-intact cells (ANIC) was determined. Figure 2 shows the ANIC of the hamburgers at different cutting set compositions.

The ANIC of the hamburgers ranged from 10.82 ± 0.84 vol% in the system equipped with one inclined cutting level (1CL/inclined) to 14.43 ± 0.18 vol% in the system with two straight cutting levels and a 7.8 mm middle hole plate (MHP) (2CL/7.8 mm/straight). The statistical analysis revealed that there was a significant difference between the 1CL/inclined and 2CL/straight with both sizes of MHP. All other combinations showed no significant differences (Fig. 2). As initially hypothesized, the cutting set with the inclined drill holes resulted in lower or comparable ANIC as the straight drill holes. This is in agreement with the results of Büchs [34] and Haack [43], who reported that the use of inclined hole perforated discs in the grinding process improved the quality of the resulting ground meat. This might be caused by the entrance angle of the meat in the cutting set, which is lower if the drill holes are inclined; thus frictional forces are reduced, and fewer cells get disintegrated [4, 33, 34, 43]. Further, the assumption that fewer cutting levels cause less cell disintegration could be confirmed. This result contrasts with the finding of Barbut [2] and Haack, Schnäckel [3], who stated that the size reduction is most gentle if the size is reduced gradually. Considering the working principle and size reductions mechanism in a meat grinder, which is based on pressure buildup and shearing, the difference can be explained by less frictional force and less pressure acting on the meat if fewer cutting levels are used [3, 17, 44, 45]. The effect of reduced forces probably outweighs the large difference in the particle size before and after grinding.

However, the difference between the lowest and the highest ANIC amounts to about 4 Vol.%, thus structural changes due to cutting set variations were relatively small. Furthermore, none of the examined cutting set variations exceeded the legal limit of 20 vol% of destructed cells [42].

Changes in mechanical process control parameters

The specific mechanical energy input was used as a parameter to rate the mechanical load of the material during the second grinding [18, 40, 41]. The SME during the second grinding with different cutting set compositions is illustrated in Fig. 3.

Figure 3 shows that the SME was significantly reduced at fewer cutting levels (1CL/inclined: 1.2 ± 0.05 kJ/kg; 2CL/7.8 mm/inclined: 2.4 ± 0.3 kJ/kg) and when hole plates with inclined drill holes were used (1CL/inclined: 1.2 ± 0.05 kJ/kg; 2CL/straight: 1.54 ± 0.06 kJ/kg). This might also be attributed to the entrance angle of the meat to the drill holes, as previously described [17, 23, 33]. However, the use of different sizes of MHP did not significantly affect the energy input during grinding. Since Haack, Schnäckel [3] and Schnäckel, Krickmeier [46] reported a gentler grinding if particle sizes were reduced gradually, it was assumed that the 7.8 mm MHP might result in lower energy use, as the size reduction was more uniform. However, this could not be proven in this study.

Figure 4 shows the grinding screw torque during the second grinding with different cutting set compositions.

Similar to the SME, the torque was lower when using fewer cutting levels (1CL/inclined: ca. 25 Nm; 2CL/straight: ca. 40 Nm). Torque is defined as a measure of the energy the motor needs to provide into the process [18]. Following this, higher torque values go along with a stronger load in the processed meat which confirms the higher ANIC when using more cutting levels (Fig. 2). Furthermore, it must be emphasized that pressure differences in the cutting set compositions occurred (Fig. 4). Although the pressure in the cutting set using one cutting level was higher than that using two cutting levels, the ANIC (Fig. 2) and SME (Fig. 3) wewre lower. A pressure difference between the same composition at different geometry, e.g., 1CL/straight vs. 1CL/inclined, was not detected, and thus the small difference in total drill hole area did not influence the pressure buildup. One can thus conclude that the additional shear forces due to the additional cutting plate outweigh the influence of the higher pressures.

A Pearson correlation analysis between the process-related parameter SME and the structural parameter ANIC showed a significant, positive correlation (r = 0.387, p = 0.020). This underlines the hypothesis that increased mechanical stress caused more cell disintegration and is in agreement with previous studies [6, 47, 48]. It further indicates that both the composition of the cutting set as well as the choice of the hole plates and the size of the drill holes influence the induced frictional forces occurring during the grinding process and thus the quality of the end product. This conclusion was also reached by Haack, Schnäckel [3].

Influence on physicochemical and functional properties of hamburgers

The effect of cutting set composition on the physicochemical and functional properties of the hamburgers was investigated in terms of the raw hamburgers drip loss (DL) and firmness, the extracted meat solutions’ soluble protein content (SPC), the myoglobin (Mb) and metmyoglobin (MetMb) content, and the fried hamburgers hardness. An optical and sensory evaluation was performed to assess the quality of the hamburgers. Further, possible correlations of the parameters with the ANIC and SME were checked and are summarized in Table 2.

The drip loss of the raw hamburgers ranged from 3.79 ± 0.99% for the sample produced with one cutting level and inclined drill hole to 4.87 ± 1.07% for the sample produced with two cutting levels, the 10 mm EHP and straight drill holes, as shown in Fig. 5.

However, no statistical differences could be found between the samples. Since literature reports an increased leakage of intracellular contents from samples with an increased number of destructed cells [3, 25], it was initially postulated that the DL of the samples increases with increasing ANIC and SME. However, Pearson correlation analyses revealed no statistically significant correlation of the DL with the ANIC (r = 0.082, p = 0.634) or with the SME (r = -0.167, p = 0.329).

The firmness of the raw ground meat was found to range from 254.27 ± 4.69 N (2CL/10 mm/straight) to 272.67 ± 28.77 N (1CL/inclined). There too, no statistically significant differences were detected between the samples (Fig. 5). In their research, Acton [25] and Chesney, Mandigo [49] reported that with decreasing particle sizes, the cohesiveness and binding strength of burger patties increased due to increased cell disruption and release of intracellular contents. Based on those findings, it was assumed that samples having a higher ANIC and thus consisting of a higher number of smaller cells would have a firmer structure. A Pearson correlation analysis, however, did not show a correlation between the firmness and the ANIC in the present study (r = − 0.187, p = 0.288).

The hardness of the grilled hamburgers was analyzed using the Warner–Bratzler shear cell and varied between 2.92 ± 0.18 N (2CL/7.8 mm/straight) and 4.62 ± 0.69 N (2CL/10 mm/inclined) (Fig. 5). Figure 5 shows that there is no statistically significant difference between samples ground with different cutting set compositions. As the Pearson correlation analysis revealed a significant negative correlation between the hardness and the ANIC (r = − 0.337, p = 0.045, Table 2), the results are in line with the findings of Chesney, Mandigo [49] who reported that the maximum shear force in flaked pork meat decreased with decreasing particle size.

The SPC in the samples produced with different cutting sets ranging from 4.05 ± 0.96% (2CL/7.8 mm/straight) to 5.02 ± 5.07% (1CL/inclined) with no statistically significant differences between the different treatments (Table 3). Based on previous findings that intracellular compounds such as proteins or myoglobin may leak out when cell gets disintegrated, an increased SPC was assumed [3, 25, 49]. The Pearson correlation analysis revealed again no significant correlation between the SPC and the ANIC (r = − 0.224, p = 0.188, Table 2), but a significant, negative correlation between SPC and the SME (r = − 0.409, p = 0.013, Table 2). This indicates a reduced SPC with increasing SME and might result from the incorporation of soluble proteins in network formation upon increasing energy input. The results of this study are in line with the findings of a previous work, where the authors also found a decrease of SPC with increasing mechanical treatment of the samples [6]. However, this is in contrast with the report of Acton [25] and Haack, Schnäckel [3], as the present correlation would mean a reduced SPC with increasing SME.

The Mb content of the extracted meat solutions was determined as a measure for chemical changes, such as oxidation. Mb is an intracellular compound and is released during intense processing. Similar to the SPC, it was therefore assumed that the Mb content increases in samples with higher ANIC [38, 50]. Contrary to that hypothesis, no differences in the Mb content in the samples’ meat extract could be detected in the present study (Table 3). The Mb content of the samples produced with different cutting set compositions was around 0.05 mg/mL for all samples. A Pearson correlation analysis (Table 2) based on this, however, was able to find a significant negative correlation between Mb and ANIC (r = − 0.336, p = 0.028), as well as a highly significant negative correlation between Mb and SME (r = − 0.542, p = 0.001). This shows that the correlation is generally valid, but does not apply to the range of the examined parameter variations, since the differences are too marginal.

The sensory and optical perception of the hamburgers was tested by a sensory panel. The quality of the hamburgers was rated in terms of hardness, juiciness, texture, and overall acceptability in the sensory analysis as well as the coarseness, the amount of batter-like substance, and the overall acceptability in the optical analysis. Table 4 shows the results of the sensory and optical evaluation by the panel. All parameters in the sensory evaluation ranged around a sensory score of 5, indicating that all tested samples were comparable with each other and the pre-defined standard (= sensory score of 5). The statistical differences in the sensory attributes of the hamburgers produced with different cutting set compositions were either non-existent (juiciness, overall acceptance, Table 4) or only marginally expressed (hardness, texture, Table 4). A Pearson correlation analysis between the firmness of the hamburger in the forward extrusion testing and the sensory parameters juiciness and acceptability, respectively, revealed a significant negative correlation (juiciness: r = − 0.246, p = 0.040, acceptability: r = − 0.303, p = 0.011). This indicates that the samples were rated juicier and better than the standard if the ground meat was less firm, i.e., less force was necessary to extrude the sample in the forward extrusion. An explanation for this might be that samples with lower firmness might be able to better keep the moisture which improves the sensory perception of juiciness. Comparable results were also obtained in the sensory evaluation of the samples, as the sensorially determined hardness positively correlated to the juiciness of the samples (r = 0.595, p = 0.001), Thus, this trend was underlined.

The overall acceptability of all hamburgers in the optical evaluation ranged around the standard with a sensory score of 5 and was therefore comparable among all samples (Table 4). However, some differences were detected in the optical evaluation in terms of particle size. The hamburger produced with the inclined cutting set using one cutting level (1CL/inclined) was rated as the coarsest sample, whereas the hamburger produced with the straight cutting set having a 7.8 mm MHP was rated the finest. Comparable results were obtained for the ANIC, which is reasonable since they are interrelated. A Pearson correlation analysis indicated a significant positive correlation between the firmness of the ground meat in forward extrusion and the optical assessed particle size (coarseness: r = 0.359, p = 0.003, amount of batter-like substance: r = 0.323, p = 0.006). These results indicate that finer meat masses with smaller particle sizes were softer and less cohesive. Those observations are in accordance with the findings of Berger, Witte [7], who found a lower firmness in samples with finer particle sizes. The highly significant negative correlation between the optically assessed particle size and the SME (r = − 0.217, p = 0.001) underlines the previous statement. Samples with lower SME input during grinding were rated as coarser, whereas samples with higher SME were described as having a finer structure.

A two-way ANOVA (p ≤ 0.05) was performed, which compared the influence of cutting set composition and the geometry of the drill holes on the sensory parameters. It was found that the differences are small and if differences occur, the cutting set combination had a stronger influence than the geometry of the drill holes. In most cases, the combination 2CL/7.8 mm differed from the other samples. However, even though small differences in the individual sensory parameters could be identified, the overall acceptability in the sensory and optical evaluation was the same for all samples.

As the differences in the sensory and optical analyses are quite small, all samples range around the standard reference (sensory score of 5). This indicates that the sensory quality of the samples is neither increased nor decreased by the cutting set composition. These results go along with the analytical physicochemical (Table 3) and functional parameters (Fig. 5), which also did not point out any major differences between the samples produced with different cutting sets.

Taking all results together, it can be concluded that the variation of the cutting set did not, or only to a small extent, influence the functional and quality parameters of the hamburgers.

Conclusions

When grinding with different cutting set compositions, differences in SME and smaller differences in ANIC were observed, i.e., the variation in the cutting set influences the stress and the structure of the meat to some extent. However, these relationships cannot be determined analytically or by sensory analysis in the present study. This shows that although the SME of the grinding with variating cutting sets differed significantly, the structure of the meat (ANIC) was only altered to a small extent. The study confirms previous assumptions that the grinding process due to the short residence time of meat in the grinding zone is already designed to be relatively gentle and that fluctuations in ANIC are more likely to be caused by raw material variations, e.g., different breeds, age, species of cattle, or processing temperature. Under the conditions tested, the composition of the cutting set was found to be of minor importance to product quality and functionality. Moreover, results suggest that even though structural parameters vary as a function of process parameters (SME), this may not noticeably influence the function and quality of the product, as long as the cutting set operates optimally (i.e., holes plates are not abraded, and knives remain sharp). The results of this study are of practical relevance, as they broaden the possibilities of production processes design and setup without having an impact on the product functionality and quality.

Data availability

All relevant data is included in the article, and further details are available upon request.

References

Deutscher Fleischerverband (2020) Jahrbuch 2020.

Barbut S (2015) The science of poultry and meat processing.

Haack E, Schnäckel W, Haack O (2003) Optimal Fördern und Zerkleinern: Grundlagen und Vorgänge bei der Fleischbearbeitung mit Maschinen der Wolftechnologie. Fleischwirtschaft 83(6):41–47

Haack E, Schnäckel W, Haack O (2003) Probleme, Ursachen und Lösungen: Grundlagen und Vorgänge bei der Fleischbearbeitung mit Maschinen der Wolf-technologie. Fleischwirtschaft 83(4):52–56

Bakieva A, Akimov M, Abdilova G, Ibragimov N, Bekeshova G (2019) Developing new type of disk plate for meat chopper and its effect to water-binding capacity and yield stress of minced meat. Int J Mech Prod Eng Res Dev 9(6):377–390

Berger LM, Gibis M, Witte F, Terjung N, Weiss J (2022) Influence of meat batter addition in ground beef on structural properties and quality parameters. Eur Food Res Technol 248(10):2509–2520

Berger LM, Witte F, Terjung N, Weiss J, Gibis M (2022) Influence of processing steps on structural, functional, and quality properties of beef hamburgers. Appl Sci 12(15):7377

Lazou AE (2022) Food extrusion: an advanced process for innovation and novel product development. Crit Rev Food Sci Nutr. https://doi.org/10.1080/10408398.2022.2143474

Oppen D, Berger LM, Gibis M, Weiss J (2022) Sensory texture and mastication physics of multi-phase meat products. Appl Sci 12(21):11076

Witte F, Sawas E, Berger LM, Gibis M, Weiss J, Röser A et al (2022) Influence of finely chopped meat addition on quality parameters of minced meat. Appl Sci 12(20):10590

Tomasevic I, Witte F, Kühling RE, Berger LM, Gibis M, Weiss J et al (2023) Effect of frozen to fresh meat ratio in minced pork on its quality. Appl Sci 13(4):2323

Dobraszczyk BJ, Ainsworth P, Ibanoglu S, Bouchon P (2005) Baking, extrusion and frying. Food processing handbook. Wiley, Hoboken, pp 237–290

Suchenko Y, Suchenko V, Mushtruk M, Vasyliv V, Boyko Y (2017) Research into mechanical properties of minced meat and finished products. EUREKA: Life Sci (4): 43–51

Brown T, James SJ, Purnell GL (2005) Cutting forces in foods: experimental measurements. J Food Eng 70(2):165–170

Haack E, Sielaff H (2005) Der Rohstoff Fleisch hat seine Tücken. Fleischwirtschaft 10:59–64

Lepetit J, Culioli J (1994) Mechanical properties of meat. Meat Sci 36(1):203–237

Haack E, Schnäckel W, Haack O (2003) Voraussetzungen für gute Leistung: Grundlagen und Vorgänge bei der Fleischbearbeitung mit Maschinen der Wolftechnologie. Fleischwirtschaft 5:28–33

Morales Alvarez JC (2020) Engineering aspects of extrusion: Extrusion processing as a multiple-input and multiple-output system. In: Ganjyal GM (ed) Extrusion cooking. Woodhead Publishing, Sawston, pp 29–71

Krickmeier J (2015) Modellierung der Bedingungen beim Schneiden insbesondere in einer Wolfmaschine mit dem Ziel der Optimierung des Zerkleinerungsprozesses sowie der Erhöhung der Produktqualität. Martin-Luther Universität Halle-Wittenberg, Halle/Saale

Brennan JG (2005) Mixing, emulsification and size reduction. Food processing handbook. Wiley, Hoboken, pp 513–558

Ranken MD (2000) Handbook of meat product technology. Blackwell Science, Malden

Rust RE (2004) Processing equipment mixing and cutting equipment. Encyclopedia of Meat Sciences: Elsevier London. p. 1057–61.

Haack E, Schnäckel W, Krickmeier J (2012) Wirkungsgrade deutlich verbessern. Fleischwirtschaft 92(6):25–33

Meuser F, Meuser S, Wiedmann W (2004) Grundlagen des Extrudierens. In: Heiss R (ed) Lebensmitteltechnologie: Biotechnologische, chemische, mechanische und thermische Verfahren der Lebensmittelverarbeitung. Springer, Berlin, pp 523–539

Acton JC (1972) The effect of meat particle size on extractable protein, cooking loss and binding strength in chicken loaves. J Food Sci 37(2):240–243

McNeill J, Kakuda Y, Findlay C (1988) Influence of carcass parts and food additives on the oxidative stability of frozen mechanically separated and hand-deboned chicken meat. Poult Sci 67(2):270–274

Renerre M, Dumont F, Gatellier P (1996) Antioxidant enzyme activities in beef in relation to oxidation of lipid and myoglobin. Meat Sci 43(2):111–121

Zhang M, Li C, Zhang Y, Pan J, Huang S, Lichao H et al (2021) Impact of salt content and hydrogen peroxide-induced oxidative stress on protein oxidation, conformational/morphological changes, and micro-rheological properties of porcine myofibrillar proteins. Food Chem 370:131074

Haack E, Schnäckel W, Stoyanov S (2007) Der Rohstoff spielt eine Doppelrolle: Konstruktionsqualität und abgestimmte Messergeometrien ermöglichen neue Leistungsbereiche. Fleischwirtschaft 87(1):50–55

Kenmegne Kamdem AT, Hardy J (1995) Influence of various conditions on meat grinding characteristics. J Food Eng 25(2):179–196

Zhao Y, Sebranek JG (1997) Technology for meat-grinding systems to improve removal of hard particles from ground meat. Meat Sci 45(3):389–403

Schnäckel W, Krickmeier J, Oktaviani SD, Micklisch I (2011) Untersuchungen zur Optimierung des Wolfprozesses - Teil 1: Modellierung der Bedingungen beim Schneiden in einer Wolfmaschine. Fleischwirtschaft 07:83–87

turbocut Jopp GmbH (2013) Schneidwerkzeuge im Fleischwolf - Grundwissen für Praktiker.

Büchs HP (1994) Innovative Wolftechnik bei der Rohwurstherstellung. Fleischwirtschaft 74(6):590–594

Prändl O, Fischer A, Schmidhofer T, Sinell HJ (1988) Handbuch der Lebensmitteltechnologie: Fleisch - Technologie und Hygiene der Gewinnung und Verarbeitung. Handbuch der Lebensmitteltechnologie: Fleisch - Technologie und Hygiene der Gewinnung und Verarbeitung: Ulmer-Verlag,Stuttgart. p. 188, 332‐4, 72‐74, 497, 550‐63, 609‐10, 81‐

Bundesamt für Verbraucherschutz und Lebensmittelsicherheit, (ed) (2006) Amtliche Sammlung von Untersuchungsverfahren nach § 64 LFGB, § 38 TabakerzG, § 28b GenTG: Verfahren zur Probenahme und Untersuchung von Lebensmitteln. Beuth, Berlin

Mariotti F, Tomé D, Mirand PP (2008) Converting nitrogen into protein - beyond 625 and Jones’ factors. Crit Rev Food Sci Nutr 48(2):177–184

Trout GR (1989) Variation in myoglobin denaturation and color of cooked beef, pork, and turkey meat as influenced by pH, sodium chloride, sodium tripolyphosphate, and cooking temperature. J Food Sci 54(3):536–540

Fang Y, Zhang B, Wei Y (2014) Effects of the specific mechanical energy on the physicochemical properties of texturized soy protein during high-moisture extrusion cooking. J Food Eng 121(1):32–38

Godavarti S, Karwe MV (1997) Determination of specific mechanical energy distribution on a twin-screw extruder. J Agric Eng Res 67(4):277–287

Villmow T, Kretzschmar B, Pötschke P (2010) Influence of screw configuration, residence time, and specific mechanical energy in twin-screw extrusion of polycaprolactone/multi-walled carbon nanotube composites. Compos Sci Technol 70(14):2045–2055

Leitsätze für Fleisch und Fleischerzeugnisse (2019)

Haack E (2016) Das große Messer Duell. Fleischerei Technik 1:26–27

Roth DM, McKeith FK, Brewer MS (1999) Processing parameter effects on sensory and instrumental texture characteristics of reduced-fat ground beef patties. J Muscle Foods 10(2):163–176

Schnäckel W, Krickmeier J, Schnäckel D, Micklisch I, Haack O (2012) Untersuchungen zur Optimierung des Wolfprozesses - Teil 4: Anwendung des Wolfprozesses auf die Feinbrätherstellung. Fleischwirtschaft 7:91–96

Schnäckel W, Krickmeier J, Pongjanyanukul W, Schnäckel D, Micklisch I, Haack O (2012) Untersuchungen zur Optimierung des Wolfprozesses - Teil 3: Bestimmung der Eindringeigenschaften tierischer Gewebe in die Bohrungen einer Lochscheibe beim Wolfen. Fleischwirtschaft 3:148–153

Honikel KO (2014) Minced meats. In: Dikeman M, Devine C (eds) Encyclopedia of meat sciences, 2nd edn. Academic Press, Oxford, pp 422–424

Raudsepp P, Brüggemann DA, Henckel P, Vyberg M, Groves K, Oksbjerg N et al (2017) Performance of conventional histochemical methods relative to a novel immunolabeling technique in assessing degree of degradation in comminuted chicken meat. Food Control 73:133–139

Chesney MS, Mandigo RW, Campbell JF (1978) Properties of restructured pork product as influenced by meat particle size, temperature and comminution method. J Food Sci 43(5):1535–1537

Tyszkiewicz I, Kłossowska BM, Wieczorek U, Jakubiec-Puka A (1997) Mechanical tenderisation of pork meat: protein and water release due to tissue damage. J Sci Food Agric 73(2):179–185

Acknowledgements

This research project was supported financially by the German Ministry of Economic Affairs and Energy (via AiF) and the FEI (Research Association of the German Food Industry, Bonn) within the project “Ground Meat and Ground Meat Products”, project number AiF 20384N. Furthermore, we would like to thank master butcher Kurt Herrmann and CTA Barbara Maier for their help during sample preparation and analysis.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Contributions

LMB: conceptualization, data curation, formal analysis, investigation, visualization, project administration, resources, writing—original draft, writing—review and editing, methodology, software, validation. FA: data curation, investigation. MG: funding acquisition, project administration, supervision, validation, writing—review and editing. FW: funding acquisition, project administration, writing—review and editing. NT: funding acquisition, project administration. JW: funding acquisition, project administration, supervision, writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Compliance with ethics requirements

All procedures performed in the study were in accordance with the ethical standards of the institutional committee.

Informed consent

Informed consent was obtained from each panelist prior to their participation in the study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Berger, L.M., Adam, F., Gibis, M. et al. Effect of cutting set variations on structural and functional properties of hamburgers. Eur Food Res Technol 250, 701–713 (2024). https://doi.org/10.1007/s00217-023-04414-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-023-04414-7